Chandler 406RB-1 User manual

I

400 VETERANS BLVD, CARLSTADT

NJ

07072

From the library of: Superior Sewing Machine & Supply LLC

From the library of: Superior Sewing Machine & Supply LLC

u

From the library of: Superior Sewing Machine & Supply LLC

From the library of: Superior Sewing Machine & Supply LLC

CONTENTS

1.

MAIN

PARTS

NAMES·································································..................................................................

-1

2. SPECIFICATIONS··········································································································································1

3. WORK TABLE AND MOTOR........................................................................................................................2

4. INSTALLATION·············································································································································3

4-1:

Installing the rubber hinge and the corner rubber····

........

···········

....

··

..

·····

..

···..

················

....·..

··

....

·······

..

··....···3

4-2.

Installing the oil pan···......·...

··

..

······

....

·········

.....

··············

.....···

..

···················

......·

..

···...

··············

...·

..

·········

·3

4--3. Installing the machine

head···············

...······

..

·················

..

·

..

······················

..

··

..

···

..

·....···

..

················

..

·

..

·

..

·····3

4-4.

installing the spool pin... ·······....····...·.....

···················

..

····...···

..

···

..

··············

.....·····

..

······

..

··

..

··················

....

-4

4-5.

installing the knee lifter

assembly··············································································································

-4

4-6.

Installing the belt······

..

····

..

···

..

··············

..

················

..·

..

·····················

..

··

..

················································

·5

4-7.

Installing the bobbin winder

..

···················

..

·

..

··············································

..

·····································

..

····5

4-8.

Installing the belt guard{L)························································································································6

4-9.

Installing the thread

stand············

..

·············

..

················

..

··········

..

·····

..

······················

..

···············

..

··········

..

·6

4-1

0.

Lubrication···················································

·······················································································7

4-11.

Checking the machine pulley rotating direction··

..

···············

..

··

...·

..

···

..

··············

..

······......···

..

··········

..

··

..

·········

·8

5. PREPARATION BEFORE SEWING..................................................................................................................g

5-1.

Installing the needle····

..

··

..

··

..

········

....·

..

··

..

···

..

···......····......

·······

..

····

..

····......···

..

····....··......····

..

···················

·9

5-2.

Removing the bobbin case············

........

·················

..

·····························

....

·······································

....·····9

5-3.

Winding the

lower

thread················-

.......................................................................................................

10

5-4.

Installing the bobbin case·..·..

········································

....

···········

..

···············

..

·······································

·1

0

5-5.

Threading the upper

thread·············································

..................

················································

······11

5-6.

Adjusting the stitch

length·································

..

········································

···························

..

················11

6. SEWING······················································································································································12

6-1.

Sewing················································································································································12

6--2.

Backtacking·························································-·······

.........................................................................

12

7.THREAD TENSION····································........··········......··········································································

·13

7-1.

Adjusting the thread tension··.....

················

.........

··········

.....

···························································

.....······13

7-2.

Adjusting the presser foot

pressure·····················

.....................

····························································

···13

8.STANDARD ADJUSTMENTS········································

..

··············································································14

8-1.

Adjusting the thread controller

spring···················

..

································

..

···············································

..

·14

8-2.

Adjusting the height

of

the feed dog·.....

·········

......

······························

...

·········

...

····································

···15

8-3.

Adjusting the feed dog position (longitudinal)····..

···········································································

····..

······15

8-4.

Adjusting the positions

of

the needle

and

needle hole

of

the feed

dog··················

...

···············

...

·········:.·

......

··

·16

8-5.

Adjusting the timing the needle

with

feed

...................................................................................................

18

8-6.

Adjusting the height

of

the needle

bar·····································································································

·18

8-7.

Adjusting the timing between the needle and hook

......................................................................................

-19

8-8.

Adjusting the clearance between rotary hook and opener (thread release

finger)···············································

·20

8--9. Adjusting the clearance between feed forked connection

and

feed fork

collar··················································

·21

8--10. Adjusting the height

of

the presser

feet····················:···························

.....

···········································

···21

s-·11. Adjusting the presser foot

movement

amount·······························································

...............

···

·········22

8-12.

Adjusting the timing

of

the vibrating presser foot...

·······

..

····

..

·····································································

·23

8-13.

Adjusting the

L0d

regulator···········································-··············

........................................................

24

9.SAFETY CLUTCH MECHANISM····..............................................................................................................25

From the library of: Superior Sewing Machine & Supply LLC

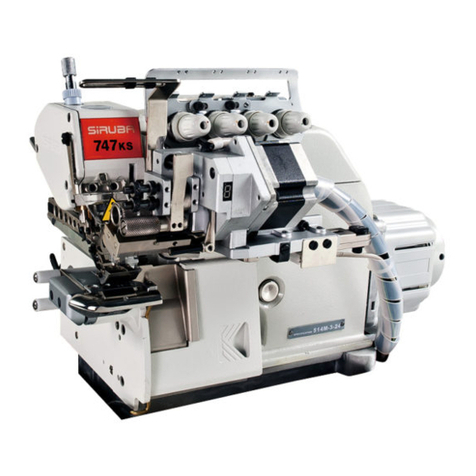

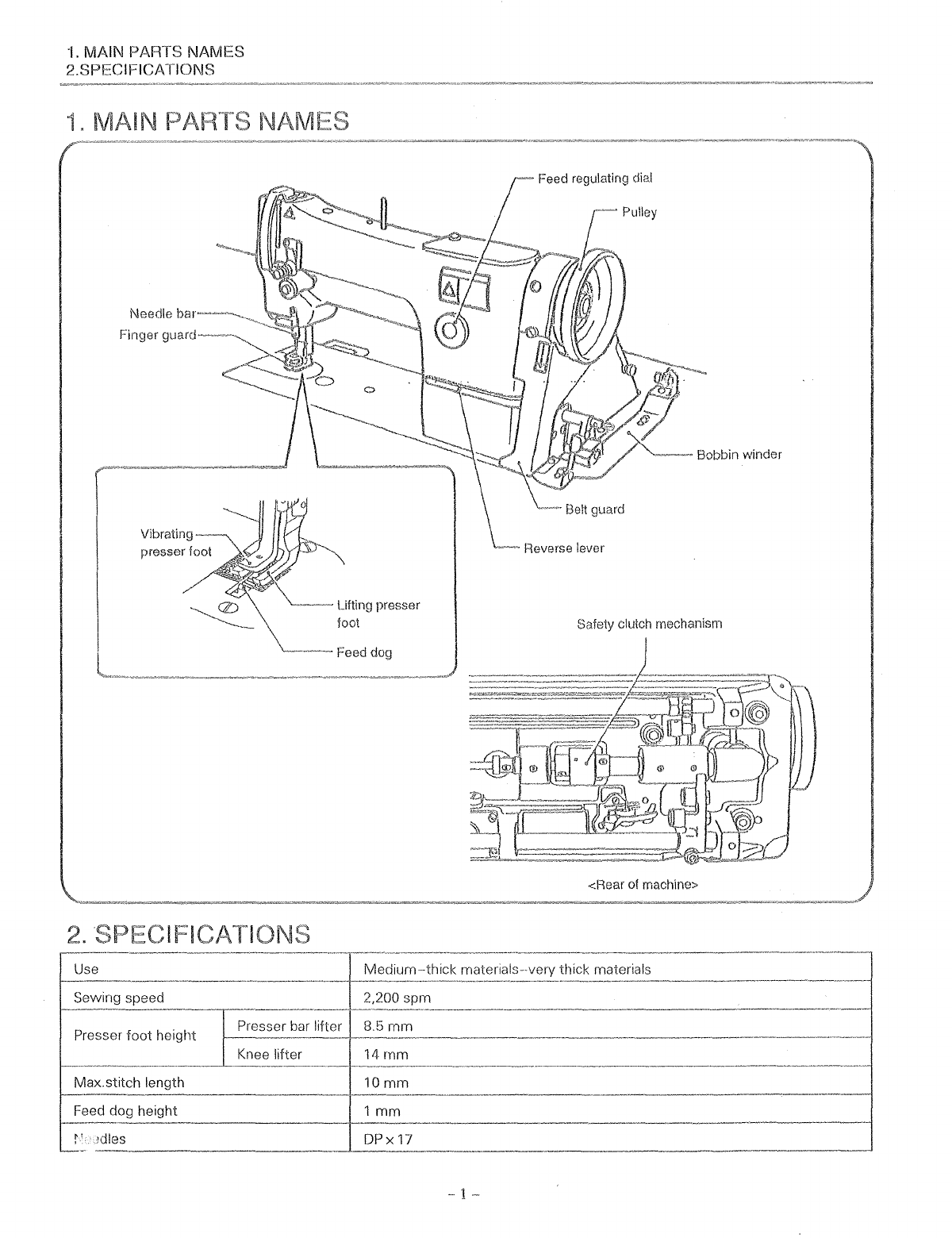

1.

MAIN PARTS NAMES

2.SPECIFICATIONS

1"

MAIN

Vibrating

presser foot

~-

lifting presser

foot

-~Feed

dog

Feed regulating dial

Safety clutch mechanism

<Rear

of

machine>

materials--very thick materials

-

1-

From the library of: Superior Sewing Machine & Supply LLC

3.WORK TABLE AND MOTOR

3.WORK TABLE AND MOTOR

Work Table

• When using a table made by another manufacturer, drill holes

in

the table

as

shown

in

the figure below.

• The top

of

the table should be 40

mm

in

thickness and should be strong enough to hold the

weight

and withstand the

vibration

of

the sewing machine.

Work

table

processing

diagram

14

Head

Motor mounting holes

!<:nee

lifter installation

position

Thread stand hole

A-A

cross section

B-B

cross section Oil pan installation position

15.5mm

Work Table

<Motor>

• All cords which are connected to the

motor

should be secured at least 25

mm

away from

any

moving

parts.

Furthermore,

do

not

excessively bend the cords or secure them too

firmly

with

staples, otherwise them

is

the

danger that fire or electric shocks could occur.

• Sek;ct

UiG

correct motor from those listecl

in

the table.

f{,:Jfor

to

the instruction manual for the motor for details on

installing and using the motor.

<M0tor pulley and

V-belt>

Select the correct motor pulley and V-belt by referring to the table

to

suit

the

power frequency of your area.

-2-

• Install the correct belt guard which

to the motor being used.

Power

Motor

motor

50

HZ

Motor

pulley 55

41

inches

2,000 spm

60HZ

Motor

pulley 45

41

inches

From the library of: Superior Sewing Machine & Supply LLC

4.

INSTALLATION

4.

INSTALLATION

o The sewing machine should only be installed

by a qualified technician.

• Ask your dealer or a qualified electrician for any

electrical

work

that may need to be done.

· The sewing machine

weights

more than 29 kg.

The installation should be carried out by

two

or

more people.

o Do not connect the

power

cord until installation

is

complete,

otherwise

the

m8chine

will

oper8te ifthe treadle is

prEJSSt)cl

by mistake,

v;hich could result in injury.

Be

sure to connect the ground. If the ground

connection is not secure, serious electric

shocks will result.

• Install the belt guard to the machine head.

4-1.

Installing the rubber hinge and the corner rubber

4~2.

Installing the oil pan

4-3.

Installing the machine head

--

3

1.

Install the rubber hinge

(1)

on the table

with

nails

(2

(Two places)

2.

Install the corner rubber Q) at the four corners

of

the

table

with

nails

Fit oil pan

with

4 nails into the opening

in

the table, and secure it

(Refer to the

work

table processing diagram on page

2.)

1.

Insert the

two

bed hinge connections

CD

into the holes

in

the machine bed.

2.

Fitthe bed hinge connection to the rubber hinge

and then place the machine head onto the corner

rubber

3.

Tap the head rest into the table hole.

NOTE:

Tap

the head rest securely into the table hole. If

the head rest

is

not pushed in

as

far

as

it will go,

the machine head will

not

be sufficiently stable

when

it is tilted back.

From the library of: Superior Sewing Machine & Supply LLC

4.

INSTALLATION

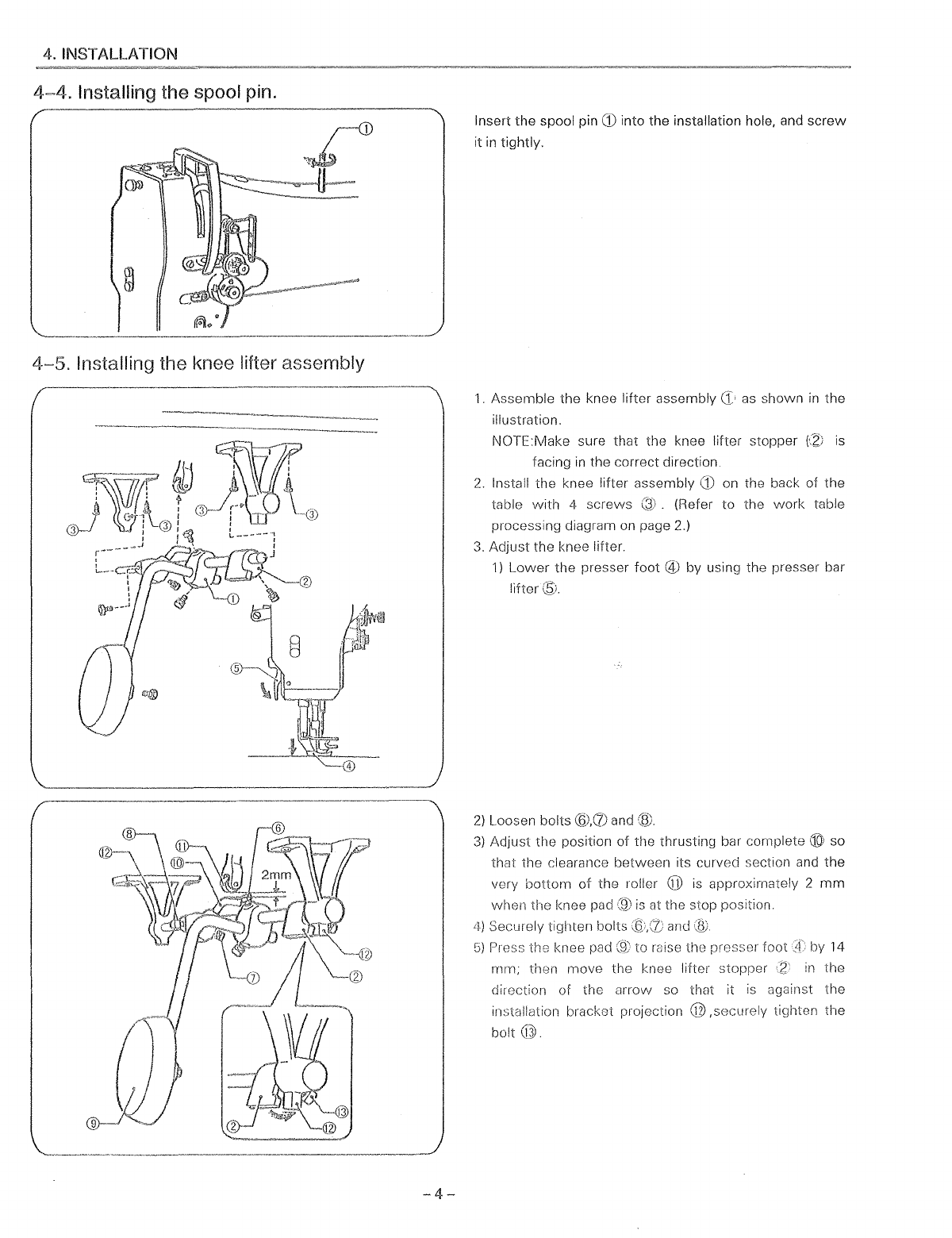

4~4.

Installing the spool pin.

4-5.

Installing the knee lifter assembly

-4-

Insert

the

spool pin

CD

into the installation hole, and

screw

it

in

tightly.

1.

Assemble

the

knee lifter assembly as shown

in

the

illustration.

NOTE:Make sure that the knee lifter stopper

fZ:;

is

facing

in

the correct direction.

2.

Install

the

knee lifter assembly

CD

on the back of

the

table

with

4

screws

(Refer

to

the

work

table

processing diagram on page 2.)

3.

Adjust

the knee lifter.

1)

Lower

the

presser

foot

@

by

using the presser bar

lifter®.

2)

Loosen bolts

@.(1)

and

(til

3)

Adjust

the

position

of

the thrusting bar complete ® so

that

the

clearance

between

its curved section and

the

very

bottom

of

the

roller @ is approximately 2

mm

when

the

knee pad

(9)

is

at the stop position.

4)

Securely tighten bolts and

G)

Press the knee pad

to

mise the presser

foot

!f

by 14

mm;

then

move

the knee lifter stopper

:z

in

the

direction of the

arrow

so that it

is

against

the

installation bracket projection

@,securely

tighten

the

bolt@.

From the library of: Superior Sewing Machine & Supply LLC

4.

INSTALLATION

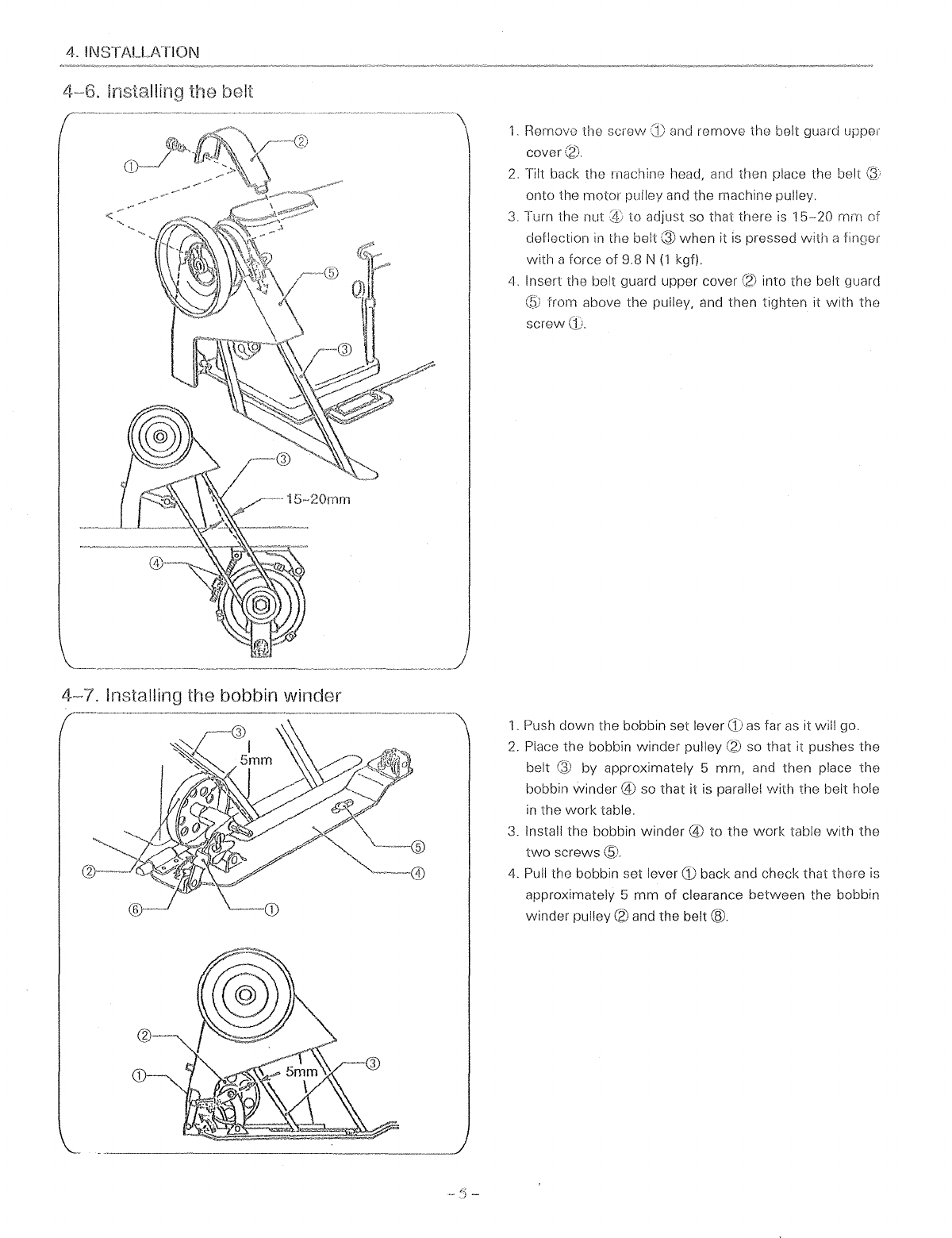

ling thH belt

4-7.

Installing the bobbin winder

1.

Remove the screw

(1)

and

romove the belt guard upper

cover

2.

Tilt back the rnachine head, and then place the belt

onto the

motor

pulley and the machine pulley.

3.

Turn the nut to adjust so that there

is

15-20

mm

of

deflection

in

the belt Q)

when

it

is

pressed

with

a finQer

with

a force of 9.8 N

(1

kgf).

4.

Insert the belt guard upper cover into the belt guard

from above the pulley, and then tighten it vvith the

screw

1.

Push down the bobbin set lever

as

tar

as

it will go.

2.

Place the bobbin winder pulley so that it pushes the

belt by approximately 5 mrn, and then place the

bobbin winder @ so that it is parallel

with

the belt hole

in

the work table.

3.

Install the bobbin

winder@

to the

work

table

with

the

two

screws

@.

4.

Pull the bobbin set lever

GJ

back and check that there

is

approximately 5

mm

of clearance between the bobbin

winder pulley

(2)

and the

belt®.

From the library of: Superior Sewing Machine & Supply LLC

4. INSTALLATION

4~8.

Installing the belt guard (L)

4-9.

Installing the thread stand

1.

Tilt back the machine head, and then remove the

V-belt

from the

motor

pulley.

2.

While tilting the machine forward, insert belt guard(L)

G) into the belt guard

(2)

from underneath, and let

it

rest

there.

3.

Place the

V-belt

back onto the pulley.

4.

Install belt guard (L) G)

with

the

two

screws @ so that

there is no clearance between the belt guard

(2)

and

belt guard (L)

G)

(position@), and so that the reverse

lever @ and the belt guard

(2)

are

not

touching

(positions @ and ©).

Assemble the thread stand

as

shown

in

the illustration,

and then install

it

to the

work

table.

* Securely tighten the nut

CD

so

that

the thread stand

does not move.

From the library of: Superior Sewing Machine & Supply LLC

4. INSTALLATION

4-"10. Lubrication

•

Do

not

connect the

power

cord until lubrication has been completed, otherwise the machine may operate ifthe

treadle

is

pressed by mistake, which could result

in

injury.

•

Be

sure

to

vvear protective goggles

and

gloves when handling the lubricating oil, so that no oil gets into your

eyes or onto your skin, otherwise inflammation can

result

Furthermore, do not drink the oil under any circumstances,

as

it can cause vomiting and diarrhoea.Keep the oil

out

of

the reach

of

children.

The sewing machine should always be lubricated and the oil supply replenished before it

is

used for the first time, and also

after long periods

of

non-use.

Use only the lubricating oil.

• Add

1-2

drops

of

oil

in

the places indicated by the arrows.

Add oil to other sliding parts also, while being careful to avoid oil leaks.

Oiling

must

be done at least

twice

daily

in

continuous use.

-7-

From the library of: Superior Sewing Machine & Supply LLC

4. INSTALLATION

II

For oiling to hook

Remove the oil plug

CD

and pour oil until the oil surface reaches to the red line of the oil indicator

\2).

After pouring oil, tighten

the

oil plug

CD

securely.

Oiling adjustment to hook

Loosen the

nut®.

adjust oiling by adjusting

screw@.

To increase oil flow, loosen the adjusting

screw@,

to

decrease oil flow,

tighten the

screw@.

After

oiling adjustments completed, tighten the

nut®

securely.

4~

11. Checking the machine pulley rotating direction

Do

not

touch any

of

the moving parts or place any objects against the machine while sewing,

as

this may result

in

personal injury or damage

to

the machine.

-8--

1.

lnsertthe

power

cord plug into the wall

outlet

and then

turn

on

the

power

switch.

2.

Depress the treadle and check that the direction

of

rotation

of

the machine pulley matches the direction

of

the arrow

CD.

* If the direction

of

rotation

is

reversed, change the

direction

of

rotation

to

the correct direction while

referring to the instruction manual for the motor.

From the library of: Superior Sewing Machine & Supply LLC

5.

PREPARATION BEFORE SEWING

5.

PR

PARATION BEFOR SEWING

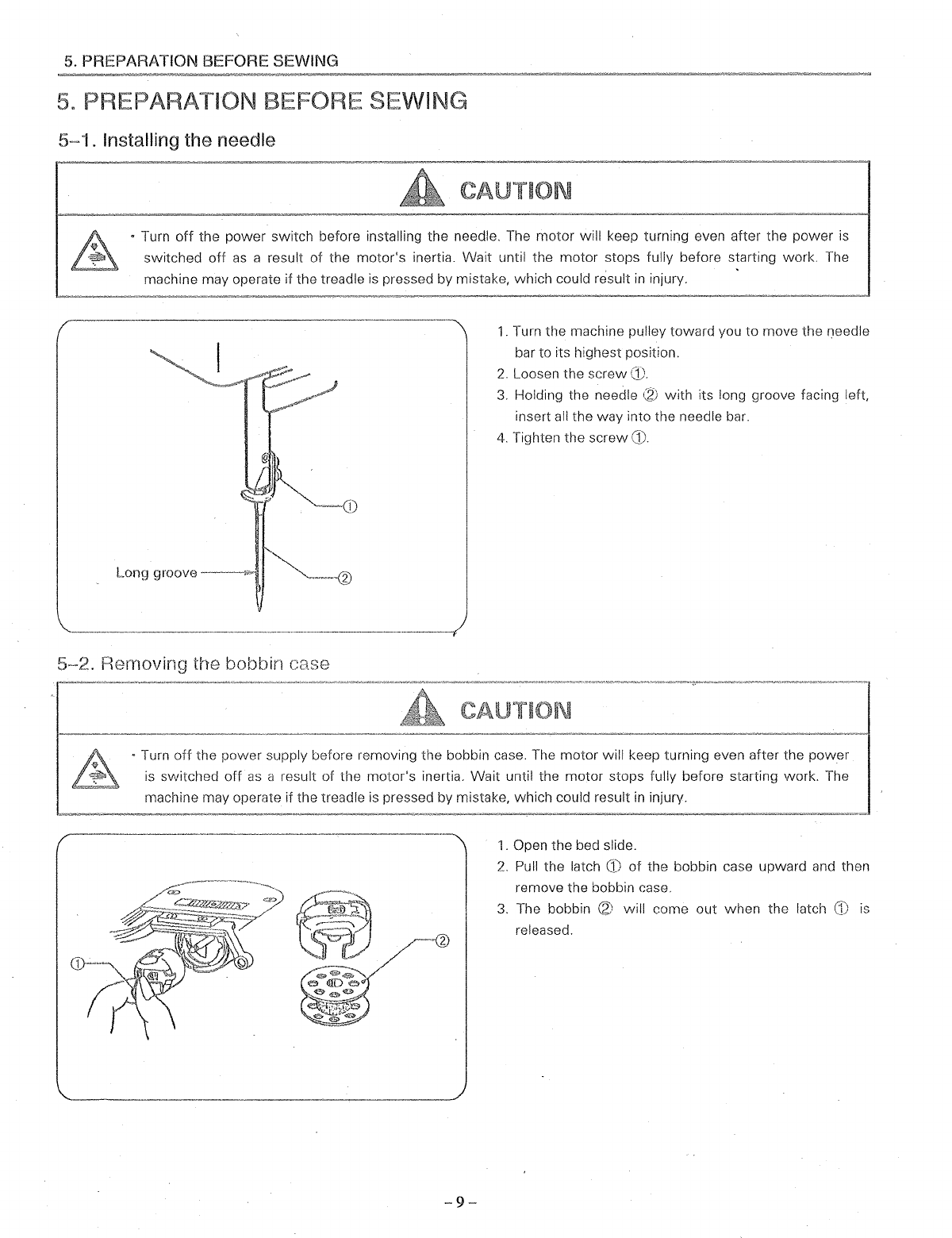

5-1

. Installing the needle

• Turn

off

the

power

switch before installing the needle. The

motor

will keep turning even after the

switched

off

as

a result

of

the

motor's

inertia. Wait until the

motor

stops fully before starting

machine may operate if the treadle

is

pressed by mistake, which could result

in

injury.

Long

groove-

~

5-2.

R£~moving

the bobbin case

1.

Turn the machine pulley toward you to move the needle

bar to its highest position.

2.

Loosen the

screw(!).

3.

Holding the needle

(2)

with

its long groove facing

left

insert all the way into the needle bar.

4.

Tighten the

screw

CD.

• Turn

off

the power supply before removing the bobbin case. The motor will keep turning even after the

power

is

switched

off

as

a result of the motor's inertia. Wait until the

motor

stops fully before starting work. The

machine may operate if the treadle

is

pressed by mistake, which could result

in

injury.

2

-9-

1.

Open the bed slide.

2.

Pull the latch

CD

of

the bobbin case upward and then

remove the bobbin case.

3.

The bobbin

(2)

will come

out

when

the latch

CD

is

released.

From the library of: Superior Sewing Machine & Supply LLC

5.

PREPARATION BEFORE SEWING

5~3.

Winding the lower thread

• Do not touch any

of

the moving parts or place any objects against the machine while winding the lower

as

this may result

in

personal injury or damage to the machine.

Thread winding amount

5~4.

Installing the bobbin case

1.

Turn

on

the power switch.

2.

Place the bobbinG:· onto the bobbin winder shaft

3. Wind the thread several times around the bobbin

<1·

in

the direction indicated the arrow.

4.

Push down the bobbin set lever Q).

5.

Raise

the presser foot

with

the presser bar lifter.

6.

Depress the treadle. Lower thread winding will then

start.

7.

Once .winding of the

lower

thread is completed, the

bobbin set

lever®

will return automatically.

* If the thread cannot be wound

on

evenly, loosen the

screw@_~

and move the bobbin winder bracket to the

side where there

is

less thread.

* Turn the adjustment screw

@j

to adjust the bobbin

winding amount.

To

increase the winding amount: Tighten the screw.

To

decrease the wincing amount: Loosen the screw.

Note:The amount of thread wound onto the bobbin

should

be

a maximum

of

80% of the bobbin

capacity.

• Turn

off

the

power

supply before installing the bobbin case.

The

motor will keep turning even after the power

is

switched

off

as

a result of the motor's inertia. Wait until the motor stops fully before starting work. The

machine may operate if the treadle

is

pressed by mistake, which could result

in

injury.

1.

While holding the bobbin so that the thread winds to

the right, insert the bobbin into the bobbin case.

2.

Pass

the thread through the slot

and

under the

tension spring

\21.

3.

Pull the thread

cut

through the hole

in

the end of the

tension spring

(2:.

4.

Check that the bobbin turns clockwise when the thread

is

pulled.

5.

Hold the latch

;.3;

on the bobbin case

and

insert the

bobbin case into the rotary hook.

6.

Close the bed slide.

From the library of: Superior Sewing Machine & Supply LLC

5.

PREPARATION BEFORE SEWING

5-5.

Threading

the

upper thread

CAUTION

• Turn

off

the power supply before installing the bobbin case. The motor will keep turning even after the power

is

switched

off

as

a result of the motor's inertia. Wait until the motor stops fully before starting work.

The

machine may operate

if

the treadle

is

pressed by mistake, which could result

in

injury.

5-6.

Adjusting

the

stitch

length

-11-

Turn the machine pulley and raise the thread take up lever

G:·

before threading the upper thread. This will make

threading easier

and

it will prevent the thread from coming

out

at

the sewing start.

Stitch length

can

be set by turning the feed regulating dial

Ci·.

Numeric figures on the dial

i.l'

show the stitch length

in

mm. The desired numeric figure

on

the dial should

be

set at just above, while depressing the revers lever

slightly.

From the library of: Superior Sewing Machine & Supply LLC

6.

SEWING

6.

"

Attach

all devices bofor:1 rnachir18. If the rnachine is used vvlthout these devices

attached, injury rnay result.

" Turn off the

powe;

switch

at the times. The

motor

will

turning evon

after

the; pnvver

is

sv\'itchcd

off

JS

a result

of

the

motor's

inertia.

Wait

until the rnmor

slops

fully before

rnayoperate if the treadle is

When

threading the needle by mistake,

which

could

msult

in injury.

When

replacing the needle and bobbin

When

not

using the machine and

when

leaving

the

machine unattended

vvork. The rnachine

• Do

not

touch any

of

the

moving

parts

or

place any objects against

the

machine

while

sewing,

as

this may

personal

injury

or

damage

to

the

machine.

6~1.

Sewing

Lower thread

6~2.

Backtacking

-12-

1.

While

holding

the

upper thread

with

your

fingers, turn

the machine pulley by hand

toward

you

until the

lower

thread

comes

out

onto

the

feed

dog.

2.

Pull the

lower

thread

toward

you

and check

that

it

pulls

out

smoothly,

3. Turn on

the

power

switch.

4. Depress the treadle

to

start

sewing,

When

the reverse lever is pushed,

the

material

feed

direction

will

be reversed, and

when

it

is returned

to

its

original position,

the

feed

direction

will

change back

to

normal.

From the library of: Superior Sewing Machine & Supply LLC

7.

THREAD TENSION

7.

THREAD TENSION

7

~

1.

Adjusting the thread tension

Upper thread

Lower thread

Lower thread

7

~2.Adjusting

the presser foot pressure

---------.

-

13-

Good even stitches

Upper thread tension too weak or

lower

thread tension

too strong

Upper thread tension too strong or

lower

thread tension

too weak

II

Upper thread tension

The tension

of

the upper thread

is

adjusted using the

tension thumb nut

G).

To

increase the tension

of

the upper thread,

·~urn

the

tension thumb nut

(f1

to the right.

To

decrease tension,

turn the tension thumb nut

<}1

to the left.

II

Lowerthread tension

CAUTION

Turn

off

the

power

switch before removing or

inserting the bobbin case.

The motor will keep turning even after the

power

is

switched

off

as

a result

of

the

motor's inertia. Wait until the motor stops

fully before starting work. The machine may

operate if the treadle is pressed by rl'istake,

which could result

in

injury.

Adjust by turning the thread tension

nut

(2J

until the bobbin

case will not drop by its

own

weight

while

the thread end

coming out

of

the bobbin case is held.

Adjust the presser foot pressure to

lower

as

much

as

possible

so

that the presser foot can properly hold down

material by turning the

screw

(f•.

From the library of: Superior Sewing Machine & Supply LLC

8.

STANDARD ADJUSTMENTS

8.

STAN ADJUSTMENTS

Maintenance and inspection

of

the sewing

machine should only be carried out by qualified

personnel.

Ask your dealer or a qualified electrician

to

carry

out

any maintenar.ce and inspection

of

the

electrical systern.

If any safety devices have been rernoved,be

sure

to

m-install

them to their

original positions and check that they operate

correctly before using the machine.

8-1.

Adjusting the thread controller spring

-14-

power cord from the wall outlet at the

times, otherwise the machine may operate if

treadle

is

by mistake, which could

in

injury. However, the motor will keep

even after the power

is

switched

off

as

a

the motor's inertia. Wait until the

fully before starting work.

When carrying out inspection,

maintenance

When replacing consumable parts

rotary hook

If the

power

switch needs

to

be

left

on

carrying

out

some adjustment. be

careful to observe

all

safety precautions.

Operating range

of

spring

The standard operating range for spring

CD

is

5-1

Omm.

1.

Loosen the

screw

\2·,

and then turn the thread con

troller spring stop

~

to adjust the operating range.

• For more operating range, move the spring stop

~~?!

to

the right.

• For less operating range, move the spring stop

Qi

to the

left.

2.

Tighten the

screw

(2_:.

Tension

of

the spring

The standard tension for spring

is

0.39-0.78

N (40-80g).

1.

Loosen the tension

thumb

nut

\4;

and

screw@.

2.

Turn the tension stud (§l to adjust the tension.

To

increase the spring tension, slightly turn the tension

stud ®!counterclockwise.

To

decrease the tension, turn the stud clockwise.

3.

After adjustment, tighten the tension thumb nut

0\)

and

screw\!?).

From the library of: Superior Sewing Machine & Supply LLC

8. STANDARD

ADJUSTMENT~;

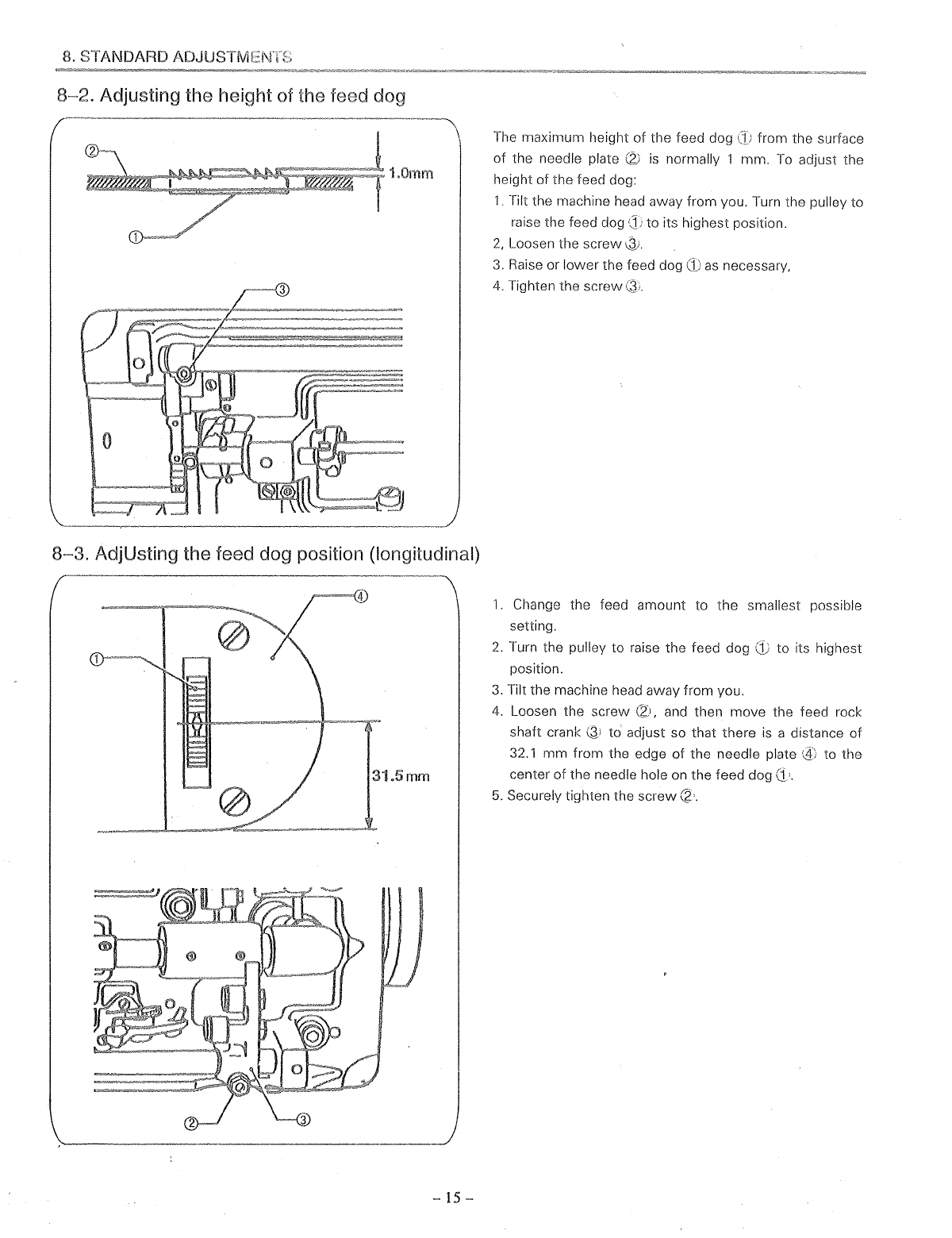

8~2.

Adjusting the height of the feed dog

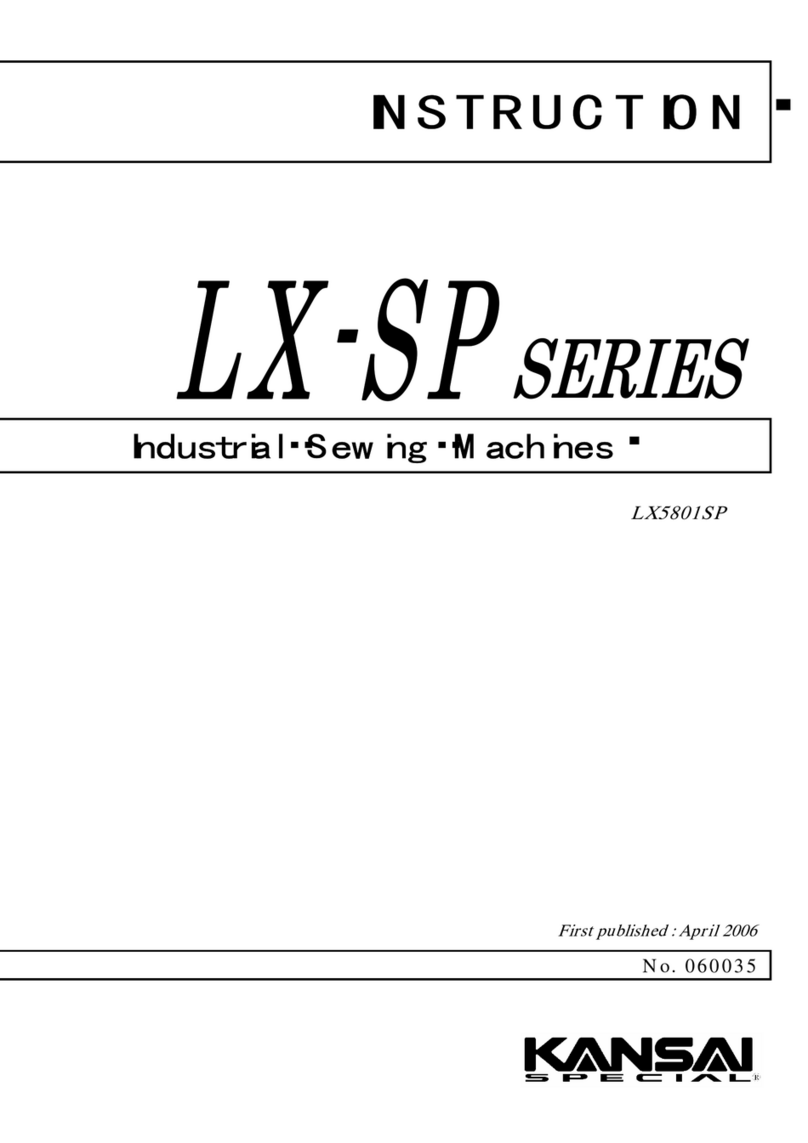

8~3.

AdjUsting the feed dog position (longitudinal)

31.5mm

-

15-

The maximum height

of

the feed dog from the surface

of

the needle plate

(2)

is

normally 1 mm.

To

adjust the

height

of

the feed dog:

1.

Tilt the machine head away from you. Turn the pulley to

raise the feed dog to its highest position.

2,

Loosen the

screw~.

3.

Raise or lower the feed dog

CD

as

necessary,

4.

Tighten the

screw

Q

..

1.

Change the feed amount to the smallest possible

setting.

2.

Turn the pulley to raise the feed dog

position.

3.

Tilt the machine head away from you.

to its highest

4.

Loosen the screw (2), and then move the feed rock

shaft crank

~'

to

adjust so that there

is

a distance

of

32.1

mm

from the edge

of

the needle plate to the

center

of

the needle hole on the feed dog

(1•.

5.

Securely tighten the

screw

CZ·.

From the library of: Superior Sewing Machine & Supply LLC

Other manuals for 406RB-1

1

Table of contents

Other Chandler Sewing Machine manuals

Popular Sewing Machine manuals by other brands

KANSAI SPECIAL

KANSAI SPECIAL LX-SP Series instructions

Brother

Brother Upgrade KIT III Operation manual

Brother

Brother Innov-is NV1800Q Quick reference guide

Kenmore

Kenmore 19110 - Computerized Sewing Machine owner's manual

Brother

Brother Innov-is PC420 Operation manual

Butterfly

Butterfly M21 instruction manual