Certa CTINV35GENA User manual

Warnings

Please pay attention to the following warnings when you see them in this manual.

WARNING: Indicates a strong possibility of severe personal injury or death if

instructions are not followed.

CAUTION: Indicates a strong possibility of severe personal injury or death if

instructions are not followed. If a problem should arise, or if you have any

questions about the generator, please contact the Kogan customer support team.

CARE: The generator is designed to give safe and dependable service if

operated according to instructions. ead and understand the user manual before

operating the generator. Failure to do so may result in personal injury or

equipment damage.

Safety Instructions

WARNING: Exhaust contains poisonous carbon monoxide. Do not operate the

generator in a confined environment. Only use outdoors, away from open doors,

windows or vents.

WARNING: The muffler becomes extremely hot during operation, and remains

hot for a while after stopping the engine. Be careful not to touch the muffler

while it is hot. Let the engine cool before storing the generator indoors.

WARNING: The engine exhaust system will be heated during operation and will

remain hot immediately after stopping the engine. To prevent scalding, pay

attention to the warning labels on the generator.

CARE: Do not connect other cables to receptacles during use or use a special

jack as it may cause electric shock.

WARNING: Fuel is extremely flammable, and is even explosive under certain

conditions. efuel unit in a ventilated area with the engine stopped.

WARNING: Keep away from cigarettes, smoke and sparks when refuelling the

generator. Always refuel in a well ventilated location.

WARNING: Connecting the unit to a building electrical system as a standby

power source must be performed by a qualified electrician. The connection must

isolate the generator from utility power, and must comply with all applicable laws

and electrical codes. Improper connections to a building's electrical system can

allow electrical current from the generator to backfeed into the utility lines. Such

backfeed may electrocute utility company workers or others who contact lines

during a power outage, and the generator may explode or catch fire when utility

power is restored.

WARNING: To avoid accidents and equipment damage, check the generator

every time before starting the engine.

WARNING: Keep the generator at least 1 meter away from other equipment

during operation.

WARNING: Keep the generator horizontal when running. If the generator is

tilted, it may cause fuel spillage.

WARNING: Generator operators must be trained, must know how to stop the

generator quickly and understand the purpose and operation of all controllable

parts. Untrained operators must not be allowed to use the equipment.

WARNING: Keep children and pets away from operation area.

WARNING: Keep away from rotating parts during operation.

WARNING: Do not operate unit with wet hands.

WARNING: Do not operate the generator in rain or snow, or let it get wet.

CAUTION: Wipe up any spilled fuel at once.

1

Table of Contents

Warnings...................................................................................................................................................... 1

Safety Instructions.............................................................................................................................. 1

Product Layout........................................................................................................................................ 3

Unit Body............................................................................................................................................... 3

Control Panel........................................................................................................................................ 3

Smart Throttle..................................................................................................................................... 3

Safety Label Locations.................................................................................................................... 3

Pre-operation Checks...................................................................................................................... 4

Checking the Oil................................................................................................................................. 4

Checking the Fuel Level................................................................................................................. 4

Check the Air Cleaner...................................................................................................................... 5

LCD Display Layout.......................................................................................................................... 6

Attaching the wheels to the generator ..................................................................................7

Using the remote controller & emergency button..............................................................7

Using the Generator.............................................................................................................................. 8

Starting the Engine........................................................................................................................... 8

High Altitude Operation................................................................................................................. 9

Generator Use..................................................................................................................................... 9

AC Applications................................................................................................................................ 10

Output and Overload Indicators............................................................................................... 10

DC Applications................................................................................................................................ 12

Starting the Engine.......................................................................................................................... 13

Oil Alert System................................................................................................................................ 13

Stopping the Engine....................................................................................................................... 14

Maintenance............................................................................................................................................. 15

Maintenance Schedule................................................................................................................... 15

Changing Oil....................................................................................................................................... 15

Air Cleaner service........................................................................................................................... 17

Spark Plug Servicing....................................................................................................................... 17

Transporting and Storage.................................................................................................................. 18

Transporting the generator.......................................................................................................... 19

Before storing the unit for an extended period.................................................................19

Muffler Fire Net Service................................................................................................................. 19

Troubleshooting.................................................................................................................................... 20

Engine will not start....................................................................................................................... 20

Deficient AC Output........................................................................................................................ 21

Equipment connected to generator won't start................................................................21

There is no power in the DC electric outlet..........................................................................21

Specifications......................................................................................................................................... 22

Product dimensions........................................................................................................................ 22

Engine................................................................................................................................................... 22

Generator ........................................................................................................................................... 22

2

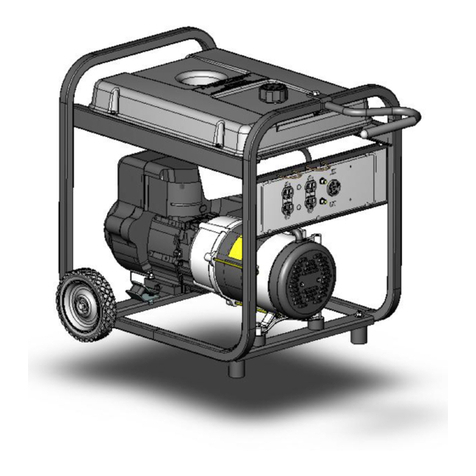

Product Layout

Unit ody

Control Panel

Smart Throttle

The engine speed is kept at idle automatically when an electrical appliance is

disconnected, and will return again to proper speed when an electrical appliance

is connected. This is designed to minimise fuel consumption during operation.

Safety Label Locations

These labels warn you of potential hazards that can cause serious injury. ead the

labels and safety notes and precautions described in the manual carefully.

3

Air Vent Knob

Fuel

Cap

Top Maintenance

Cover

Control

Panel

Starting Grip

Muffler

Cover Fuel Valve

Primer Bulb

Maintenance

Access

Overload Indicator

Light

Output Indicator

Light

Oil Alert Indicator Light

Eco Throttle Switch

Engine Switch

DC

Socket

DC Circuit

Breaker

Grounding

Terminal

AC Socket

AC V

Socket

Avoid Fire

Label

Avoid Burns

Label

Parameter

Label

Ventilation

Label Primer Bulb

Label

EPA Label

EPA Label

Pre-operation Checks

•Be sure to check the generator is on a level surface with the engine

stopped.

•Check the engine oil level.

•Using 2-stroke engine oil could shorten the engine's service life. Use a

premium quality 4-stroke engine oil.

Checking the Oil

•Loosen the cover screw and remove the left side maintenance cover.

emove the oil filer cap, then wipe the dipstick with a rag. Check the oil

level by reinserting the dipstick into the filler hole without screwing it in.

•If the oil level is below the end of the dipstick, refill up to the top of the oil

filler neck.

Note: The Oil Alert System will automatically stop the engine before the oil level

falls below the safe limit, however to avoid the inconvenience of an unexpected

shut-down, it is still advisable to visually inspect the oil level regularly.

Checking the Fuel Level

•Turn the fuel cap lever to the “OFF” position before transporting.

•Use unleaded automotive fuel.

Note: DO NOT use any fuels containing alcohol. Fuel system damage or engine

performance problems resulting from the use of fuels that contain alcohol are not

covered by warranty.

4

Dipstick

Lowest oil

level allowed

•Never use an oil/petrol mixture or dirty fuel.

•Avoid getting dirt, dust or water in the fuel tank.

•After refuelling, tighten the fuel filler cap securely.

•Petrol is extremely flammable under certain conditions.

•efuel in a well-ventilated area with the engine stopped.

•Do not smoke or allow flames or sparks in the area where the engine is

refuelled or where petrol is stored.

•Do not overfill the fuel tank. After refuelling, make sure that the tank cap is

closed properly and securely.

•Be careful not to spill fuel when refilling. Spilled fuel or fuel vapours may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

•Avoid repeated or prolonged contact with skin, or the breathing of vapour.

•KEEP FUEL OUT OF EACH OF CHILD EN

Check the Air Cleaner

Check the air cleaner element to ensure it is clean and in good working condition.

1. Loosen the cover screw and remove the left side maintenance cover.

2. Press the latch tab on top of the air cleaner body, remove the air cleaner

cartridge, then check the element.

3. Clean and replace the element if necessary.

Never run the engine without the air cleaner. apid engine wear will result from

airborne contaminants such as dust and dirt being drawn through the carburettor

and into the engine.

It is normal for a little oil to appear under the air filter box if the generator is

running for a long period of time or if a lot of oil is in the engine. Wipe up excess

oil after each use and after stopping the generator.

5

Fuel Cap

Open

Air Cleaner

Cartridge

Air Cleaner

Case

Screws

Access Panel

Screws

Access Panel Air Cleaner

Element

LCD Display Layout

The LCD display will light up after the generator has started up, and will be

functioning after 3-5 seconds.

Running display instructions

•U : Voltage

Displays the current voltage (V). The XXX.X (V) format (one decimal).

•I : Current

Displays the current Current (A). The XX.X (A) format (one decimal).

•F : Frequency

Displays the current frequency (Hz). The XX.X (Hz) format (integer).

•P : Power

Displays the current Power (W). The format is XXXX.X (W) (integer).

•Oil : Fuel

Invalid

•Time : Running Time

Displays the total running time. The format is xxx: xx: xx (hr: m: sec)

Overload / Oil Sensor light

Overload

The LCD screen will display the current output when the

generator is running normally. When the generator is

overloaded or short circuited, the generator will not

supply power to appliances. The voltage, current and

frequency will display “0” and the power display will

show “OVE ”.

At this time, the generator is not automatically shut down.

Please manually shut the generator down and investigate the reason of the

overload.

6

0

Over

Oil Sensor

The oil sensor system is to prevent engine

damage due to not enough oil being in the

reservoir. The oil sensor light will light up in

red before the oil level is under the safe line

in the crankcase, while the oil system

shutdown of the generator is automatic.

Attaching the wheels to the generator

1. Fix the wheel to the axle.

2. Fix the washer onto the wheel axle.

3. Fix the dowel onto the axle.

Using the remote controller & emergency button

Note: the generator can be started by using the starting

key & remote control.

•Use the starting key, not the remote controller, to

stop the generator when the generator has been

started by the starter key.

•Use the remote controller, not the starting key, to

stop the generator when the generator has been

started by the remote control.

•The emergency stop button can be used to stop

the generator at all times, no matter which method

was used to start the generator.

7

Oil sensor

light

Axle

2 wheels,

2 washers,

2 dowels

Dowel

Washer

Wheels

Wheel

assembly

Fix dowel

on axle

emote

controller

Starting

key

Emergency

stop button

Stop

Start

Press button

twice to start

generator.

Generator

remote control

Starter key

Using the Generator

Starting the Engine

1. Before starting the engine, disconnect any load from the DC receptacle.

Turn the fuel cap lever fully clockwise to the ON position.

2. Set the fuel valve to the ON position.

3. Set the motor switch to the ON position.

4. Pull slightly on the start cord until you feel resistance, then yank hard and

swiftly.

•Do not let the start cord retract by itself, but instead guide it back by hand.

•Hold the carry handle firmly to prevent the generator from falling over

when you pull the start cord.

Note: A hot motor will not start if there is too much fuel in the cylinder. If this

happens, wait for five to ten minutes before trying again.

8

Fuel Cap

Lever

Turn the fuel

valve knob to

the ON position

Engine Switch

Once the engine has started, allow the engine to run continuously and warm up.

If the engine stops and will not restart, check the engine oil level before

troubleshooting in other areas.

Before using a device once it is connected, switch the ECO switch off.

High Altitude Operation

At high altitudes, the standard carburettor air/fuel mixture will be excessively rich.

Performance will decrease and fuel consumption will increase.

High altitude performance can be improved by installing a smaller diameter main

fuel jet in the carburettor and readjusting the slow tempo screws. If you always

operate the generator at altitudes higher than 1,500m (4,000 feet) above sea

level, have a specialist perform these carburettor modifications.

Even with suitable carburettor jetting, engine horsepower will decrease by

approximately 3.5% for each 300m (1,000 feet) increase in altitude. The effect of

altitude on the horsepower will be greater than this if no carburettor modification

is made.

Note: Operation of the generator at an altitude lower than the carburettor is

jetted for may result in reduced performance, overheating and serious engine

damage caused by excessively lean air/fuel mixture.

Generator Use

•To prevent electric shock from faulty appliances, the generator should be

grounded. Connect an electric conductor (cable) of at least 1.5mm2

between the generator's ground terminal and an external ground source.

•Connections for standby power to a building's electrical system must be

made by a qualified electrician and must comply with all applicable laws

and electrical codes. Improper connections can allow electrical current

from the generator to feedback into the utility lines.

•Do not exceed the current limit set by any one receptacle.

•Do not connect the generator to a household circuit. This could cause

damage to either the generator, or to electrical appliances in the house.

•Do not modify or use the generator for any purpose other that what it is

intended for.

•Keep the generator away from other electrical cables or wires such as the

distribution network.

•The DC receptacle can be used while AC power is in use. If you use both at

once, ensure you do not exceed the total power for AC and DC.

•Most appliances require more than their rated wattage for start up.

9

Starting Grip

AC Applications

Start the engine and make sure that the output indicator light (green) illuminates.

Confirm that the appliance to be used is switched off, then plug the appliance in.

Substantial overloading that continuously lights the overload indicator light (red)

may damage the generator. Marginal overloading that temporarily lights the

overload indicator light may shorten the life of the generator.

Be sure that all appliances are in good working order before connecting them to

the generator. If an appliance begins to operate abnormally, becomes sluggish or

stops suddenly, turn the generator engine switch off immediately. Then

disconnect the appliance and examine it for signs of malfunction.

Output and Overload Indicators

The output indicator light (green) will remain lit during normal operating

conditions.

If the generator is overloaded, or there is a short in the connected appliance, the

output indicator light will go OFF, the overload indicator light (red) will go ON

and current to the connected appliance will be shut off.

Stop the engine if the overload indicator light goes ON and investigate the

overload source.

Note: Before connecting an appliance to the generator, check that it is in good

working order and that its electrical rating does not exceed that of the generator.

Then connect the power cord of the appliance and start the engine.

Note: Before sure all equipment is turned off before connecting the power cord.

When an electric motor is started, both the overload indicator light (red) and the

output indicator light (green) may go on together. This is normal and the

overload indicator light should go out after about four seconds.

If the overload indicator light stays on, contact the Kogan customer support

team.

10

Overload Indicator

Light ( ed)

Output Indicator

Light (Green)

Overload

Indicator ( ed) Output

Indicator (Green)

Oil Alarm Indicator

Connect the ground terminal.

Start the engine according to the “Starting the Engine” chapter of this manual.

Note: If the output indicator light (green) does not light, and the overload

indicator light (red) lights up instead, set the engine switch to STOP, stop the

engine at once, then start the engine again.

Confirm that the equipment to be used is switched off, and insert the plug of the

appliance to be used into the AC receptacle.

Note: Double check that the equipment to be used is switched off before

plugging it in. Equipment to be used will operate suddenly and injuries or

accidents may be caused.

Switch the equipment on and the output indicator light should light up. In the

event of overload, the output indicator light will go out and the overload indicator

light will come on. No power will be output, however the engine will not have

stopped, so the engine must be stopped by setting the respective engine switch

to STOP.

Note: When equipment requires a large starting power, the overload indicator

light and the output indicator light may light together for a short time. This is not

an abnormality. Once the equipment has started, the overload indicator light will

go out and the output indicator light will stay lit.

AC Electric Lamps Power Tools Electromotor DC Battery

Power Factor 1 0.8 ~ 0.9 0.4 ~ 0.7 (efficiency 0.86)

3700 0-2600W 0-2000W 0-10002

ated Voltage: 12V

ated current: 8A

11

Grounding

Mark

When overloaded

or short-circuited,

overload indicator

will illuminate (red).

Normal operations:

output indicator will

illuminate (green).

DC Applications

For charging 12V automotive batteries:

Idling voltage (V) Loading voltage (V) Loading current (A)

DC Max. Output Power 37 13.5 8.5

The generator cannot sense a sensibility load with the same power, which the

manual indicates. It can only sense 40%-70% power.

Example:

Model 3700

Generator ated Output 3.2KVA

Frequency Power Factor

AC 1.0 3.2KVA

0.4 ~ 0.75 0-1.3KVA ~ 2.4KVA

DC 100W

(12V/8.3A)

•When using the DC output, turn the smart throttle to the OFF position. The

DC current will be below 5A if you turn on the smart throttle without AC

current output.

•When charging batteries, a person must always be present to monitor the

voltage. Charging must be stopped once the voltage of the batteries is

above 16V, or it may cause the battery to explode, causing serious injury or

death.

•To prevent the possibility of creating a spark near a battery, connect the

charging cable to the generator first, then to the battery. Disconnect the

cable first at the cable.

•Before connecting charging cables to a battery that is installed in a vehicle,

disconnect the vehicles grounded battery cable. econnect the vehicles

grounded battery cable after the charging cables are removed. This

procedure will prevent the possibility of a short circuit and sparks if you

make accidental contact between a battery terminal and the vehicles frame

or body.

•Do not attempt to start an automobile engine while the generator is still

attached to the battery. The generator may be damaged.

12

Charging

Wires

•Connect the positive battery terminal to the positive charging cord. Do not

reverse the charging cords, or you may damage the battery or generator.

•The battery gives off explosive gases; keep sparks, flames and cigarettes

away. Provide adequate ventilation when charging.

•The battery contains sulphuric acid (electrolyte). Contact with skin or eyes

will cause severe burns. Wear protective clothing and a face shield.

If electrolyte gets on your skin, flush with water.

•If electrolyte gets in your eyes, flush with water for at least 15 minutes and

call 000.

•If electrolyte gets swallowed, drink large quantities of water or milk, then

follow with milk of magnesia or vegetable oil. Call 000.

•KEEP OUT OF EACH OF CHILD EN, PETS AND UNT AINED PE SONS.

Starting the Engine

•The DC receptacle may be used while the AC power is in use.

•An overloaded DC circuit will trip the DC circuit protector. If this happens,

disconnect the DC load before pushing in the circuit protector to resume

operations.

Oil Alert System

The oil alert system is designed to prevent engine damage caused by an

insufficient amount of oil. The alert system will automatically shut down the

engine (the engine switch will remain in the ON position).

If the oil alert system shuts down the engine, the oil alert indicator light (red) will

come on when you operate the starter, and the engine will not run. If this occurs,

add engine oil.

13

DC Circuit Breaker

Oil Alarm Indicator ( ed)

Stopping the Engine

To stop the engine in an emergency, turn the engine switch to the OFF position.

In normal use:

1. Switch off the connected equipment and pull the inserted plug out.

2. Turn the engine switch to the OFF position.

3. Turn the cap lever fully counter-clockwise to the OFF position.

Note: Be sure that both the fuel cap lever and the engine switch are in the OFF

position before stopping, transporting and/or storing the generator.

14

Plug

Engine Switch

Turn the fuel

valve knob to the

OFF position.

Open

Close

Air Vent Knob

Maintenance

The purpose of the maintenance and adjustment schedule is to keep the

generator in the best operating conditions.

Inspect or service as scheduled in the table below.

Note: Shut off the engine before performing any maintenance. If the engine must

run during it, make sure the area is extremely well ventilated. The exhaust does

contain poisonous carbon monoxide gas.

Maintenance Schedule

egular service period (1)

___________________________

Item operation to perform

Each Use First month or

20 hours

Every 3

months or 50

hours

Every 6

months or 100

hours

Every year or

200 hours

Engine oil Check level ●

Change ● ●

Air cleaner Check ●

Clean (2)●

Spark plug Check / adjust ●

Combustion chamber Clean ●

Valve clearance Check / adjust (3)●

Fuel tank and filter

tank

Clean (3)●

Fuel line Check Every 2 years – replace if necessary (3)

1. Log hours of operation to determine proper maintenance.

2. Service more frequently when used in dusty areas.

3. These items should be serviced by a qualified technician, unless the owner has the proper tools and is

mechanically proficient.

Temperature (°C) Time between oil changes (hour) ecommended Power Factor

25 Normal 100%

30 18 95%

35 15 85%

40 12 70%

Note: if the temperature of the external environment reaches 45°C or higher, the

generator should not be used, as it may be damaged. If the external

environment reaches -5°C or lower, the generator should not be used.

Changing Oil

Drain the oil while the engine is still warm to ensure rapid and complete draining.

Note: make sure to turn the engine switch and the fuel cap vent lever OFF before

draining the oil.

1. Lean the generator to the side.

2. Fasten the oil lead pipe onto the oil exhaust as shown in the picture

overleaf. Then pour out the oil.

3. efill with new oil and check the oil position in the crankcase.

4. Once the crankcase has new oil in it, please gently shake the generator

from left to right a few times to ensure that the bobber used for the oil

alarm system is floating.

15

Engine oil capacity: 0.9L

Wash your hands with soap and water after handling used oil.

Note: Please dispose of used motor oil in a manner that is compatible with the

environment. We suggest that you transport it in a sealed container to your local

service station or municipal waste disposal facility for reclamation.

DO NOT dispose of it in the trash, pour it on the ground or pour down a sink or

into a stormwater drain.

16

Generator

Oil Drain

Pipe

Oil Container

Dipstick

Lowest oil

Level allowed

Air Cleaner service

A dirty air cleaner/filter will restrict airflow to the carburettor To prevent

carburettor malfunctions, service the air cleaner/filter regularly. Service more

frequently when operating the generator in extremely dirty areas.

Note: do not use gasoline or low flash point solvents for cleaning. They are highly

flammable and explosive under certain conditions.

1. Loosen the cover screw and remove the access panel.

2. emove the screw under the air filter case.

3. Pull the air filter cartridge down 30mm and remove the air filter cartridge.

4. emove the air filter iron clip and check the air filter element. Clean or

replace the element if necessary.

5. einstall the air filter parts after cleaning or replacing the air filter element.

Spark Plug Servicing

Please use high quality spark plugs for best performance.

To ensure proper engine operation, the spark plug must be properly gapped and

free of deposits.

1. emove the bolts on top of the maintenance cover and the cover.

2. Take out the ignition coil rubber boot.

17

Air cleaner case

Air cleaner

cartridge

Screws

Access panel

screws

Access panel Air cleaner

element

Top maintenance cover

Spark plug wrench

Ignition coil rubber boot

3. emove the spark plug with the spark plug wrench.

4. Visually inspect the spark plug. Discard if the insulator is cracked or

chipped. Clean the spark plug with a wire brush if it is to be reused.

5. Install the spark plug carefully by hand to avoid cross threading.

6. After a new spark plug has been seated by hand, it should be tightened ½

turn with a wrench to compress its washer. If a used plug is being

reinstalled, it should only require a 1/8 to turn after being seated.¼

7. einstall the ignition coil rubber boot on the spark plug securely.

8. einstall the control panel.

Note: the spark plug must be securely tightened. An improperly tightened plug

can become extremely hot and may damage the generator. Never use a spark

plug with an improper heat range.

Never use a spark plug without damping resistance, or it will cause no AC output.

Transporting and Storage

To prevent spillage when transporting or during temporary storage, the generator

should be secured upright in its normal operating position, with the engine switch

OFF.

The fuel cap vent lever must be turned counter-clockwise to the OFF position.

Allow the engine to cool completely before turning the fuel cap vent lever to the

OFF position.

18

Spark plug

wrench

Screwdriver

Insert the screwdriver into the hole of the spark plug wrench and remove the spark plug.

0.6 ~ 0.7mm

(0.024 ~ 0.028”)

Transporting the generator

•Do not overfill the tank. (There should be NO fuel in the filler neck.)

•Do not operate the generator while it is in a vehicle. Take the generator out

of the vehicle and operate it in a well ventilated area.

•Avoid a location exposed to direct sunlight when putting the generator in a

vehicle. If the generator is left in an exposed vehicle for many hours, the

high temperatures inside the vehicle may cause fuel to vapourise, resulting

in a possible explosion.

•Do not drive on a rough road for an extended period of time with the

generator on board. If you must travel with the generator on board over

rough roads, drain all of the fuel from the generator beforehand.

efore storing the unit for an extended period

1. Be sure the storage area is free of excessive humidity and dust.

2. Drain the fuel.

Note: fuel is extremely flammable and explosive under certain conditions.

Do not smoke or allow flames or sparks in the area.

3. Completely drain the fuel from the tank. Open the fuel valve, start the

engine and operate in the idle position until all remaining fuel is gone and

the engine stops automatically.

4. Discharge the oil.

5. emove the spark plug and fill the cylinder with 2cc's of fresh oil. Pull the

start motor 3-4 times to discharge the remaining oil, then reinstall the

spark plug.

6. Pull the starting cord slowly until the resistance is strong. At this time, the

piston is moving to the top of the compression stroke and the valves will be

closed.

Muffler Fire Net Service

A dirty muffler will result in high operating noise, and will also affect the engine's

running quality. Clean and maintain the fire net in the muffler, to ensure that the

machine is cooling efficiently.

1. emove the M6 screws and open the muffler cover.

2. emove two M4 screws on the fire net.

19

Fuel

Container

Other manuals for CTINV35GENA

1

Popular Portable Generator manuals by other brands

Yamaha

Yamaha EF3000iSE - Inverter Generator - 3000 Maximum AC... owner's manual

Porter-Cable

Porter-Cable BSI550-W instruction manual

Generac Power Systems

Generac Power Systems PowerBOSS 8000 PowerMaster owner's manual

Powermate

Powermate PM0525312.01 owner's manual

MasterCraft

MasterCraft 55-0343-4 owner's manual

Keysight

Keysight EDU33210 Series user guide