- 6 - (800) 666-3133CentralVac International

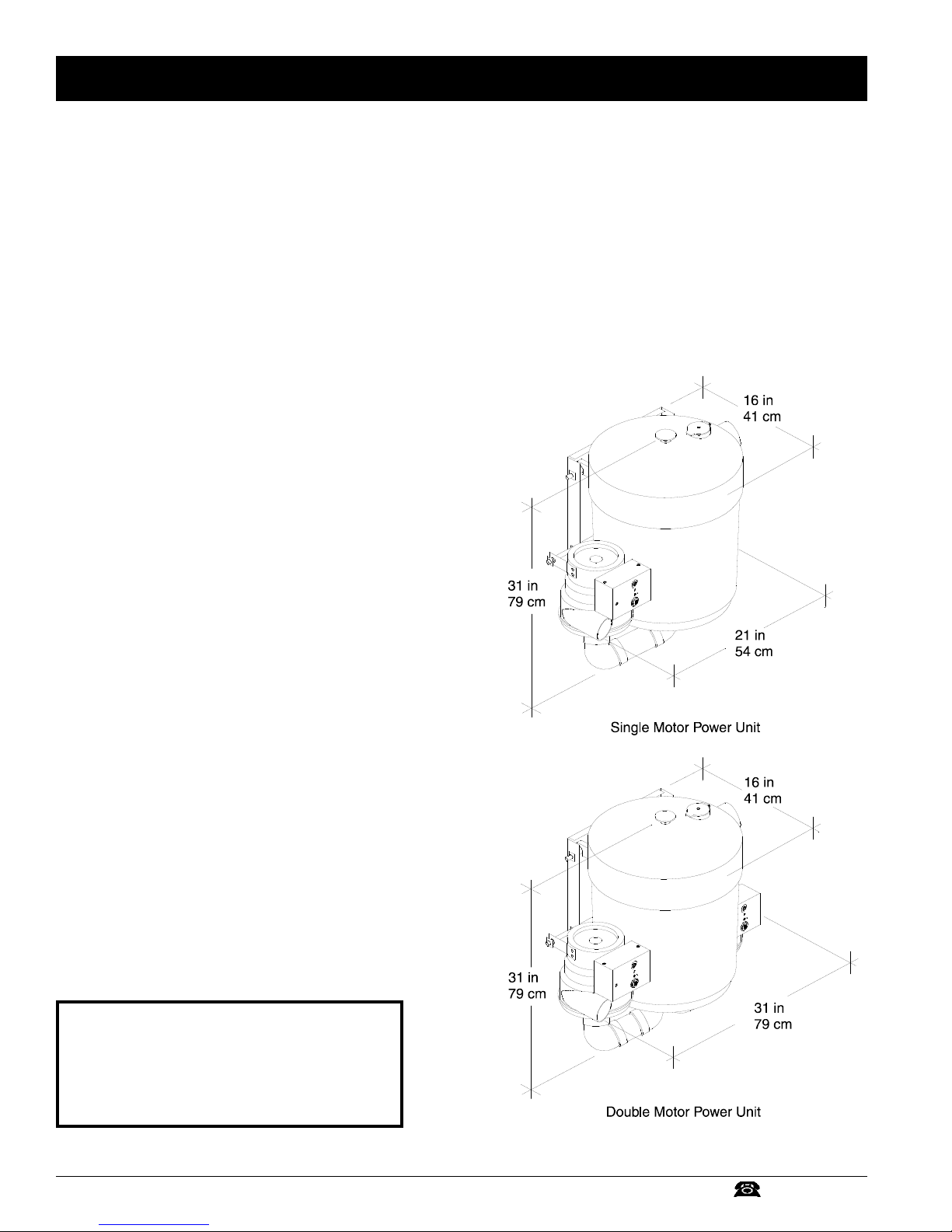

The power unit and canister will mount in the basement,

garage, utility room, or other remote area, preferably on a

firm, outside wall away from heat-producing units, such as a

boiler, water heater, dryer, etc.

lLocate the power unit away from the general living

area.

lDo not install the power unit in the attic.

lDo not locate the power unit close to a source of

extreme heat (i.e., water heater) or in an area with

high ambient temperature (i.e., attic, furnace room).

lIt is important that you also plan the installation of an

exhaust tube to the outdoors if ventilation is not

adequate. It is usually best to exhaust out the rear of

the house avoiding patios, windows, and entrance

areas.

lLocate the power unit in an accessible area for ease in

changing the paper bag filter and periodically cleaning

the cloth bag filter.

lLocate the power unit within 4 feet of a grounded elec-

trical outlet. The power unit requires a 120 VAC power

source with sufficient capacity to service the unit.

lDo not use extension cords.

lIf the power unit is located in a closet or a small utility

room, make sure the area is well-ventilated (i.e., with

door louvers).

lThe power unit has an auxiliary inlet for a garage,

basement, utility room, etc. However, installing a

separate inlet is the preferred method. It is more

convenient to use a hose with an inlet valve which

uses a low voltage control circuit to start and stop the

power unit automatically, than to use the auxiliary inlet

which must be switched on and off manually.

Determine the Location of the Power Unit

Determine the Size of the Power Unit

There is not a simple formula for choosing the correct size power unit

for your cleaning system. If you live in a high altitude area (5,000 to

7,000+ ft. above sea level), you may need to move to the next larger

size power unit, or go with a double motor unit.

Remember, you can never have a power unit that is too big, or have

too many inlets in your home!

Area to be Cleaned (sq. ft.) ............Recommended Power Unit

7,000+ ............................................CVS-16DP

up to 7,000 ......................................CVS-11DP

up to 6,000 ......................................CVS-07DP

up to 5,000 ......................................CVS-16

up to 4,000 ......................................CVS-11

2,000 or less ..................................CVS-07

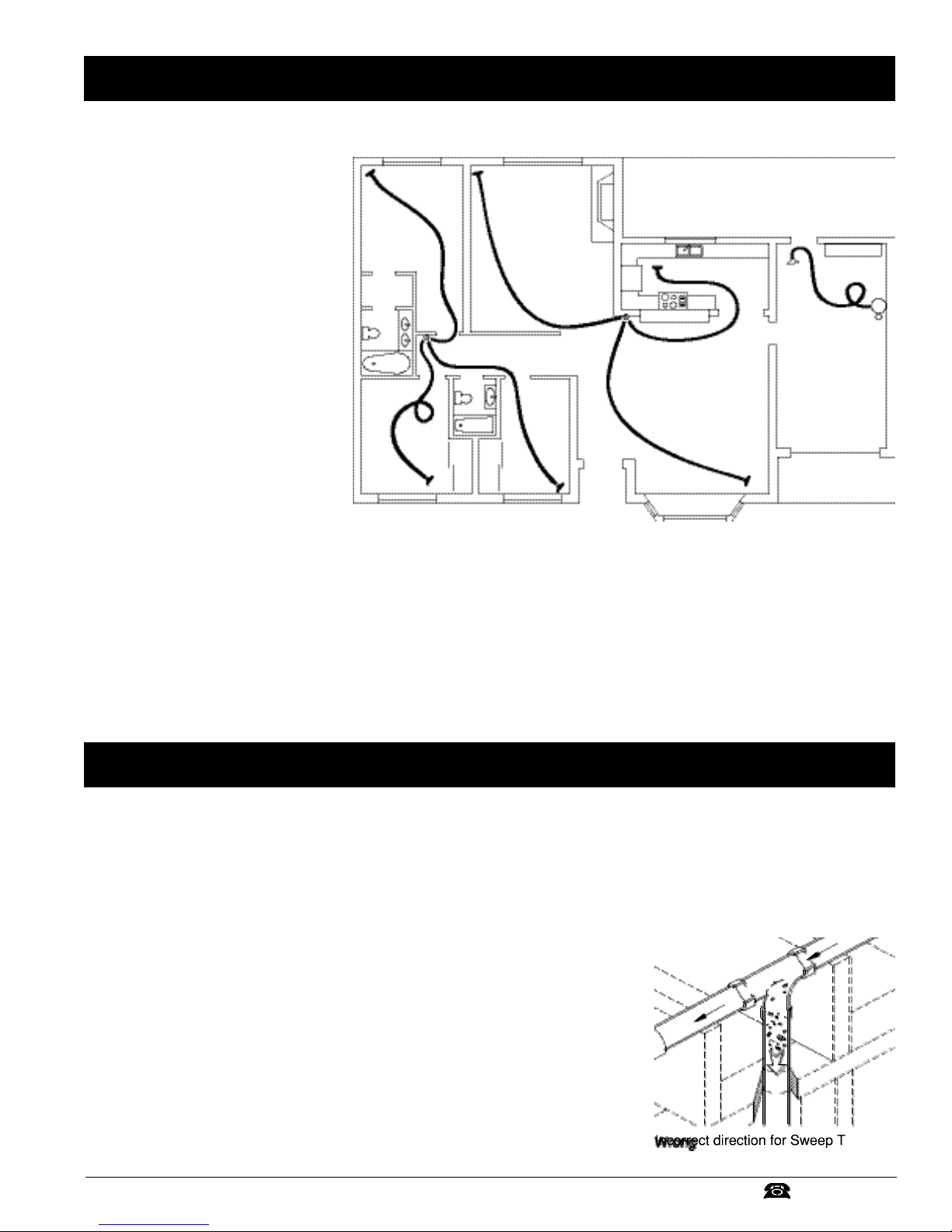

Planning the Installation

WARNING

THE POWER UNIT MUST NOT BE MOUNTED

IN AHIGH AMBIENT TEMPERATURE AREA

SUCH AS ATTIC, FURNACE ROOM, ETC. IF

NECESSARY, PLEASE CONSULT FACTORY.