Certa CT18VIMPWRA User manual

Table of Contents

General Tool Safety Warnings......................................................................................................2

Work Area........................................................................................................................................2

Electrical Safety.............................................................................................................................2

Personal Safety..............................................................................................................................2

Power Tool Use and Care..........................................................................................................3

Battery Tool Use and Care........................................................................................................3

Additional Warnings Applica le for the Impact Driver................................................4

Important Safety Instructions for Battery Charger........................................................4

Important Safety Instructions for the Battery Pack.......................................................5

Sym ols.................................................................................................................................................6

Product Information.........................................................................................................................6

Layout................................................................................................................................................6

Intended Use...................................................................................................................................7

Technical Specifications.............................................................................................................7

Charging Battery Pack.....................................................................................................................7

Impact Driver Operations...............................................................................................................8

Changing the Tool........................................................................................................................8

Inserting the Battery ...................................................................................................................8

Reversing the Rotational Direction.......................................................................................8

ON/OFF switch..............................................................................................................................8

Adjusting the Speed....................................................................................................................9

Usage Advice..................................................................................................................................9

Screw Applications with Hard, Spring-loaded or Soft Seat........................................9

Recommendations for Optimal Handling of the Battery ..........................................10

Maintenance and Servicing..........................................................................................................10

1

General Tool Safety Warnings

Save all warnings and instructions for future reference.

The term “power tool” refers to your mains operated (corded) power tool or

attery-operated (cordless) power tool.

Work Area

1. Keep your work area clean and well lit. Cluttered enches and dark areas

invite accidents.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flamma le liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep ystanders and children away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

2. Avoid ody contact with grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your

ody is grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

4. Do not a use the cord. Never use the cord to carry the tools or pull the

plug from an outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords increase the

risk of electric shock.

5. When operating a power tool outdoors, use an extension cord suita le for

outdoor use. Use of a cord suita le fir outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a damp location is unavoida le, use a Ground

Fault Circuit Interrupter (GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

Personal Safety

1. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use tool while tired or under the influence

of drugs, alcohol, or medication. A moment of inattention while operating

power tools may result in serious personal injury.

2. Use personal protective equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

3. Prevent unintentional starting. Ensure the switch is in the off-position

efore connecting to power source and/or attery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

2

energizing power tools that have the switch on invites accidents.

4. Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can e caught in moving parts.

5. Remove adjusting keys or wrenches efore turning the tool on. A wrench

or a key that is left attached to a rotating part of the tool may result in

personal injury.

6. Do not overreach. Keep proper footing and alance at all times. The

ena les etter control of the power tool in unexpected situations.

7. Only use safety equipment that has een approved y an appropriate

standards agency. Unapproved safety equipment may not provide

adequate protection. Eye protection must e ANSI-approved and

reathing protection must e NIOSH-approved for the specific hazards in

the work area.

Power Tool Use and Care

1. Do not force tool. Use the correct tool for your application. The correct

tool will do the jo etter and safer at the rate for which it is designed.

2. Do not use tool if switch does not turn it on or off. Any power tool that

cannot e controlled with the switch is dangerous and must e repaired.

3. Disconnect the plug from the power source and/or the attery pack from

the power tool efore making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures reduce risk of starting

the tool accidentally.

4. Store idle power tools out of the reach of children and other untrained

persons. Power tools are dangerous in the hands of untrained users.

5. Maintain tools with care. Check for misalignment or inding of moving

parts, reakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired efore

use. Many accidents are caused y poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly maintained tools with sharp

cutting edges are less likely to ind and are easier to control.

7. Use only accessories that are recommended y the manufacturer for your

model. Accessories that may e suita le for one tool may ecome

hazardous when used on another tool.

Battery Tool Use and Care

1. Ensure the switch is in the off position efore inserting attery pack. Insert

the attery pack into power tools that have the switch on invites

accidents.

2. Recharge only with the charger specified y the manufacturer. A charger

that is suita le for one type of attery pack may create a risk of fire when

used with another attery pack.

3. Use power tools only with specifically designated attery packs. Use of

any other attery packs may create a risk of injury and fire.

4. When attery pack is not in use, keep it away from other metal o jects

like paper clips, coins, keys, nails, screws, or other small metal o jects that

can make a connection from one terminal to another. Shorting the attery

3

terminals together may cause urns or a fire.

5. Under a usive conditions, liquid may e ejected from the attery, avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the attery may

cause irritation or urns.

Additional Warnings Applicable for the I pact Driver

•Hold power tool by insulated gripping surfaces, when perfor ing an

operation where the cutting accessory or fastener ay contact hidden

wiring. Cutting accessory and fasteners contacting a “live” wire may make

exposed metal parts of the power tool “live”, which can give the operator

an electric shock.

•Use appropriate detectors to deter ine if utility lines are hidden in the

work area or call the local utility co pany for assistance. Contact with

electric lines can lead to fire and electric shock. Damaging a gas line can

lead to explosion. Penetrating a water line causes property damage and

may cause an electric shock.

•Switch off the power tool i ediately when the tool insert ja s. Be

prepared for high reaction torque that can cause kick ack.

•Hold the achine with a fir grip. High reaction torque can riefly occur

while driving in and loosening screws.

•Secure the work piece. A work piece clamped with clamping devices or in

a vice is held more securely than y hand.

•Be extra careful when cutting in high or hard-to-reach locations. Avoid

sawing overhead. Be on the lookout for hidden wires and falling de ris.

•Keep your workplace clean. Blends of materials are particularly

dangerous. Dust from light alloys can urn or explode.

•Always wait until the achine has co e to a co plete stop before

placing it down. The tool insert can jam and lead to loss of control over

the power tool.

•Do not open the battery. Danger of short circuiting. Protect the attery

against heat, e. g., also against continuous sun irradiation and fire. There is

danger of explosion.

•In case of da age and i proper use of the battery, vapours ay be

e itted. Provide fresh air and seek medical help in case of complaints.

The vapours can irritate the respiratory system.

•When the battery is defective, liquid can escape and co e into contact

with adjacent co ponents. Check any parts concerned. Clean such parts

or replace them, if required.

I portant Safety Instructions for Battery Charger

•Before using battery charger, read all instructions and cautionary

arkings on battery charger, battery pack, and product using battery.

•Use only the charger which acco panied your product or direct

replace ent. Do not su stitute any other charger. Use only same supplier

approved chargers with your product.

•Do not disasse ble charger or operate the charger if it has received a

sharp blow, been dropped or otherwise da aged in any way. Incorrect

4

reassem ly may result in a risk of electric shock, electrocution or fire.

•Do not recharge battery in da p or wet environ ent. Do not expose

charger to rain or snow. If battery case is cracked or otherwise da aged,

do not insert into charger. Battery short or fire may result.

•Charge only sa e supplier approved rechargeable batteries. See

Functional Description and Specifications. Other types of atteries may

urst causing personal injury and damage.

•Charge battery pack in te peratures above 0ºC and below 45ºC. Store

tool and battery pack in locations where te peratures will not exceed

49ºC. This is important to prevent serious damage to the attery cells.

•Pull by plug rather than cord when disconnecting charger or when

disconnecting cords using the daisy chain feature. This will reduce risk of

damage to electric plug and cord.

•Make sure that cord is located so that it will not be stepped on, tripped

over, or otherwise subjected to da age or stress.

•Do not use an extension cord unless it is absolutely necessary. Use of

improper extension cord could result in risk of fire, electric shock, or

electrocution.

•Do not operate charger with da aged cords or plugs — have them

replaced immediately.

•Disconnect the charger fro the outlet before atte pting any cleaning.

This will reduce the risk of electric shock. Removing the attery pack will

not reduce this risk.

I portant Safety Instructions for the Battery Pack

•Do not incinerate the battery pack even if it is severely da aged or is

co pletely worn out. The attery pack can explode in a fire. Toxic fumes

and materials are created when lithium ion attery packs are urned.

•Do not charge or use battery in explosive at ospheres, such as in the

presence of fla able liquids, gases or dust. Inserting or removing the

attery from the charger may ignite the dust or fumes.

•If battery contents co e into contact with the skin, i ediately wash

area with ild soap and water. If attery liquid gets into the eye, rinse

water over the open eye for 15 minutes or until irritation ceases. If medical

attention is needed, the attery electrolyte is composed of a mixture of

liquid organic car onates and lithium salts.

•Contents of opened battery cells ay cause respiratory irritation.

Provide fresh air. If symptoms persist, seek medical attention.

•Charge the battery packs only in the charger which acco panied your

product.

•DO NOT splash or i erse in water or other liquids. This may cause

premature cell failure.

•Do not store or use the tool and battery pack in locations where the

te perature ay reach or exceed 40°C (such as outside sheds or etal

buildings in su er).

•When batteries are not in tool or charger, keep the away fro etal

objects.

•DO NOT put batteries into fire or expose to high heat. They may explode.

5

Sy bols

The following sym ols or initials may e used on the tool. Please see elow to

learn their meaning. Proper interpretation of these sym ols will allow you to

operate the tool etter and safer.

Sy bol Na e Designation/Explanation

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

Kg Kilograms Weight

Min Minutes Time

s Seconds Time

Ø Diameter Size of its, grinding wheel etc..

noNo load speed Rotational speed at no load

…/min Revolutions or

reciprocation per minute

Revolutions, strokes, surface speed,

or its etc.. per minute

0 Off position Zero speed, zero torque...

Arrow Action in the direction of the arrow

Direct current Type or a characteristic of current

Read manual sym ol Alerts user to refer to the manual

Wear eye protection Alerts user to wear eye protection

Class II construction Dou le insulated construction tools

Product Infor ation

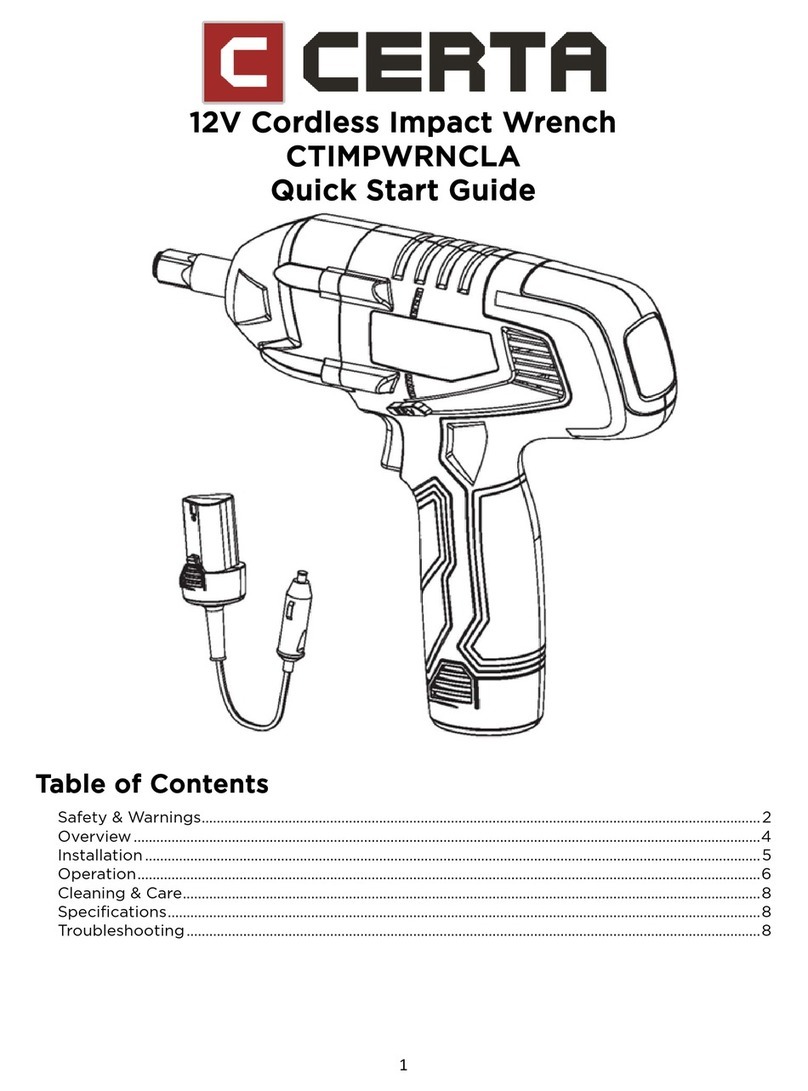

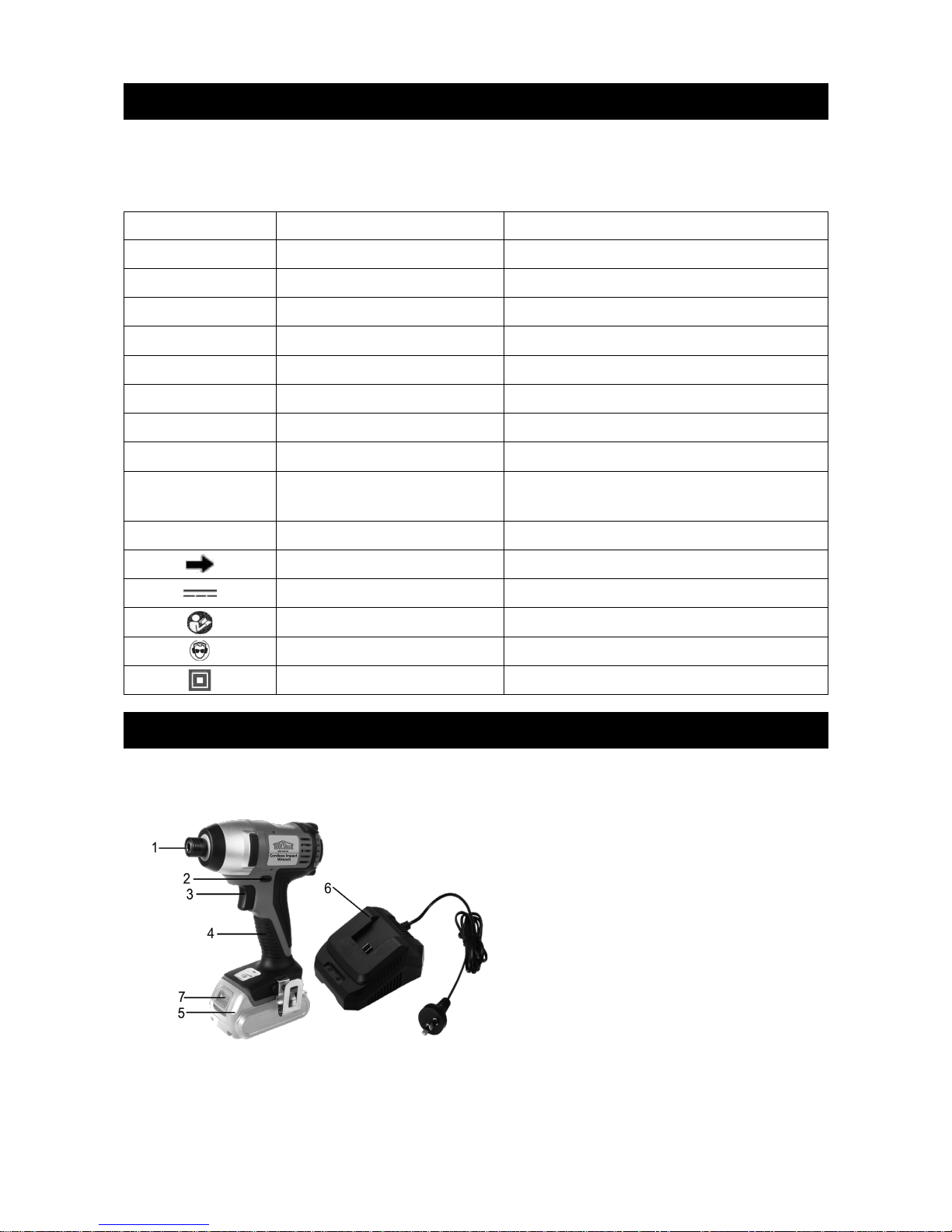

Layout

1. Tool Holder

2. Rotational Direction Switch

3. ON/OFF Switch

4. Handle

5. Battery Pack

6. Battery Charger

7. Pushlock Button

6

Intended Use

This tool is intended for driving in and loosening screws as well as for drilling

into wood, metal, ceramic and plastic.

Even when a tool is used as prescri ed, it is not possi le to eliminate all residual

risk factors. The following hazards may arise in connection with the tool's

construction and design:

•Damage to lungs if an effective dust mask is not worn.

•Damage to hearing if effective hearing protection is not worn.

•Health defects resulting from vi ration emission of the power tool when

eing used over long periods of time, not eing adequately managed or

properly maintained.

Technical Specifications

Voltage Supply DC 18V

No Load Speed 0-2400 min-1

Maximum Torque 180Nm

Forward & Reverse Rotation Yes

Battery Capacity 1300mA

Rating Voltage for Charger AC 100-240V~/50-60Hz

Charging Time 1 hour

WARNING! This machine produces an electromagnetic field during operation.

This field may under some circumstances interfere with active or passive

medical implants. To reduce the risk of serious or fatal injury, we recommend

persons with medical implants to consult their physician and the medical

implant manufacturer efore operating this machine.

Charging Battery Pack

Note: The attery is supplied partially charged to prevent possi le pro lems.

Therefore, you should charge it prior to use. Batteries will not reach full charge

the first time they are charged. Allow several charging/discharging cycles for

them to fully charge.

1. Remove the attery pack (5) from the handle, pressing the pushlock

utton (7) downwards to do so.

2. Check that your main voltage is the same as that marked on the rating

plate of the attery.

3. Plug the mains plug of the charger (6) into the mains socket outlet, then

turn on the power and the green LED will illuminate.

4. Push the attery pack onto the attery charger. The green LED will

extinguish and the red LED will illuminate, indicating that the attery pack

is eing charged.

5. When the charging period is completed after approx 1 hour,the green LED

will illuminate and the red LED will extinguish.

7

Do not continue to press the On/Off switch after the achine has been

auto atically switched off. The attery can e damaged. The attery is

equipped with an NTC temperature control which allows charging only within a

temperature range of etween 0°C and 45°C.

A long attery service life is achieved in this manner.

If the attery pack fails to ecome charged, please check

•whether there is voltage at the socket-outlet

•whether there is proper contact at the charging contacts on the charger.

If the attery continues to fail charging, please contact the Kogan customer

support team.

To ensure that the attery pack provides long service you should take care to

recharge it promptly.

You must recharge the attery pack when you notice that the power of the

cordless screwdriver drops.

Never fully discharge the attery pack. This will cause the attery pack to

develop a defect.

I pact Driver Operations

Changing the Tool

Before any work on the power tool (e.g., aintenance, tool change, etc.) as

well as during transport and storage, set the rotational direction switch to the

center position. Unintentional actuation of the On/Off switch can lead to

injuries.

Inserting the Battery

Use only original this brand Li-ion batteries with the voltage listed on the

na eplate of your power tool. Using other atteries can lead to injuries and

pose a fire hazard. Set the rotational direction switch to the center position to

protect the power tool against accidental starting. Insert the charged attery

into the handle so that it can e felt to engage and sits flush against the handle.

Reversing the Rotational Direction

The rotational direction switch is used to reverse the rotational direction of the

machine. The impact driver must e turned off efore you can use the switch.

•Right Rotation: For driving in screws and tightening nuts, press the

rotational direction switch through to the left stop.

•Left Rotation: For loosening and unscrewing screws and nuts, press the

rotational direction switch through to the right stop.

ON/OFF switch

To start the driver, press the On/Off switch and keep it pressed.

To switch off the driver, release the On/Off switch.

8

Adjusting the Speed

The speed of the switched on power tool can e varia ly adjusted, depending

on how far the On/Off switch is pressed. Light pressure on the On/Off switch

results in a low rotational speed. Further pressure on the switch results in an

increase in speed.

Usage Advice

Apply the power tool to the screw/nut only when it is switched off. Rotating

tool inserts can slip off. The torque depends on the impact duration. The

maximum achieved torque results from the sum of all individual torques

achieved through impact.

The maximum torque is achieved after the impact duration of 6–10 seconds.

After this duration, the tightening torque is increased only minimally. The impact

duration is to e determined for each required tightening torque. The actually

achieved tightening torque is always to e checked with a torque wrench.

When working with an application tool, pay attention that the application tool is

firmly seated on the tool holder. When the application tool is not firmly

connected with the tool holder, it can come loose again and not e controlled.

Screw Applications with Hard, Spring-loaded or Soft Seat

When in a test, the achieved torques in an impact series are measured and

transferred into a diagram, resulting in the curve of a torque characteristic. The

height of the curve corresponds with the maximum reacha le torque, and the

steepness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

•Strength properties of the screws/nuts

•Type of acking (washer, disc spring and seal)

•Strength properties of the material eing screwed/ olted together

•Lu rication conditions at the screw/ olt connection

The following application cases result accordingly:

•A hard seat is given for metal-to-metal screw applications with the use of

washers. After relatively short impact duration, the maximum torque is

reached (steep characteristic curve). Unnecessary long impact duration

only causes damage to the machine.

•A spring-loaded seat is given for metal-to-metal screw applications,

however with the use of spring washers, disc springs, studs or screws/nuts

with conical seat as well as when using extensions.

•A soft seat is given for screw applications, e.g., metal on wood or when

using lead washers or fi re washers as acking. For a spring-loaded seat

as well as for a soft seat, the maximum tightening torque is lower than for

a hard seat. Also, longer impact duration is required.

9

Reco endations for Opti al Handling of the Battery

Protect the attery against moisture and water. Store the attery only within a

temperature range etween 0°C and 45°C. As an example, do not leave the

attery in the car in summer.

Occasionally clean the venting slots of the attery using a soft, clean and dry

rush. A significantly reduced working period after charging indicates that the

attery is used and must e replaced.

Maintenance and Servicing

To prevent serious injury or death fro accidental operation, turn the Power

Switch of the tool to its “OFF” position and disconnect battery pack fro tool

before perfor ing any inspection, aintenance, or cleaning procedures.

•Clean out dust and de ris from vents and electrical contacts y lowing

with compressed air. Always wear safety goggles when cleaning tools

with compressed air.

•Keep tool handles clean, dry and free of oil or grease.

•Use only mild soap and a damp cloth to clean the tool, keeping away from

all electrical contacts.

Note: Certain cleaning agents and solvents are harmful to plastics and other

insulated parts. Some of these include gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning solvents, ammonia and household detergents

containing ammonia.

Tool maintenance must only e performed y qualified repair personnel. If the

tool is not working properly, do not attempt to repair it yourself. Contact the

Kogan customer support team.

10

Other Certa Power Tools manuals