Certa CTCHSH350WA User manual

350W CHAINSAW

SHARPENER

CTCHSH350WA

WARNING: Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed below may result in electric shock,

fire and/or serious injury.

• Save all warnings and instructions for future reference.

• The term "power tool" in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

Work area safety

• Ensure your work area is clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical safety

• This power tool plugs must match the power outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

• Do not abuse the power cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

SAFETY & WARNINGS

Personal safety

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of distraction while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that

have the switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

• Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce

dust-related hazards.

• Do not let familiarity gained from frequent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause severe

injury within a fraction of a second.

Power tool use and care

• Always use the correct power tool for your application.

• The correct power tool will do the job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk

of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools and accessories. Check for misalignment or seizing of moving

parts, breakage of parts and any other condition that may affect the power tool’s

operation. Many accidents are caused by poorly maintained power tools. If

damaged, cease use immediately and contact Kogan.com for support.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to seize and are easier to control.

• Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

• Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control

of the tool in unexpected situations.

Service

• Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

• If the replacement of the supply cord is necessary, please contact Kogan.com for

support.

Safety instructions for cut-off machines

Cut-off machine safety warnings

• Position yourself and bystanders away from the plane of the rotating wheel. The

guard helps to protect the operator from broken wheel fragments and accidental

contact with wheel.

• Use only bonded reinforced cut-off wheels for your power tool. Just because an

accessory can be attached to your power tool, it does not assure safe operation.

• The rated speed of the accessory must be at least equal to the maximum speed

marked on the power tool. Accessories running faster than their rated speed can

break and fly apart.

• Wheels must be used only for recommended applications. For example: do not

grind with the side of a cut-off wheel. Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to these wheels may cause them to shatter.

• Always use undamaged wheel flanges that are of correct diameter for your

selected wheel. Proper wheel flanges support the wheel thus reducing the

possibility of wheel breakage.

• The outside diameter and the thickness of your accessory must be within the

capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

• The arbour size of wheels and flanges must properly fit the spindle of the power

tool. Wheels and flanges with arbour holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate excessively and may

cause loss of control.

• Do not use damaged wheels. Before each use, inspect the wheels for chips and

cracks. If the power tool or wheel is dropped, inspect for damage or install an

undamaged wheel. After inspecting and installing the wheel, position yourself and

bystanders away from the plane of the rotating wheel and run the power tool at

maximum no load speed for one minute. Damaged wheels will normally break

apart during this test time.

• Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing

protectors, gloves and shop apron capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of stopping flying debris generated

by various operations. The dust mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged exposure to high intensity noise

may cause hearing loss.

• Keep bystanders a safe distance away from work area. Anyone entering the work

area must wear personal protective equipment. Fragments of workpiece or of a

broken wheel may fly away and cause injury beyond immediate area of operation.

• Position the cord clear of the spinning accessory. If you lose control, the cord may

be cut or snagged and your hand or arm may be pulled into the spinning wheel.

• Regularly clean the power tool’s air vents. The motor’s fan can draw the dust inside

the housing and excessive accumulation of powdered metal may cause electrical

hazards.

• Do not operate the power tool near flammable materials. Do not operate the power

tool while placed on a combustible surface such as wood. Sparks could ignite

these materials.

• Do not use accessories that require liquid coolants. Using water or other liquid

coolants may result in electrocution or shock.

• Operate the grinder within its indicated design specification. Your grinder has a

plate indicating:

1. Size of arbour.

2. No-load speed in revolutions per minute.

3. Proper grinding wheel.

• Keep work area clean. Cluttered areas and benches are safety hazards. Ensure

that the working area of the grinding wheel is free of tools or other objects before

starting up the grinder. Frequently clean grinding dust from beneath the grinder.

• Do not use power tools in damp or wet environments or expose them to rain. Be

sure to keep the work area well lighted.

• Check the position of the power cord during operation making sure that it remains

outside the range of action of the grinding wheel and is not under tension. Never

operate in the vicinity of other electrical cables/cords.

• Ensure the workshop is child proof with padlocks and master switches. Also, do not

allow anyone but the operator to touch the power cord or remain in the close

vicinity of the grinder while operating.

Note:

The power supply cable/cord comes complete with terminals and circuit protection.

Connecting the power supply cable/cord terminals directly into the switch

completes the electrical system for the grinder. The final electrical connection to the

outlet should be made in such a way as to prevent damage by individuals or

passing vehicles that could endanger both them and the operator.

• Before starting the grinder, ensure that the grinding wheel is correctly secured and

positioned in the up, rest position. Do not over-tighten the wheel mounting flange

nut.

• Use the vice to hold the chain. It frees both hands for moving the grind head/wheel

down to grind the chain.

• Never stand on an unstable platform.

• Always work in a stable and safe position. Serious injury could occur if the grinder is

tipped or if the cutting tool is unintentionally contacted.

• Maintain tools with care. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

WARNING: The grinder must be used only in a place that is protected from

dust and dampness, that is well-lit, out of the reach of children and away

from gases or other flammable or explosive liquids.

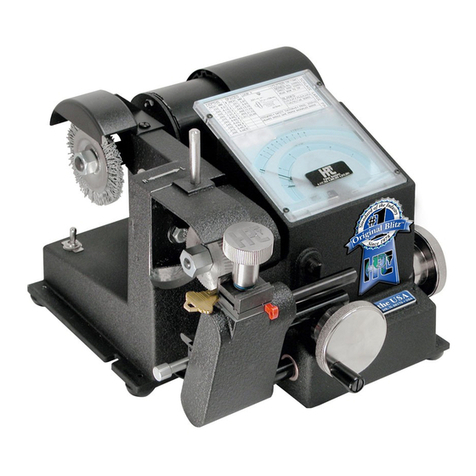

Part List

1

Handle

2

Grinding disk lateral guard

3

Depth adjustment screw

4

Cutting edge angle adjustment wheel

5

Base

6

Screw clam cradle

7

Angle adjustment wheel

8

Scale

9

Clamping lever

10

Mean distance adjustment screw

11

Guide flap valve

12

Screw clamp

13

Guide position set screw

14

Setting screw

15

Grinding disk

16

Grinding disk protective enclosure

OVERVIEW

Mounting Base Unit to Bench/Wall

1. Mount base assembly on a bench top or post, using x2 lag bolts or nuts and bolts

(not provided). Mount at chest height for best visibility and ease of operation.

2. For bench mounting, ensure the base unit extends out from the bench edge

clearing the extending tabs of the base unit as shown (Figure 1).

3. For wall application (Figure 2) use lag or expansion bolts (not provided).

Note: For wall mounting, the position adjustment knob (

4

) (Figure 4) will need to be

replaced with the supplied nut and washer (

2 & 3

).

INSTALLATION

Mounting Motor/Head Assembly to Base Unit

1. Mount pivot point on the motor/head assembly into the pivot hole located in the

centre of the base assembly back (Figure 3).

2. Insert bolt through the holder at the base of the motor/head assembly into the

base assembly back (Figure 3).

3. Attach washer and knob onto bolt on the back side of the base assembly back

(Figure 4).

Mounting Operating Handle

1. Attach operating handle to motor/head (Figure 5).

Selecting and Mounting the Grinding Wheel

1. For the appropriate size grinding wheel;

2. Ensure that the grinding wheel is in perfect condition. Hang the wheel by the

centre hole and tap it lightly with a metal object on one side near the perimeter. If a

flat tone is heard it may be cracked or broken. Do not use! (Figure 6).

3. Insert the bolt through the arbour (Figure 7).

4. Position the grinding wheel inside the shield guard assembly onto the motor flange

and insert arbour bolt, with washer, through the wheel centre hole into motor shaft.

Tighten the arbour bolt, with the large 5.5mm Allen wrench (Figures 8 and 9). Do

not over -tighten this bolt, as doing so may cause damage to the wheel, rendering

it unusable.

Dressing the Grinding Wheel

1. Set the motor/head to the 90-degree position.

2. With the grinder in the “OFF” position. Check the profile of the wheel using the

special template (provided with this unit). If the wheel profile is not correct

according to the template, the wheel will need to be dressed until it does fit the

proper profile.

3. Connect the power cord to the outlet and turn the grinder to the “ON” position.

4. From a safe distance at the side of the unit, observe the grinding wheel as it turns

to make sure it does not oscillate either laterally or transversally. If wheel turns in a

true and even rotation, allow wheel to turn for one minute before wheel is dressed.

Note: If the wheel does not run true, turn the unit off, troubleshoot and correct the

problem before proceeding.

5. Begin dressing the full radius of the wheel with the use of the dressing brick

provided with this unit (Figure 11). For best results use quick, light strokes with the

brick to form the desired profile (Figure 10).

6. Tu r n t h e u n i t OFF and use the special orange template to re-check the profile of

the wheel (Figure 11).

Note: If necessary, turn electrical power on and repeat steps 5 and 6 until desired

profile of the wheel is obtained.

11

\\

Grinding a Chain

There is risk of serious personal injury for chain saw operators or bystanders from improperly

sharpened saw chain. Read and follow all manufacturer’s instructions for your saw chain.

• For best results it is recommended that the chain be clean before grinding.

• Always wear approved eye protection during all steps of the grind operation and

when the grinding wheel is in motion.

• Grind all cutters of the same type (left or right) before positioning the grinding

wheel to the opposite side.

• When changing the grind position, ensure the unit is turned to the “OFF” position

(white on/off switch or toggle on/off switch located on the top of the motor support

arm) and the wheel has come to a full stop before making any adjustments.

• To a v o i d o ve r l o a d i n g t h e m o t o r a n d t o p r e v e nt d a m a g e t o t h e s a w c h a i n , r e m o v e

only the minimum amount of material necessary and do not grind any one tooth

for too long a period. Using 2-3 light strokes per cutter will help avoid the possibility

of any cutter burns.

• Do not use cooling liquids while grinding.

• Replace worn grinding wheels when the diameter of the wheel reaches 70mm

(2.8”).

OPERATION

WARNING: Immediately unplug the power cord if the motor does not

turn the wheel when the grinder power switch is in the “on” position.

Grinding for Bench or Wall Mounted Workstations

Note: All adjustments must be made prior to applying power to the unit.

1. Position the saw chain to be ground onto the vice (Figure 12).

2. Setting top-plate cutting angle:

Set grinder head angle to correct degree (Figure 13). Adjustment is made by loosening

adjustment knob, at the back end of the grinder and rotating the grinder head to the

desired angle. (Figure 14).

3. Set cutter top-plate grind angle by rotating vice assembly to the right of centre (0°)

(Figure 15).

4. Rotate vice assembly to the left of centre (0°) (see Figure 16).

5. Setting vice-tilt angle:

The cutting chain vice assembly has a tilting feature, (Figure 17), that is used to

control the side plate hook angle on some chains. Use centre mark for chains

requiring 90°

5. Tilt vice to INWARD position for left-hand cutters (Figure 18).

6. Tilt vice to OUTWARD position for right hand cutters (Figure 19).

7. Set the chain stop. Using the cutting chain stop centring knob, centre the chain

stop behind the cutter as shown (Figure 20). Make final adjustments to the chain

stop by adjusting the knob at the back of the chain stop support.

8. Centre the cutting chain in the vice.

Loosen lock nut with 10mm wrench (Figure 21). Centre chain by using 5.5 Allen

wrench (Figure 22). Once centred, retighten nut.

Note: This setting will keep the left and right hand cutters equal when grinding top-

plates.

9. Set grind depth. Locate the chain cutter for grinding. Lower the grinding wheel

(with motor off) into the gullet (Figure 23). Set depth of grind by using the depth

adjustment knob (Figure 24).

10. Grind the cutters. Grind all right-hand cutters, rotate vice and grind all left-hand

cutters.

ASSEMBLY

Table of contents

Other Certa Power Tools manuals

Popular Power Tools manuals by other brands

EINHELL

EINHELL TE-CD 14,4-2 2B Li Original operating instructions

SCANMASKIN

SCANMASKIN Scan Combiflex Handyman Operation manual & spare parts list

Fast Mover

Fast Mover FMT7560 Product instruction manual

Castellari

Castellari RYNO Series manual

Wahl

Wahl Fusion C302-S2 instruction manual

Bosch

Bosch 1587AVSP-1 - 5 Amp Top-Handle Jig Saw parts list