CFR Perfect Heat Pro 750 Series User manual

Perfect Heat, P

ro

500

and Pro 750 S

eries

72671A 01/2005

INSTRUCTION MANUAL

Read all instructions before using this machine.

IMPORTANT SAFETY INSTRUCTIONS

This manual is to ensure that the CFR Pro Series is operated correctly.

All operators must read, understand and practice the following safety instructions.

INTRODUCTION

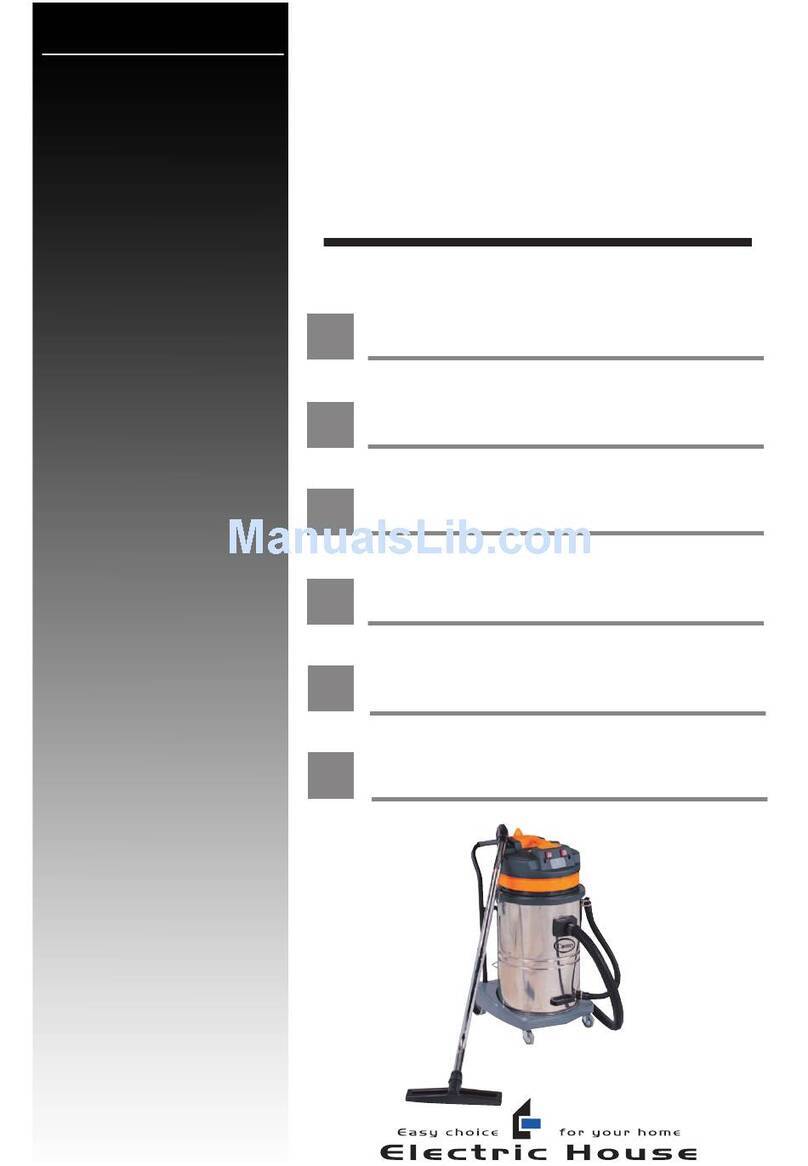

Congratulations on your purchase of a CFR Pro 500/750.

Read this entire manual before operating or servicing the .

Please complete and return the enclosed warranty card.

Parts and Service

The Paramount is covered by CFR’s Preventative

Maintenance Program which is designed to maintain the

Paramount on a quarterly basis. The program focuses on:

inspecting the equipment, replacing covered parts as

required, and identifying potential situations where a more

in-depth service or training may be required.

If service is required, it must be performed by an authorized

CFR repair center. Contact your local dealer or call

1.800.533.2557 for the location of a repair center.

Serial Number

The serial number of the machine is located on the name-

plate, located next to power switch. This information is

needed when ordering parts or scheduling repairs. Fill in

the information below for future reference:

Serial Number ___________________________________________________________________

Part Number _____________________________________________________________________

Purchase Date _________________________________________________________________

CFR PRO SERIES

2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .2

Unpacking instructions . . . . . . . . . . . . . . . .3

Safety instructions . . . . . . . . . . . . . . . . . . . .3

Preparing for cleaning . . . . . . . . . . . . . . . . .4

Operating instructions . . . . . . . . . . . . . . . . .4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . .5

Parts and drawings . . . . . . . . . . . . . . . . . . .8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .12

UNPACKING INSTRUCTIONS

Your Pro 500/750 was thoroughly inspected, tested, and

packaged to deliver the equipment in good operating con-

dition. The freight carrier received and signed for the

equipment in good condition. Damage can occur during

shipping and to protect your interest, all cartons must be

inspected for damage (including any concealed damage)

that might have occurred during shipment. Any damage is

the responsibility of the freight carrier and should be

reported immediately to the carrier. It is your responsibility

to issue a claim and to receive compensation from the

freight carrier for any damage done in transit. Shipping

damage is not warranted.

CAUTION

Read All Instructions, Warnings and Cautions

Before Using

These guidelines are provided for your protection and con-

venience. Please read them carefully.If you have any

questions regarding the use of your equipment call CFR

Technical Service at 800.533.2557 Failure to adhere to

instructions provided can potentially void any warranties.

Precautions and safety warnings are provided for your

protection Failure to observe these warnings could result

in personal injury and damage to the equipment. When

using an electrical appliance, basic safety precautions

should always be followed.

WARNING!

To avoid fire, do not use with a flammable or combustible

liquid to clean floor.

IMPORTANT SAFETY INSTRUCTIONS

The Pro 500/750 is intended for use only as described in

this manual. Using the equipment in any manner not

described in this manual can void the warranty.Use only

manufacturer’s recommended accessories.

READ ALL INSTRUCTIONS BEFORE USING

THIS PRODUCT IS INTENDED FOR

COMMERCIAL USE ONLY

When using a electrical piece of equipment basic precau-

tions should be followed, including the following:

CFR PRO SERIES 3

WARNING! To reduce the risk of electric

shock, fire, or injury:

1. Operators must read and understand this manual

completely before operating the equipment.

2. Make sure all caution, warning, and instructional

decals are in place and legible. Replace damaged or

missing labels.

3. Do not leave unit when plugged in. Unplug from outlet

when not in use and before servicing.

4. Connect to a proper grounded outlet only.

(See Grounding Instructions.)

5. Do not use with damaged cord or plug.

6. Do not handle plug or unit with wet hands.

7. Do not pull or carry by cord, use cord as a handle,

close a door on cord, or pull cord around sharp edges

or corners. Do not run appliance over cord. Keep cord

away from heated surfaces.

8. Turn off all controls before unplugging.

9. Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

10. Do not put any object into openings. Do not use with

any opening blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

11. Do not pick up anything that is burning or smoking,

such as cigarettes, matches, or hot ashes.

12. Do not use without filters in place.

13. Use extra care when cleaning stairs.

14. Do not use to pick up flammable or combustible liquids

such as gasoline or use in areas where they may

be present.

15. Do not expose to rain. Store indoors.

16. If unit is not working as it should, has been dropped,

damaged, left outdoors, or dropped into water, take it

to a local CFR service center.

GROUNDING INSTRUCTIONS

This unit must be grounded. Grounding provides the path

of least resistance for electric current, in the event of mal-

function or breakdown, to reduce the risk of electric shock.

This unit is equipped with a cord having an equipment-

grounding conductor and grounding plug. The plug must

be inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING! Improper connection of the

equipment-grounding conductor can result in a risk of elec-

tric shock. Check with a qualified electrician or service per-

son if you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the appli-

ance – if it will not fit the outlet; have a grounded outlet

installed by a qualified electrician.

SET UP INSTRUCTION

Filter Installation

There are three filters in the Pro 500/750: inlet filter, main

filter and pump protection filter. It is imperative to the effi-

cient operation of the Pro 500/750 that the filters are

installed properly.

Pump Protection Filter –Position on brass fitting on

the filter mound. Slide it down.

Main Filter – Wet the rim of the filter and position it on

the filter mound. (white plastic disc) Twist and slide over

the mound by pushing downward.

Inlet Filter – Position on top of the tank.

OPERATING INSTRUCTIONS

1. Remove lid and inlet filter.

2. Check main filter. Make sure the main filter is

installed snugly.

3. Fill tank with water to a desired level. Use solution

level gauge.Maximum water temperature to be used

is 120 to 130 degrees F.

4. Add CFR in-tank cleaner per chemical label use

instructions. In addition, pre-spraying is often desirable

and will assist in producing the fastest and best

cleaning results. See chemical product labels for more

information. Note: Use caution when moving machine

(especially on inclines) with fluid in the tank to prevent

fluid from entering vacuum standpipe at back of

machine tank and flooding the vacuum.

CFR chemicals have been speically

formulated to work with this machine.

5. Prime pump by re-circulating fluid through priming

hose included for 15/30 seconds. Re-circulating the

fluid primes the pump and expels trapped air from the

system.

6. Replace inlet filter and lid

7. Attach hose assembly to machine. Connect fluid hose

to the quick-disconnect found on the front of machine.

8. Attach the desired tool to the valve end of the

hose assembly.

9. Close tank cover lid, turn on vacuum and pump

switches.

10. Clean surface with tool attached to hose assembly.

11. During the cleaning process, the fluid level will be

reduced and the lower level float switch will shut off

the pump. When the pump shuts off, drain and rinse

tank, rinse main filter, refill with fresh water and

cleaning chemical, and continue cleaning.

CAUTION! When cleaning, monitor foam in

the machine's tank. Areas cleaned with other cleaning

equipment or chemicals may cause excessive foam to col-

lect in the tank.

WARNING! EXCESSIVE FOAM IN THE

TANK MAY CAUSE VACUUM MOTOR FLOODING AND

MACHINE DAMAGE. Pour one to two ounces of CFR

Defoam directly into the tank or into the vacuum hose

while the vacuum is running. CFR Defoamer has

been speically formulated to work with this

machine.

When finished cleaning, perform the daily maintenance

procedure. Be sure that all filters are cleaned thoroughly

and replaced in machine. Leave lid offfor drying.

Perfect Heat System

WARNING! The Perfect HeatTM Plus System can pro-

duce very hot water that could damage some delicate fabrics

and fibers. Please ensure the surface being cleaned will not be

damaged by hot water up to 200 degrees Fahrenheit.

This machine is equiped with the Perfect HeatTM Plus System for

heating the cleaning solution. This system uses a combination

of the patent pending Perfect HeatTM coils and an inline electri-

cal heater.

Operation:

1. Follow operating instructions steps for filling the machine

with water and cleaning solution.

2. Turn on electrical heater, switch is located on panel.

3. Pre-heat machine for 5-10 minutes before use.

NOTE: There is a valve in the upper compartment that either

sends the water through the heating components, or bypasses

them. The machine is preset in the “HOT” position. To clean

with cold water, turn the valve to “COLD” or UP position. This

should be done prior to filling the tank with water.For gener-

al cleaning, it is recommended leaving the valve in the “HOT”

or down position and cleaning with hot water.

CFR PRO SERIES

4

drain hose

pump filter

main filter

inlet filter

switch panel

valve

CFR PRO SERIES 5

MAINTENANCE

Daily Maintenance

To maintain optimum performance the equipment, tools

and filters should be cleaned after each use. Replace any

filters that cannot be cleaned or are damaged. Nozzles

that cannot be cleared should be discarded. Wipe down

the equipment with a damp cloth to keep clean and pre-

serve the appearance.

1. Wands and Tools

Rinse opening of tool with water to eliminate

any debris.

Wand only – open and clean in-line strainer.

A. Disconnect the In-line Strainer by using the quick

disconnect coupler.

B. Remove the filter and rinse with water.

C. Remove any debris from the strainer.

D. Keep o-ring and threads of the plug lubricated.

CFR DEFOAM is a good lubricant or use a

non-petroleum based lubricant. This will ensure a

tighter seal.

Wipe tool with damp cloth and store with head up to

prevent clogging of nozzle.

2. Filters

In-Line Strainer Filter – Disconnect the In-line Strainer

Filter on the wand by using the quick disconnect

coupler. Remove the filter and rinse with water.

Remove any debris from the strainer.Keep o-ring and

threads of the plug lubricated. CFR DeFoam is a good

lubricant or use a non-petroleum based lubricant.

This will ensure a tighter seal.

Inlet Filter – Remove the inlet filter. Dump and clean debris

at the end of each cleaning job.

Main Filter – Remove the main filter sleeve and rinse out

and clean thoroughly.

Pump Protection Filter – This ball-shaped filter should be

in place when the tank is cleaned and rinsed. Remove

and rinse only after the tank is rinsed.

Periodic Maintenance

1. Check power cord for any breaks, separations, or cuts.

Make sure the ground pin on the connector is intact or

the machine will be unsafe. Make sure the ground pin

on all three prongs on the twist lock connector

are intact.

2. Check for plugged nozzles when using tools. If

streaking occurs during cleaning, a plugged nozzle

may be the cause. A plugged or partially plugged

nozzle can be identified by holding the tool 5-7" above

the surface and checking for an even spray pattern.

To clean a plugged nozzle, remove the nozzle and

direct pressurized air backwards through the nozzle or

backwash the nozzle with water. A convenient method

is to insert the nozzle into a garden hose ball valve,

tighten the ball valve to a faucet, and turn on the

water. (CFR has ball valves available, part #7AX020).

Inspect nozzle and repeat cleaning procedure, if

necessary. Discard nozzles that cannot be cleared.

Tool nozzles wear and must be replaced after 200-250

hours of use.

3. Occasionally open the base and inspect hose and

other connections for leaks. Repair or replace any

leaking parts. Always disconnect power cord, before

removing side panels.

Periodic Maintenance

4. It is very important to monitor machine operating hours

for proper maintenance of the motors and pumps. After

700 hours of operation, the vacuum motor brushes

should be inspected by an authorized repair station

and replaced if worn (length is .5 inches or less).

5. Check vacuum motor performance using a vacuum

gauge. Place this gauge on the tank inlet fitting with

the vacuum turned on. Water lift should be between

135 and 150 inches. If the reading is lower, check for

air leaks in the tank, cover gasket, and drain hose.

6. Check pump performance occasionally against built-in

pressure gauge. Pump running pressure on the Pro

500 should be 500 + 10 p.s.i, Pro 750 should be 750+

15 p.s.i. If the pumping pressure is outside of this

range, call your dealer or authorized station. After 400

hours, the pump valves should be replaced. After 700

hours of operation the pump cam bearing and plunger

should be replaced. The pressure regulator should be

rebuilt after 400 hours of operation.

A

B

CFR PRO SERIES

6

SPECIFICATIONS - Pro 500

Power Cord ..............One Cord, 12 Ga, 3 Wire, Molded End

Plug

Voltage . . . . . . . . . . . . . . . . . . 115/120 volts AC, 60 HZ

Vacuum Motor . . . . . . . . . . . . 1’ amps

Pump Motor . . . . . . . . . . . . . . 3 amps

Tank Volume. . . . . . . . . . . . . . 15 gallons max

Fill Level . . . . . . . . . . . . . . . . . 1” below the bottom of the Inlet filter.

Vacuum Motor . . . . . . . . . . . . (2) 2 stage with150" water lift

Pump Motor ..............1/2 hp AC motor

Pump . . . . . . . . . . . . . . . . . . . plunger type; 0 to 500 psi.

Weight . . . . . . . . . . . . . . . . . . 124 lbs.

Height...................41"

Width ...................29"

Length. . . . . . . . . . . . . . . . . . . 22"

Wheels . . . . . . . . . . . . . . . . . . non-marking wheels

Casters..................non-marking wheels

Body . . . . . . . . . . . . . . . . . . . . rotomolded polyethelene

Filters . . . . . . . . . . . . . . . . . . .three filters: inlet filter,main filter, and

pump protection filter.

Circuit Breakers: Overload circuit breakers are placed in both the

pump and vacuum circuits to protect against unusually heavy current

(ampere) loads. If either breaker trips, the pump motor or vacuum

motor is overloaded.

SPECIFICATIONS – Pro 750

Power Cord . . . . . . . . . . . . . .One Cord, 12 Ga, 3 Wire, Molded End

Plug

Voltage . . . . . . . . . . . . . . . . . .115/120 volts AC, 60 HZ

Vacuum Motor . . . . . . . . . . . .5.4 amps

Pump Motor . . . . . . . . . . . . . .3 amps

Tank Volume . . . . . . . . . . . . .15 gallons max

Fill Level . . . . . . . . . . . . . . . . .1” below the bottom of the Inlet filter.

Vacuum Motor . . . . . . . . . . . .3 stage with135" of maximum water lift

Pump Motor . . . . . . . . . . . . . .1/2 hp AC motor

Pump . . . . . . . . . . . . . . . . . . .plunger type; 0 to 750 psi.

Weight . . . . . . . . . . . . . . . . . .128 lbs.

Height . . . . . . . . . . . . . . . . . . .41"

Width . . . . . . . . . . . . . . . . . . .29"

Length . . . . . . . . . . . . . . . . . .22"

Wheels . . . . . . . . . . . . . . . . . .non-marking wheels

Casters . . . . . . . . . . . . . . . . . .non-marking wheels

Body . . . . . . . . . . . . . . . . . . . .rotomolded polyethelene

Filters . . . . . . . . . . . . . . . . . . three filters: inlet filter, main filter, and

pump protection filter.

Circuit Breakers: Overload circuit breakers are placed in both the

pump and vacuum circuits to protect against unusually heavy current

(ampere) loads. If either breaker trips, the pump motor or vacuum

motor is overloaded.

vac motor

pump

pressure

guage

tank inlet

Vacuum or pump will not run Check that electrical cord is firmly seated in wall outlet.

Check and reset building circuit breaker if tripped.

Check vacuum/pump switch. It should be in the “on” position.

Trips building circuit breaker Circuit is overloaded – move cord to a different wall outlet.

If using an additional extension cord, make sure it is in good condition, less than 70 feet long

and #10 gauge or heavier.

Check plug end and cord for damage.

Vacuum won’t run. Check vacuum switch. It should be in the “on” position.

Check fuses and replace if tripped. (located on base of machine)

Pump won’t run Check pump switch – it should be in the “on” position.

Check pump circuit breaker (5 amp) and reset if tripped.

Check fluid level, must have at least 5 gallons in tank.

Check fluid level inside of Main Filter Cage – pump float must be at highest position to operate.

If fluid is lower inside filter, drain tank and remove and clean filter.

Pump tries to run and then blows circuit breaker Check power cord for frayed, cut or worn spots.

If using an extension cord,make sure it is in good condition, less than 70 feet long and #10

gauge or heavier.

Check pump static PSI – must be 400 psi or less

Check wall outlet voltage. If below 105 volts, pump will not work.

Pump starts and stops Check for dirty Main Filter. Water level should be the same inside and outside of filter.

Check for sticking pump float.

Check fluid level – must have at least 5 gallons in tank.

Water dripping from bottom of machine exhaust. Check machine for excess foaming. Add CFR Defoam to tool hose and tank. Open machine top

cover and let vacuum run for 10 minutes to dry out vacuum motor,then close lid and

resume cleaning.

Vacuum hose or tool leaks. Leave vacuum running for 1 minute when finished cleaning to clear hose.

Check for holes/breaks in vacuum hose.

Make sure the inline strainer is properly tightened and fluid hose connectors are fully seated.

Carpet too wet. NOTE: CFR floor tool is used in forward direction only.

Check carpet tool position – head must be completely “seated” on carpet to provide good

drying times.

Check tool and hose for any obstructions.

Check lid cover sealing properly – is filter case properly seated in tank? Is lid gasket in good

shape with no cuts, cracks, or worn/compressed areas?

Check for cracks in lid cover.

Check drain hose and fittings for cracks and tears.

Check tool hose for holes, cracks, or cuts.

Check hose cuffs – must seat firmly on tank fitting and tool.

Check water dripping from bottom of machine exhaust. If present, check machine for

excess foaming.

Check carpet installation. Some carpets are installed on uneven surfaces with ridges and

bumps. It is difficult to get good drying times with this type of installation.

Streaks on carpet. Check tool and hose for obstructions.

Check and clean inline strainer filter.

Check and clean main filter.

Check and clean stainless back flush filter screen inside tank.

Check nozzles for full spray. Clean if clogged or replace if worn.

Check pump pressure drop while cleaning. Should not drop more than 100 p.s.i. Make sure air

is out of system by re-priming pump. If there is still a problem, remove and clean back

flush filter screen.

Make sure strokes overlap a minimum of 3 inches.

Check CFR chemical usage instructions for proper application.

Multiple cleanings may be needed to clean deeply imbedded dirt that is pulled to the surface

by CFR’s deep cleaning technology. Offset cleaning passes by 6 inches.

Excessive pressure drop when cleaning. Adjust static pressure to 500/750 p.s.i. when not cleaning.

(exceeds 100 p.s.i.) Check and clean main filter and inner stainless back flush filter.

Check and replace worn spray nozzles and loose or leaking fittings on hose.

Purge excess air from pumping system using hose with no nozzle or priming hose.

CFR PRO SERIES 7

TROUBLE SHOOTING GUIDE

CFR PRO SERIES

8

Base Assembly

CFR PRO SERIES 9

Base Assembly

Ref # Part # Description

1 72620AM Base, PFX1350, Maroon

2 72633A Axle, 23.375” Long

3 X9066+ Wheel, 12” x 1.75” Non-Marking

4 7GL002 Push Nut, 1/ 2”

5 7CM007 Washer, 1/ 2 USS Flat, 18-8 SS

6 72635A Spacer, 1/ 2” ID x 3/ 4” OD x 1/ 4” Long

7 72640A Gasket, Vac Manifold, Long

8 72623A Cover, Vacuum manifold

9 7CW002 Screw, #6 x 3 /4 Phil Pan TS, Type A 18-8 SS

10 X9204+ Rod, 10-24, “T” Bolt

11 72000A Rod, 3/16 x 5-1/2, All Thread Stud, 18-8 SS

12 72651A Spacer, VAC Motor, 2.375”

13 70020B Gasket, Vacuum Motor Seal

14 1942-C Vacuum Motor, 115VAC, 2 – satage

72365A Vacuum Motor, 3 stage, 120V For Pro 750

72611A Vacuum Motor, 3 stage, 230V, 5.7IN

15 7BF003 Nut, Kep, #10-24 Zinc

16 7CM003 Washer, #10 USS Flat, 18-8 SS

17 72624A Cover, Vacuum manifold, Shor

72630A Cover, Vacuum manifold, Flat

18 72641A Gasket, Vac manifold, Short

19 72662A Screw, #10 x 1/ 2”, Flat Phill SM, Black

20 72638A Pressure regulator plate

21 72636A Cover Plate, Bottom

22 72388A Screw, #10 x 5/8, Tap phil, SS pan Head

23 PX65 Caster, 4” Black

24 7DT001 Screw, 5/16-18 x 5/8, Hex Tap Zinc

25 X8851 Screw, 10-32 x 1’ Phil, Pan MS, Black, Zinc

26 72639A Gasket, mounting pressure regulator

27 7BF008 Nut, kep, 10-32 Zinc

28 X8239 Washer, 1/ 2 USS Flat Zinc

29 PX6 1/ 4 x 1/ 4 Female Quick disconnect, Brass

30 7CX002 Nipple, Hex 1/ 4 MPT

31 7AV001 Tee, Union, 1/ 4 NPT

32 72642A Gasket, Vac manifold, Circle

33 72625A Cover, Vacuum manifold, Circle

34 7DL003 Clamp, Hose 1/ 4”

35 71521A Tee, barb, 1/ 2” x 1/ 2”

36 X9069 End Loop, SS, w / 2 holes, 16G

37 X8848 Jacknut, 1/ 4 -20 Steel, #8 LJN

38 7GF033 Pad, Motor mount

72667A Washer, Rubber, 29 ID, .688OD, .093THK

39 72643A Pump Assembly, 500 PSI

72644A Pump Assembly, 750 PSI, .140 CAM

40 71644A Screw, #10 x 1 Phil Pan TS, 18-8 SS

41 70079C Hose, 1/ 4” Wire Reinforced

42 7DL008 Clamp, 1/ 4” Worm Gear, SS, Hex Slot, Phil HD

43 X8235 Washer, 1 /4 Flat USS Zinc

44 7EW001 Screw, 1 /4-20 x 3/ 4” Phil pan MS SS

45 7BS003 Screw, 1 /4-20 x 1 /2, Phil, pan, MS 18-8 SS

46 X9014 Hinge

47 72020A Screw, #12 x 1”, Self tap, PHMS, Zinc

48 PF1750 Heater Unit, 1750 Watts

PF1750-2 Heater unit, 220V

Ref # Part # Description

49 PX212 Fitting, Brass, 90 degree elbow, 1 /4 NPTM

50 PD8 Strain Relief, 1/ 2” NPT

51 7FC010 Circuit Breaker, 8A

71653A Circuit Breaker, 10A

72710B Circuit Breaker magnetic, 5A

53 X9173 Hole plug, Switch Hole

54 72411A Hour meter, AC

71544A Hour meter, 230V

55 72387A Screw, #8 x 5/8, Black, Tap Phil, Pan Head

56 PX112 Pigtail, Black, 12/3 SJT x 39” Long

57 72632B Switch Panel, With fan

72715A Switch Panel, Perfect Heat (no fan)

58 X8008N Nut, Lock, 1 /2” Steel Conduit

59 71379A Relay, 25A, 120V

71379B Relay, 240V

60 72684A Screw, 1 /4-20 x 2-1/2 Phil, Pan

61 72665A Insert, Tee Nut, 1 /4 -20 Thread

62 72661A Wand Holder

63 71952A Convertor Kit, OZ Long

71953A Convertor Kit, OZ Long, 230V

64 71716AP carbon Filter

65 72698A Cover, Carbon Filter, Pro Series

66 X9179 Pump motor, 100 PSI, 115V

67 71775A Elbow, 1 /2” Hose x 3/8” NPT, 90deg Plastic

68 7GG003 Hose A/S Braided

69 71570A Injector, ozone

70 71810A Hose, Clear, tygon, 1/8” ID x 1 /4” OD

71 71629A O-ring, Shaft end pulley

72 71999A Barb Hose, 1/2H

73 72702A Cover, Fan

74 72699A Foam, Switch panel

72718A Foam, Switch Panel , Pro 400

75 72700A Fan, Cooling, 115V, 92mm, 35CFM

72701A Fan, Cooling, 230V,92mm, 50CFM

76 72703A Screw, 8-32 x 2” L, phil, Pan MS, Zinc

77 71743A Screw, 8-32 x3/16” PHMS

78 7CY006 Washer #8 Internal Tooth Lock, 18-8 SS

79 X8260+ Nut, 8-32 Lock w/ Nylon Insert

80 71804A Plug, 1 /2” Hole, Black Nylon

81 72142A Plug, 7/8” black nylon

82 X8256 Mut, 8-32, keps, Zinc

83 X8254 Hose, Solution, 1 /4” Id, 400 PSI

84 PC66 Fitting, Brass, 1/8 NPTM x 1 /4 Barb Hose

85 71130A Coupler QD, 1/8 M

86 70101A Nipple, QD, 1/8F, Brass

87 72713A Heater Coil, 2- stage vacuum

72713B Heater Coil, 3- stage Vacuum

88 X8244 Screw, 1—24 x 2”, Phil, Pan MS, Zinc

89 7AT003 Barb, Hose, 1/4H – 1/4M

90 PC38 Connector, Double thread, female

91 72726A Valve, 3-way

92 SW158 1 /4” Cable Clamp

93 7BF030 Nut, 10-24, Nylon Insert Lock, 18-8 SS

CFR PRO SERIES

10

Tank Assembly

CFR PRO SERIES 11

Tank Assembly

Ref # Part # Description Qty

172619A Tank, Recycling 1

2 PX25+ Fitting, Plastic, 1- ?” NPT x 1- ?” Hose Barb 1

3 X9014+ Tank Hinge 2

4 7BS003 Screw, ?-20 x 1/2” Phil Pan MS 18-8 SS 4

5 71644A Screw, #10 x 1” Phil Pan TS 8

6 71920A Ring Washer 1

7 72388A Screw, #10 x 5/8, Tapping Phil, SS Pan Head 4

8 72631A Latch Bracket 2

9 72666A Inlet Fitting, Short 1

10 PX14A+ Dump Valve Gasket 1- ?”, 2.5 OD x 1.75 Rubber2

11 72173A Spring Clip, Black Vinyl Coated 2

12 72224B Main Filter, New, Smaller 1

13 72326A Filter, Inlet 1

14 72323B Gasket, Lid 43” 1

15 72321A Lid, Tank 1

16 7DE016 Nozzle H 1/8 VV CH SS 11001 2

17 71576A Nipple QD 1/8 M SS 1

18 71495A Pump Protection Filter 2

19 7AT006 Barb Elbow, 90°, ?-1/8 1

20 71817A Hose, ?” Braided 22”

21 7DL003 Hose Clamp, ?” 1

22 71897A Gasket, Filter Mount 1

23 7DL008 Hose Clamp, ?” SS 2

24 70079C Hose, ? Wire Reinforced 42”

25 PC25+ ?” to ?” Male/Male Barb 2

26 7AF003 Plug, Counter Hex ?” 1

Ref # Part # Description Qty

27 72317A Filter Mount 1

28 70343A Switch Float 2 Pole 1

29 71553A E-Ring, Float Switch 70143A 1

30 70100A Coupler QD 1/8F 1

31 7CX001 Nipple Hex 1/8 1

32 SW139+ Elbow, 1/8 Street (90 degree) 2

33 71485A Header Backflush Nozzle 1

34 72628A Vacuum Standpipe, New Pro 1

35 PX63+ Coupler, Plastic, 1- ?” Slip 1

36 X8235+ Washer, ?” Flat, USS Zinc 4

37 72486A Spacer, 1.625 Long, .50 OD, .313 ID 2

38 7DL005 Clamp Worm Gear 1-1/2 SS 3

39 PAS37+ Drain Hose 1

40 PAS36+ Expansion Plug Drain 1

41 72645A Bolt, 5/16-18 x 2-1/4, Hex 2

42 X8025+ Wheel, Black, 4” x 1-1/4” 2

43 7BH004 Screw, 10-32 x 3/8” Phil Pan 18-8 SS 4

44 72656A Hose, 1-1/2” Wire-Reinforced, Black 32”

45 72476A Fitting, Nylon Hose Barb, 1-1/4” ID, 1-1/2” NPT 1

46 72598A Screw, 1/4-20 x 3/4” Phil Flat, SS 1

47 72589A White Delrin Hollow Rod, 1/2" OD, 1/4" ID, 7” Long

1

48 72659A Decal, Water Level Gauge 1

49 72588A Heat Shrink Tubing, Clear PVC,

5/8” Exp. ID, 7.5”L1

50 72660A Rope 26”

72671A 01/2005

3101 Wichita Court ■Fort Worth, TX 76140 ■800.533.2557 ■www.CFRcorp.com

Warranty

CFR, a Tacony company, warrants new products manufactured and sold under the name CFR to be free from defects in

materials and workmanship under normal use and service. CFR’s obligation under this warranty is limited to repairing or

replacing, at our option, such products or parts which are returned to our factory authorized service center, freight pre-

paid, within the warranty period and are found to be defective in materials or workmanship. For rotationally molded poly-

ethylene housings and aluminum frames and chassis this warranty expires 60 months from the date of registration; if the

warrant is not registered, it expires 60 months from the factory shipment date. For all other components, with the excep-

tion of wear items (i.e. filter, nozzles, etc.) this warranty expires 12 months from the date of registration on the warranty.

If not registered, is expires 12 months from the factory shipment date. For hoses, tools, and other attachments manufac-

tured and sold by CFR, this warranty expires 12 months form factory shipment date. Parts replaced or repaired under

warranty are guaranteed for the remainder of the original warranty period. Replacement parts that have become defec-

tive through wear or abuse are not included in this warranty. CFR will pay service labor to the distributor or authorized

service repair center per the warranty flat rate schedule. Service labor will be paid for two years on all warranted poly-

ethylene housings, aluminum frames and chassis, and one year on all other warranted components.

CFR systems are designed for use only with specially formulated CFR Recyclable Cleaning Chemicals. Use of any other

chemical in CFR systems may cause damage to the pump, motor and other components and may void the warranty.

This warranty shall cease to be in effect if repairs, replacements or alternations are made by the purchaser or any non-

authorized service station. This warranty does not apply to damage caused by misuse, abuse, or negligence of the

buyer or third party, or damage due to transportation of product.

CFR MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATIONS, ANY WARRANTIES OF

FITNESS OR MERCHANTABILITY, EXCEPT AS EXPRESSLY SET FORTH ABOVE WITH RESPECT TO SUCH PROD-

UCTS OR PARTS THEREIN. NOR SHALL CFR HAVE INCURRED ANY OTHER OBLIGATIONS OR LIABILITIES ON

ITS PART OR BE LIABLE FOR ANY ANTICIPATED OR LOST PROFITS, INCIDENTAL DAMAGES, CONSEQUENTIAL

DAMAGES, TIME CHARGES OR ANY OTHER LOSSES INCURRED IN CONNECTION WITH THE PURCHASE,

INSTALLATION, REPLACEMENT OR REPAIR OF SUCH PRODUCTS OR ANY PARTS THEREIN WHETHER ORIGI-

NAL EQUIPMENT OR INSTALLED AS A REPLACEMENT, COVERED BY THIS WARRANTY OR OTHERWISE; AND

CFR DOES NOT AUTHORIZE ANY PERSONA TO ASSUME FOR CFR ANY OTHER LIABILITY IN CONNECTION

WITH THE PRODUCTS OR PARTS THEREIN.

For more information about top quality CFR products please see your local CFR distributor or visit us at

www.CFRcorp.com

Thank you for purchasing

CFR Cleaning Systems.

Table of contents

Other CFR Vacuum Cleaner manuals