Congratulations! You are in possession of the most useful, yet simple to operate

Evaporative Emissions System (EVAP) diagnostic tester available today. The LeakMaster

NE240’s versatile 12-volt design was specifically developed to diagnose vehicle EVAP

systems for leaks. However, it will also diagnose many other closed systems where you

may suspect a leak. Its unique Dual-Phase design allows the operator to confirm the

integrity of the system being tested by utilizing a metered-air system. If the tool has

confirmed a leak in the EVAP system being tested, the tool then introduces a special non-

toxic diagnostic marked-vapor (smoke) into the system, using an inert gas such as nitrogen

for safer EVAP testing. To locate the source of the leak you simply look for the smoke

exiting the leak or use a conventional ultraviolet (UV) lamp to view the UV deposit left

behind, pinpointing the exact location of the leak. The LeakMaster technology has become

“THE” choice of major auto manufacturer’s for verifying and detecting OBD-II EVAP leaks

and is the “Essential” tool they specify for their dealer service programs.

Note: The LeakMaster NE240 arrives filled with a full charge of Smoke-Producing Solution

that will last approximately 1000 tests before the solution may need to be replenished.

Dual-Phase Operation:

Unique to its design, the LeakMaster NE240 leak tester is a Dual-Phase tool. Phase-one utilizes

an inert gas such as Nitrogen to test the integrity of the vehicle’s fuel vapor recovery system by

quickly determining if in fact a leak exists. Phase-two quickly finds the leak utilizing both visual-

vapor (smoke) and UltraTraceUV technology. UltraTraceUV is a unique chemical bonded to the

smoke that deposits an ultraviolet ‘fingerprint’ at the exact location of the leak.

This dual-phase operation is accomplished automatically. Your LeakMaster NE240’s internal

pressure regulator automatically sets the critical pressure that must be maintained during EVAP

testing. You don’t need to set flow rates and you don't need to be concerned with ambient

temperatures or barometric pressures. The LeakMaster NE240 will not spill its solution regardless

of the position you set it in and is refillable by the end-user when the smoke-producing solution is

depleted. The smoke it produces, as well as the UltraTraceUV dye, is non-toxic and non-corrosive.

The LeakMaster NE240 needs no assembly, it is self-calibrating, and requires no maintenance

other than a recommended annual smoke-solution change.

Read this manual in its entirety prior to performing any actual tests on a vehicle. This leak

tester is to be operated by a properly trained and qualified professional only.

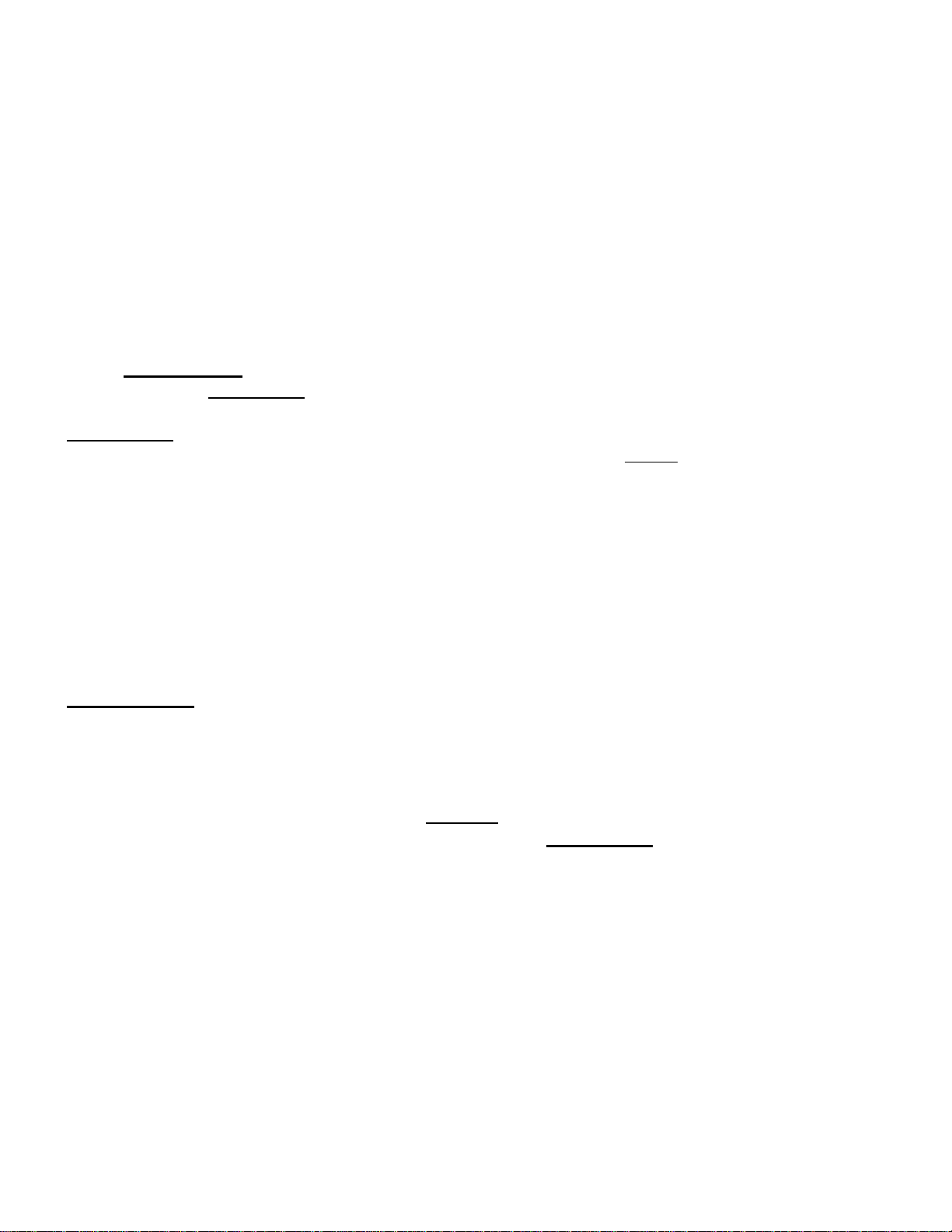

Technical Specifications:

LeakMaster NE240

Height

Width

Depth

Weight

Ship weight

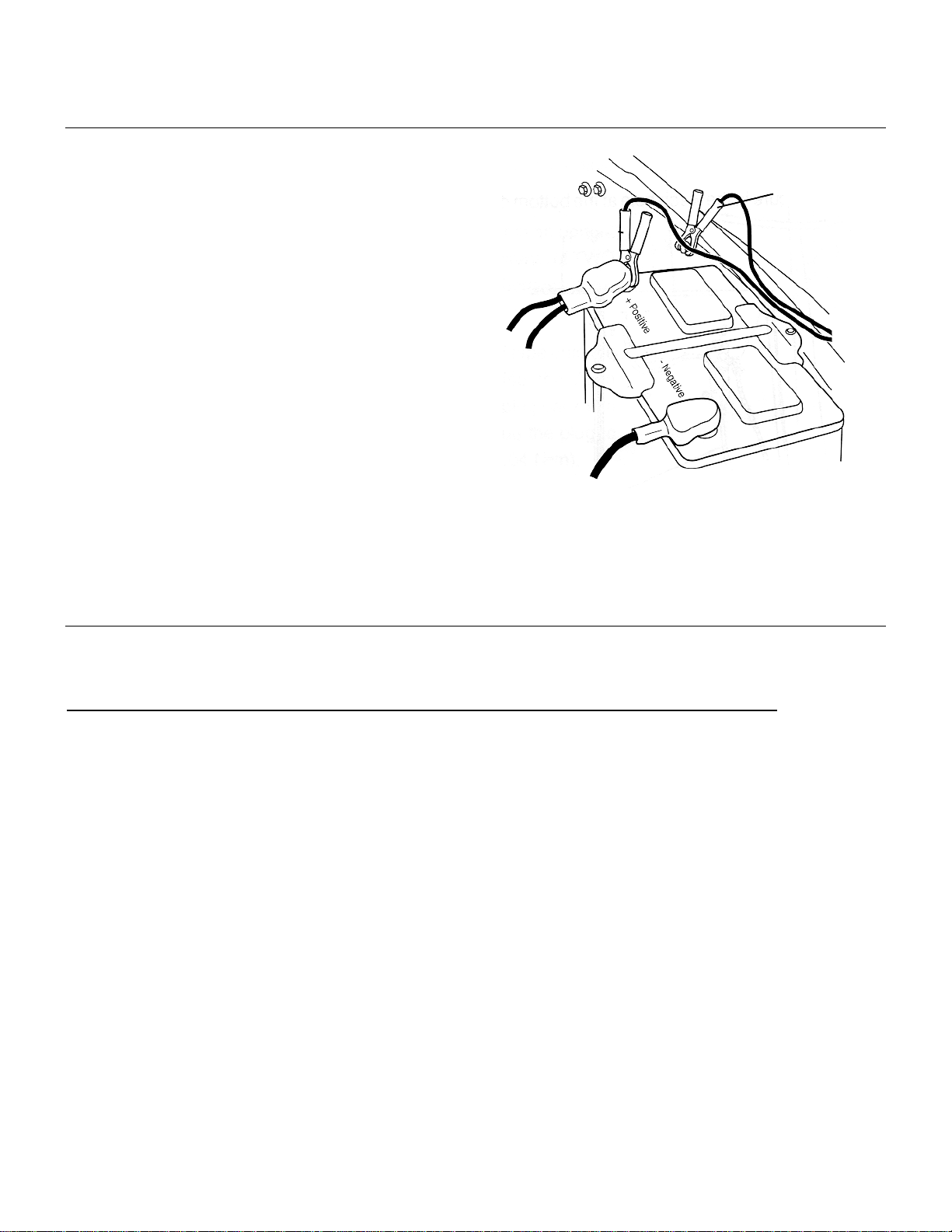

Power supply

Amperage usage

23 in. (58.4 cm)

18 in. (45.7 cm)

9 ½ in. (24.1 cm)

17 lb. (7.6 kg)

20 lb. (9.0 kg)

12-volt DC

15 amps.

Supply pressure

Supply volume

Operating temp. range

Air supply line (Clear)

Smoke supply line (Black)

Power supply line

Remote starter cable

13.0 in. H2O (.032 bar)

15 liters per minute

45°F to 140°F (7.2°C to 60°C)

12 feet (3.6m)

12 feet (3.6m)

12 feet (3.6m)

12 feet (3.6m)

3