Changan BENNI MINI 2011 User manual

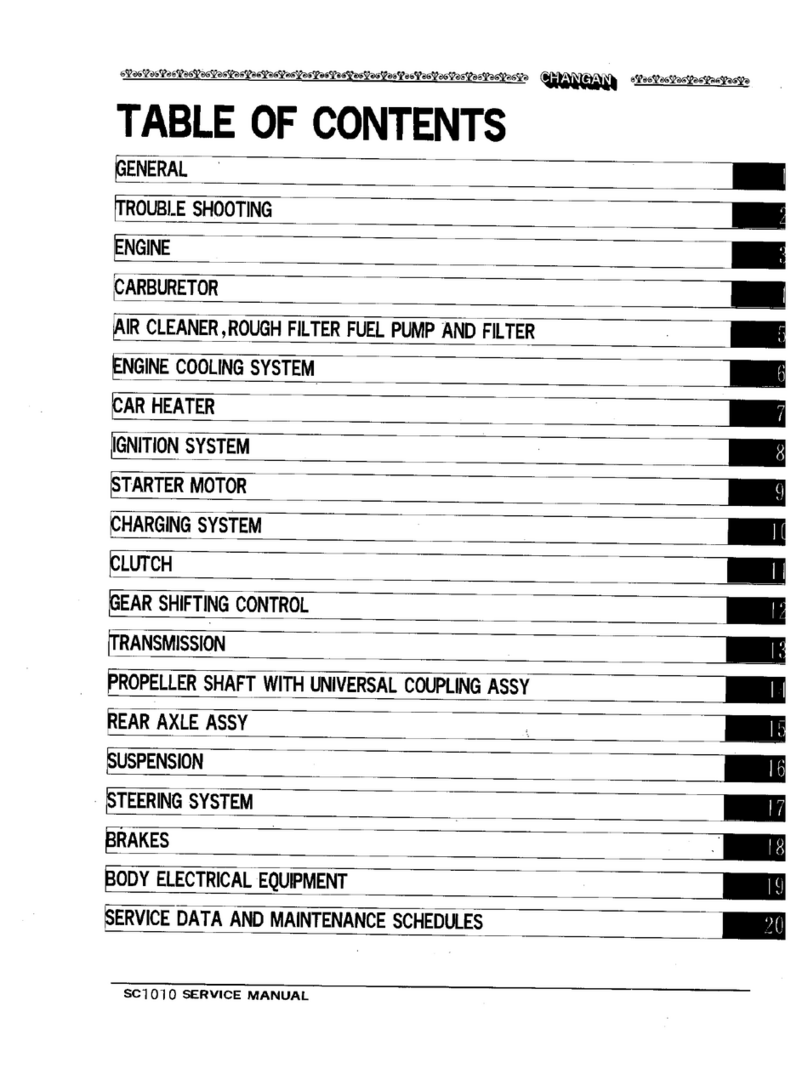

2011

BENNI MINI SERVICE MANUAL

2011 Changan Automotive Co., Ltd.

Copyright ©

Information up to Nov 2011.

Without written permission, any form of duplicate, storage or distribution (including, but not limited to, electronic copying, photocopying,

scanning and recording) of any part of this manual is not allowed. This statement applies to all texts, figures and tables.

This service manual consists of BENNI MINI repair information

Maintenance Manual of BENNI-MINI

100-00-1 Overview

100-00-1

Section 100-00 Overview

Contents Page

Instruction and Operation

About the Manual ............................................................................................................................................ 100-00-3

Brief Introduction ............................................................................................................................................ 100-00-4

Spare Parts Substitution................................................................................................................................... 100-00-3

Special Tools ................................................................................................................................................... 100-00-3

Important safety instruction............................................................................................................................. 100-00-3

Warning, Caution and Prompting.................................................................................................................... 100-00-4

How to Use the Manual ................................................................................................................................... 100-00-3

Examples ......................................................................................................................................................... 100-00-4

Precautions of Health and of Safety................................................................................................................. 100-00-5

Brief Introduction ............................................................................................................................................ 100-00-5

Acid and Alkali Metals.................................................................................................................................... 100-00-5

Safety Air Bag ................................................................................................................................................. 100-00-5

Air-conditioning Cooling Agent...................................................................................................................... 100-00-6

Sealing Agent and Adhesive Agent................................................................................................................. 100-00-6

Anti-freezing Fluid .......................................................................................................................................... 100-00-6

Electrolyte........................................................................................................................................................ 100-00-7

Clutch Plate and Brake Shoe ........................................................................................................................... 100-00-7

Braking Fluid................................................................................................................................................... 100-00-7

Braze Welding................................................................................................................................................. 100-00-7

Chemical Substance......................................................................................................................................... 100-00-7

Clutch Oil ........................................................................................................................................................ 100-00-8

Clutch Friction Disc and Friction Lining......................................................................................................... 100-00-8

Corrosion Preventing Material......................................................................................................................... 100-00-8

Cutting............................................................................................................................................................. 100-00-8

Paraffin Removal............................................................................................................................................. 100-00-8

Dust.................................................................................................................................................................. 100-00-8

Electric Shock.................................................................................................................................................. 100-00-8

Engine Oil........................................................................................................................................................ 100-00-8

Exhaust Gas..................................................................................................................................................... 100-00-8

Acoustic Insulation Fiber................................................................................................................................. 100-00-8

Fire Prevention................................................................................................................................................. 100-00-9

First Aid........................................................................................................................................................... 100-00-9

Foam-polyurethane.......................................................................................................................................... 100-00-9

Cooling Agent.................................................................................................................................................. 100-00-9

Fuel.................................................................................................................................................................. 100-00-9

High Pressure Cylinder.................................................................................................................................... 100-00-9

Gas................................................................................................................................................................... 100-00-9

General Purpose Maintenance Tool / Device .................................................................................................. 100-00-10

Testing Device for High Pressure Air, Lubricating Oil and Oil Fluid............................................................. 100-00-10

Legal Affairs.................................................................................................................................................... 100-00-10

Lubricating Oil and Lubricating Grease .......................................................................................................... 100-00-10

Noises............................................................................................................................................................... 100-00-10

Acoustic Insulation Material ............................................................................................................................ 100-00-10

Paints .............................................................................................................................................................. 100-00-10

Pressure Device................................................................................................................................................ 100-00-11

Solder ............................................................................................................................................................... 100-00-11

Solvent.............................................................................................................................................................. 100-00-11

Suspended Load ............................................................................................................................................... 100-00-11

100-00-2 Overview

100-00-2

Sealing on Vehicle Base................................................................................................................................... 100-00-11

Soldering .......................................................................................................................................................... 100-00-11

Warning Signs on Vehicle................................................................................................................................ 100-00-12

Petroleum Solvent Oil...................................................................................................................................... 100-00-13

Standard Workshop Operating Manual ............................................................................................................. 100-00-14

Vehicle in the Maintenance Workshop ............................................................................................................ 100-00-14

Vehicle Traction............................................................................................................................................... 100-00-14

Connect the Auxiliary Battery with the Jumper Wire ...................................................................................... 100-00-14

Component Cleaning........................................................................................................................................ 100-00-15

Calibration of the Important Measuring Equipment......................................................................................... 100-00-15

Solvent, Sealing Agent and Adhesive Agent.................................................................................................... 100-00-16

Brief Introduction............................................................................................................................................. 100-00-16

General Specifications...................................................................................................................................... 100-00-16

Test of Road or Rolling Testing Platform........................................................................................................ 100-00-17

Check before Testing........................................................................................................................................ 100-00-17

Engine Starting................................................................................................................................................. 100-00-17

Test of Road or Rolling Testing Platform........................................................................................................ 100-00-17

Braking Test..................................................................................................................................................... 100-00-18

100-00-3 Overview

100-00-3

Instruction and Operation

DESCRIPTION AN D OPERATION

About the Manual

Brief Introduction

The compiling format of this manual aims to satisfy

the requirements of the maintenance skill men, and

this manual provides the general instructions for

completing the service and maintenance. The

reliability of the work can be enhanced according to

the maintenance specified in the manual.

Spare Parts Substitution

The

maintenance fittings of Chang’an Automobile

Company Limited are manufactured according to

the original factory standard. Thus, when the

maintenance service is performed, only the original

maintenance fittings manufactured by Chang’an

Automobile Company Limited can be used.

Special Tools

All the special tools required by the maintenance

every time are provided in the Special Tool List

before every procedure. Moreover, when necessary,

illustrations are additionally provided for the

identification of these special tools.

The special tools can be ordered from Chang’an

Automobile Company Limited.

Important Safety Instruction

Suitable maintenance methods and correct

maintenance procedures are vital for the operation

reliability of all vehicles and the safety of the

maintenance personnel.

This manual can not foresee all circumstances and

provide the relevant warning and suggestions.

Anyone who does not follow the instructions in this

manual must identify that the selected maintenance

method, tool and parts can not endanger the

personnel safety and the automobile integrity.

Warning, Caution and Prompting in the Manual

Warning: used for indicating the possible

personnel injury if the Manual is not

observed.

Caution: used for indicating that the

vehicle and the applied maintenance

device can be damaged if the operation is

not carried out according to the

appropriate procedures.

Prompting: used for providing other information

for the complete and satisfied maintenance service.

When reading this manual, you may encounter the

signs of “Warning”, “Cautious” and “Prompting”.

The signs of “Warning”, “Caution” and

“Prompting” are provided at the beginning of each

step.

How to Use the Manual

The descriptions in this manual are given in the

form of sections, and the sections of the specific

system are gathered in the relevant chapters.

Each chapter gives a brief description of a specific

part of automobile. This manual is divided into five

chapters: Overview, Chassis, Power Steering

System, Electricity, Vehicle Body and Coating.

Page numbers of all the chapters and sections are

provided in the first page of this manual. Each

chapter includes the contents of Overview,

Introduction and Operation and Maintenance

Adjustment and Check.

If the parts need to be dismounted or disassembled

according to instruction or sequence, the splitting

procedures with the corresponding diagrammatic

drawing and description are provided and are noted

in sequence. (Please see Example.)

The left and right sides of vehicle are determined

by looking forward form the driver seat position.

The left and right sides of the engine are

determined by looking towards the front end belt of

camshaft from the flywheel.

Inspection and Identification

This chapter comprises the Visual Inspection Table,

Failure Phenomenon Table, other information table

(such as Diagnosis Procedures) and Supplemental

Testing Procedures and Technical Standards or

Specific Testing Procedures which guides the

mechanic how to perform.

Failure

Phenomenon Table

This table is used for indicating the failure

phenomenon, causes and diagnosis procedures

under some certain circumstances.

Fixed Point Test

As for the electric failure, the causes of the failure

should be gradually identified according to the

logical procedures by referring to the Fixed Point

Test Table. The Fixed Point Test Table comprises

two columns: Inspection Items and Concrete

Procedures/ Results/ Measures.

Many diagrams and icons (with or without titles)

are shown in the column Inspection Items. The

explanatory notes concerning the test procedures or

the special handling measures are provided in the

Concrete Procedures/ Results/ Measures.

The number marks are used for indicating the serial

numbers of inspection items.

Component Testing

When some step is over complicated and therefore

can not be arranged in the signal page fixed point

test or a plurality of fixed point tests require to

measure one identical component, the component

testing should be performed.

100-00-4 Overview

100-00-3

Instruction and Operation

Illustration Indication

The testing diagram shows the required

measurement or test in some certain testing

procedure.

The typical test diagram is suitable for the use of a

voltage gauge and an ampere meter.

When a signal diagram shows the multi-step test,

the solid line draws the conducting wire until the

multi-step measured conducting wire branch points,

and the conducting wire of multi-step measuring

points after the branch point should adopt the dotted

line.

The double circle testing pin is used for indicating

the disaster box type instrument. The testing pin

should be labeled with pin number.

Examples

When the special tool is required, its figure and use

method will be provided, or the tool number will be

listed. The preset torque value will be given at the

corresponding position in the procedures.

100-00-5 Overview

100-00-3

Instruction and Operation

Precautions of Health and of Safety

Brief Introduction

Many operations in connection with the service and

maintenance of the vehicle will threaten and

endanger the human health. Plenty of dangerous

operations and its relevant dangerous articles and

equipment are listed below in the alphabetical

(English) order. Please pay special attention to the

following dangerous articles.

Listed contents are not always complete, therefore

the safety and health should be always considered

first during the practical operation.

Before the use of any product, the safety

specification table of the material supplied by the

manufacturer or the supplier of the products should

be firstly consulted.

Acid and Alkali Metals

See Section Electrolyte.

Such as corrosive soda ash or sulfuric acid.

Electrolyte and cleaning material.

Irritable and corrosive substances to skins, eyes,

noses, throats and clothes, inflammable articles and

substances which can damage the normal protection

clothes.

These substances should be avoided from splitting

on skin, eyes and clothes. Suitable protective

overall, gloves and glasses should be worn. Never

inspire the acid fume.

Eye washing bottles, water taps and soaps are

positioned nearby for the use at ay time when

unexpected accident happens.

Signs of Harmful to Eyes shall be placed.

Safety Air Bag

See Section Inflammable Chemical Substance.

Inflammable and Explosive Substance--observance

of the non-smoking regulation.

The safety air bag is installed on the instrument

panel before the steering wheel and passenger(s) for

protecting the life safety of driver and passengers.

Highly explosive substance is contained in the

safety air bag, and when the substance is ignited,

gases of high temperature and high pressure

(2500°C) will be generated.

The gas generating agent used for the air bag is

sodium azide. The sodium azide is sealed in a

module and can be fully released when the air bag

is extended. Never try to open the air bag by

yourself, or the sodium azide will be exploded. If

the gas generator is broken, the complete protective

working clothes must be worn during the treatment.

After the air bag is normally extended, the

protective gloves and glasses must be worn on site

during the treatment.

The used safety air bag should be packed by

using the plastic bags according to the local

regulations strictly and then discarded at the

designated disposal site for chemical waste.

If directly contact with the generated gas, please:

– Use water to thoroughly clean the site

(affected area).

– Seek medical assistance if necessary.

Air Bag--operations which shall be performed

– Position the air bag vertically.

– Keep the air bag dry.

– The unsealed face shall be toward the human

body when the air bag is carried.

– The sealed side of the air bag should be placed

upwards.

– Carefully inspect whether the air bag is

damaged.

– Stand at the side face when the air bag is

connected.

– Identify that all the testing devices have been

correctly calibrated and maintained.

– Clean both hands when the expanded air bag is

carried away.

Air Bag--operations which shall be forbidden

– It is forbidden to place the inflammable

substance or gas generator together with the air

bag.

– The storage temperature of gas generator can

not be more than 80°C.

– The air bag can not be inversed.

– It is forbidden to open the housing of gas

generator.

– It is forbidden to place the gas generator near

open fire or heat source.

– It is forbidden to position any object on the air

bag.

– It is forbidden to use the damaged air bag.

– It is forbidden to contact the air bag and the gas

generator after they are burnt in ten minutes.

– It is forbidden to use the electricity meter probe

on the air bag circuit.

100-00-6 Overview 100-00-6

Description and Operation (Continued)

Air-conditioning Cooling Agent

See Section Chemical Substance.

Inflammable substance—observance of the

non-smoking regulation

Frostbite can be caused when the cooling agent is

contacted with skin.

The manufacturer’s guidance must be strictly

observed. The protective gloves and glasses can

avoid the strong light exposure.

If the cooling agent is inadvertently contacted with

skins or eyes, please wash with water immediately.

The suitable cleaning agent should be used to wash

if the cooling agent is split into the eyes, never rub

your eyes. Seek medical assistance if necessary

Air-conditioning Cooling Agent—forbidden

items

– It is forbidden to expose the air-conditioning

cooling agent under sunshine or heat the

air-conditioning cooling agent.

– When the cooling agent is filled, never position

the filling bottle vertically, and the filling

opening should be positioned downwards.

– Prevent the frostiness on the air-conditioning

cooling agent bottle.

– Prevent the dropping of the air-conditioning

cooling agent bottle.

– It is forbidden to vent the air-conditioning

cooling agent under any circumstances.

– It is forbidden to use the cooling agent in a

mixing way, such as fluorine R12 and R134a.

Sealing Agent and Adhesive Agent

See Chapter Inflammable Chemical Substance.

Inflammable Substance--observance of the

non-smoking regulation.

In general, the sealing agent and the adhesive agent

should be placed in the non-smoking area and must

be preserved cleanly, for example, put the sealing

agent and the adhesive agent on the storage rack

covered by disposable paper towel, it is advisable

that the sealing agent and the adhesive agent are

taken out of the package boxes to position them

separately; the package boxes include subpackage

boxes on which corresponding labels should be

applied.

For melting and sealing agents and adhesive

agent, see Section Melting Agent

Follow the instruction book of the manufacturer.

Water Soluble Sealing Agent and Adhesive

Agent

The water soluble viscose glue based on

macromolecule emulsion and latex may contain

small amount of volatile toxic substances and

chemicals harmful for human body. Avoid making

the substances contact with eyes and skins, please

make sure good ventilation when the water soluble

viscose glue is used.

Hot Melt Viscose

The solid hot melt viscose is safe. Under the molten

state, the hot melt viscose can be burnt and will

release harmful gases, therefore being harmful to

health.

Wear suitable protective working overalls, use a

constant temperature heater with self-deenergizing

function, and enough air drafting equipments

should be provided.

Resin Sealing Agent and Adhesive Agent, such

as Epoxide and Formaldehyde Resin

The adhesive agent should be mixed in the places

of good ventilation because harmful or toxic

volatile substances will be released during mixing.

Dermatitis can be caused when the skin contacts

with the tacky resin and hardening agent, some

harmful and toxic chemical substances will be

absorbed by skin.

The spatters can injure eyes.

Keep good ventilation and avoid contacting with

skins and eyes.

Anaerobic Cyan Acrylate Adhesive and Acrylic

Acid Adhesive

Most of the adhesive has irritation, causes the

irritability or the damage to the skin and the

respiratory tract. Some of them have strong

irritation to eyes.

Avoid such substances contacting skin and eyes and

follow the instruction book of the manufacturer.

Forbid the cyan acrylate adhesive to contact

with skin and eyes. If contact for carelessness,

please put the clean and wet cloth immediately

100-00-7 Overview 100-00-7

Description and Operation (Continued)

or go to hospital. Forbid to touch the wound

position by hands. Select the places of well

ventilation because the steam will stimulate

eyes and nose.

Isocyanate (Polyurethane) Sealing Agent and

Adhesive Agent

See Resin Adhesive.

Any person suffering asthma and other

respiratory system diseases can not touch or

close to such substances.

Excessively exposing such substances will

stimulate eyes and the respiratory system. If the

concentration is over high, the substances will

stimulate the nervous system, and will make

the person lose consciousness in the severe

situation. Touching such substance for a long

time will influence the good health.

Touching with the skin for a long time will

stimulate skin, and will cause the dermatitis

when the situation is severe. If entering into

eyes, the eyes will be hurt.

Any sprinkling action must be performed in the

places of well ventilation, and the steam and

the sprinkled grains shall be far away from the

respiratory area.

Wear the proper the gloves, the glasses and the

respirator.

Anti-Freezing Fluid

See Section Combustibles and Melting Agent.

The anti-freezing fluid includes isopropanol,

ethylene glycol and methanol.

High inflammable, inflammable and combustible.

Solutions used in the automobile cooling system

and the water spraying system of wipers.

The anti-freezing fluid will generate the steam

when being heated. Avoid inhale such gas.

The anti-freezing fluid or other harmful materials

may enter into the human body through the skin. If

the anti-freezing fluid is drunk for carelessness, it

may cause the deadliness, and the person must go to

hospital immediately.

Forbid to use any of such substances in the cooling

or industrial water use system related to the food

manufacturing or drinking system.

Electrolyte

Please see Section Acid and Alkali Metal

simultaneously.

When the battery cell is charged, the released gas

will cause explosion. Forbid to use the open fire or

the mars when the battery cell is charged.

Ensure good ventilation.

Braking Fluid

Please see Section Fire Prevention.

If the braking fluid is splashed on skin and eyes,

there will have slight stimulus. Possibly avoid the

braking fluid touching skin and eyes. Because the

steam pressure is lower, the harmful steam can not

be inhaled at normal temperature.

Braze Welding

See Section Welding.

Chemical Substances

See the contents of the laws and regulations.

The chemical substance includes melting agent,

sealing agent, adhesive, paint, resin foam,

electrolyte, anti-freezing agent, braking fluid, fuel,

oil and grease. Be careful when use and store the

substance. They may be noxious, harmful, and has

corrosive irritability and are inflammable and will

cause generate some harmful gas and dust.

If the chemical substance is exposed for a long time,

the human health will be influenced to different

extents.

Chemical Substance--operations which shall be

performed:

– The labels on the dangerous articale vessel and

the corresponding promotion information and

instruction book shall be carefully read to

obtain the relevant safety information. The

safety and health data table of the substance

can be obtained from the manufacturer.

– If being polluted by the chemical substance,

the skin and clothes shall be cleaned in time.

Replace the severely polluted clothes and

clean them.

– The operation regulation shall be compiled, and

wear the protective clothes to avoid the

substance polluting skin and eyes, avoid

inhaling the harmful gas, acid mist, dust and

100-00-8 Overview 100-00-8

Description and Operation (Continued)

smog, etc. and avoid the combustion and

explosion caused by such substance.

– Clean hands immediately after touching the

substance.

– The working area shall be kept clean and tidy

without leakage.

– The chemical substance shall be managed and

stored strictly in accordance to the national

and local regulation.

– Avoid the children touching.

Chemical Substance--Forbidden Operations:

– Forbid to mix the chemical substance arbitrarily

without following the manufacturer’s guiding.

Mixing some chemical substances will

generate the harmful substance; the noxious

and harmful gas will be released or the

explosion occurs.

– Forbid to spray the chemical substance in the

narrow space, such as in the automobile with

persons, especially to spray the melting agent

chemicals.

– Forbid to heat or burn the chemical substances

arbitrarily without following the

manufacturer’s guide, some chemical

substances are combustible, and some

substance will release the noxious or harmful

gas when burnt.

– Do not openly put the vessel, the gas emitted

in the vessel will cause the poison to the

human body or cause the explosion. Some

gases lighter than air will accumulate in the

small section.

– Do not transport the chemical substances with

the vessel without being labeled.

– Forbid to wash hands or clothes with the

chemical substances. The chemical substances,

especially the melting agent and fuel will

make the skin dry, and also stimulate the skin

to catch dermatitis, or the hands or clothes

will absorb some noxious and harmful gas

through the skin.

– Forbid to store other articles with the empty

tank which once used to store the chemical

substance without the special treatment.

– Do not smell the chemical substance. The

sudden gases of high concentration will cause

the poisoning or cause the injury.

Clutch Oil

See Section Braking Fluid.

Corrosion Preventing Material

Please see Sections Melting Agent and Fire

Prevention simultaneously.

Because the corrosion preventing material belongs

to the inflammable substance, please follow the

regulation of No Open Flames.

Because the substance has various types, please

follow the instruction book of the manufacturer.

The melting agent, the resin or the product oil may

be contained in the substance. The substance shall

be avoided touching skin and eyes. The substance

can not be sprayed in the enclosed space and only

can be sprayed in the conditions of well ventilation.

Cutting

Please see Section Wielding.

Wax Removal

See Section Melting Agent And Fuel (Kerosene).

Dust

The dust may be poisonous and stimulate the

human skin. Avoid inhaling the ash of the powder

chemical substance or other ashes. Wear the

respirator when the air is not smoothly circulated.

The extra fine dust of the inflammable material will

cause the explosion. The explosive threshold and

ignition source shall be avoided.

Electric Shock

Incorrectly using or using the electrical equipment

with defects will cause the electric shock.

The electrical equipment shall be regularly detected

and the equipment shall be ensured to be perfect.

The equipment with defects shall have the clear

label and be removed from the working area.

Ensure that the conducting wire, the cable, the

plug and the socket have no abrasion, knotting,

cutting, cracking or other damages.

Do not make the electrical equipment and the

electric wire contact with water.

Ensure that the electrical equipment is

protected by the fuse.

Correctly use the electrical equipment and do

not use the device with problems, and violation of

this operation will cause the fatal danger.

100-00-9 Overview 100-00-9

Description and Operation (Continued)

The electric wire of electric appliance shall be

ensured not to be intercepted or damaged when the

automobile is hoisted.

Ensure that the electrician be trained in first aid.

If electrically shocked:

– Cut off the power source before touching the

electric shocker.

– If the power source can not be cut off, use the

dry and non conducting materials to push away

the sufferer or draw the sufferer away the

power source.

– Perform the cardio-pulmonary resuscitation

immediately.

– Seek the medical help.

Engine Oil

Please see Section Lubricating Oil and Grease.

Waste Gas

The waste gas includes the noxious, harmful

and smothering chemical materials, such as

carbon monoxide, nitrogen monoxide,

acetaldehyde, aromatic hydrocarbon and lead

containing gas, etc. The engine can only be

started after the waste gas is discharged or in

the places of air circulation.

Gasoline Engine

The gasoline engine has no symptom before

generating the noxious and harmful gas. The harm

of the noxious and harmful gas can be immediate

and also can be latent.

Acoustic Insulation Fiber

See Section Dust.

The acoustic insulation fiber is used for insulating

the sound and the noise.

The cellulose and the cutting scrap will cause the

skin stimulation. This is often the physical effect

but not the chemical reaction.

The working practice guide must be complied, and

the gloves must be worn to avoid the substance

contacting with the skin for a long time.

Fire Prevention

See Welding, Foam and Legal Affairs.

Most of the substances related to the automobile

maintenance are the inflammable substances. The

noxious or harmful gas can be released when some

of them are burnt.

When the inflammable substances or the melting

agents are stored or used, especially when welding

or being close to the electrical equipment, the fire

safety shall be strictly noted.

Before using the welding device or the heating

device is used, ensure that there are no

combustibles around, and place the extinguisher

nearby.

First Aid

Besides meeting the legal requirements, the

maintenance workshop must be equipped with the

personnel who have been trained for first aid.

After any substance is sprayed in eyes, the eyes

must be washed for at least ten minutes with clean

water.

After polluted by the chemical substance, the skin

shall be washed with water and the toilet soap.

Wash and cool with cold water immediately after

burnt by some substances.

If inhale the dust, go to the places with fresh air

immediately. If this method does not take effect,

please send to the hospital immediately.

If drink some liquid for carelessness, please go to

hospital immediately and say the name and

composition of the liquid. Do not try to vomit

unless there has special instruction on the label.

Foam - polyurethane

See Section Fire Prevention.

The foam is used for isolating the sound and the

noise. There are also foams in the seat and the

shock absorber.

Operate by strictly following the instruction book

of the manufacturer.

The unreacted components have irritability and will

cause damage to skin and eyes. Please wear gloves

and the protective glasses.

The person suffering from the chronical respiratory

system diseases, asthma and bronchitis or person

100-00-10 Overview 100-00-10

Description and Operation (Continued)

with allergic history is not allowed to operate in the

unvulcanized material place or nearby.

Some components, steam or spray will have

irritability and may have damage.

Do not inhale the steam and the spray. These

substances must be used in the places of well

ventilation and well take the measures of protecting

the respiratory system. After spraying, do not take

off the respirator until the spray is completely

dispersed.

Burning the unslaked components and the slaking

foam will generate the noxious and harmful gas.

Forbid to smoke and use the open fire or the electric

tool in treating the foam. Any operation for heating

and cutting the foam must be performed in the

places of air circulation. Please see Vehicle Body

and Maintenance Manual.

Cooling Agent

Please see Air-Conditioning Cooling Agent.

Fuel

See Fire, Legal Affairs and Melting Agent.

Avoid the fuel contacting with the skin as best as

one can. If touch for carelessness, wash with the

clean water and the toilet soap.

Gasoline

Inflammable substance--the regulation on no

smoking must be followed.

Swallowing the gasoline for carelessness will

stimulate mouth and throat, if the gasoline is

absorbed by the stomach, it will cause sleepiness

and unconsciousness. A small quantity of gasoline

will cause the death of the child. When the inhaled

fluid reaches the lung, the severe damage will be

caused.

Contacting the gasoline for a long time will make

the person’s skin dry and have the strong irritability.

The gasoline entering in eyes will cause blindness.

A great amount of benzene is contained in the

gasoline, inhaling the benzene will make person

poison. The gasoline concentration must be very

low, the excessively high concentration will

stimulate person’s eyes, nose and throat and make

person vomit, dizziness and dyspnea chest

discomfort, even make person lose consciousness.

The gasoline shall be transported or used in the

places of air circulation. The damage to human

respiratory system due to the gasoline leakage must

be strictly avoided.

For the cleaning and maintenance of gasoline

storage, there must have special preventive

measures. The gasoline can not be used as the

cleaning agent and also can not be siphoned with

mouth.

Kerosene (Paraffin)

The kerosene can be taken as the heating fuel, the

melting agent and the cleaning agent at the same

time.

The kerosene belongs to the inflammable

articles--the regulation on no smoking must be

followed.

Swallowing the kerosene for carelessness will

stimulate mouth and throat.

Contacting with such substance for a long time will

make the person’s skin dry and have the irritability.

The kerosene sprayed in eyes will have the slight

irritating sensation.

Generally, the harmful team can not be generated

due to a small quantity of volatilization. The

volatilization due to the high temperature shall be

avoided (the acid mist will be generated in the

dewaxing process). Avoid touching the skin and

eyes as best as one can and ensure the air

circulation.

High pressure cylinder

See Section Fire Prevention.

The oxygen, acetylene, argon and propane with air

pressure of 138 bar (2000 pa) are generally

contained in the high pressure cylinder. Be

extremely careful when treating such high pressure

gas bottle, the mechanical damage of the high

pressure cylinder or the high pressure cylinder

switch device shall be avoided. The gases in each

high pressure cyclinder shall be clearly marked.

The high pressure cylinder shall be stored in the

places of well ventilation and avoid the rain and

snow or direct solarization. The acetylene and

propane gas bottles shall not be put near the oxygen

bottle.

The leakage of the high pressure cylinder shall be

strictly avoided and the fire sources shall be

avoided.

100-00-11 Overview 100-00-11

Description and Operation (Continued)

Gas

See Section High Pressure Cylinder.

General Purpose Maintenance Tool / Device

All tools and devices shall be kept in the intact state,

and the appropriate safe device shall be used if

necessary.

The use of the maintenance tool / device does not

exceed the designing scope. The maintenance

device, such as the lifting device and the jack can

not be overloaded for use. Because the damage to

the device caused by the overload generally is not

significant, the fatal damage may occur when being

used for the next time.

Forbid to use the damaged or defective tool / device,

especially the high speed running device, such as

the grinding wheel. The damaged grinding wheel

will be fragmented in the conditions without any

signs and make person severely injured.

The eye protection tool shall be worn when the

grinding wheel, the chisel or the sand blasting

device is used.

The appropriate protective mask shall be worn

when the sand blasting device, the substance

containing asbestos or the mist spraying device is

used.

Confirm that there are places of well ventilation to

control the dust, acid mist and smoke.

High Pressure Air, Lubricating Oil and Oil

Testing Device

See Section Lubricating Oil and Lubricating

Grease.

Regularly check the high pressure device,

especially the connector and keep the device good.

Forbid to face the high pressure pipe orifice, such

as the diesel oil filling mouth to the human skin

because the oil will penetrate the human

subcutaneous tissue and cause the severe disease.

Legal Affairs

The material use and disposal in the

maintenance workshop shall conform to the legal

articles with regard to safety and health.

To create a safe working environment and avoid the

environmental pollution, the personnel in

the

maintenance workshop must be familiar with the

national legal articles with regard to safety and

health.

Lubricating Oil and Lubricating Grease

Avoid touching the mineral oil for a long time. All

the lubricating oil and lubricating grease have

irritability to eyes and skin.

Used oil

Touching the mineral oil for a long time will make

the person’s skin dry and have the irritability to the

person to catch dermatitis. In addition, if one uses

the mineral oil containing the toxic and harmful

substance, he will suffer from the skin cancer. The

appropriate devices for protecting and cleaning skin

must be provided.

Forbid to use the used oil as the lubricating oil or in

any device which can contact with the skin.

Health Precautions:

– Avoid touching the oil, especially the engine oil

for a long time.

– Wear the protective clothes, including the

gloves.

– Please do not put the wiping cloth with oil

stains in the pocket.

– Avoid the oil polluting the clothes.

– Please do not wear the clothes and shoes

seriously stained with oil. The protective

clothes shall be regularly cleaned.

– If injured for carelessness, perform the first aid

immediately.

– Protect hands with the protective cream before

working.

– Please wash with the toilet soap and the clear

water.

– Forbid to wash the skin with gasoline, diesel oil,

kerosene, diluents and melting agent.

– If the skin is abnormal, please go to hospital

immediately.

– Please degrease the oil first if possible.

– If the oil will cause damage to eyes, wear the

protective goggles.

Environmental Protection

The depleted engine oil only can be burnt in

the approved places. If the places can not be

confirmed, please confirm with the local authority.

The depleted engine oil must be treated by the

approved waste disposal contractor or the waste oil

100-00-12 Overview 100-00-12

Description and Operation (Continued)

recycling dealer in the designated site. Consult with

the local authority if have doubts.

Directly dumping the depleted engine oil to the

ground, the sewer, the drainage ditch or the water

sources is illegal.

Noise

The high noise generated by some operation

may damage the hearing, and the ear defender shall

be worn at this time.

Acoustic Insulation Material

See Section Foam, Insulation Fiber.

Coating

See Sections Oil and Chemical Substance at the

same time.

The paint belongs to the inflammable substances,

and the regulation on no smoking must be followed.

Monocomponent

Some toxic and harmful pigment, drying agent and

other melting agent may be contained. The coating

only can be performed in the places of well

ventilation.

Multi-component

Some toxic and harmful and unreacted resin and

resin firming agent may be contained. The

manufacturer’s guide must be followed, please see

Section Resin Adhesive Agent.

The coating must be performed in the places of well

ventilation and far away from the crowded. The

operation personnel shall wear the protective

respirator.

Pressure device

See Sections High Pressure Gas, Lubricating Oil

and Oil Testing Device.

Solder

The solder is the polymetal mixture, and the

melting point of the mixture is lower than the

composed metal (generally the lead and tin).

Generally, the harmful gases containing lead can

not be generated during the welding process. The

oxygen bearing acetylene flame can not be used

because the leady smog will be generated due to the

high temperature of the oxygen bearing acetylene

flame.

Some smog may be generated when the flame

is sprayed on the surface with grease, and the smog

is avoided inhaling.

Remove the surplus solder with extreme care,

and ensure that the fine lead dust is not generated,

for example, the lead dust will injure the human

body when the human body inhales. The gas mask

must be worn.

The leaking material and filings of solder must

be collected uniformly and treated rapidly to avoid

air being polluted by the lead.

Avoid uptaking the lead or inhaling the dust of

solder.

Solvent

Refer to Sections Chemical Materials, Fuels and

Fire Prevention.

The common solvent includes: propanone,

petroleum solvent oil, methylbenzene, dimethyl

benzene, chloroform and the like.

Use the clean dewaxed substance, paint, plastics,

resin and diluting agent. Some substances are

inflammable articles. The long-term contact with

the substances will make the skin dry and have

irritability. Some toxical and harmful substances

will be absorbed through skin.

If carelessly splashed into the eyes by accident, it

will have strong irritability and even lead to

blindness.

The steam or smog produced by the solvent of high

concentration which is exposed in the air will

irritate eyes and throats of people, and make people

dizzy and headachy. People will lose consciousness

when the circumstances are serious.

The steam or smog produced by the solvent of low

concentration which is exposed excessively in the

air for a long term will produce severe poison

because it is without obvious symptom.

In order to prevent the substances from spattering

onto the eyes, skins and clothing, the protective

work clothes, the protective gloves and the

protective glasses should be worn.

When using the substances, ensure that the

ventilation conditions of the field are good, try to

prevent the inhalation of the smog, steam and spray,

and keep the container sealed. It is prohibited to use

in the narrow space.

100-00-13 Overview 100-00-13

Description and Operation (Continued)

When spraying the substances with the solvent,

such as oil paint, adhesive agent, ensure that the

ventilation conditions of the field are good, if the

air ventilation is poor, use the gas mask.

The heating and combustion operation are

performed only under the manufacturer’s special

guide.

Suspended Load

Warning: it is prohibited to piece together

the hoisting device temporarily.

When the heavy article is raised or suspended, there

is dangerous. Never operate under the objects

without being supported, suspended or raised, such

as the suspended engine.

Ensure the equipment such as the hoisting devices

of hoisting jack, lifter, axle stand and assist strap to

be intact, and regularly inspect them.

Sealing on Vehicle Base

Refer to the Section Corrosion Preventing Material.

Welding

Refer to Fire Prevention, Electric Shock and High

Pressure Cylinder.

The welding procedures include (resistance welding)

spot welding, arc welding and gas welding.

Resistance Welding

The spot welding will release plentiful high speed

melting metal grains, so pay attention to protect

skins and eyes.

Arc Welding

During the arc welding, there has a great amount of

ultraviolet radiation, and the ultraviolet radiation

will damage the skins and eyes of the operators and

the nearby staff. The gas shielded welding is

extremely dangerous, so the personal protective

clothes should be wore, and the protective screen

should be used to protect other people.

The contact glasses wearer is suggested to wear

the normal glasses when using the arc welding.

The arc light will release microwave which will

make the space between the cornea and the

glasses of the contact glasses wearer dry, even

lead to blindness.

There will be metal splashing during the use of the

arc welding, so the correct protection measures for

the eye and the skin should be taken.

When the welding core or its protective layer is

polluted, the heat quantity of welding arc light will

enable the metal melting pond to produce smog and

gases during the welding, the gases may have

poison, thus avoiding inhaling the gases. The toxic

gases within working area muste be eliminated,

especially when the air circulation is poor and the

large quantity of welding is known in advance. The

oxygen mask should be worn while welding is

performed under the special cases or in the small

section.

Gas Welding (Gas Cutting)

The oxuacetylene furnace will be used for cutting

during welding and cutting, be cautious to the

leakage of the gases, and carelessness will lead to

combustion and explosion.

When the gas welding is adopted, the metal

splashes will be produced, thus the proper

protective measures for the skins and the eyes must

be taken.

The welding flame is much glared, so the eyes must

be protected. As the ultraviolet light produced by

the gas welding is less than that produced by the arc

welding, the protective glasses can be used.

When the gas welding is adopted, some harmful

gases may be produced, but the harmful gases are

produced by the welding coating, especially the

cutting damaged parts. Avoid inhaling the gases.

During the braze welding, the metal in the braze

welding bars will produce harmful gases, and it is

extremely dangerous if the braze welding bars have

cadmium. Be extremely cautious to avoid inhaling

the harmful gases when the circumstances happen,

and ask for help from specialists.

The special preventive measures should be taken

before any welding or cutting in the automobile

with inflammable materials (such as the fuel which

is volatilized or boiled away from the oil tank).

Warning Signs on Vehicle

The warning signs will be seen on the various

automobile components.

It is prohibited to move these signs. The owner of

the vehicle or the maintenance staff should pay

attention to the warning signs.

The marks of most commonly seen warnings are as

follows and are attached with notes.

100-00-14 Overview 100-00-14

Description and Operation (Continued)

1. The above figure shows that the relevant parts of

the special instruction manual should be referred

while contacting or trying to adjust and maintain

any components.

2. The above figure indicates that the internal high

voltage should be watched out. It is prohibited to

touch the engine or ignition device which is running.

Refer to the Section Electric Shock.

3. This mark shows that the corrosive materials in

the components should be watched out. Please refer

to Section Acid and Alkali Metals.

4. The mark shows that there are inflammable and

explosive fluids or steam nearby. It is prohibited

to use open fire. Refer to Section Fire Prevention.

5. The mark (usually connected with the above 5

warning signs) shows that there are objects which

will explode nearby.

6. The mark shows that kids are not allowed to

enter the place without management.

Petroleum Solvent Oil

Refer to the Section Solvent.

100-00-15 G

eneral Introduction

100-00-15

Instruction and Operation

Standard Workshop Operating Manual

Automobile in Maintenance Workshop

When the automobile in the maintenance workshop

is maintained, the following items shall be ensured:

– Apply parking brake or fix the wheel in order to

avoid the automobile moving forward and

backward.

– Take off the ignition key during the front

operation of the automobile.

– If the automobile engine will be started, ensure

that the field ventilation is good, or exhaust the

waste gas with the waste gas centralized

exhausting pipe.

– Enough space should be needed to hoist the

automobile for replacing the tyres if necessary.

– The fender flap pad should be provided during

the maintenance in the engine compartment.

– Firstly cut off the power source of battery when

the engine is maintained or the maintenance or

automobile hoisting is performed at the vehicle

base.

Warning: firstly cut off the generator

wiring harness when the arc welding of the

automobile are performed in order to avoid

possible and excessively strong current which

may damage the generator internal

components.

If the welding device is used in the automobile,

the extinguisher should be placed nearby.

Traction Automobile

Warnings: During the traction process of

the automobile, the ignition switch of automobile

must at the position II. (Open the steering lock

and start the indicating lamp), and thus the

steering lamp, the loudspeaker and the brake

lamp can operate normally; otherwise, the

personal injury can be caused.

Notes: The movable towing hook is provided with

a left rotating thread, and the left rotating thread

must be screwed completely before the traction

automobile. When the traction automobile is

required, the traction hook shall be adopted. The

hook must be fastened firmly through the traction

rope, and the traction rope must be connected on

the other automobile, to avoid the vehicle body

entangled with the rope.

When the automatic speed-changing automobile is

dragged, the gear position must be at the N position.

The pulling speed of the automatic speed-changing

automobile can not exceed 50 km/h or the trailer

car distance can not exceed 50 km. If the distance

of the traction automobile must be ultra-long, the

driving wheels must lift off completely.

The automobile can be transported through the

trailer car with the low boarding or the traction

automobile.

Connect the auxiliary battery through the

jumper wire

Warnings: If the auxiliary battery has been

charged and processed with gas, during

connecting with the jumper wire, the upper

ventilator of the plug or the wet clothing cover

shall be adopted, thus the explosive hazard

caused by the ignition of the electrical arc is

reduced during connecting with the jumper wire.

If the operation is not achieved according to the

procedures, the personal injury can be caused.

Warnings: The battery can be discharged

due to the current short circuit, and if the

electric discharge phenomenon exists, the

energized circuit still exists in the automobile

after the normal circuit is cut off. When the

jumper wire is connected, the casing of the

battery can be distorted.

Warnings: When the vehicle is not

required to jump and start, it can be

considered as the only feasible method to start

the vehicle if necessary. On this condition, the

discharged battery must be charged

immediately again after jumping and starting,

to avoid the permanent damage.

– Check whether the jumper wire can bear load,

and use the heavy-load conducting wire.

– Ensure that the auxiliary battery shall have the

identical voltage with the vehicle battery. Two

batteries must be connected.

– Before the jumper wire is connected, check

whether the circuit of available switch control is

cut off. Thus, when the final connection is

performed, the danger of electrical arc generated

can be reduced.

100-00-16

General Introduction

100-00-16

Instruction and Operation (Continued)

Warnings: When the conducting wire is

connected onto the battery, check whether the

terminals of jumper wire are not contacted

mutually or connected with the ground through

the vehicle body. If the battery charged

completely can charge by over 1000 A current

and generate strong electrical arc during the

short circuit through the

jumper wire. The fast

heating of jumper wire and binding post even

can make the battery explode. If the operator

does not conform to the rules, the personal

injury can be caused.

Connect the jumper wire according to the following

sequence:

– Firstly connect the anode of the auxiliary battery,

and then connect the anode of the automobile

battery.

– Connect the cathode of the auxiliary battery, and

then the other end is connected at the ground

terminal at least 12 inches (300 mm) away from the

automobile battery terminal, such as on the engine

hoisting ear.

Before the jumper wire is disconnected, the engine

speed shall be reduced.

Before the jumper wire is removed from the

automobile of the battery without being fully

charged, open the air heater or the wind blower of

the rear bumper glass, to reduce the high voltage

generated during disconnecting the jumper wire.

Disconnect the jumper wire according to the

sequence opposite to the connection and the short

circuit can be avoided by all means at the rear end

of the jumper wire

.

The electric quantity of battery can be restored by

the engine, because if the engine is used to charge,

the engine must work continuously for over 8 hours

when the battery is without any other loads.

Component Cleaning

In order to avoid dirtying the entry, the dirt

accumulation, grease, the decomposing component

or the assembly shall be eliminated before

disconnecting the jumper wire.

During the reassembly, the components shall be

cleaned carefully and then checked and assembled.

Cleaning Method:

– Dry cleaning

– Eliminate accumulated dirt with the soft brush.

– Raze dirt with the sheet metal or the batten.

– Wipe with the cleaning cloth.

Warnings: The water content of

compressed air is high sometimes, so pay more

attention when the compressed air is

particularly used in the hydraulic system.

–Clean dirt with the compressed air. (When being

in this method, a pair of protective glasses shall

be worn.)

–Clean dry dust with the cleaner. The method is

usually used to clean dust of the friction disc.

–Steam cleaning method.

Warnings: Most of melting agents are

harmful for the human body, thus the

processing shall be performed cautiously. See

“Safety and Health Precautions” and Safety

Protection Instructions of the Manufacturer. If

the operation is performed without conforming

to the specification, the injury will be brought

for the human body.

There is abundant melting agent suitable for

cleaning the components. Some components are

listed such as the braking hydraulic pressure

element, the electric assembly, etc, and the

cleaning is performed with the electric assembly.

Please see “Melting Agent, Sealing Agent and

Adhesive Agent” and relevant manuals.

Calibration of the important measuring equipment

Warnings: If the operation is performed

without conforming to the following suggestion,

the personal injury or the damage of the

components can be caused.

Some important equipment are important properly,

such as the torque spanner, the universal meter,

the waste gas analyzer and the check line, etc, and

the equipment must be calibrated regularly

according to the guiding of the manufacturer.

Table of contents

Other Changan Automobile manuals