Chandler 543 User manual

®

an

er

INSTRUCTION

BOOK

&

PARIS

BOOK

TACKERS

&

BUTTON

SEWERS

CLASSES:

543, 546, 548,

552, 554, 555, 558, 560,

600, 660, 710

cJ..ancller

~

CHAN

DL

ERM~HINE

CO

•

oyer,

mass.Ol432 u.

s.a

,

tel.

(617)

772

-

3393

From the library of: Superior Sewing Machine & Supply LLC

CURRENT PRODUCTION MODELS OF

CHANDLER CLASS 600 & 710 MACHINES

FLAT

BUTTON

SEWERS

...............Model 710-1 ...............................

16

stitch. side vih

..

auto

clamp lilt.

Model 710-5 ...............................

12

stitch. side vih.,

auto

clamp

lilt.

Model 710-10 .............................24 stitch, side vih

..

Model 710-35 .............................

16

stitch. hack & forth.

auto

ch1mp hft.

Model 710-55 .............................

16

stitch, cross (X) stitch.

auto

clump lift.

Model 710-85 .............................

12

stitch, back & forth,

auto

clamp lift.

Model 710-120 ...........................24

sti~ch,

square

pattern.

auto

clump lift.

HOOK

AND

EYE .............................Model 710-1HE ..........................

l6

stitch. side vib

.•

auto

clamp

lil1.

Modei710-5HE

..........................

l2

stitch, side vib.,

auto

clamp

lift.

WHIPPING

.......................................Model 710-12 .............................24 stitch. for whipping suit buttons.

NECKING .........................................Model 710-IN ............................

16

stitch. side vib.

SHANK

BU

ffON

SEWERS

............Model 710-IS .............................

16

stitch. side vib

..

side loading.

Model

71

0-5S .............................

12

stitch. side

vi

b

..

side loading.

Model710-50

.............................

12

stitch. hack & forth, front loading.

Model 710-65 .............................

16

stitch.

h<~ck

& forth, front loading. shank master.

TACKERS

.........................................Model 600-15 .............................6 stitch. back & forth

Model 600-25 .............................8 stitch, back & forth

Model 600-25S ...........................8 stitch, side

vih_-

Model 600-60 .............................6 stitch, side vih.

Model 600-75 .............................

12

stitch,

combination

vib.,

dmpery.

Model

600-750

..........................

12

stitch.

combination

vib..

dmpery

extra

hea

'Y

needle

Model 600-75K ..........................

12

stitch.

combination

vib., drapery knife thread

cutter

Model 600-75KD .......................

(both

of

above)

Model 600-95 .............................6 stitch,

combination

Vlb.

BONE

RING

.....................................

Model600-BR

............................

12

stitch, back & forth vib.

Model 600-BR.500 .....................

12

stitch, back & forth vih.

Yt

stroke

for

extra

large bone rings.

JOKERS

............................................

Model

600- .................................Special machines for

attaching

labels

and

other

removable objects. Normally modified square patterns.

BAR

TACK

.......................................Model 710-70BT ........................24 stitch zig-zag pattern.

HIG~

LIFT

.......................................

Model

658

or

758 .......................Full

~

inch bigger

stroke.

Designed

for

extra

large

shank

buttons.

Bulky tacking problems. etc. Specify

above

machine desired.

Change prefix from "600"

to

"651<".

NOTE: Any

of

the

above

machines may be

equipped

with a

built

in

knife mechanism. Add suffix

"K"

TWIN

NEEDLE

f

ACKER

...............Model 660- .................................8 stitch. back & forth,

Please specify needle gauges from

I~

-

2~

in

~,.

increments. Non adjustable.

STAND

..............................................Model 2Tc-600-l ........................Board only

Stand,

complete .........................

Complete

"H"

legs. I

IOV.

Stand

..........................................

Complete

"K"

legs. IIOV.

Stand

..........................................

Complete

"K"

legs. 220V.

CLAMPS

...........................................

Flat

button

Shank

button-

..

:-.;;

.......................Side loaaang ·

Shank

button

.............................

Front

loading

(shank

master)

Snap

...........................................Adjustable,

round

or

square

Snap

...........................................Non-adjustable, square.

Hook

and

eye

Whipping

Necking

Tacking

Tacking ......................................

Compensating

Bone ring ...................................

Compensating

Flat

button

.................................

Front

part

only

This

edltion

printed

10.1972

~----~------------~CHANDLER~--------------------

NOTE:

FOR

BUTTONROBOTS, HOPPERS,

AUTOMATIC

FEEDING DEVICES CONTACT

CHANDLER SALES & SERVICE CO.,

246

7th

AVE

.•

N.Y., N.Y.

10001

TEL.

212-226-7300

From the library of: Superior Sewing Machine & Supply LLC

MECHANICS

INSTRUCTIONS

THREADING DIAGRAM

:..

.....

INSTRUCTIONS

FOR

THREADING

Facing

the

Machine

as

shown in

the

illustration,

proceed

as

follows:

1 From Spool

A,

pass

thread

thru Spool

Stand

Arm

B.

2

Then

forward thru

Rear

Guide

Pin

·C.

3

Slide

thread

between

Rear

Tension

Disc

D on

the

left

hand

side

of

Tension

Post

E,

then to

the

right hand

side

of

Pin

F

as

above

in

detailed

view.

4

Repeat

step

number 3 for

Front

Tension.

5

Pass

thread

forward

t·hru

hole

in

Thread

Slack

Pull-of£

Lever

G,

Front

Guide

Pin

H

and

Thread

Guide I

in

top

of

Face

Plate.

6

Slide

thread

into

slot

J and down to

the

right

of

Pin

K.

7

Pass

down and around

Roller

in Lower Guide

Plate

L.

8

Insert

thru

Needle

Bar

Take-up

M

(left

to right).

9

Thread

under

Tension

Disc

Face

Plate

N.

10

Catch

thread

in

Needle

Bar

Thread

Guide

0 and

pass

it

thru

the

eye

of

the

Needle

from

front to

back.

(For

all models

having

Needle

Bar

Thread

Guide)

~--------------~CHANDLER~--------------~

CHANDLERl

From the library of: Superior Sewing Machine & Supply LLC

-CHANICS

IISTRUOIOIIS

TIMING

LOOPER

TO

NEEDLE

BAR

The

usual

procedure

for timing the Looper

and

Needle

Bar,

is

first

to time the Loop-

er

and then

set

the

height

of

the Needle

to

the point

of

the

Looper.

This

is

ac-

complished

as

follows:

1

Insert

new Needle

fuJl length

of

the

Needle

Bar hole and

tighten Screw A

(Fig.1)

2 As a preliminary

setting,

make

sure

the

point

of

the

Needle

is

approximately in

line

with the

center

of

the

Looper Shaft when the

Needle

Bar

is

at

the

1owest depth of

its

stroke.

FIGURE

1

t.Boftom

ol

(Neeel/e

Sirek

FIGURE

2

Adjustment

is

made by means

of

Screw B (Figure 1).

FIGURE

2A

3 Turn

the

machine by hand,

rotating

the

Looper

counterclockwise,

thus

raising

the Needle

5/32

of

an inch

from

the bottom

of

its

stroke

as

shown in

Figure

2.

At

this

time,

the

point

of

the

Lqoper

should

be

barely

visible

on

the

left

side

of

the

Needle

as

shown in

Figure

2.

To

adjust,

loosen

Screws C (Figure 3) and

rotate

Knurled

Looper

Holder

desired

amount in

either

direction.

Tighten

Screws C

securely.

4

There

should

be a

space

of

light

barely

visible

between the

point

of

the

Looper

and the

Needle

as

shown in

Figure

2A.

Adjust

for

proper

clearance

by

loosening

Screw D

(Figure

3) and moving

the

Looper

in

or

out the

desired

amount.

5 As a final

setting,

now

that

the Looper

is

properly timed in re-

lation

to

the

lift

(or up

stroke),

the Needle

Bar

can

be.

readjusted

(as

described

in

preceeding

item 2)

so

that

the point

of

the

looper

when

passing

the

Needle

is

approximately

1/32

of

an

inch

above

the

Needle

Eye.

This- final

setting

may

have

to

be

varied

slightly

depending upon

the

weight and

softness

of

the thread

or

material

being

used.

The

break

of

the

loop (or loop formation)

at

the

Needle

Eye

may

vary

according

to

the

thread

used.

This

will

possibly

require

setting

the

point

of

the

Looper

closer

or

further

from

the

eye

of

the

Needle but within a range

of

approximately

1/32

of

an inch.

----------------~CHANDLER~----------------

CHANDLER2

From the library of: Superior Sewing Machine & Supply LLC

MECHANICS

IISTRUOIOIIS

TIMING

THE

FINGER

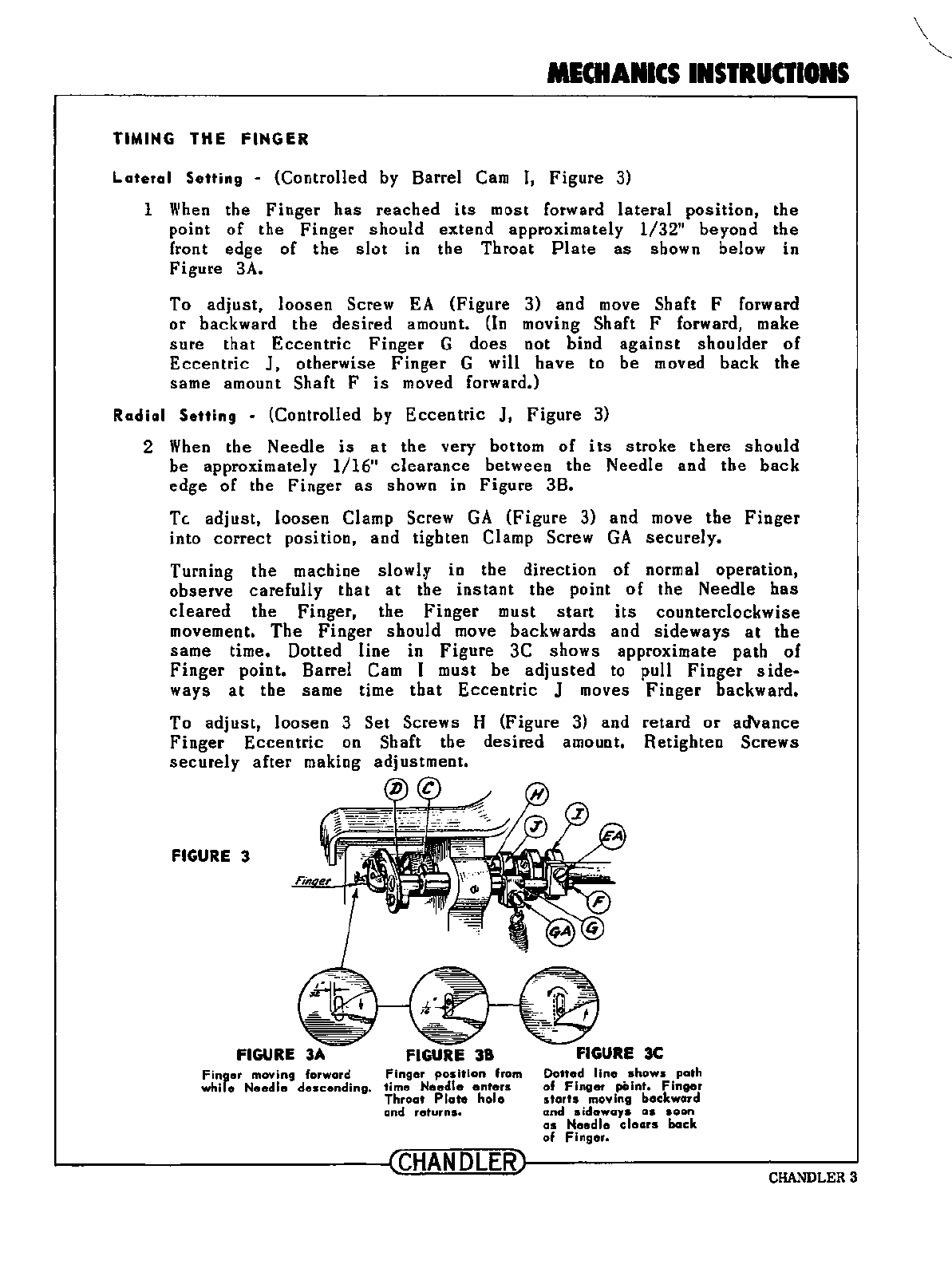

Lateral

Setting

-(Controlled by Barrel

Cam

I,

Figure

3)

1

When

the

Finger

has

reached

its

most forward

lateral

position,

the

point

of

the

Finger

should

extend

approximately

1/32"

beyond

the

front edge

of

the

slot

in

the

Throat

Plate

as

shown below in

Figure

3A.

To

adjust,

loosen

Screw

EA

(Figure

3) and move Shaft F forward

or

backward

the

desired

amount.

{In

moving Shaft F forward, make

sure

that

Eccentric

Finger

G

does

not bind

against

shoulder

of

Eccentric

J,

otherwise

Finger

G will

have

to

be

moved

back

the

same amount Shaft F

is

moved forward.)

Radial

Setting

-(Controlled by

Eccentric

J,

Figure

3)

2

When

the

Needle

is

at

the very bottom

of

its

stroke

there

should

be

approximately

1/16"

clearance

between the

Needle

and

the

back

edge

of

the

Finger

as

shown in

Figure

3B.

Tc.

adjust,

loosen

Clamp Screw

GA

(Figure

3) and move

the

Finger

into

correct

position,

and

tighten Clamp Screw

GA

securely.

Turning

the

machine

slowlf

in

the

direction

of

normal operation,

observe

carefully

that

at

the

instant

the point

of

the Needle

has

cleared

the

Finger,

the

Finger

must

start

its

counterclockwise

movement.

The

Finger

should

move backwards and

sideways

at

the

same

time. Dotted

line

in

Figure

3C

shows

approximate

path

of

Finger

point. Barrel Cam I must be

adjusted

to pull

Finger

side-

ways

at

the same time

that

Eccentric

J moves

Finger

backward.

To

adjust,

loosen

3

Set

Screws H (Figure 3) and

retard

or

ad'vance

Finger

Eccentric

on Shaft the

desired

amount.

Retighten

Screws

securely

after

making

adjustment.

FIGURE

3

FIGURE

3A

FIGURE

38

Finger

moving forward

Finger

position

from

while

Needle

descending.

time

Needle

enters

Throat

Plate

hole

and

returns.

Dotted

II

ne

shows

path

of

Finger

point.

Finger

starts

moving

backward

and

sideways

as

soon

as

Needle

clears

back

of

Finger.

~--------------~CHANDLER~--------------~

CHANDLERS

\

~

From the library of: Superior Sewing Machine & Supply LLC

MECHANICS

INSTRUCTIONS

TH

R

EA

D

LO

CK

TIMING

ADJUST

MENT

\\'hen the

Needle

Bar

has

ascen

d

ed

to

within

1/8

or 5/

32

inch

from

the

hi

ghest

po

int

of

of

the

Needle

Bar

stroke

on

comp

le

tion

of

the

last

stroke

of

the

sewi

ng

cycle,

the

thr

ead

shou

ld

be

lo

cked

by

th

e

fo

rward

pr

essure

of

Plunger

A

against

PI

ate B

(Figu

re

1A).

The

Thr

ead

shoul d

be

l

ocked

wh

e n the m

ac

h-

ine

stops,

the

thread

br

ea

k when

is

1

ift

ed.

other

wi

se

will

not

the

Clamp

FIGURE lA FIGURE 1

C

au

t

ion

:

Excessive

pressure

of

th

e P l

unge

r on li

ght

or

w

eak

thre

ad

will

have

a t

ende

n

cy

to

frac

tur

e

the

thr

ead

causi

ng

excessive

t

hread

br

eakage.

To a

dju

st,

loose

n L

oc

k

Nu

t C

(F

igu

re

2)

and

turn Adj

usting

Screw

D in

or

out

the

des

ir

ed

amount.

Be

su

re

to

tigh

ten L

ock

Nut

C

secure

ly.

FIGURE 2

N o

te

: Machi

nes

are

usually

e

quipped

with

li

ght

Lo

ck

Spring

for

use

on light

thread

.

For

h

eavy

th

r

eads

us

e

heavier

Lo

ck

Spring

(See

Plate

1 ).

On r

esuming

the

first

st

r

oke

of

the

n

ew

sew

-

ing

cycle,

the

Thre

ad

L

ock

must

r

elease

the

thr

ead

some

time

befo

re

the

Ne

edle

Bar

reache

s

the

l

owest

point

of

the

s t

roke

so

that

the

t

hread

is

not

he

ld

ti

gh t

when

the

Take

-up E

(F

ig

ur

e 1)

above

s

tarts

i

ts

r

eturn

u

pward

s t

roke

.

Br

acket

F (

Fi

g

ure

12)

1s

provided

with

slots

so

t

hat

the

Tr

ip

Lock

Leve

r may

be

re

ta

r

ded

or

adv

an

ce

d for proper

ti

ming

.

~------

----

--------~CHANDLERr---

-

------------

--

--~

CHANDLER

4

From the library of: Superior Sewing Machine & Supply LLC

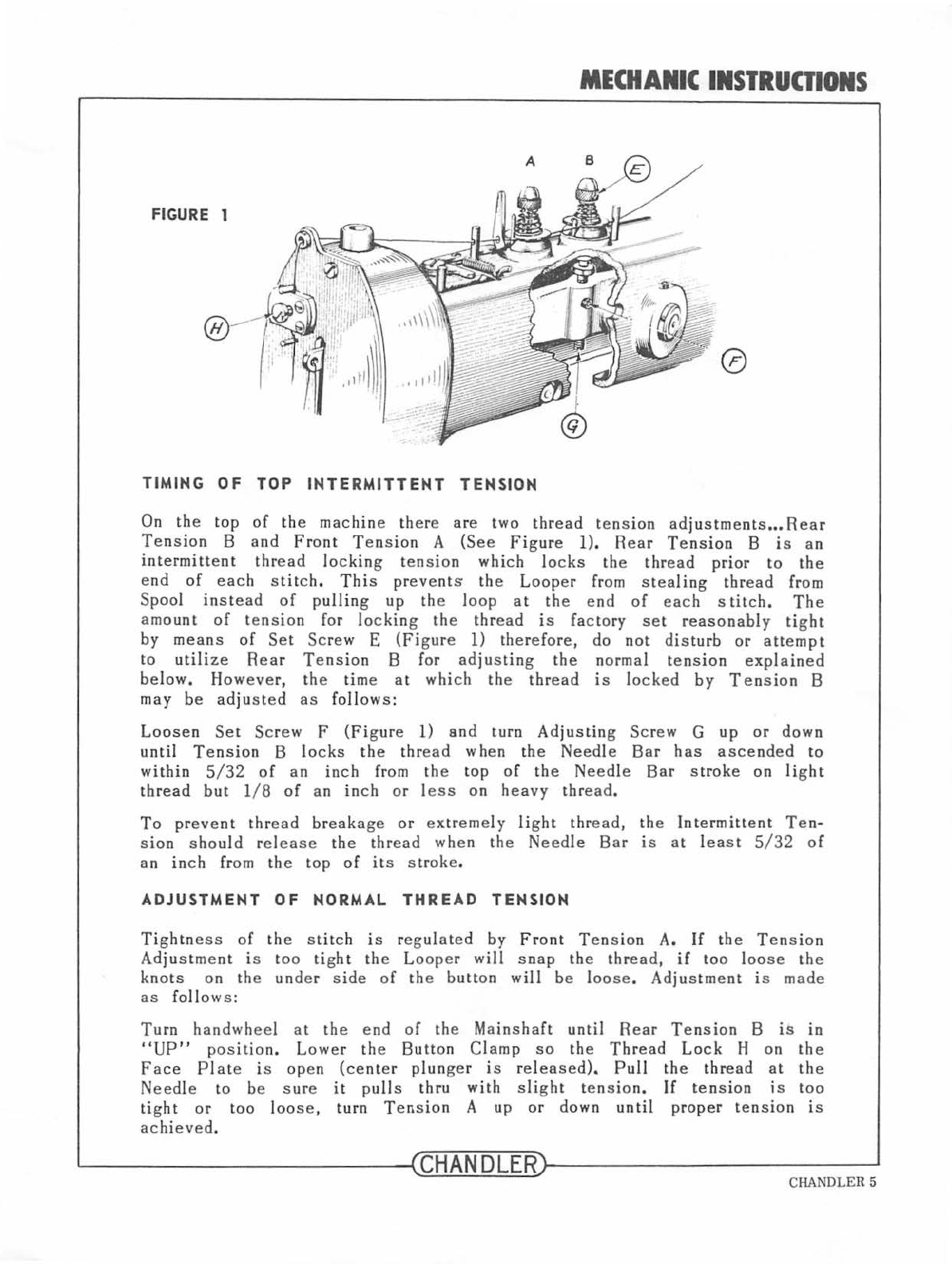

MECHANIC

INSTRUCTIONS

FIGURE 1

0

TIMING

OF

TOP

INTERMITTENT

TENSION

On the

top

of

the

machin

e th

ere

are two

thread

t

ens

ion

ad

justment

s

•••

Rear

Te

nsion

B

and

Front

Tens

ion

A (See

Fi

gure 1).

Rear

Tension

B

is

an

intermittent

thr

ead

lo

cking t

ens

ion

which

lo

cks

the

thr

ead

prior

to

the

e

nd

of

each

stitch.

Thi

s

pr

eve

nts the

Loop

er from s t

ea

ling

thr

ead

from

Spoo

l

instead

of

pulling

up

the l

oop

at

the

end of

each

stitc

h.

The

amo

unt

of

tension

for l

ock

ing

the

thr

ead

is

factory

set

reasonably

tight

by means

of

Set

Screw

E

(Figure

l)

therefore,

do

not

dist

urb or

atte

mpt

to

utili

ze

Rear

Tension

B for

adjust

in

g

the

n

orma

l

tension

expl

ained

b

elow.

However,

the time a t

which

the

thread

is

locked

by

Tension

B

may

be

adjusted

as

follows :

Loosen

Se

t

Sc

r

ew

F

(Fi

gure

l)

and

turn

Adjusting

Screw

G

up

or

down

until

Tension

B

locks

the

thr

ead

wh

en

the

Needle

Bar

has

asce

nd

ed

to

within

5/32

of

an

inch

from the top

of

the

Needle

Bar

s

trok

e

on

li

g

ht

th

re

ad

but

l/ 8

of

a n

inch

or l

ess

on

heavy

thread.

To

prevent

thread

breakage

or

ex

tr

eme

ly

li

ght

thread,

the

Intermittent

Ten-

sion

s ho

uld

r

elease

the

thr

ead

when

the

Needle

Bar

is

at

l

eas

t 5/

32

of

an

in

ch from th e

top

of

its

stroke

.

ADJUSTMENT

OF

NORMAL

THREAD

TENSION

Tightness

of

the

s

tit

ch is r

eg

ulated

by

Front

Ten

sio

n A.

If

the

Tension

Adjus tme

nt

is too

ti

g

ht

the

Looper

will

s n

ap

the t

hr

ead,

if

t

oo

l

oose

the

knots

on the

under

side

of

the

b

utt

on

will

be

l

oose.

Adjustm

ent

is

made

as

fol

lo

ws

:

Turn

handwheel

at

the

end

of

the

Mainshaft

until

Rea

r

Te

n

sion

B

is

in

"UP"

position.

Lower

the

Button

Clamp

so

the

Thread

Lock

H on

the

Face

Plate

is

open

(center

plun

ge

r

is

rele

ased

).

Pull

the

thread

at

the

Need

le to be

sure

it

p

ull

s

thru

with

slight

tension.

If

ten

sion is

too

tight

or

too l

oose,

turn

Tension

A up

or

down

until

prop

er

tension

is

achieved

.

~------

----------

--~CHANDLER~

--

----------------~

CHANDLER 5

From the library of: Superior Sewing Machine & Supply LLC

MECHANICS

INSTRUOIONS

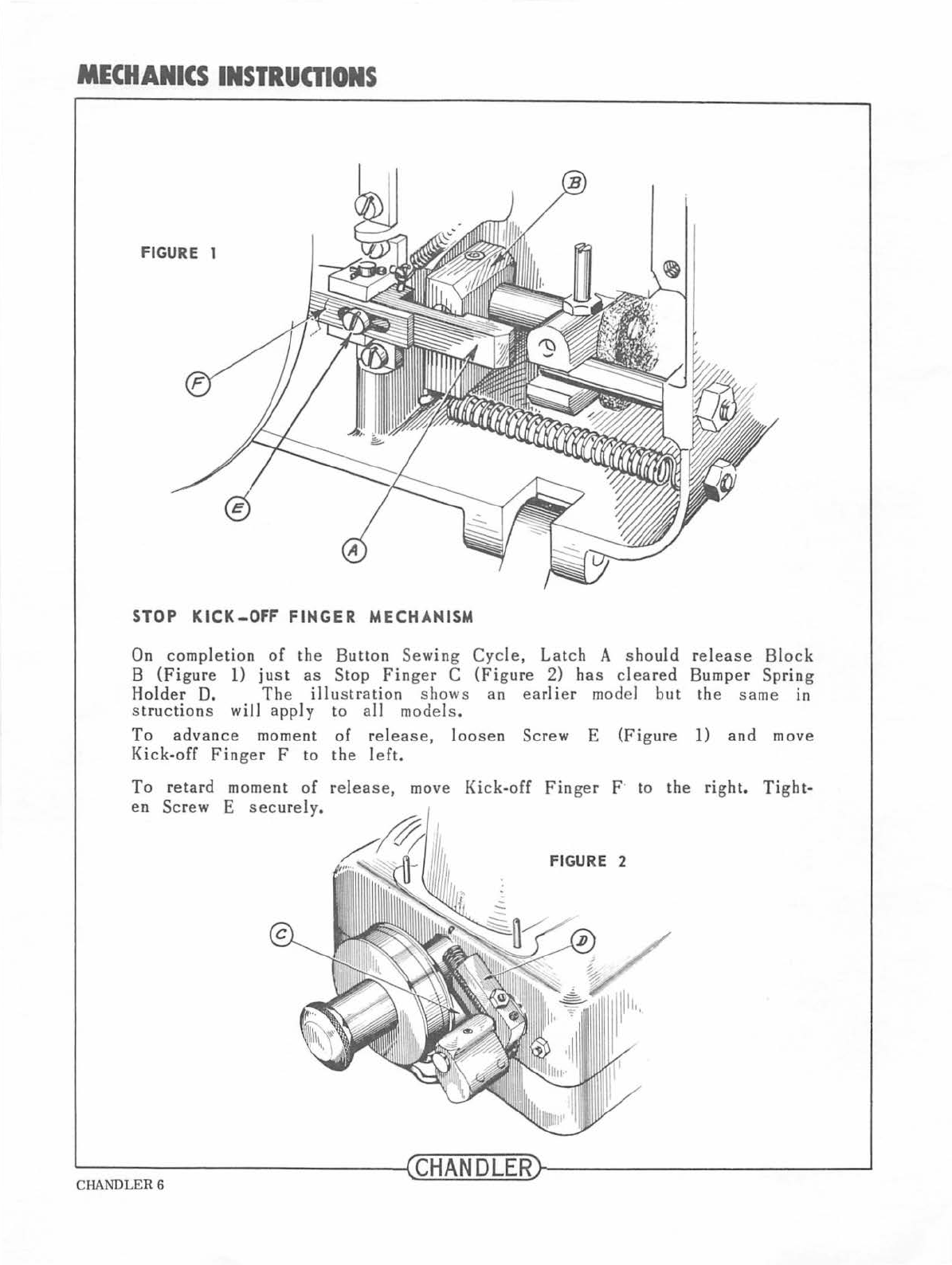

FIGURE 1

STOP

KICK-OFF

FINGER

MECHANISM

On

completion

of

the

Button

Sewing

Cycle,

Latch

A

shou

ld

release

Block

B

(Figure

1)

just

as

Stop

Finger

C

(Figure

2)

has

cleared

Bumper

Spring

Holder

D. The

illu

stration

shows

an

earlier

model

but

the

same

in

st

ruction

s will

apply

to all models .

To

advance

moment

of

rel

ease,

loo

se

n

Screw

E

(Figure

1)

and

move

Kick-off

Finger

F

to

the

l

eft,

To

retard

moment

of

release,

move

Kick-off

Finger

F· to

the

right.

Tight-

en

Screw E

securely.

FIGURE 2

~----------------~CHANDLER~----------------

~

CHANDLER 6

From the library of: Superior Sewing Machine & Supply LLC

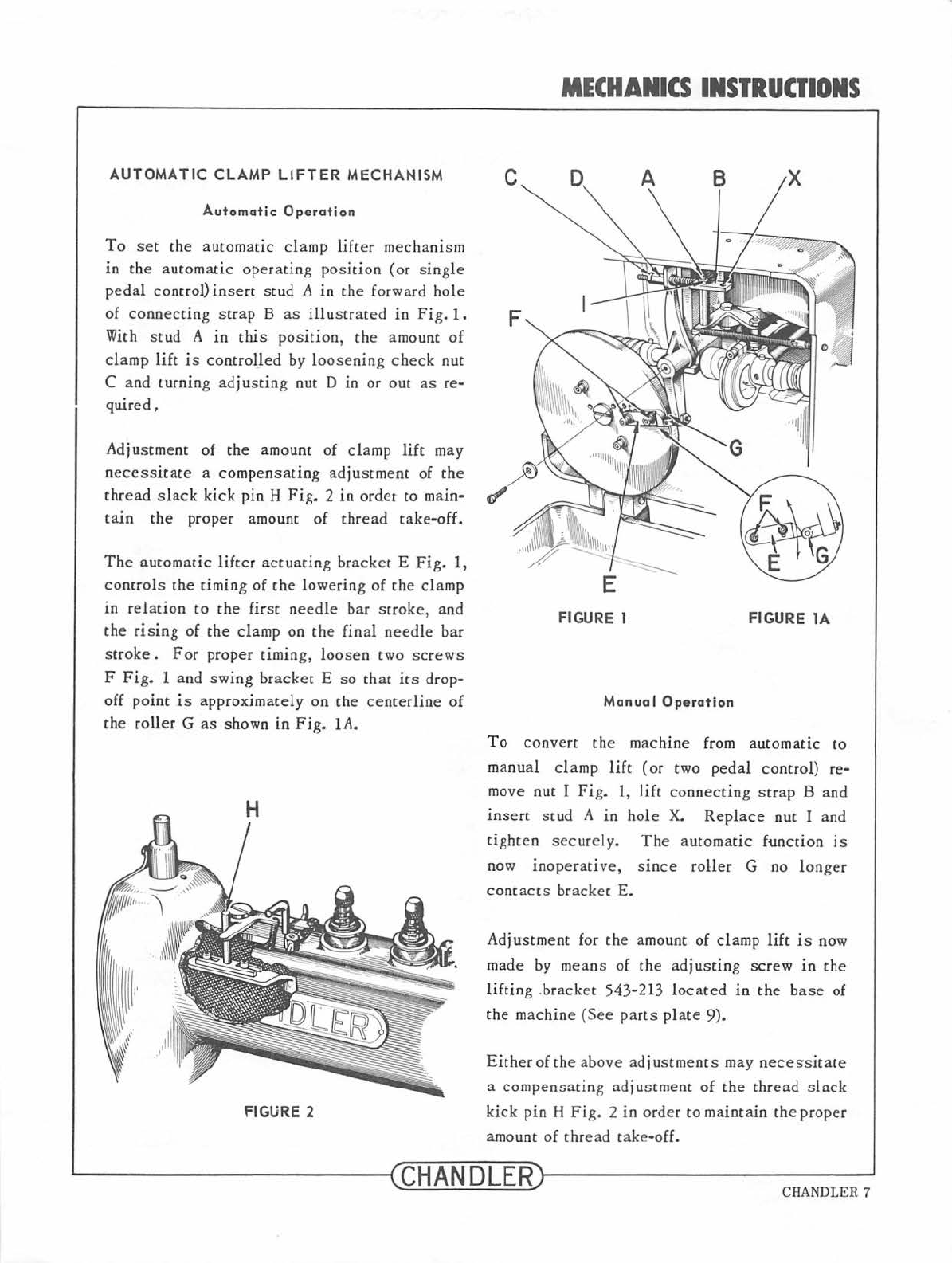

AUTOMATIC

CLAMP

LIFTER

MECHANISM

Automatic

Operation

To

s

et

the

automatic

clamp

lift

er

mechanism

in

th

e automatic

operating

po

s

it

ion

(or

s

in

gle

pedal

contro

l)

insert

stud

A

in

th

e forward hole

of

connecting

strap

B

as

illu

s

trat

ed

in

Fig.

1.

With

st

ud A

in

this

pos

ition

, the amount

of

clamp

lift

is

controlled

by l

oose

ning ch

eck

nut

C a

nd

turning adj

ustin

g nut D

in

or out

as

re-

quired,

Adjustment of

the

amount

of

cl

amp

lift

may

n

ecessi

tate

a

compensating

adjustment

of

the

thread

s

lack

kick

pin H

Fig.

2

in

ordet

to main-

tain

the

proper amount of thr

ea

d

take-off.

The

automat

ic

lifter

actuatin

g br

acke

t E

Fig.

1,

controls

the timing of

the

lo

wer

in

g of

the

clamp

in

rel

ation

to th

e first

needle

bar

scroke, and

the

rising

of

the

clamp on

the

final

ne

ed

le

bar

s

troke.

For

proper timing, loo

se

n two

sc

rew

s

F

Fig.

1 and

swing

bracket E so

th

at

it

s drop-

off

point

is approxim

ately

on the

centerli

ne

of

the

roller

G

as

shown

in

Fig.

1A

.

FIGURE 2

MECHANICS

INSTRUCTIONS

FIGURE 1 FIGURE

lA

Manual

Operation

To

convert

th

e m

ac

hine from

automatic

to

manual

cl

a

mp

lift

(or two

peda

l

contro

l) re-

mov

e nut 1

Fig.

1,

lift

connecting

st

rap B

and

insert

st

ud

A

in

hole

X.

RepLace nut I and

tighten

sec

urely.

Th

e

automatic

function

is

no

w

inoperative,

s

tnce

roller

G no

longer

contacts

bracket

E.

Ad

ju

stment

for the amount of clamp

lift

is now

made by

me

ans of

the

a

dju

sting s

crew

in

the

li

f

tin

g .bracket 543-213

lo

cated

in

the b

ase

of

the m

ac

hin

e

(See

parts

plat

e

9).

Ei

ther

of

the

above

adjustments

may ne

cess

itat

e

a compen

sat

in

g

ad

ju

st

ment of

the

thread

sl

ack

kick

pin

H

Fig.

2 in order to maintain

the

proper

amo

unt of thr

ead

take

-off.

~--------------~C

HANDLER~----------

------~

CHANDLER 7

From the library of: Superior Sewing Machine & Supply LLC

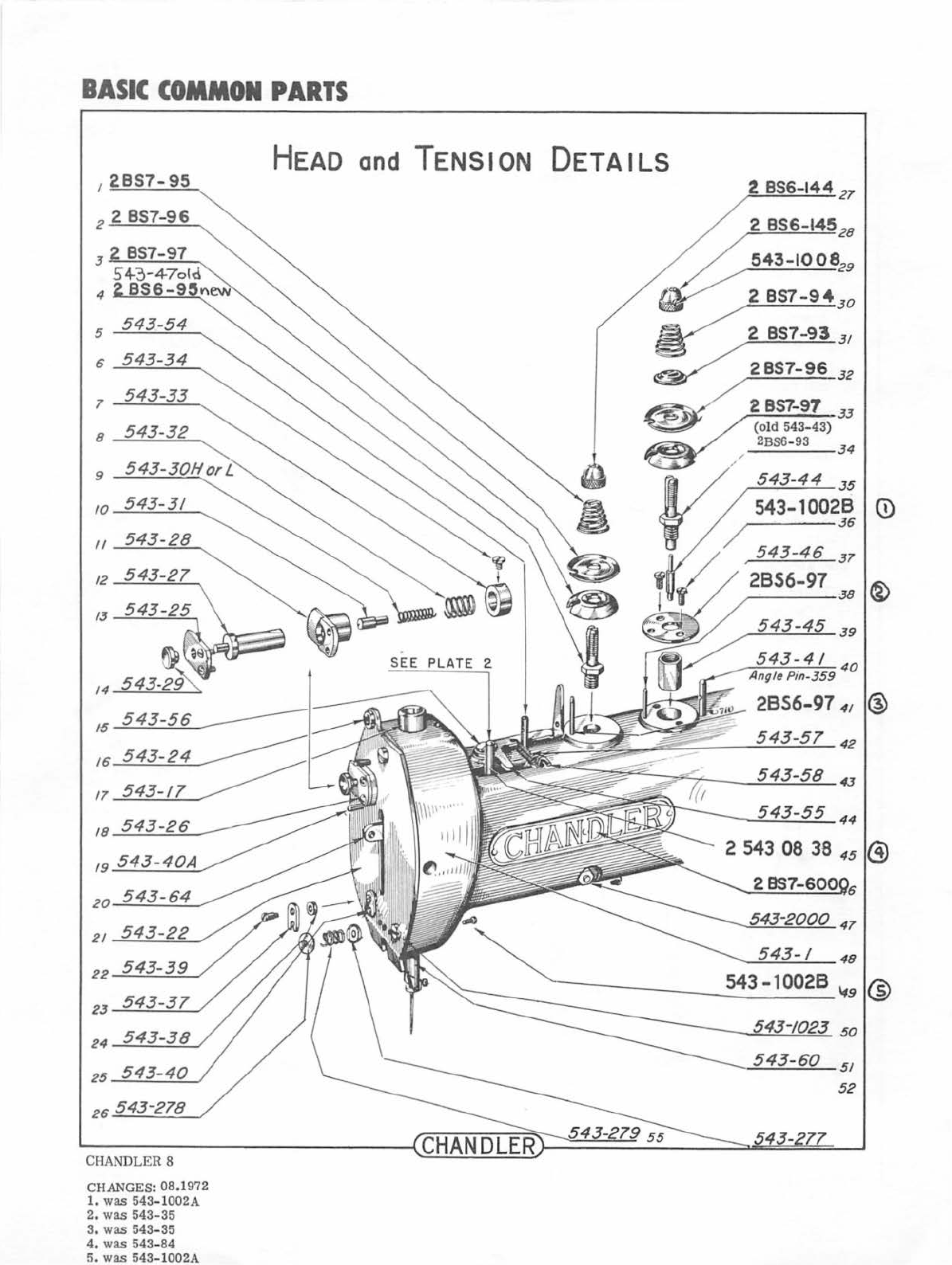

BASIC

COMMON

PARTS

I

2857-95

1

543-33

8

543

-

32

10

543-31

11

543-28

12

543

-

27

/8

19

20

21

22

23

543-37

24

54

25

26

543-

CHANDLER 8

CHANGES: 08

.1

972

1.

was

543

-1

002A

2.

was

543-35

3.

was

543-35

4.

was

543-84

5.

was

543-1002A

HEAD

and

TENSION

DETAILS

2

856-144

21

2

857-93

31

~32

.

S

EE

PLATE

2.

2

857-97

33

(old

543-

43)

2BS6-

93

34

From the library of: Superior Sewing Machine & Supply LLC

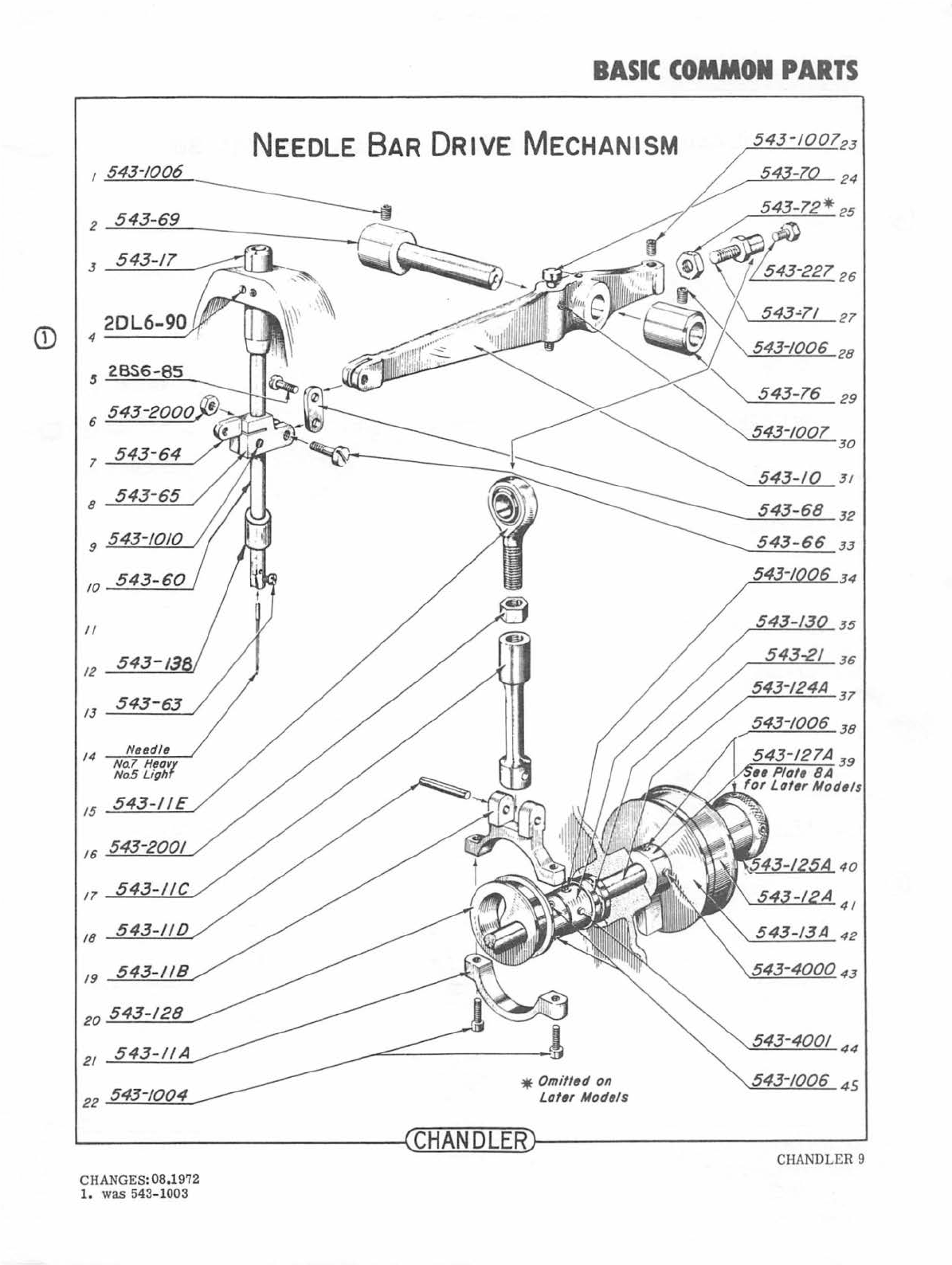

I

543

-

/006

2

543-69

7

543

-

64

8

543-65

9 543-1010

II

12

13

14

Nudls

No.7

Hsa1

No.5

Ligh

15

16

543-200/

17

18

/9

20

21

22

BASIC

COMMON

PARTS

NEEDLE BAR

DRIVE

MECHANISM

*

Omitted

on

Later

Models

543-10

543-68

543-66

3 /

32

33

34

35

36

37

38

~----------------~CHANDLERr-----------------~

CHANGES:08.1972

1.

was 543-1003

CHANDLER 9

From the library of: Superior Sewing Machine & Supply LLC

®

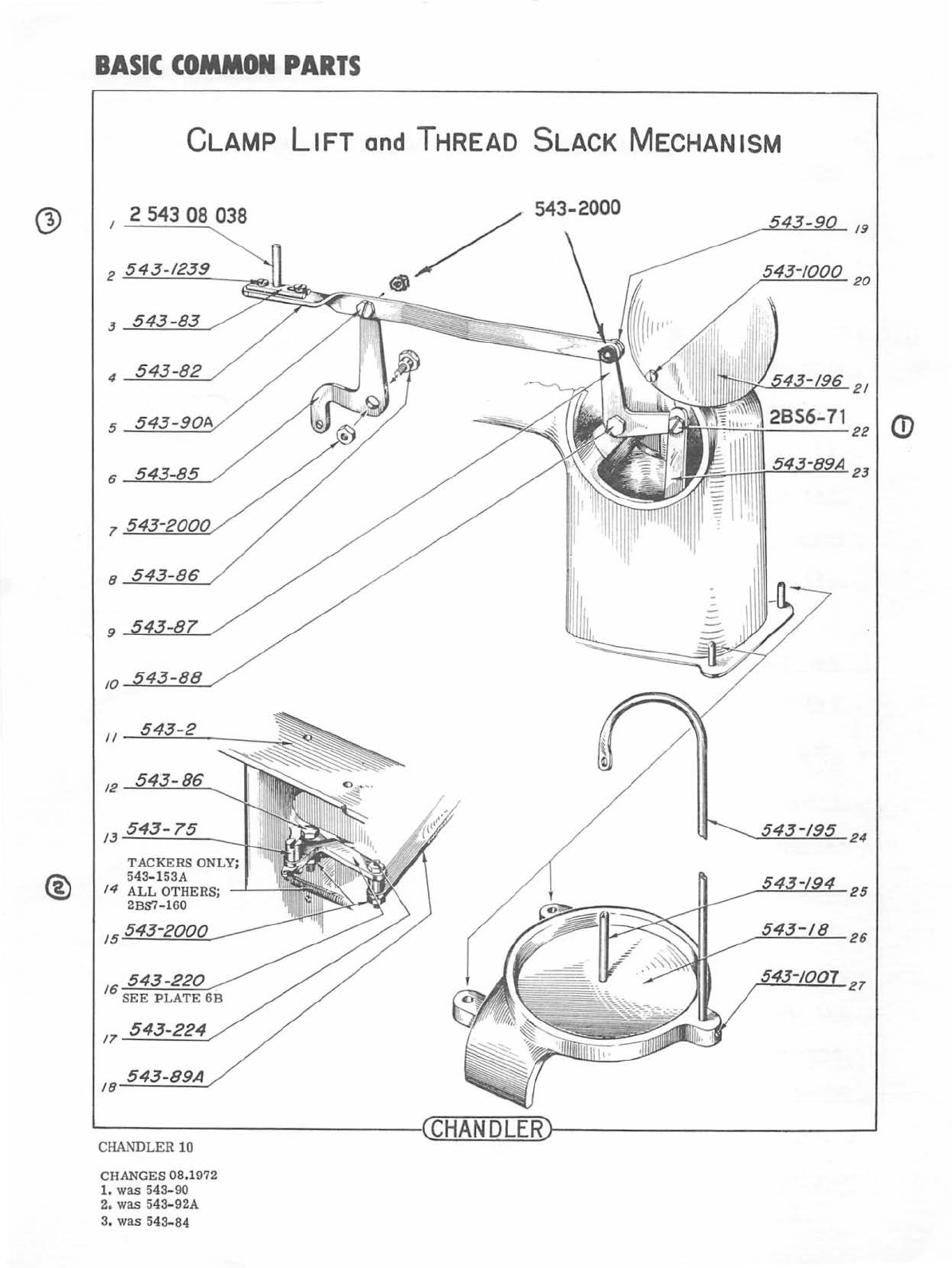

BASIC

COMMON

PARTS

CLAMP

LIFT

and

THREAD SLACK MECHANISM

2 543 08 038

8

9

10

II

12

15

.....:::5;__;4...:::..3.......:-8::....::9...:...:A._,

18-

CHANDLER

10

CHANGES

08.1972

1.

was

543-90

2. was 543

-92A

3.

was

543-84

' I

24

25

26

27

From the library of: Superior Sewing Machine & Supply LLC

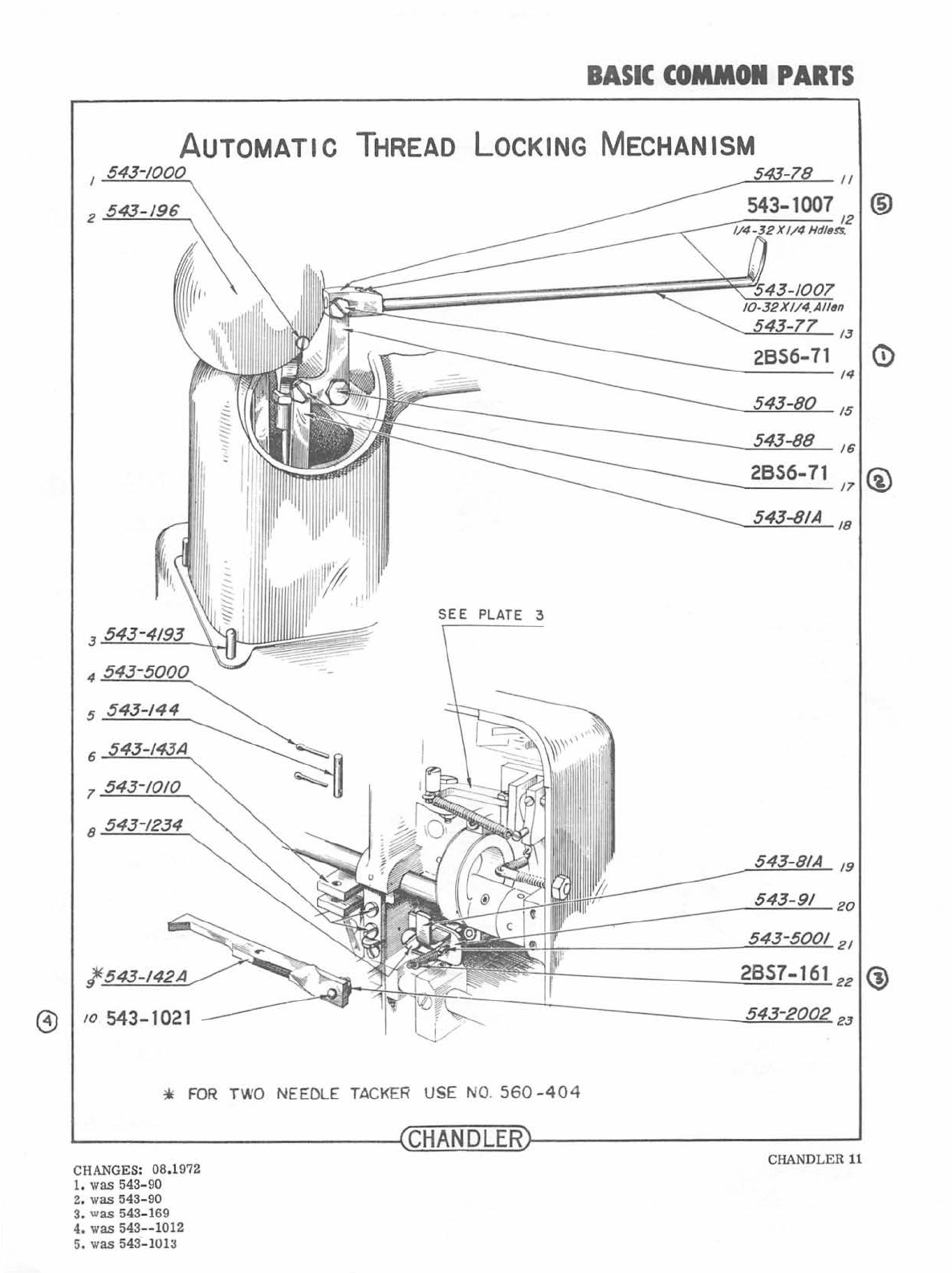

BASIC

COMMON

PARTS

AUTOMATIC

THREAD LOCKING MECHANISM

2

543-/96

13

0

14

15

16

2856-71 @

/1

/8

SEE

PLATE 3

5

543-144

6

1

8

/9

20

21

l.

2857-161

22

®

@

/0

543-1021 23

*

FOR

TWO NEEDLE T

AC

K

ER

U

SE

NO.

5

60

-40

4

CHANDLER

CHANGES:

08.1

972 CHAN

DLER

11

1.

was

543-90

2.

was

5

43-90

3.

was

54

3-169

4. was

543--

1012

5. was

5

4

3 -

10

1

~

From the library of: Superior Sewing Machine & Supply LLC

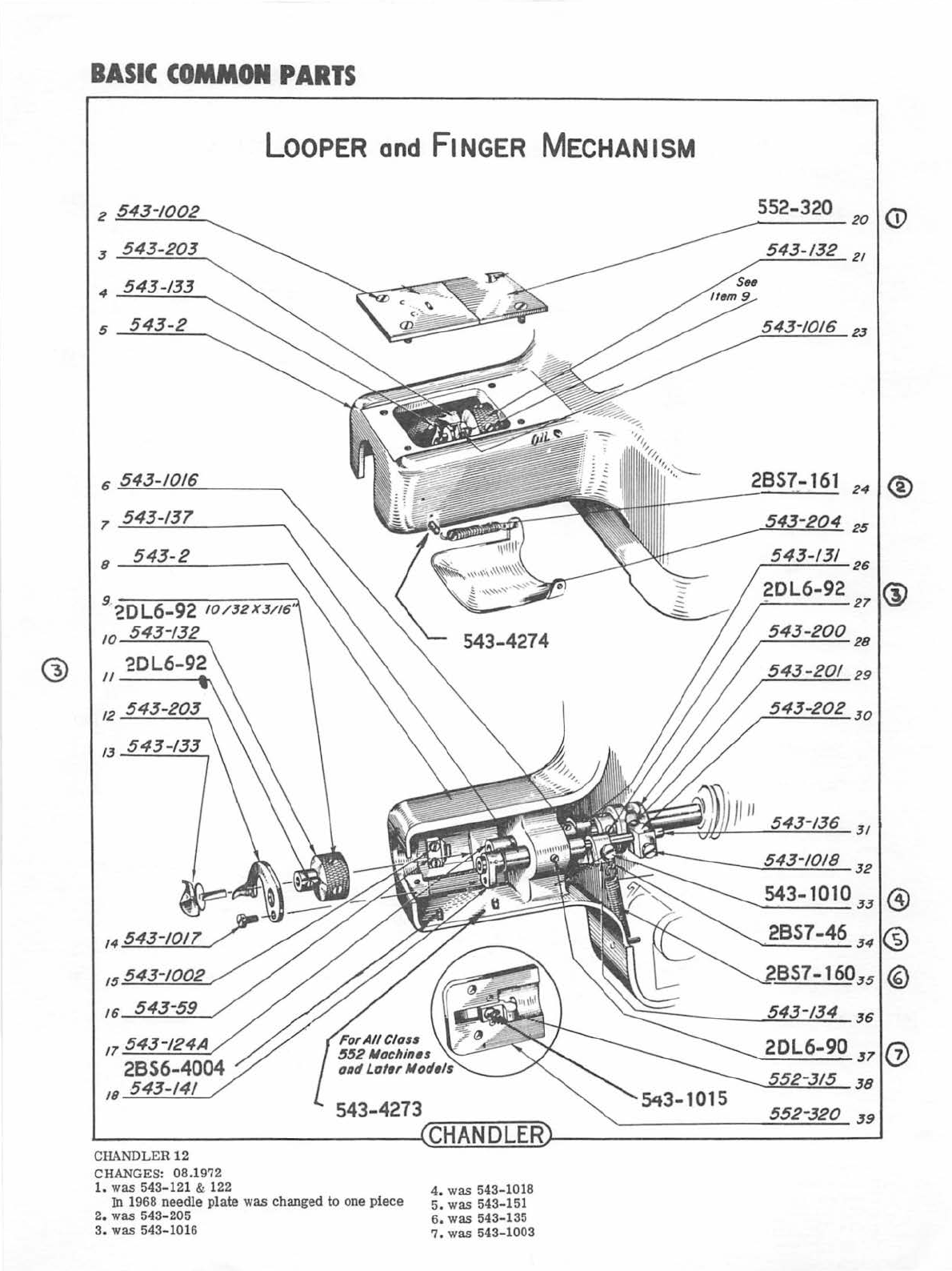

G>

B

ASIC

CO

MMON

PARTS

LOOPER

and

FINGER MECHANISM

2

543

-

1002

6

7

543-137

8

543-2

10

II

17

543-!24A

2856-400

4

18 543-141

CHAND

LER

12

CHANGES:

08.

1972

1.

was

543

-1

21 & 122

543-4273

In

1968

nee

dl

e plate was

chan

ge

d

to

one pi

ece

2.

was

543- 205

3. was 54

3-

1016

--C-HA_N

__

D~L-=E=--R

4. was 54

3-

1018

5.

was

543-15

1

6.

was

543-135

7.

was

54

3-

1003

552-320

20

<D

543

-

/32

21

2857-

161

24

®

25

26

®

29

20L6-90

JT

(J)

552-315

38

552

-

320

J9

From the library of: Superior Sewing Machine & Supply LLC

CD

®

BASIC

COMMON

PARTS

1

552-336

FoR

CLAss 552

AND

LATER MoDELS

543-326

22

552-328

2J

7

552-325

8

543-187

9

543-209

543-10028

II

543-330

/J--!:::....:..:::_-.=2

_

___

----.,

552

-

337

24

543-1002825

543-

28

JO

J/

No

Shouldu

(N~w

Sly!~)

543-140;-:A

-

~

---

~~

§.j_~'Qg?._~,B

Sho

ulder

Stud

543-140

~----------

--

----

~

~C~H~AN~D~L~E~R~

--------

--------~

CHANGES:

08

.1972 CHANDLER

13

1.

was

552-329

2.

was

543-1002A

3.

was

543-184

Q)

From the library of: Superior Sewing Machine & Supply LLC

CD

<D

@

BASIC

COMMON

PARTS

12

------..

552-313

13 543-1010

16

543-/9A

2BS7-161

17

-------,.

STOPPING MECHANISM

NOTE: BELOW SPRING

STOP

DISCONTINUED

IN 1948.

SEE

FOLLOWING PAGES

FOR

LATER

MODIFICATIONS.

NEEDLE TACKER

*

USE

NO.

560-402

T

USE

N0.560-403

L------------------4CHANDLER~--

------

--------~

CHANDLER

14

CHANGES: 08.1972

1.

was

543-169

2.

was 543-20

3.

was

543-1018

4.

was

543-235

(a!ter

1970,

"C"

clips

used)

From the library of: Superior Sewing Machine & Supply LLC

BASIC

COMMON

PARTS

STOPPING

MECHANISM

FoR

CLASS

552

MACH.

2 543 08 036

4

52-4000

5

552-1006

INTRODUCED 1952

543-391

7~~-~4~0~0~0--------~~

-

8~~~0~0~6

·

------~~------~

-

*_5::....;5::....:;2:..._-.=....3:....::1

8"-/

II

12

552-1010

FOR

TWO NEEDLE

TACKER

*

USE

NO.

560-429

t

USE

NO.

560-

403

552-33514

552-3002

'

15

552-309

16

~------------------~CHANDLERr-----------------~

CHANDLER 15

CHA

NGES: 08.1972

1. was 543-311,

also

see

assy

dwgs

From the library of: Superior Sewing Machine & Supply LLC

BASIC

CO-ON

PARTS

STOPPING

MECHANISM

FOR

CLASS

600

MACHINE

INTRODUCED 1971

~-----------600-335

~~---------552-3002

~~---------600-309

600-332A

WASHER

FOR

THOSE

WISHING

TO

CONVERT

THEIR

CLASS

552

CUSHIONSPRING

HOLDERS,

PART

NO.

600-323

ADAPTER

MUST

BE

PURCHASED.

(spring

no.

552

-332

will

be

discontinued.

)

CLASS

552

REBOUND

FINGER

STOP

GUIDE

(552-309)

WILL

BE

REPLACED

BY

A

NEW

ONE

(

600

-

309)

,

WHICH

IS

HEAVIER.

NEW

SCREWS

MUST

ALSO

BE

PURCHASED

(600-

335).

SEE PAGE 34

FOR

ASSEMBLY NUMBER

FOR

COMPLETE

UNIT.

~----------------~CHANDLER~--------------~~

CHANDLER16

CHANGES: 08ol972

1. was 552-311. also see assy dwgs

From the library of: Superior Sewing Machine & Supply LLC

BASIC

COMMON

PARTS

TREADLES

and

TRIP

LEVERS

<D

543-94 2855-177

/6

g)

2

543

-

213

543-2002

17

3

543-2002

543

-1018

18

4

543

-10

/9

543-2002

19

5

543-10/9

543

-

1021

20

®

6

21

7

543

-200

2 2

8

9

1010

24

25

II

26

/2

27

13

543-226

28

14

29

15

30

~--

--

------

----

--~~

CHruA~N~D~L&E~Rr---

--

----

------

--~

CHANDLER

17

CHANGES: 08.1972

1.

was 543

-9

3

2. was

54

3-7

9

3.

was B

S-7

7

4.

was 543-1019

From the library of: Superior Sewing Machine & Supply LLC

®

OPTIONAL

-

NOT

FOUND

ON

ALL

MACHINES

AUTOMATIC

CLAMP

LIFTER

GROOVE

PIN

4

555-380

5

6

7

555-377

8

543-3001

543-1023

9

II

555-382

555-387

13

.

555-381

14

543-2000

15

543-220A

543-2005

552-367

555-378

/6

555-379

17

543-200018

555-383

19

543-241

2 0

~

--

--------------~CHANDLER~------------------~

C

HA

NDLER 18

CHANGES: 08

.1

972

1. was 543

-101

6

2. was 543

-101

8

From the library of: Superior Sewing Machine & Supply LLC

This manual suits for next models

10

Table of contents

Other Chandler Sewing Machine manuals