Ceyear 87230 Series User manual

87230 Series

USB CW Power Sensor

Quick Start Guide

This manual is applicable to the following types of USB CW power sensors:

87230: 9 kHz ~ 6 GHz.

87231: 10 MHz ~ 18 GHz.

87232: 50MHz ~ 26.5GHz.

87233: 50MHz ~ 40GHz.

Options:

English options: English menu and English interface, for Export models

Version: A.1 March 2018, China Electronics Technology Instruments Co., Ltd

Address: No.98, Xiangjiang Road, Qingdao City, China

Tel: +86-0532-86896691

Website: www.ceyear.com

E-mail: sales@ceyear.com

Postal code: 266555

Foreword

Thank you for choosing and

using the 87230 series CW

power sensor researched and

produced by China Electronics

Technology Instruments Co.,

Ltd! Our product is high-end,

precise and sophisticated, and

embraces a high cost

performance among the

competitors of the same class.

We are devoted to providing for

you high-quality products and

first-class after-sales service

with your most concerns and

demands in mind. Our

consistent aim is providing

excellent quality and good

service, and this is our sincere

commitment for all users.

Manual No.

AV2.984.1215SK

Version

A.1 2018.03

China Electronics Technology

Instruments Co., Ltd.

Manual Authorization

This manual may be subject to

change without notice. CETI

reserves all the rights to the

final explanation for all the

information and terminologies

referred to in this manual.

This manual is the property of

CETI. Without CETI's

permission, any organizations

or individuals shall neither alter

nor duplicate/transmit this

manual for profits; otherwise,

CETI reserves the right to

pursue any liabilities therefrom.

Product Warranty

The warranty period of this

product is 18 months from the

date of delivery. Instrument

manufacturer will repair or

replace the damaged parts

according to the actual

situation in the warranty period.

The specific maintenance

matters should be subject to

the contract.

Product Quality Certification

This product is certified to fulfill

the standards indicated in this

manual from the day of delivery.

Calibration measurements

have been carried out based on

national standards. Related

information is available to the

user for reference.

Quality/environment

management

The quality and environmental

management systems have

always been implemented

during development,

manufacturing and test of this

product. China Electronics

Technology Instruments Co.,

Ltd. is properly qualified and

certified by ISO 9001 and ISO

14001 management system

standards.

Safety Precautions

"Caution" indicates a danger. It

reminds the user to be cautious

of a certain operation process,

operation method or the similar.

Failure to follow the rules or

operate correctly may result in

the minor or moderate personal

injury and equipment damage.

The conditions indicated by

CAUTION should be fully

understood and met before the

next operation.

CAUTION indicates an

important information rather

than danger. It reminds the

user to be cautious of a certain

operation process, operation

method or the similar. Failure to

follow the rules or operate

correctly may cause the

damage to the instrument or

loss of important data. The

conditions indicated by

CAUTION should be fully

understood and met before the

next operation.

ATTENTION

CAUTION

!

87230 Series USB CW Power Sensor

Table of Contents

1

Table of Contents

1 About This Manual.............................................................................................................................. 1

1.1 About This Manual................................................................................................................ 1

1.2 Related Documents.............................................................................................................. 1

2 Preparation before use....................................................................................................................... 3

2.1 Preparation before Operation............................................................................................... 3

2.2 Routine Maintenance.......................................................................................................... 10

3 Typical Applications.......................................................................................................................... 12

3.1 Selection of Power Sensor................................................................................................. 12

3.2 Virtual Power Measurement Panel..................................................................................... 12

3.3 Zeroing and Calibration Before Measurement................................................................... 14

3.4 CW Power Measurement................................................................................................... 15

4 Getting Help...................................................................................................................................... 18

4.1 Fault Diagnosis and Troubleshooting................................................................................. 18

4.2 Error Information................................................................................................................. 19

4.3 Repair Methods.................................................................................................................. 19

1 About This Manual

1.1 About This Manual

1

1 About This Manual

This chapter introduces the functions, compositions, and main content in the User’s Manual of the 87230

Series USB CW Power Sensor as well as other related documents provided to the user.

About This Manual…………………………………………………………………………… .................... 1

Related Documents……………………………………………………………………………................... 1

1.1 About This Manual

This manual introduces the basic functions and operation methods of the 87230 series USB CW power

sensor. This manual introduces the features, basic usage, measurement configuration guides, remote

control, maintenance and specifications of the instrument to help you familiarize yourself with and

master the operation methods and essentials as soon as possible. To facilitate your familiarity with the

instrument, please read this manual carefully before operating the instrument, and then follow the

instructions of manual.

The chapters included in this User's Manual are as follows:

Preparation before Use

This chapter introduces the pre-operation inspection of 87230 series CW power sensor to enable the

user to get ready for the correct and safe operation of the instrument.

Typical Applications

This chapter introduces operation methods of all functions of the instrument, including sensor selection,

virtual panel introduction, zero and calibration before measurement and continuous wave power

measurement, which is intended to make users understand and master some basic operation methods

of the 87230 series USB CW power sensor.

Getting Help

This chapter includes basic fault diagnosis, solution, error information description, and repair methods.

1.2 Related Documents

The product document related to 87230 series USB CW power sensor includes:

Quick Start Guide

User Manual

Programming Manual

Quick Start Guide

This manual introduces the settings of the instrument as well as the basic operating methods of

measurement with the aim of enabling users to quickly understand the features and basic local and

remote control operation of the instrument. Main chapters included in this manual are as follows::

About This Manual

Preparation before Use

Typical Applications

Getting Help

User Manual

This manual gives a detailed introduction of features and operation methods of the instrument, including

information about configuration, measurement, remote control, maintenance, etc. so as to provide users

with an all-round understanding of the features of the instrument and aid users in learning the most

common test procedures. Main chapters included in this manual are as follows::

About This Manual

1 About This Manual

1.2 Related Documents

2

Overview

Start Guide

Operation Guide

Remote Control

Fault Diagnosis and Repair

Technical specifications

Programming Manual

This manual describes the basics of remote control programming, basics of SCPI, SCPIs, examples of

programming, and I/O driver library, for the purpose of guiding the user to master the SCPIs and

methods of the instrument quickly and comprehensively. Main chapters included in this manual are as

follows::

About This Manual

Remote Control

SCPI

Programming Examples

Error Description

Appendixes

2 Preparation before use

2.1 Preparation before Operation

3

2 Preparation before use

This chapter introduces the precautions and routine maintenance before use of the 87230 series USB

CW power sensor to facilitate the user to have a preliminary understanding of the instrument. The

content contained in this chapter is consistent with that in relevant chapters of Quick Start Guide.

Preparations before operation…………………………………………………………………… ............. 3

Routine Maintenance………………………………………………………………………………........... 10

2.1 Preparation before Operation

This chapter introduces the precautions before the first use of the 87230 series USB CW power sensor.

Damage prevention

To avoid the electric shock, fire and personal injury:

Do not open the chassis without authorization;

Do not attempt to dismantle or modify any part not described in this manual. Improper removal may

cause the deterioration of electromagnetic shielding effectiveness, damage of internal parts, etc.

and affect the reliability of product. If the product is under warranty, we will no longer provide the

unpaid repairs.

Please carefully read relevant content of “2.2 Safe Use Guideline” of the User’s Manual and the

following precautions for safe operation. In addition, attention shall be paid to relevant specific

operating environment requirements specified in the reference data page.

During instrument operation, please pay attention to the following aspects:

Improper application site or measurement setting will damage the instrument or the connecting device.

Before powering on the instrument, please pay attention to the followings:

Keep the instrument dry;

Place the instrument horizontally and reasonably;

Ensure that the surrounding temperature is in accordance with the requirements on the reference

data page.

Ensure that the power level of the port input signal conforms to the mark range;

Ensure that the signal output port is properly connected and isn't overloaded.

ESD protection

Pay attention to the ESD protection measures in the workplace to avoid the damage to instrument. For

details, please refer to relevant content of “2.2 Safe Use Guideline” of the User’s Manual.

Attention

WARNING

!

ATTENTION

2 Preparation before use

2.1 Preparation before Operation

4

Effect of electromagnetic interference (EMI):

The electromagnetic interference can affect the measurement results, therefore, it is necessary to:

Select appropriate shielded cables, for example, use RF shielded twisted pair/network connection

cable;

close the opened and temporarily unused cable connection port or connect the matched load to the

connection port in time;

Refer to the electromagnetic compatibility (EMC) grade in the User’s Manual.

2.1.1 Unpacking

1) Visual inspection

Step 1. Check if there is any damage in the outer packaging and the anti-vibration packaging of the

instrument. If no damage is found, keep the packaging in case of future need and continue the

inspection

as per the following steps;

Step 2 Unpack the instrument and check for any damage to the main unit and attached items.

Step 3. Verify the items in the packaging box carefully by cross-checking with Table 2.1;

Step 4. If the outer package is broken, the instrument or accessories are damaged or there is any error

of the delivery, it is strictly forbidden to switch on the instrument! Please contact our service center via

the service hotline indicated on the cover,

Please contact our service consultation center through the service consultation hotline, and we will make

repairs and replacements rapidly based on individual circumstances.

2) Model confirmation

Table 2.1 Packing List of 87230 Series

Name

Quantity

Function

Main unit:

87230 series

1

Main unit

Standards:

USB cable

1

Special lockable USB cable, 2 m

CD

1

Including virtual panel, programming manual, driver, and

programming example

User Manual

1

—

Certificate of Conformity

1

Attached on the body

NOTE

2 Preparation before use

2.1 Preparation before Operation

5

2.1.2 Environment requirements

The operating place of the 87230 series USB CW power sensor shall meet the following environment

requirements.

1) Operating environment

The operating environment should satisfy the following requirements:

Table 2.2 Operating Environment Requirements of the 87230 Series

Temperature

10°C ~ 40°C

Temperature range during

error adjustment

23°C ±5°C (allowed temperature deviation during error adjustment<1°C)

Humidity

Hygrometer measurement range: 20% ~ 80% (uncondensed) when the

temperature<+29°C

Altitude

0 ~ 4,600 m

Vibration

Maximum: 0.21 G, 5 Hz ~ 500 Hz

The above environmental requirements are only defined for the operating environment of the instrument

and are not within the scope of specifications.

2) ESD protection

The static electricity is destructive to electronic components and equipment. Generally, we will use two

anti-static measures, including combination of conductive table mat and wrist combination as well as

combination of conductive floor mat and ankle strap. If these two combinations are used together, a

good anti-static protection can be provided. If the combination is used separately, only the former can

provide protection. For the safety of users , anti-static components must provide an isolation resistance

of at least 1 MΩ to the ground.

Please correctly use the following anti-static measures to reduce electrostatic damage:

Ensure that all instruments are properly grounded to avoid generating static electricity;

Before connecting the coaxial cable to the instrument, contact its inner and outer conductors with

the ground temporarily;

The staff shall wear anti-static wrist straps or adopt other anti-static measures before contacting

joints and core wires or carrying out any assembly operation.

Operating voltage range

The above anti-static measures can’t be taken in a place where the voltage exceeds 500 V.

ATTENTION

WARNING

!

2 Preparation before use

2.1 Preparation before Operation

6

2.1.3 Power on/off

1) Host system requirements

The 87230 series USB CW power sensor shall be applied with the standard USB mini-AB socket, and

shall be subject to power display or direct remote control on the computer or other test instrument with

USB host interface.

Before using the USB CW power sensor, please ensure that the host satisfies the following

requirements:

The computer or any hardware device with a USB host interface;

Support Windows98SE/ME/XP/2000/2003/Win7/WIN10 or higher version;

The host is installed with the version above VISA3.0 and the virtual power test panel provided along

with the machine;

It is also available for programming through the remote programming software including Microsoft®

Visual Basics, C++ and LabVIEW.

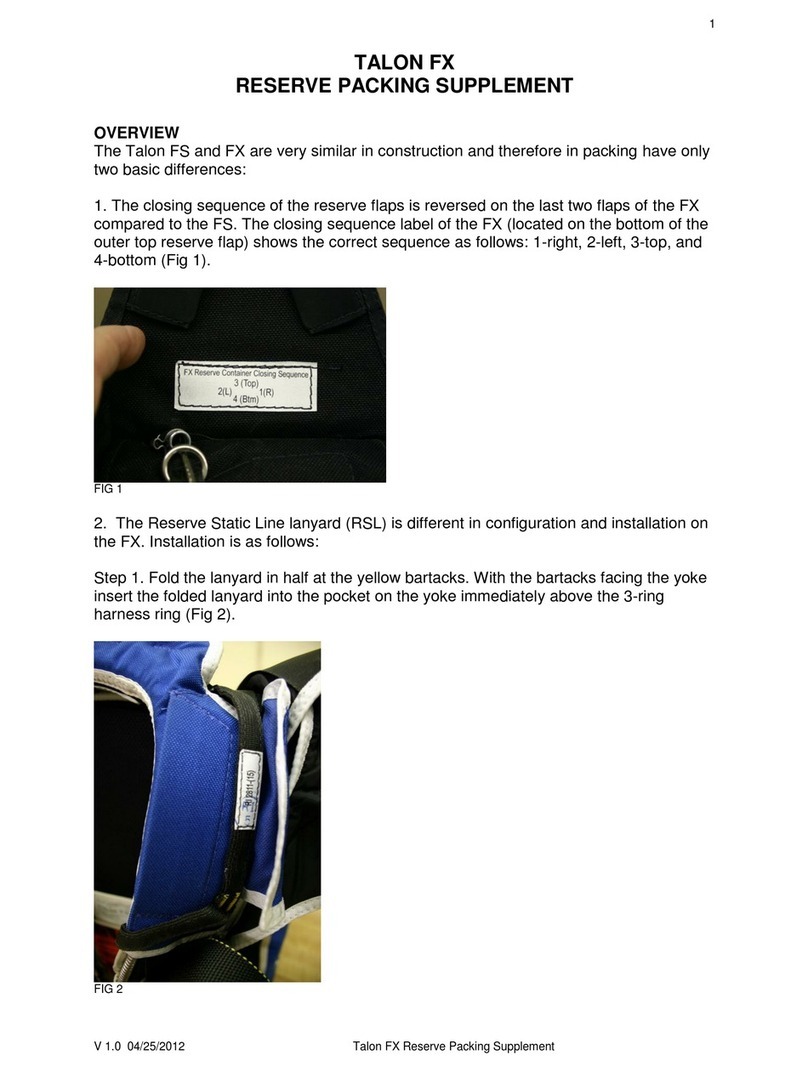

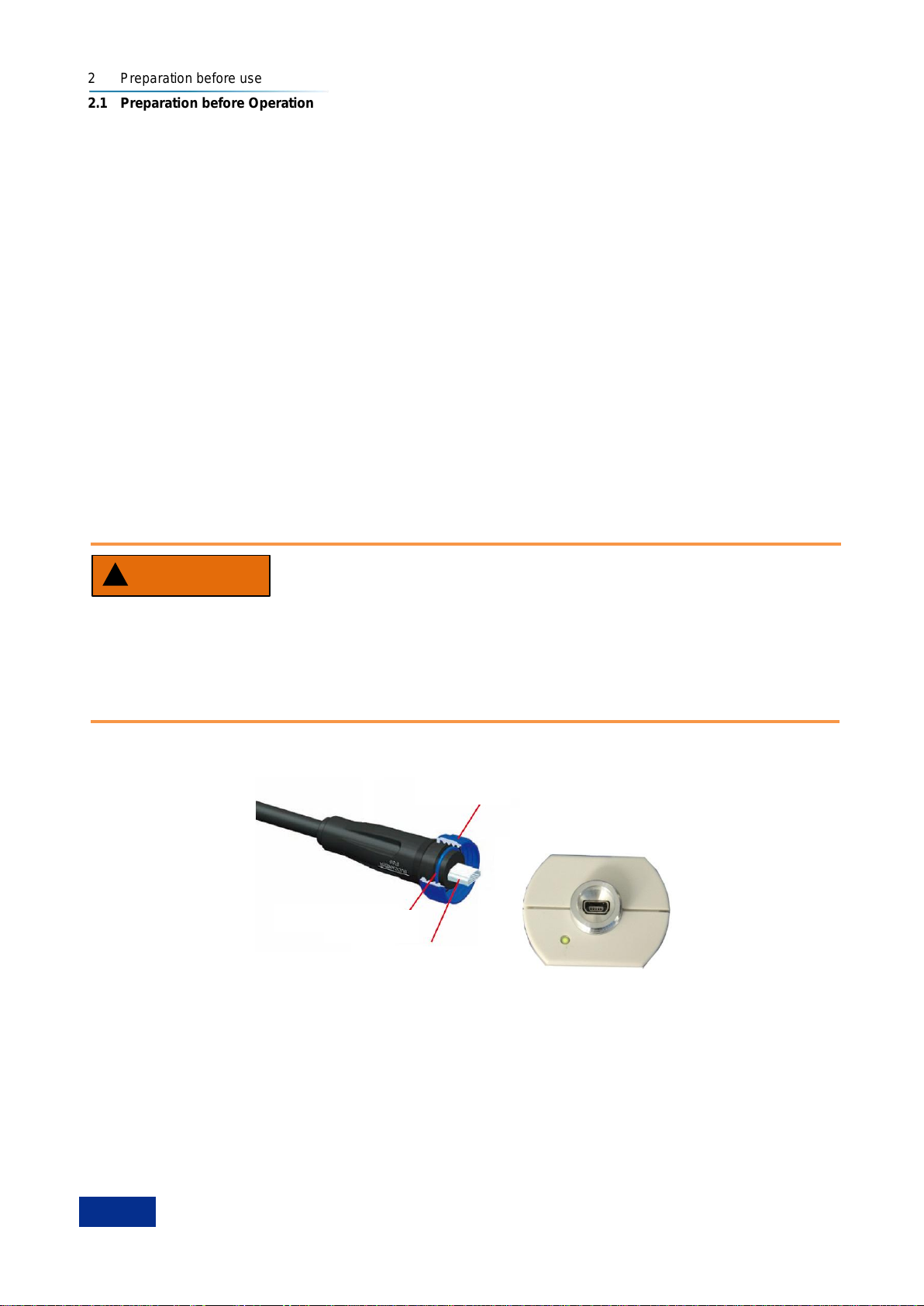

2) USB cable selection

The 87230 series USB CW power sensor is equipped with special USB cable, which can be screwed

and fixed on the body, as shown in Fig. 2.1. The user can also use his own USB cables, but shall ensure

that cables satisfy the international safety standards.

Prevent personal injury and damage to the instrument.

Poor contact or wrong wiring may lead to instrument damage or even personal injury. Therefore, the

users are recommended to use the USB cable provided by us. If other non-standard cables shall be

used, please contact our technical personnel.

Fig. 2.1 Fixable USB Cable

3) Charge of the instrument

The 87230 series USB CW power sensor is applied with the computer standard USB interface. Table 2.3

lists the power supply requirements of the 87230 series USB CW power sensor during normal operation.

WARNING

!

Fixed nut

Sealing ring

Mini USB connector

2 Preparation before use

2.1 Preparation before Operation

7

Table 2.3 Variation Range of Working Power Supply of the 87230 Series

Power Supply

Parameter

Applicable Scope

Output voltage

+5 V ±5% DC

Rated current

0.5A

The normal power consumption of the 87230 series USB CW power sensor is 1.8 W. When the

computer USB interface is inserted with multiple USB devices and it can’t guarantee that each interface

can provide 0.5A output current, the computer will prompt that some sensors can’t be found. In this case,

please use the USB HUB with external power supply.

Connect the sensor with the USB port of the host with the USB cable conforming to the requirements,

and observe whether the green indicator lamp of the sensor is lit up.

Step 1. Connect the small port of the USB cable with the 87230 series USB CW power sensor and

tighten it, and then connect its large port with the computer or measurement instrument USB host

interface, and the power sensor green indicator lamp will light up later;

Step 2. The “Equipment Manager” of the host can find the new “USB Test and Measurement Devices”.

Fig. 2.2 Connecting the USB CW power sensor to the Computer

4) Power off

Remove the USB cable to turn off the USB CW power sensor. In this case, the green LED indicator lamp

will go out.

2.1.4 Correct Use of Connectors

During test of the USB CW power sensor, it shall be connected to the USB cable and then connected to

the source to be tested. The 1.85 mm, 2.4 mm and 3.5 mm male connectors shall be used, and even

different types of switching adapters shall be used. Even though connectors are designed and

manufactured according to the highest standards, their service life is limited. Wear is unavoidable in

normal use and can make the connector performance degrade or even unable to meet the measurement

requirement, therefore, correct maintenance and measurement connections not only provide accurate

and repeatable measurement results but also prolong the useful life, reduce the measurement cost.

2 Preparation before use

2.1 Preparation before Operation

8

Note the following aspects during actual use:

1) Check of connectors

It is necessary to wear an anti-static wrist strap when checking the connectors. It is recommended to use

a magnifier to check:

1) the electroplated surface for wear and deep scratches;

2) the thread for deformation;

3) the thread and joint surface for metallic particles;

4) the inner conductor for bending and breakage;

5) the screw for improper rotation.

Check the connectors so as not to damage the instrument ports

Any damaged connector may damage the good connector connected to it even for the first time of

measurement. To protect the ports of the USB CW power sensor, the connector to be used shall be

checked before connection.

2) Connection

The connectors should be checked and cleaned before measurement and connection to ensure that

they are clean and undamaged. It is necessary to wear an anti-static wrist strap during connection. The

correct connection methods and procedures are as follows:

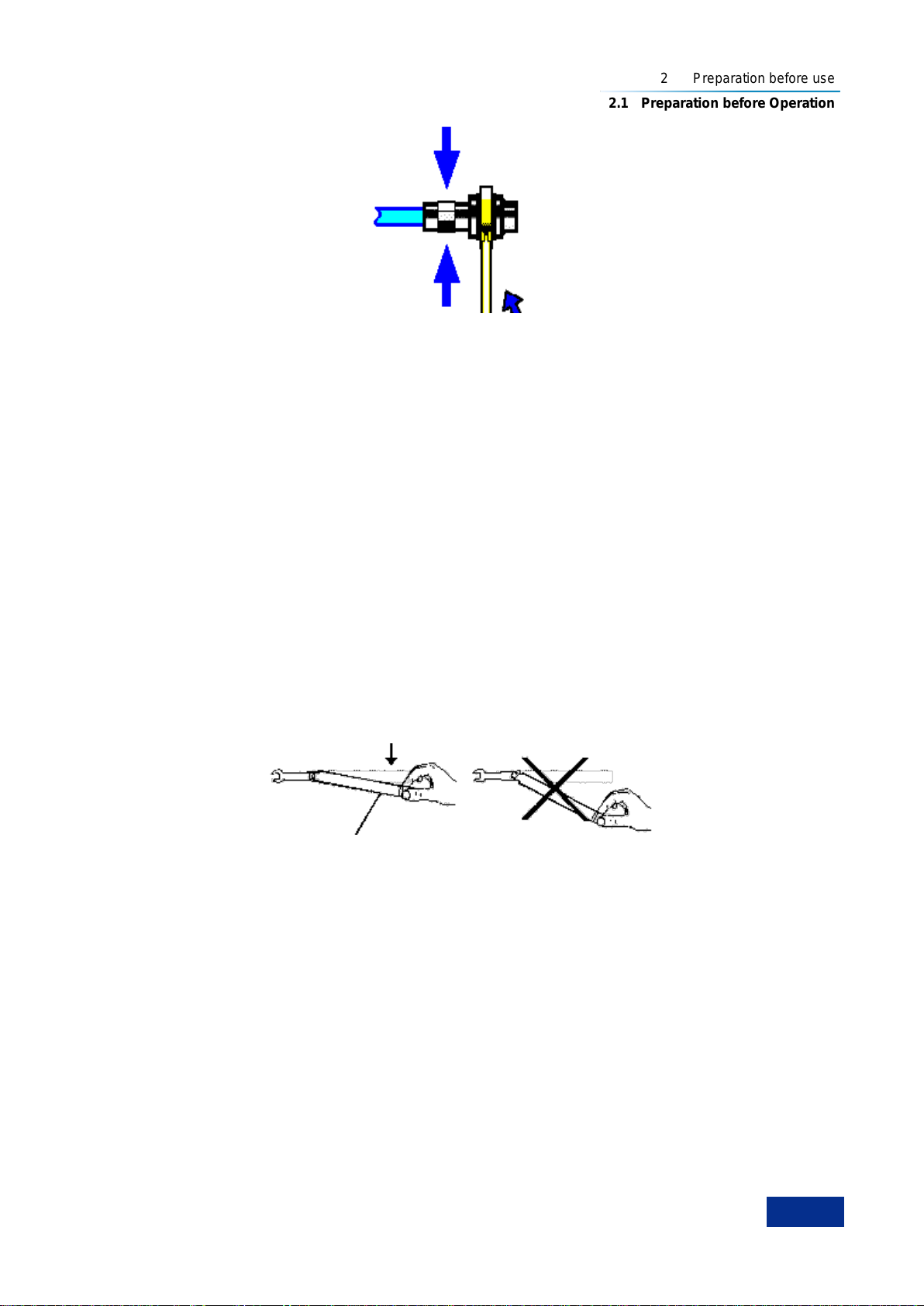

Step 1. As shown in Figure 2.3, align the axes of the two interconnected connectors to ensure that the

pin of the male connector slides concentrically into the hole of the female connector.

Fig. 2.3 CoaxialAlignment of Interconnected Connectors

Step 2. As shown in Fig. 2.4, move both connectors straight together, so that they can be connected

smoothly; rotate the threaded sleeve of connector (rather than the connector itself) until it is tightened;

during connection, there can be no relative rotary motion both connectors;

Fig. 2.4 Connection

Step 3. As shown in Fig. 2.5, use a torque wrench to tighten the connectors and finish the connection;

the torque wrench shall not exceed the starting break point and an auxiliary wrench can be used to

prevent the connector rotating.

CAUTION

!

Keep it

unmoved

Rotate the

screw

2 Preparation before use

2.1 Preparation before Operation

9

Fig. 2.5 Completion of Final Connection with a Torque Wrench

3) Disconnection

Step 1. Support the connector to prevent any part from being shaken, distorted, or bent;

Step 2. Use an open-end wrench to prevent the main connector from rotating;

Step 3. Use another wrench to loosen the screw on the connector.

Step 4. Loosen the screw by hand until the connection is completely broken.

Step 5. Separate two connectors by pulling them apart in parallel.

4) Use of the torque wrench

The torque wrench should be used as indicated in Figure 2.6. Please pay attention to the following points

when using the torque wrench:

Confirm that the torque of the torque wrench is set correctly before use;

Ensure that the angle between the torque wrench and the other wrench (used to support the

connector or cable) is less than 90obefore applying a force;

Gently grasp the end of the torque wrench handle and apply a force in the direction perpendicular to

the handle until the breakout torque of the wrench is reached.

Fig. 2.6 Use of Torque Wrench

5) Use and preservation of connectors

1) Protect the connectors with a protective sheath when not used;

2) Do not place the connectors, tools, etc. in a same box, which is the most common cause leading to

connector damage;

3) Keep the connector and analyzer at the same temperature. If the connector is held by hand or

cleaned with compressed air, the temperature will be significantly changed. The connector can be

used for calibration only after its temperature is stabilized;

4) Do not touch the joint surface of the connector because it is difficult to remove skin oil and dust

particles from the joint surface;

5) Do not place the contact surface of the connector downwards onto a hard surface; otherwise, the

electroplated layer and joint surface of the connector may be damaged.

Torque direction

Stop applying a force when the handle bends

Keep it

unmoved

2 Preparation before use

2.2 Routine Maintenance

10

6) Wear an anti-static wrist strap and work on a grounded conductive workbench mat to protect the

analyzer and connector against electrostatic discharge.

6) Cleaning of connectors

It is necessary to wear an anti-static wrist strap when cleaning the connectors as per the following steps:

1) Use clean low-pressure air to remove the loose particles on the thread and joint surface of the

connector and check the connectors thoroughly. If further cleaning is required, proceed as follows;

2) Wet (but not soak) a lint-free cotton swab with isopropyl alcohol;

3) Use a cotton swab to remove dirt and debris from the joint surface and thread of the connector.

When cleaning the inner surface, be careful not to apply an external force to the central inner

conductor or leave the cotton swab fibers on the central conductor of the connector;

4) Evaporate the alcohol and then blow the surface clean with compressed air;

5) Check the connectors to confirm that they are free of particles and residues;

6) If the connector still has visible defects after cleaning, it indicates that the connector may be

damaged. Never use a damaged connector, and confirm the causes of damage before

measurement and connection.

7) Use of adapter

When the measuring port of analyzer is different from the type of connector used, an adapter must be

adopted for measurement connection. In addition, even if the measurement port of the analyzer is the

same as the type of connector for the port of tested part, it is also a good idea to use an adapter. Under

these two conditions, the measuring port can be protected, thus extending its service life and reducing

the maintenance cost. Before connecting the adapter to the measuring port of analyzer, it should be

carefully checked and cleaned. A high-quality adapter should be used to reduce the impact of mismatch

on the measurement accuracy.

8) Joint surface of connector

An important concept in microwave measurement is the reference surface for all measurement. In the

case of calibration, the reference surface is defined as the surface on which the measuring port and the

calibration standard are jointed. Proper connection and calibration depend on whether the connectors

can be completely and straightly contact with each other at each point of the joint surface, so as to

ensure minimum power standing-wave ratio, achieve the minimum power loss, and ensure the

measurement accuracy.

Fig. 2.7 Calibration Surface

2.2 Routine Maintenance

This section introduces the daily maintenance method of the 87230 series USB CW power sensor.

2.2.1 Cleaning method

Clean the instrument surface as per the following steps:

Step 1. Power it off, and disconnect the power cord;

Step 2. Gently wipe off the surface with a piece of dry or slightly moist soft cloth, and it is not allowed to

Joint surface

N type (female)

N type (male)

2 Preparation before use

2.2 Routine Maintenance

11

wipe off its inside;

Step 3. Do not use chemical detergents, such as alcohol, acetone or diluted detergent.

2.2.2 Maintenance of testing port

The 87230 series USB CW power sensor has a USB cable connector and a microwave power signal

input port. If the connector is damaged or there is dust inside, the RF wave band test results will be

affected; therefore, please observe the following methods for maintenance of such connector:

Connectors shall be kept clean and away from dust;

To prevent ESD, do not directly contact the connector surface;

Do not use damaged connector;

Clean connectors with a dryer, and do not grind the surface with a tool like abrasive paper.

3 Typical Applications

3.1 Selection of Power Sensor

12

3 Typical Applications

This chapter introduces the selection of the 87230 series USB CW power sensor, and detailed operation

methods and measurement procedures for different measurement functions.

Model selection of power sensor……………………………………………………………………….... 12

Virtual Power Measurement Panel…………………………………………………………………........ 12

Zeroing and Calibration Before Measurement……………………………………………………………14

CW Power Measurement…………………………………………………………………....................... 15

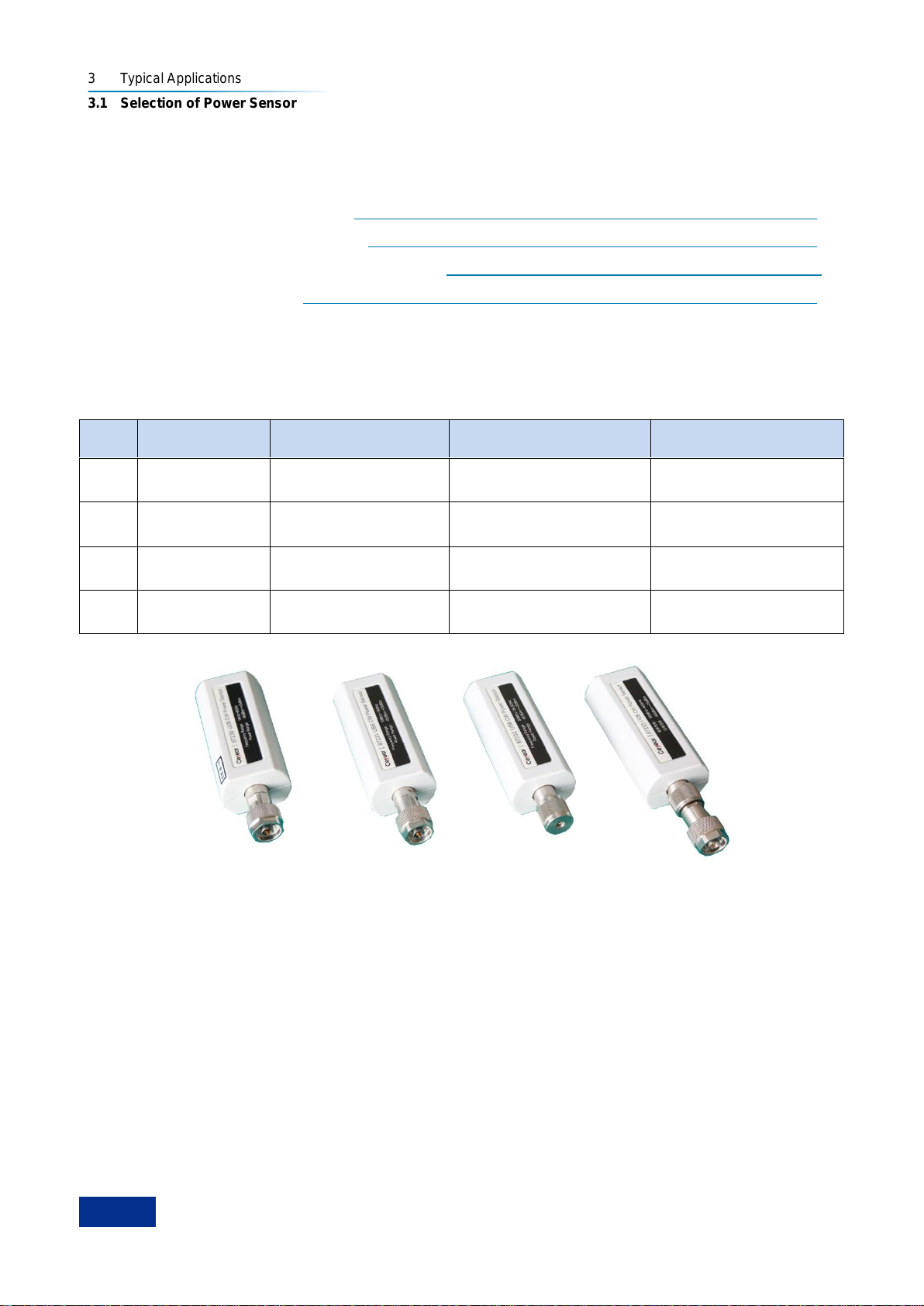

3.1 Selection of Power Sensor

The 87230 series USB CW power sensor includes four models including 87230, 87231, 87232 and

87233, as shown in the following Table.

Table 3.1 87230 Series USB CW Power Sensor

No.

Sensor Model

Power Range

Frequency range

Interface Type

1

87230

-50 dBm ~ +20 dBm

9 kHz ~ 6 GHz

N(m)

2

87231

-60 dBm ~ +20 dBm

10 MHz ~ 18 GHz

N(m)

3

87232

-60 dBm ~ +20 dBm

50MHz to 26.5GHz

3.5 mm (m)

4

87233

-60 dBm ~ +20 dBm

50MHz to 40GHz

2.4mm (m)

Fig. 3.1 87230 Series USB CW Power Sensor

The 87230 series USB CW power sensor can realize continuous wave power measurement. As the

performance specifications are different by model, the user can select the suitable sensor according to

the characteristics and measurement requirements of signals to be tested as well as the specifications of

each sensor. The basic functions of the sensor are shown in Table 3.1. Please refer to “7.3 Technical

Specifications” of the User Manual for detailed description of specifications of each sensor.

3.2 Virtual Power Measurement Panel

The USB interface of the 87230 series USB CW power sensor conforms to the USBTMC (USB Test and

Measurement) protocol, which is a kind of enumerated equipment (namely, it can be found through the

viFindRsrc function of the VISA library). The vendor ID and equipment ID (decimal) are 1204 and 4100

respectively, and the serial number are as shown in each sensor.

The user can realize the remote control of the USB sensor through the VISA library; for the specific

configuration, please refer to the Programming Manual of the 87230 Series USB CW Power Sensor, and

the virtual power test panel can also be used for the power test. The user shall install the version above

3 Typical Applications

3.2 Virtual Power Measurement Panel

13

VISA3.0 and run the virtual power test panel program provided in CD. The open virtual power test panel

is as shown in Fig. 3.2.

Fig. 3.2 Virtual Power Test Panel

Connection and operation steps of the USB CW power sensor:

Step 1. Connect the USB power sensor with the computer; open the power test panel; select the USB

device to be connected in the pop up “Instrument Connection” window in the system, and click

“Connection” button. As shown in Fig. 3.3, the measurement process is normal;

Step 2. The user can check the type, serial number and firmware version number of the USB CW

power sensor in the “System”label on the left side of the window;

Step 3. Click or button of the toolbar, and the system will display the measurement

result in the open value window or disable measurement;

Step 4. The user can set the measurement efficiency, average number of times, range selection, etc.

in the “Channel” label window;

This manual suits for next models

4

Table of contents

Popular Accessories manuals by other brands

TOPPOINT

TOPPOINT LT91130 user manual

LEGRAND

LEGRAND Wattstopper LMPC-600 quick start guide

Richelieu

Richelieu DS63202P2A1C90 user manual

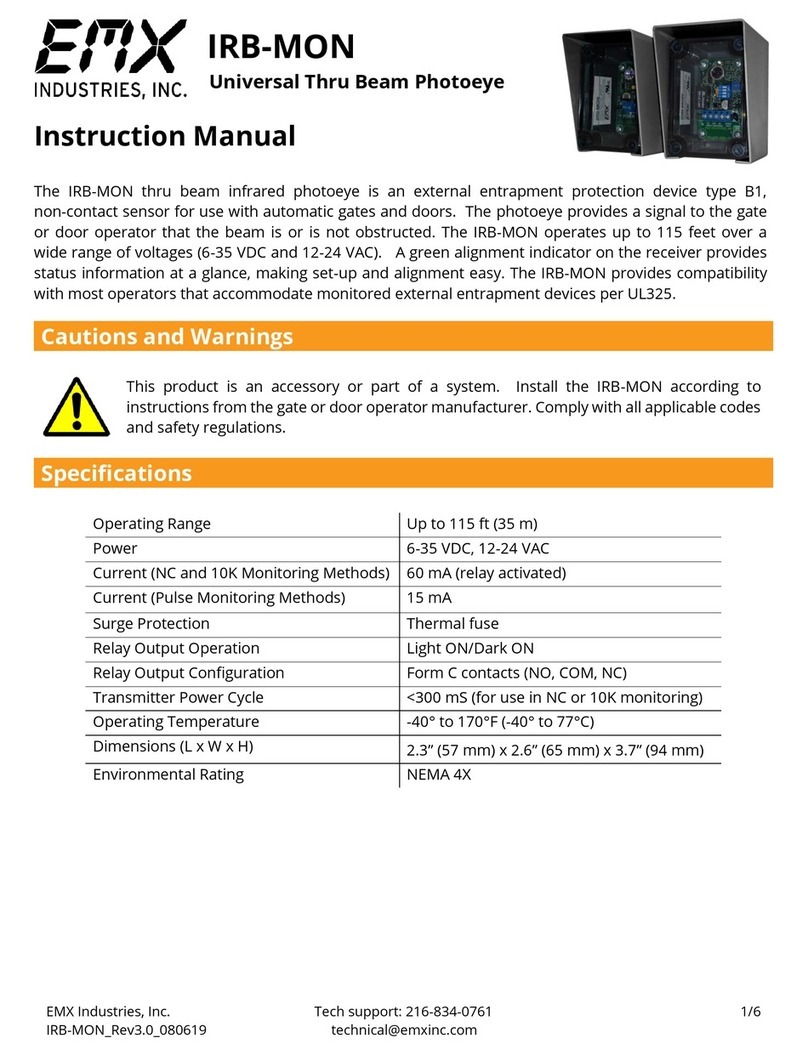

EMX Industries

EMX Industries IRB-MON instruction manual

NXP Semiconductors

NXP Semiconductors UM11227 user manual

Gordon AirPlay

Gordon AirPlay AirRingLarge owner's manual

System Sensor

System Sensor 52051E-RF Installation and maintenance instructions

Vega

Vega B-LIFT 8120 200 Evo Series manual

IFM Electronic

IFM Electronic efector 300 SU9001 operating instructions

Young Living

Young Living Desert Mist Operation manual

echoflex

echoflex TAP-31 installation guide

Sunbeam

Sunbeam TR6300 Instruction booklet