CGC Ryan 544946A Programming manual

OPERATOR / PARTS MANUAL

MAN 4163416

Rev. A 6-2008

MODELS:

544946A

JR. SODCUTTER, HONDA 18”

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some

of its constituents are known to the

State of California to cause cancer,

birth defects and other reproductive

harm.

Californie Proposition 65 Avertissement

Leséchappementsdesmoteursdieseletcertains

de leurs composés sont reconnus par l’Etat de

Californie pour être cancérigènes, provoquer

des défauts congénitaux et d’autres dangers en

matière de reproduction.

ADVERTENCIA

AVERTISSEMENT

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

California Advertencia

de la Proposicion 65

El estado de California hace saber que

los gases de escape de los motores diesel

y algunos de sus componentes producen

cáncer, defectos de nacimiento y otros

daños en el proceso de reproducción

humana.

L’

é

mission du moteur de ce mat

é

riel con-

tient des produits chimiques que l’Etat de

Californie consid

è

re

ê

tre canc

é

rig

è

nes,

provoquer des d

é

fauts cong

é

nitaux et

d’autres dangers en mati

è

re de reproduc-

tion.

El estado de California hace saber que los

gasesdeescapedeesteproductocontienen

productosquÍmicosqueproducencáncer,

defectos de nacimiento y otros daños en

el proceso de reproducción humana.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

1

Jr.

Sodcutter

06-2008

IMPORTANT MESSAGE

Thank you for purchasing this CGC, Inc. product. You have purchased a world class product, one of the best

designed and built anywhere.

This machine comes with an Operation and Safety Manual and a separate Parts and Maintenance Manual. The

useful life and good service you receive from this machine depends to a large extent on how well you read and

understand these manuals. Treat your machine properly, lubricate and adjust it as instructed, and it will give

you many years of reliable service.

Your safe use of this CGC, Inc. product is one of our prime design objectives. Many safety features are built in,

but we also rely on your good sense and care to achieve accident-free operation. For best protection, study the

manual thoroughly. Learn the proper operation of all controls. Observe all safety precautions. Follow all instruc-

tions and warnings completely. Do not remove or defeat any safety features. Make sure those who operate

this machine are as well informed and careful in its use as you are.

See a CGC, Inc. dealer for any service or parts needed. CGC, Inc. service ensures that you continue to receive

the best results possible from CGC, Inc. products. You can trust CGC, Inc. replacement parts because they are

manufactured with the same high precision and quality as the original parts.

CGC, Inc. designs and builds its equipment to serve many years in a safe and productive manner. For longest

life, use this machine only as directed in the manual, keep it in good repair and follow safety warnings and in-

structions. You'll always be glad you did.

Commercial Grounds Care, Inc.

One Bob Cat Lane

Johnson Creek, WI 53038-0469

TABLE OF CONTENTS........................................ FIGURES ................................................................... PAGE

SAFETY............................................................................................................................................................2

LABELS........................................................................................................................................................3, 4

SET-UP..........................................................................................................................................................5-8

CONTROLS................................................................................................................................................9, 10

OPERATION................................................................................................................................................... 11

SERVICE...................................................................................................................................................12-21

STORAGE ......................................................................................................................................................22

TROUBLE SHOOTING ..................................................................................................................................23

SPECIFICATIONS.......................................................................................................................................... 24

PARTS SECTION........................................................................................................................................... 25

DRIVE ASSEMBLY AND SIDE COVER .............. FIGURE 1 ................................................................... 26, 27

GEAR CASE........................................................ FIGURE 2 ................................................................... 28, 29

SIDE ARMS, PITMAN ARMS AND HANDLES.... FIGURE 3 ................................................................... 30, 31

HANDLEBAR ASSEMBLY................................... FIGURE 4 ...................................................................32, 33

2

Jr.

Sodcutter

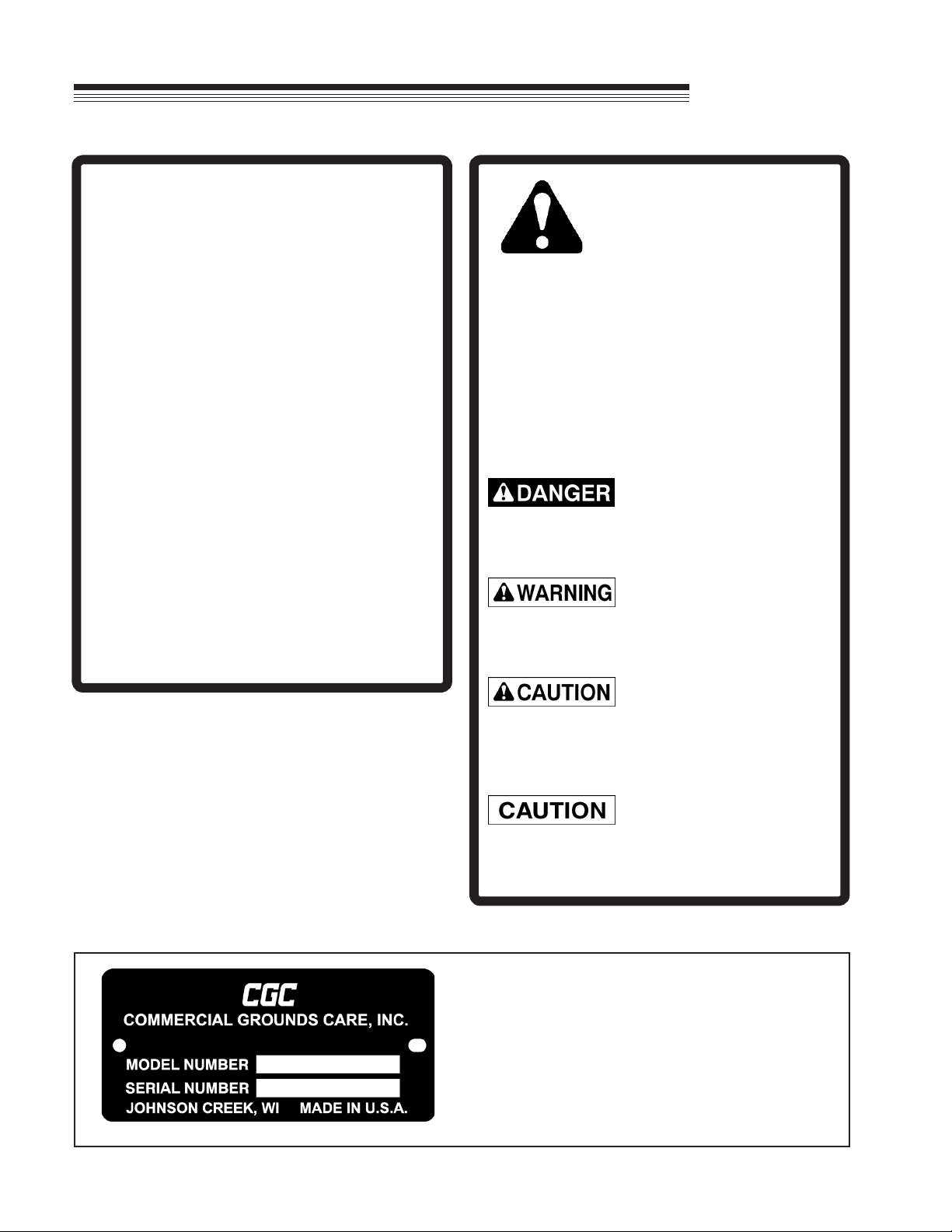

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your mower. It contains the model number

followed consecutively by the serial number.

Use this number when ordering parts or seeking

warranty information.

SAFETY

NOTICE !!!

Unauthorized modications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Commercial Grounds Care, Inc. strongly warns

against, rejects and disclaims any modications,

add-on accessories or product alterations that are

not designed, developed, tested and approved by

CGC, Inc.'s Engineering Department. Any CGC,

Inc. product that is altered, modied or changed in

any manner not specically authorized after original

manufacture–including the addition of “after-market”

accessories or component parts not specically

approved by CGC, Inc.–will result in the CGC, Inc.

Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modications,

add-on accessories or products not approved by

CGC, Inc. will be considered the responsibility

of the individual(s) or company designing and/or

making such changes. CGC, Inc. will vigorously

pursue full indemnication and costs from any party

responsible for such unauthorized post-manufacture

modications and/or accessories should personal

injury and/or property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word denitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in

this manual and on the safety labels attached

to CGC, Inc. machines. For your safety and the

safety of others, read and follow the information

given with these signal words and/or the symbol

shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION indicatesa potentiallyhazardoussituation

which, if not avoided, MAY resultinminor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage.

3

Jr.

Sodcutter

LABELS

524538

This decal informs the operator that hearing

protection should be worn if operating the

Jr. Sodcutter for extended periods of time (longer

than four hours).

dB

94

840697

009034910

This decal instructs the operator to read and

understand the Operation & Safety manual. To

prevent injury, they must be familiar with the

operation of this product and be fully aware of safe

operating procedures.

524541

The top symbol shows ngers or hands being cut or

severed. DO NOT place hands or ngers under Jr.

Sodcutter while operating the unit.

The middle symbol shows toes or feet being cut

or severed. DO NOT place feet or toes under Jr.

Sodcutter while operating the unit.

The lower symbol informs the operator and/or

bystanders to keep a safe distance away from

machinery. If you do not keep hands and feet a safe

distance from the machinery, personal injury could

occur.

524481

The throttle control decal uses the turtle to represent

slower engine speeds, the rabbit represents faster

engine speeds.

840697

The left symbol shows the possible result of working

on the machinery with safety shields removed.

Hands and ngers may become entangled in belts.

DO NOT operate the unit without safety shields in

place.

The middle symbol warns the operator and/or

bystanders to keep hands out of moving components.

The right symbol instructs the operator to read the

service section of the operators manual. Disable

the engine (disconnect spark plug wire) before

performing any service or maintenance on the unit.

4

Jr.

Sodcutter

LABELS

524485

This decal shows the direction of lever movement

used to engage the cutter blade of the Jr. Sodcutter.

Movement in the opposite direction will stop the

cutter blade.

4124337

This decal shows the operating instructions for the Jr.

Sodcutter.

524480

This decal shows the direction of lever movement

used to engage the drive belt of the Jr. Sodcutter.

Push the lever forward to engage the drive belt.

Pull the lever rearward to disengage the drive belt.

3. ADJUST BLADE TO CUT SOD 3/4 TO 1 INCH THICK.

HARD SOIL OPERATION:

1. TIP BLADE FORWARD BY LOOSENING LOCKING LEVER (BLACK HANDLE RIGHT SIDE "H" FRAME). PUSH "H" FRAME FORWARD AS REQUIRED AND

LOCK LEVER.

DEPTH OF CUT:

1. LOOSEN UPPER RIGHT HAND LOCKING LEVER. TIP MACHINE FORWARD AND MOVE CENTER DEPTH CONTROL LEVER TO DESIRED DEPTH. LOCK IN

POSITION BY ROTATING LOCKING LEVER CLOCKWISE.

2. LOOSEN DEPTH STOP LOCKING LEVER AT CENTER OF "H" FRAME. RAISE DEPTH STOP UNTIL IT CONTACTS DEPTH CONTROL LEVER AND LOCK

IN PLACE.

TO MOVE WITHOUT POWER:

DISENGAGE DRIVE WHEEL SHIFTER LEVER (ON FRONT-RIGHT SIDE OF MACHINE) BY ROTATING DOWNWARD.

TO MOVE MACHINE UNDER POWER:

1. DISENGAGE CUTTING BLADE SHIFTER LEVER (ON FRONT-RIGHT SIDE OF MACHINE) BY ROTATING DOWNWARD.

2. ENGAGE DRIVE WHEEL SHIFTER LEVER (ON FRONT-RIGHT SIDE OF MACHINE) BY ROTATING UPWARD.

3. WITH ENGINE RUNNING, HOLD OPERATOR PRESENT LEVER AGAINST HANDLEBAR AND PUSH CLUTCH LEVER FORWARD TO THE ENGAGED

POSITION.

5. WITH MACHINE TIPPED FORWARD ON FRONT BUMPER AND OPERATOR PRESENT LEVER HELD AGAINST HANDLEBAR, PUSH CLUTCH LEVER

FORWARD, AT THE SAME TIME LOWER THE MACHINE SO BLADE ENTERS THE GROUND.

3. ENGAGE DRIVE WHEELS BY ROTATING SHIFTER LEVER ON FRONT RIGHT SIDE OF MACHINE UPWARD.

4. ENGAGE CUTTING BLADE BY ROTATING SHIFTER LEVER ON REAR RIGHT SIDE OF MACHINE UPWARD.

2. START ENGINE PER INSTRUCTIONS ABOVE AND SET THROTTLE TO FULL SPEED.

1. MAKE REQUIRED BLADE ADJUSTMENTS AS STATED ABOVE.

6. TO STOP MACHINE, PULL BACK FIRMLY ON CLUTCH LEVER, THIS APPLIES A BRAKE.

7. STOP ENGINE BY MOVING STOP SWITCH TO "OFF" POSITION.

OPERATING INSTRUCTIONS

TRANSPORTING MACHINE

BLADE ADJUSTMENTS

4. SET CHOKE AND START ENGINE.

1. FILL FUEL TANK WITH REGULAR GASOLINE.

2. PULL CLUTCH LEVER BACK TO DISENGAGED POSITION.

3. SET THROTTLE TO 1/2 OPEN POSITION AND MOVE STOP SWITCH TO "ON" POSITION.

STARTING ENGINE

SOD CUTTING INSTRUCTIONS

524486

This decal shows the direction of lever movement

used to engage the drive wheels of the Jr. Sodcutter.

Movement in the opposite direction will stop the drive

wheels.

5

Jr.

Sodcutter

SET-UP

GENERAL NOTE: FRONT, REAR, RIGHT HAND AND LEFT HAND REFERENCES BELOW

ARE WITH RESPECT TO AN OPERATOR AT THE CONTROLS.

NEVER disable the operator presence control by

altering or modifying it in any way.

The Sodcutter is very heavy, to prevent serious

injury, use an adequate lifting device (i.e., hoist,

fork lift, etc.) to remove from shipping pallet.

1. Cut the banding securing the aerator to the pallet

Banding is under tension and may snap back

when cut. Wear eye protection and stay clear

when cutting the band.

2. Remove and discard reinforced tape securing

handlebar and clutch control assembly to pallet.

3. Using an adequate lifting device, remove Jr.

Sodcutter from shipping pallet.

4. Remove hardware bag and empty contents onto

a surface where they will not be misplaced or

lost.

5. Loosen, remove and retain hardware securing

large belt cover guard to side of unit, Remove

guard to allow access to idler assembly and

brake band components.

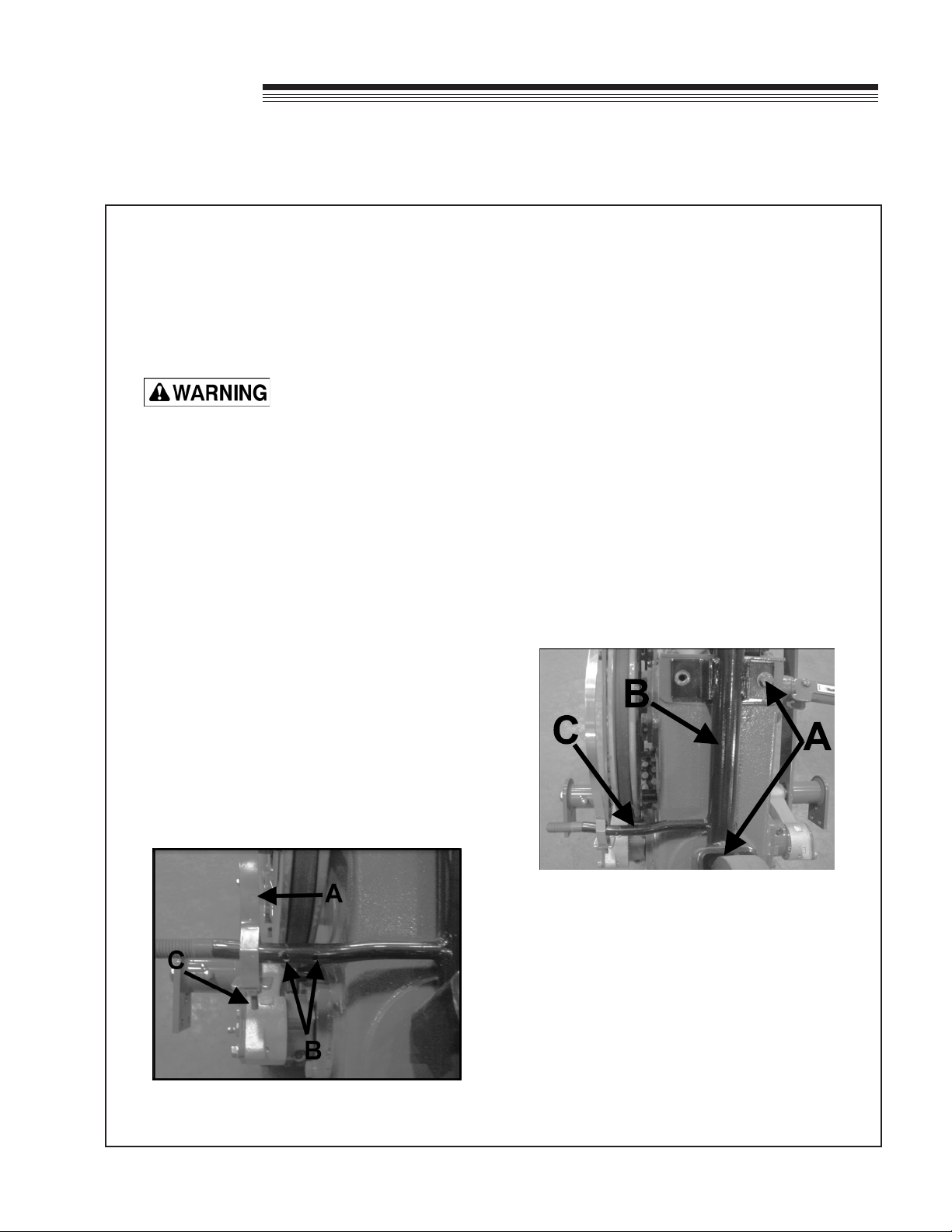

6. Slide adjustment end of brake band over the

guard support rod as shown in Figure 1.

FIGURE 1

A. Brake Band

B. Cotter Pin Holes

C. Adjustment Screw

7. Insert one cotter pin on each side of brake band,

using the two cotter pin holes shown in Figure

1. BE SURE the heads of the cotter pins are

on the pulley side of the support rod to prevent

interference between cotter pin and belt.

NOTICE

To prevent loss of gear lube from bottom hole in

gear case, tip unit forward until lifting handle on

front of unit is resting on the ground.

8. Remove and retain the upper two screws and

lockwashers from the rear of the gear case.

Loosen the lower screw in the slot behind the

wheel far enough to allow the handle bar to slide

behind the screw and washer. Figure 2.

FIGURE 2

A. Crankcase Screws

B. Handlebar Support

C. Guard Support Rod

9a. Apply Permatex gasket compound or an

equivalent to the three screws in step 8.

6

Jr.

Sodcutter

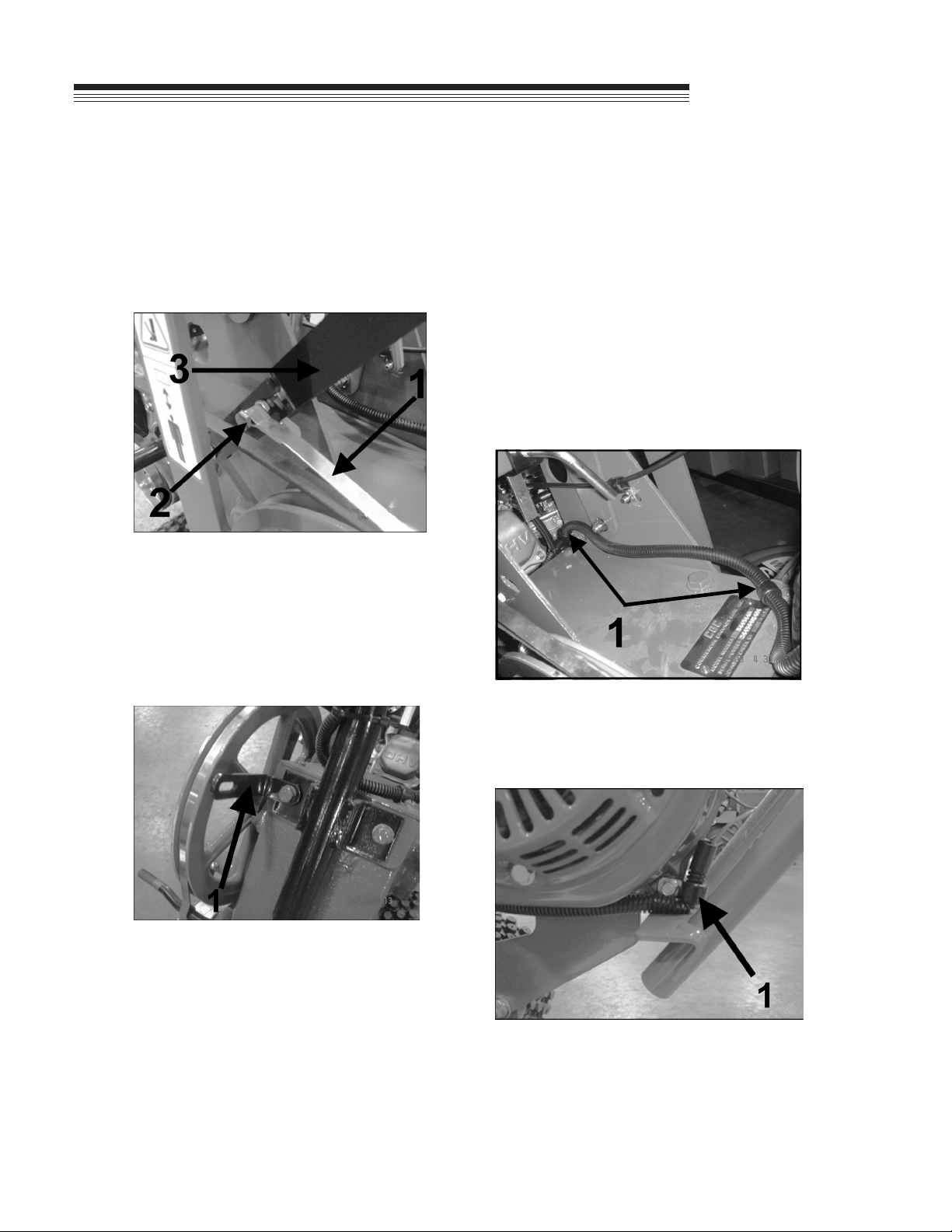

9b. NOTE: in this step, it is necessary to do three

things at one time.

1. The clevis assembly must be positioned just

to the right side of the belt, near the belt idler

arm.

Figure 3.

FIGURE 3

1. Brake Band

2. 1/4-20 Screw

3. Clevis

2. The brake band is positioned over the belt in

the large pulley groove. Figure 4.

FIGURE 4

1. "L" Bracket

3. The handle support is positioned, in the

bottom slot behind wheel, Figure 2, and then the

upper two bolts are attached with the "L" bracket

in the left hole. Figure 4. BE SURE the slotted

side of the "L" brackets is facing toward the large

pulley.

10. Connect the at end of the clevis assembly to the

idler arm as shown in Figure 3. The hardware

needed is on the clevis assembly. This should

pivot freely after it is tightened.

11. Route convoluted tubing from the control panel to

the front of the engine and attach at three points

with clips shown in Fiugre 5 and 6. Route wiring

and cable on the inside of the bracket. Route

convoluted tubing next to the hour meter wire

ty-rap together below the clip on the convoluted

tubing. Figure 7.

FIGURE 5

1. Tubing Clips

FIGURE 6

1. Tubing Clip

SET-UP

7

Jr.

Sodcutter

FIGURE 7

1. Convoluted Tubing

2. Hour Meter Wire

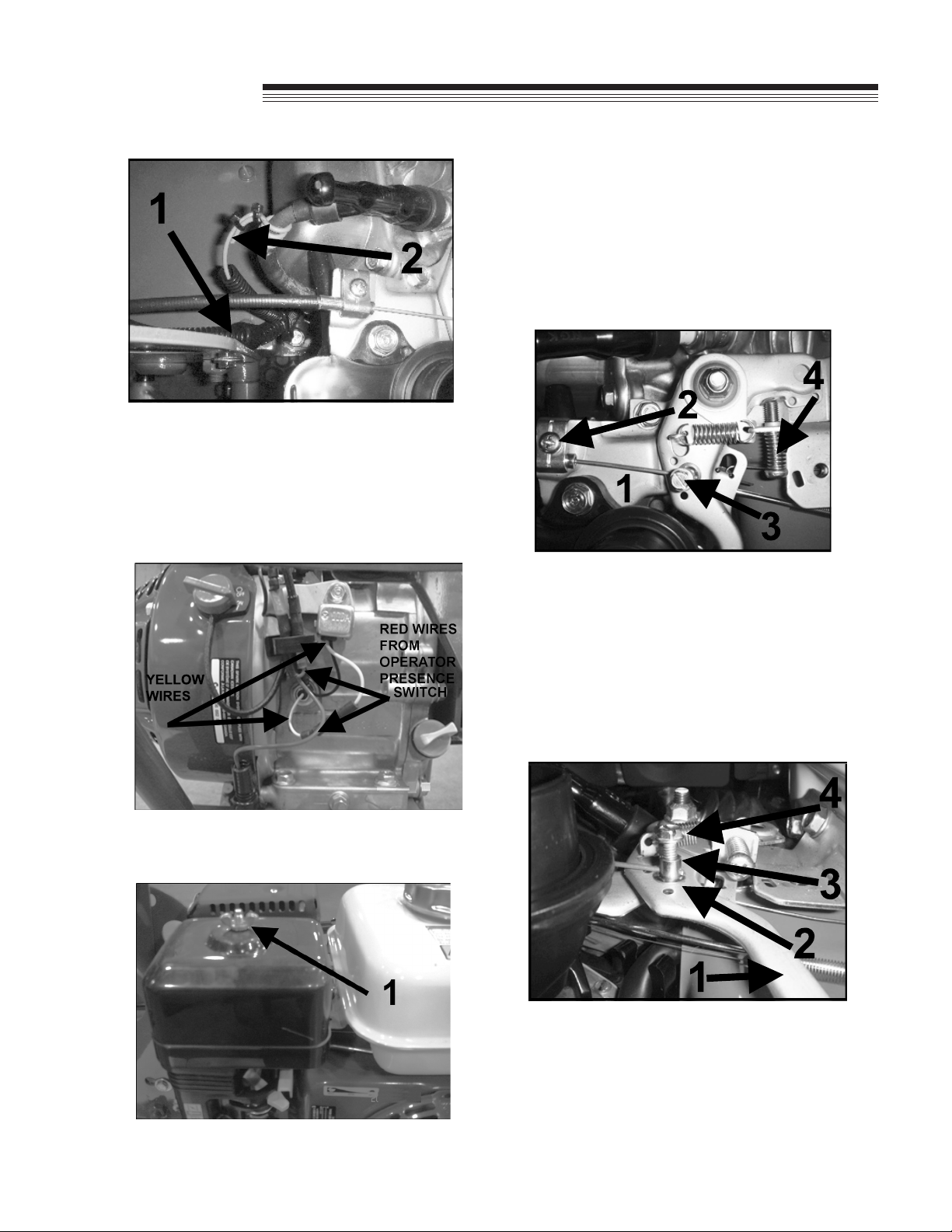

12. Connect red wire with male connector from

convoluted harness to the black female

connector on the front of the engine. Figure 8.

FIGURE 8

13. Loosen and remove wing nut securing air cleaner

cover. Remove cover and element to allow

access to the throttle. Figure 9.

1. Wing nut on Engine

14. Route the throttle cable on the inside of the

bracket. See Figure 5.

15. Route the throttle cable through the throttle

bracket as shown in Figure 10. The cable end

shoulder should be positioned as shown against

the end of the throttle bracket. Tighten down

throttle bracket making sure not to overtighten.

FIGURE 10

1. Throttle Cable

2. Throttle Bracket

3. Swivel

4. Throttle Stop Screw

16. The swivel needs to be inserted up through the

bottom of the engine throttle lever, the swivel

washer goes on and then the swivel screw.

Figure 11.

FIGURE 11

1. Throttle Lever

2. Swivel Washer

3. Swivel

4. Swivel Screw

SET-UP

8

Jr.

Sodcutter

17. Move throttle control on control panel to low idle

speed position while inserting cable end through

the swivel. See Figure 11.

18. Rotate engine throttle to high idle speed posiiton.

Move throttle control to high idle spped. Tighten

swivel screw to secure cable.

DO NOT overtighten cable stop.

19. Pull throttle control on panel back to low idle,

then push back to high idle.

20. If the engine throttle lever is not contacting the

end of the throttle stop screw, the swivel screw

must be loosened and the throttle cable wire

pulled through the cable stop further. Re-tighten

the swivel screw. Recheck to ensure the throttle

lever is contacting the end of the throttle screw, if

not, repeat.

21. Re-install the air cleaner element and cover.

Secure with the original wing nuts.

22. Use wire ties to secure convoluted tubing to

handlebar support. Figure 12.

FIGURE 12

1. Wire Ties

23. Pull the clutch control lever back to the

disengaged position. Adjust brake band by

turning the adjusting screw at the bottom of the

brake band with an allen wrench. Adjustment

should be snug enough but not too tight to cause

smoking of the drive belt. Install locking nut to

hold the brake band adjustment in place.

24. If brake band cannot be adjusted, reposition

engine. Slot on engine plate should be showing

7/32" to 1/4". See Figure 13.

FIGURE 13

25. Install one (1) 1/2-13 angelock nut (ange side

towards the outside of the unit) onto the guard

support rod before guard is reinstalled. (the

guard support rod is shown in Figure 2.

26. Reinstall guard onto side of unit using original

hardware. Secure "L" bracket to guard using

5/16-18 X 5/8" ange bolt and ange nut.

27. Insert two (2) 15 1/2" (394mm) cable ties through

the holes in the literature mounting plate. Figure

14. Secure literature tube using the large cable

ties.

FIGURE 14

1. Literature Mounting Plate

28. Attach the cutting blade using six (6) 5/16-24

X 1" grade 8 screws, lockwashers and nuts.

Torque attaching hardware to 30ft/lbs. (40.7 Nm)

USE ONLY the special grade 8 cap screws provided.

Screws below grade 8 will not withstand the

recommended torque requirements.

29. Install one (1) 1/2" angelock nut to the guard

support rod to complete the guard installation

from step 26.

SET-UP

9

Jr.

Sodcutter

CONTROLS

JR SODCUTTER CONTROLS

Clutch Control Lever - A

Engages or releases drive belt and applies brake

action to drive belt when pulled FIRMLY to rear.

Throttle Control - B

Speeds up or slows down the engine.

Engine Switch

Turn to "ON" position to start engine. Turn to "OFF"

position to stop engine.

Operator Presence Control - C

With clutch control engaged, engine will stop if

operator presence lever is not depressed.

Blade Depth Control Lever - D

Raises or lowers cutting blade.

Blade Depth Control Locking Lever - E

Locking lever holds blade depth control in desired

position.

Blade Angle Locking Lever - F

Adjusts cutting angle of blade.

Depth Gauge - G

Allows resetting of blade depth to the previous

cutting height.

Hour Meter - H Shows how many hours that the

engine has run. The far right digit is tenths of an

hour (1/10).

- The wire from the hour meter is wrapped around

the spark plug wire four (4) turns and secured with

Ty-raps.

10

Jr.

Sodcutter

CONTROLS

JR SODCUTTER CONTROLS

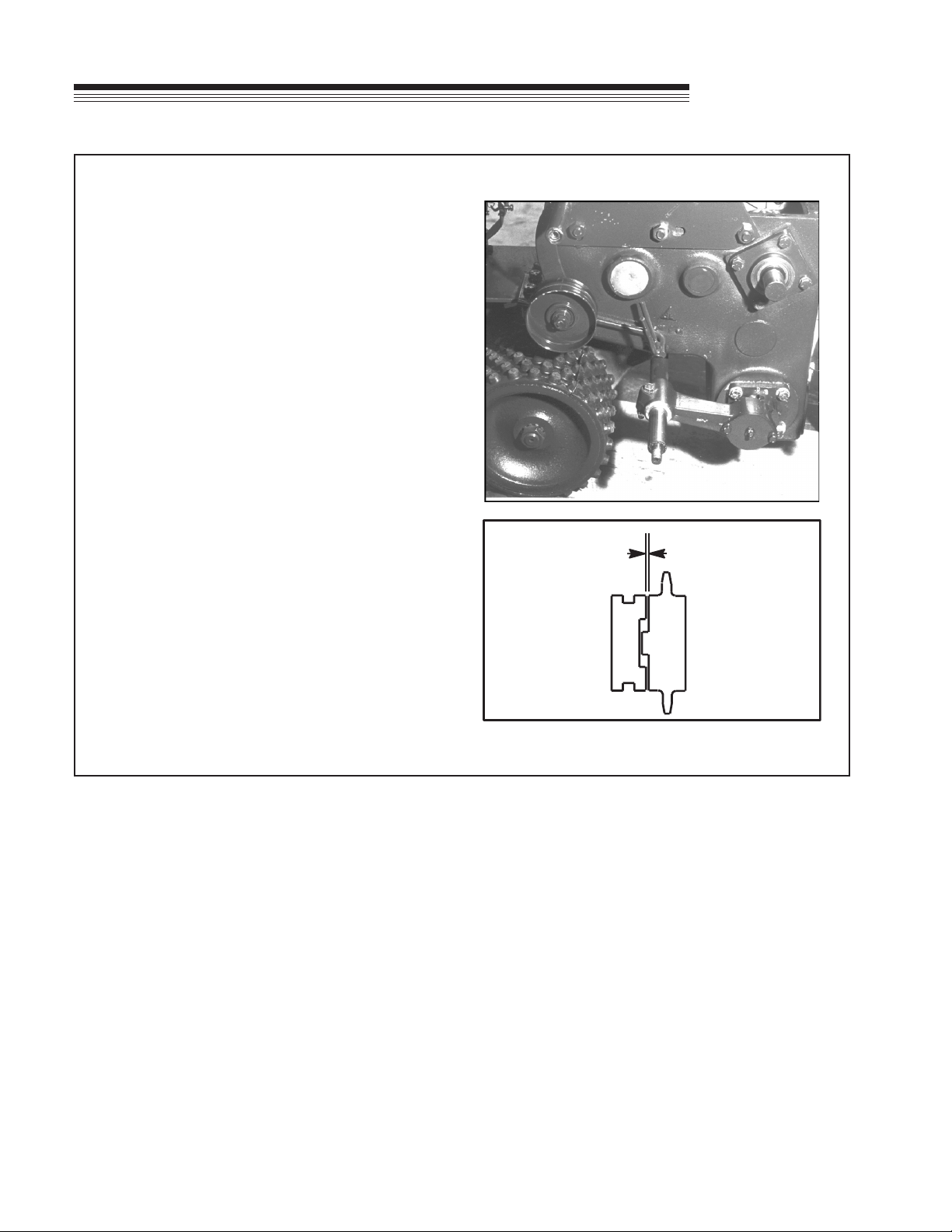

Blade (H) and Wheel (J) Shifter Handles : Engage

or disengage blade for cutting and gears for driving

Sodcutter.

"DISENGAGED" "ENGAGED"

SHIFTER HANDLE

GEAR

CASE

GEAR

CASE

SHIFTER

11

Jr.

Sodcutter

OPERATION

PRE-OPERATION CHECK

1. Visually check all moving parts and all fasteners.

If loose or broken, tighten or replace. Check

belt for fraying, wear and proper adjustment (see

SERVICE section).

2. Lubricate all lubrication ttings before each days

use or after every eight hours of operation (see

SERVICE section).

3. Check the engine crankcase oil level with the

engine resting in a level position. Add oil if

necessary.

4. Check the gear case oil level. Add oil if

necessary.

5. Check the air lter. Replace if necessary.

6. Sharpen cutting blade (see SERVICE section).

7. Follow the engine manufacturer's

recommendations for the correct type and

amount of oil. Fill the fuel tank according to the

engine manufacturer's specications.

Gasoline is extremely ammable and highly

explosive under certain conditions. Always stop

the engine and do not smoke or allow open

ames or sparks when refueling. BE SURE to

install fuel cap after refueling.

Do not ll containers in a vehicle or on a truck or

trailer bed with a plastic liner. Fill containers on

the ground away from the vehicle.

Refuel equipment on the ground. If equipment

must be fueled on a truck or trailer, refuel from

a portable container rather than a dispenser

nozzle.

Keep the dispenser nozzle in contact with the rim

of the fuel tank or container opening until fueling

is complete. Do not use a nozzle lock-open

device.

NEVER start or run the engine inside where

exhaust fumes can collect. Carbon monoxide

present in the exhaust is an odorless and deadly

gas.

DO NOT operate equipment without shields in

place. DO NOT make adjustments or perform

any maintenance while the engine is running.

Before operating, check the area and remove

any object which may present a safety hazard or

damage the equipment.

STARTING ENGINE

1. Be sure gas is turned on. Check Shut-off valve

located on the bottom of the fuel tank

2. Place all controls in "Disengaged" position.

3. Put Throttle lever at half speed.

4. Turn engine switch to "ON" position.

5. Pull recoil starter, and choke as required to start

engine. Allow engine to warm up.

MOVING THE JR SODCUTTER

To move unit without running blade :

1. Place blade shifter handle Hin "disengaged"

position (handle will point straight out from unit).

2. Set engine speed at slow speed.

3. Engage drive shifter handle.

4. Depress operator presence control.

5. Engage clutch control lever.

6. Adjust throttle to desired walking speed.

To move unit without running engine:

1. Put drive shifter handle and clutch control lever in

"Disengaged" position.

To transport the unit:

1. When transporting unit on trailer or truck, shut fuel

vavle "OFF" beneath fuel tank.

CUTTING SOD

1. Engage drive wheel shifter handle.

2. Engage blade shifter handle.

3. Standing on the right side of the unit, lift handle

with left hand, and lower blade to preset depth

with right hand. Tighten the locking lever.

4. Adjust throttle to full speed.

5. Push clutch lever forward and lower handle.

6. After cutting a short distance, stop unit and check

thickness of sod. Adjust if necessary.

7. At end of each cutting pass, lift up on handle to

clear cutting blade from sod, retard throttle and

turn Jr. Sodcutter around for return pass.

12

Jr.

Sodcutter

SERVICE

When replacement parts are required, use

genuine CGC, INC. parts or parts with equivalent

characteristics, including type, strength and

material. Failure to do so may result in product

malfunction and possible injury to the operator

and/or bystanders.

Carbon monoxide present in the exhaust is an

odorless and deadly gas. Never start or run the

engine inside where exhaust fumes can collect.

Provide enough fresh air to keep fumes from

getting too strong.

Any warning decal that becomes illegible should

be replaced immediately.

840697

STOP engine and disconnect spark plug wire

before servicing or making adjustments to unit.

The preceding decal shows what could happen

if the engine is not stopped or disabled before

removing safety covers. Hands may become

entangled in moving belts, gears, chains or other

parts.

Use adequate lifting device (i.e., hoist, fork lift,

etc.) to raise unit.

Use adequate supports when unit is raised for

servicing.

Wear protective eye equipment when using

hammers, chisels and punches.

BLADE SHARPENING

1. Hand le bottom blade at 45O angle until no at

remains.

2. To keep cutting edge less than 1/16" on 45O

angle, grind milled surface back at 15Oto less

than 1/16".

3. Hand le side blades at 45O until no at remains.

4. To keep cutting edge less than 1/16" on 45O

angle, grind milled surface back at 15Oto less

than 1/16".

THIS

1/16"

Maximum

45

O

15

O

FILE

DIRECTION

SURFACE

SMOOTH

(No Burrs)

BOTTOM BLADE

MILLED

EDGE

FILE

DIRECTION

1/16" MAX

THIS SURFACE SMOOTH

(No Burrs)

FILE

DIRECTION

SIDE BLADE

13

Jr.

Sodcutter

SERVICE

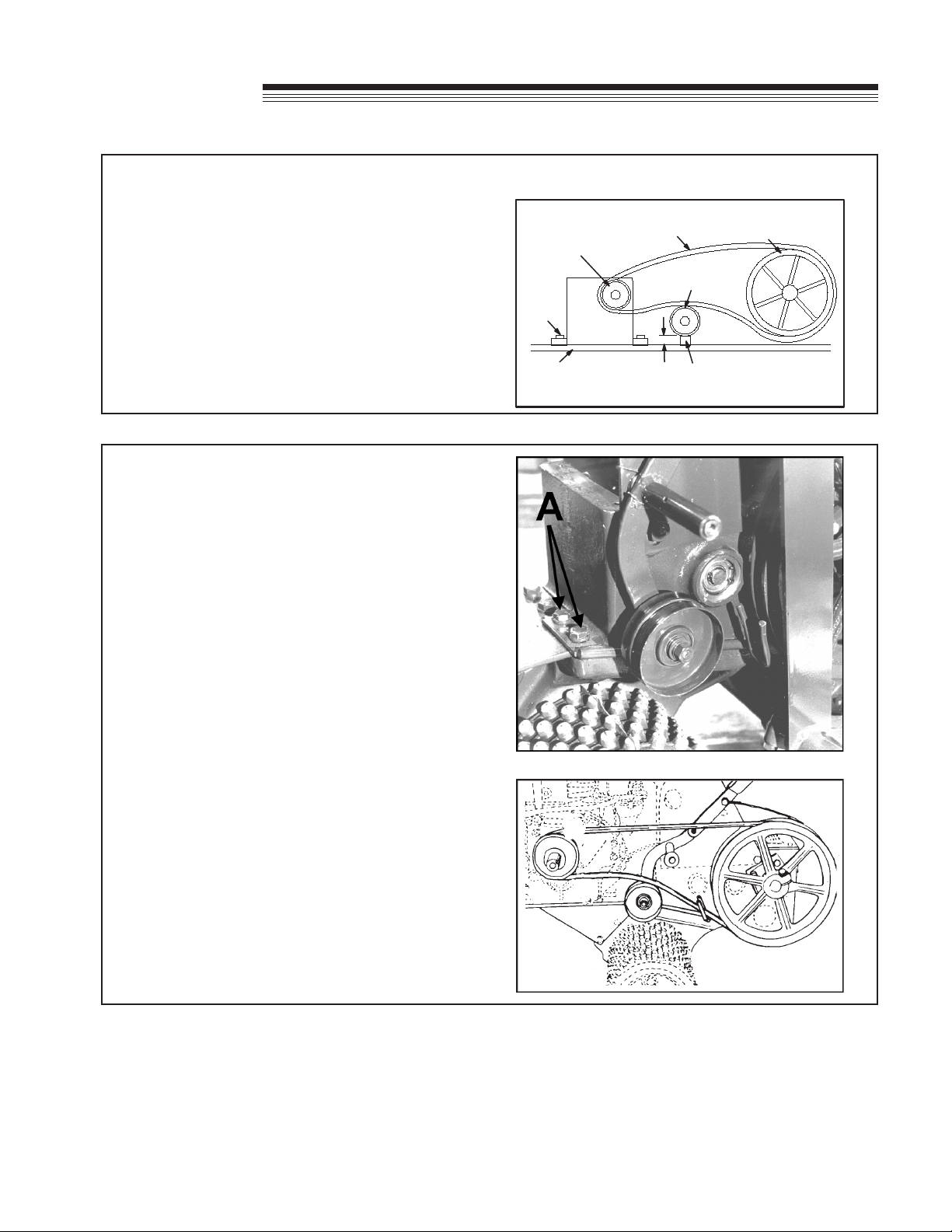

DRIVE BELT ADJUSTMENT

Keep belt free of oil and dirt, and adjusted to

proper tension at all times.

Belt tension is adjusted by loosening four (4)

engine mounting bolts and shifting engine on the

base.

The belt should be taut when the clutch lever is

pushed forward (engaged) and the idler wheel is

1" (25.4 mm) from the engine mount plate.

ENGINE

ENGINE

BOLT

ENGINE

PULLEY

BLOCK

ENGINE

MOUNT PLATE

1" (25.4 mm)

IDLER

PULLEY

BELT DRIVE

PULLEY

DRIVE BELT REPLACEMENT

1. Remove shield on left side of unit.

2. Remove nut securing brake band to clutch

control rod.

3. Remove cotter pin on outside of guard support

rod and move brake band over to nut on rod.

4. Loosen two bolts Asecuring belt guide to

provide clearance when removing belt.

5. Install new belt in reverse procedure. Route the

belt as shown.

14

Jr.

Sodcutter

SERVICE

DRIVE CHAIN REMOVAL

1. Raise unit, place on adequate supports and

remove belt guard.

2. Remove four (4) screws securing cover.

3. Remove throttle cable from engine and lay

behind cam case.

4. Remove dipstick from cover.

5. Remove screw, at washer, nut and bushing from

right lower side of "H" frame.

6. Using a screwdriver, lift cover to break sealant

bond and remove cover.

7. Drain oil out of front cavity on case, and turn

drive wheels until master link is on top of

sprocket.

8. Remove master link and continue rotating drive

wheels until chain is off bottom sprocket.

9. Install new chain in reverse procedure. Clean

mating surfaces on case and cover. Apply 3M

Scotch Grip 847 or an equivalent adhesive to

case cover before installation.

BLADE DRIVE CHAIN REPLACEMENT

NOTE: To prevent small components from falling

down into oil cavities and causing damage

to unit, cover opening with clean rags,

cardboard, etc.

1. Follow steps 1 thru 6 in drive chain removal.

2. Remove bottom screw on bearing cage to drain

oil from rear cavity.

3. Rotate pulley shaft until master link is to front of

top sprocket. Remove master link.

4. Rotate blade drive shaft until chain is free.

5. Install new chain in reverse procedure. Use 3M

Scotch Grip 847 or an equivalent adhesive on

case cover and bearing retainer screw.

15

Jr.

Sodcutter

SERVICE

UPPER DRIVE SPROCKET & SHAFT

1. Remove drive chain according to steps 1 thru 6

in drive chain removal section.

2. Remove master link from chain. Chain does not

need to be removed from lower sprocket.

3. Remove drive shifter assembly from gear case.

4. Remove blade and side arms from pivot brackets

for easier access.

5. Remove plugs on both ends of shaft.

6. Remove snap rings Bfrom left bearing.

7. Using a punch and soft hammer (lead, leather,

etc.), drive shaft out left side of unit and remove

large gear.

8. Using a bearing puller or slide hammer, remove

bearing. Shaft is now removable through cam

case cover opening.

9. Dog clutch half is removable from gear by

removing snap ring.

10. Assemble in reverse procedure.

11. After installing blade shifter assembly, adjust

dog clutch to provide .015" (0.39 mm) clearance

between clutch faces, as shown.

12. Apply 3M Scotch Grip adhesive or an equivalent

to gear case cover before installation.

.015

(0.39 mm)

16

Jr.

Sodcutter

SERVICE

DRIVE WHEEL CHAIN SPROCKET SHAFT

1. Follow steps 1 thru 7 in drive chain removal

section.

2. Remove master link and remove chain from top

sprocket.

3. Remove both drive wheels and axle keys.

4. Remove seal in case and snap ring retaining

bearing in case.

5. Install axle nut on end of shaft, opposite the side

of snap ring previously removed.

6. Using a soft hammer (lead, brass, etc.), drive

shaft out of case. Sprocket can now be removed

by lifting up on chain.

7. Top sprocket and chain should be checked for

wear and replaced if necessary.

8. Reassemble in reverse procedure using new

seals and gaskets.

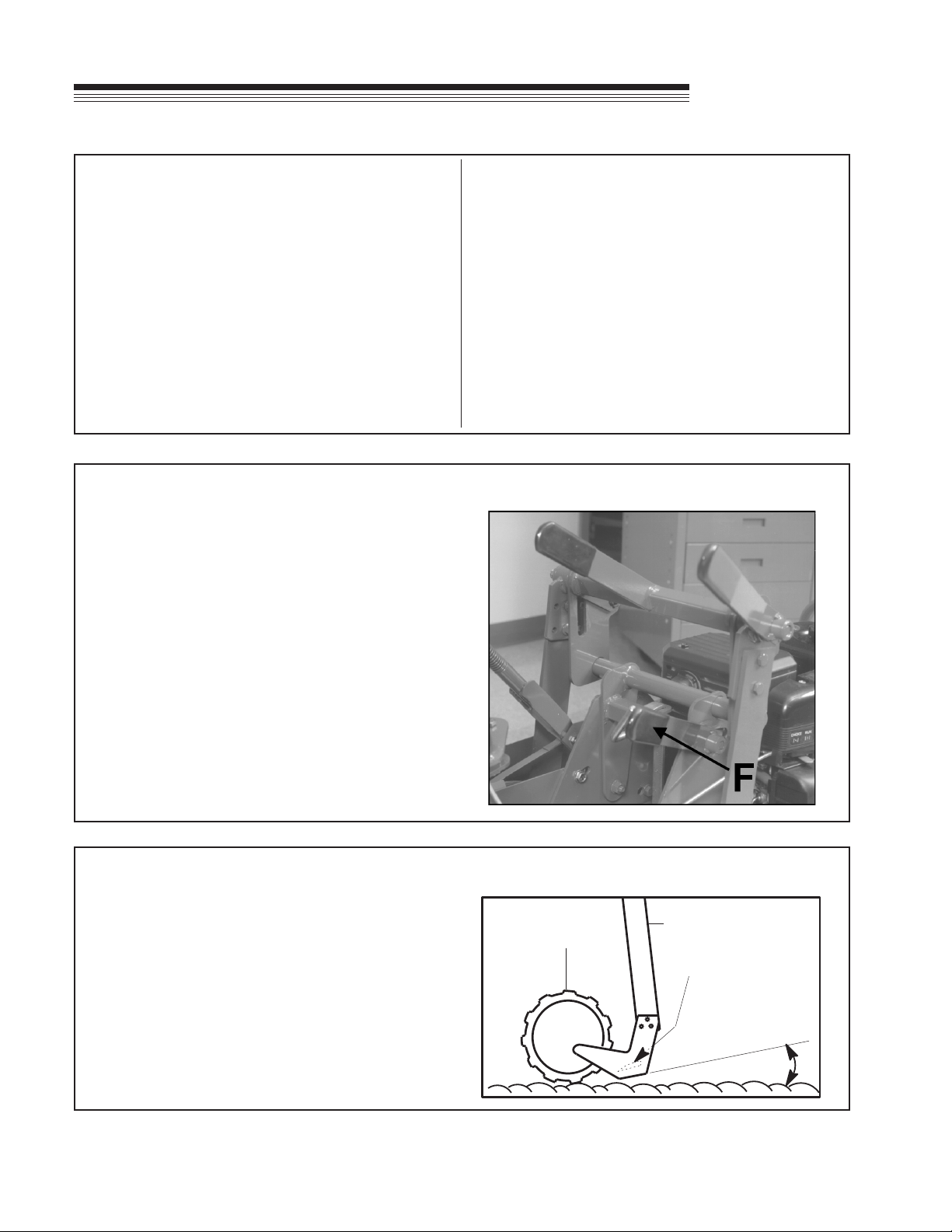

ADJUSTING BLADE ANGLE

1. Loosen blade angle control locking lever Fand

move H-frame forward or backward until blade is

at desired angle of pitch.

2. Tighten blade angle control locking lever F.

SIDE ARM

DRIVE

WHEEL

BLADE

BOTTOM

BLADE

ANGLE

(Pitch)

BLADE ANGLE (PITCH)

Under normal operating conditions, blade angle

is minimal (blade bottom is at). In extremely

hard soil or when cutting with a dull blade, the

blade may want to ride out of the ground. It may

then help to adjust blade angle downward (see

Adjusting Blade Angle above). A short trial run

will indicate which is the best blade angle.

17

Jr.

Sodcutter

SERVICE

ADJUSTING DEPTH OF CUT

1. Make a trial run in turf. Set depth to cut

approximately 3/4" of soil.

2. Loosen depth gauge handle. Adjust depth gauge

Gto contact bottom on depth control lever D.

3. Loosen depth control locking lever Eand lower

depth control Duntil it rests on depth gauge G.

4. Tighten depth control locking lever E.

NOTE: Numbers on depth gauge do not necessarily

represent thickness of sod being cut.

ADJUSTING OPERATOR PRESENCE CONTROL

1. To adjust operator presence cable, pull clutch

control handle Arearward as far as possible.

2. Press operator presence handle (right handlebar)

down as far as possible.

3. Adjust cable until the pivot arm Ccontacts the

arm extending from the operator presence switch

B.

4. Tighten cable clamp to secure cable. Check for

proper operation.

18

Jr.

Sodcutter

PULLEY SHAFT

1. Follow steps 1 thru 4 in belt replacement section

and steps 2 thru 6 in drive chain removal section.

2. Remove blade from unit and remove left side

arm.

3. Remove blade shifter assembly.

4. Turn pulley until master link is on top of sprocket.

Remove chain from top sprocket.

5. Remove belt pulley and key.

6. Remove four (4) bearing cage screws and pull

gears out left side of unit. Dog clutch and double

sprocket will slide off as shaft is removed.

7. To remove gear and bearing, remove snap ring,

slide gear off shaft and remove key. Remove

bearing snap ring and remove bearing.

8. Assemble in reverse procedure. After blade

shifter assembly is installed, adjust dog clutch

to provide .015" (0.39 mm) clearance between

clutch faces, as shown.

9. Apply 3M Scotch Grip 847 adhesive or equivalent

to gear case cover before installation.

SERVICE

.015

(0.39 mm)

Table of contents