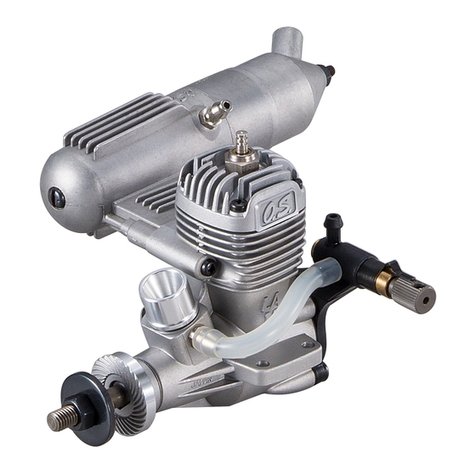

Changchai V402 Series User manual

Changchai brand

V402/3M78/M403TCI series

Multi-cylinder national four diesel

engine maintenance manual

Production license:XK06-002-00185

Implementation Standards:

Q/320400CC044、 Q/320400CC070

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

Preface

Thank you very much for purchasing Changchai diesel engine, in order to ensure better

performance and safe operation of the diesel engine, please read this instruction manual in detail

before you use the diesel engine.

Changchai brand diesel engine is widely used as the ideal power for tractors, harvesters,

construction machinery, generator sets, tricycles and other machinery.

Changchai brand diesel engine has superior quality level, plus the user - your correct operation and

regular maintenance according to the provisions, do not make the diesel engine with disease operation,

Changchai brand diesel engine will be able to help you to make a fortune.

With Changchai brand diesel engine series deformation varieties continue to increase and change,

for the content can not be exhaustive notice, please prevail in kind, please pay attention to the majority

of users and understanding.

⊙Please note that you should pay attention before using:

Before you start using the diesel engine for the first time, please read the manual carefully, which

includes very important instructions on diesel engine installation, use and safety.

①Please follow the manual strictly for break-in, use and maintenance.

②The cooling system must use qualified coolant, otherwise the resulting failure will not be free of

warranty.

③Use lubricant (oil) of the required level, otherwise the resulting failure will not be free of warranty.

④It is strictly forbidden to run the diesel engine without air filter, the unfiltered air into the diesel

engine will cause early wear and tear of the diesel engine and can not work normally.

⑤The electrical wiring must be correct and firm.

⑥After 50 hours of break-in, clean kerosene or diesel oil should be used to clean the oil pan, replace

the oil filter, and replace all the oil.

If you do not follow these instructions, the factory will not be responsible for any problems with the

diesel engine once they occur.

Prohibit children, slow-moving elderly people and other (after drinking, etc.) non-normal ability to

approach and operate the diesel engine.

⊙In Use:

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

1. Each time you start the diesel engine, must idle (3 ~ 5) minutes, after the normal operation of the

diesel engine parts, before running high-speed operation. Do not allow cold suddenly increase the

throttle, otherwise it will damage the corresponding parts, accelerate the damage to the diesel engine

moving parts (supercharger, etc.), thus shortening the service life of the diesel engine.

2. Strictly according to the nameplate on the calibration power and speed for the correct package,

prohibit over-speed, overload or long-term operation under low load, low speed. It is forbidden to use

the diesel engine unattended.

3. When the diesel engine is working, the temperature of the supercharger, exhaust pipe, muffler,

radiator, etc. is high, so special attention should be paid not to touch the running parts (flywheel, starter

shaft, pulley, etc.) to prevent injury, the fuel tank (diesel) should pay attention to fire prevention, and

the exhaust port should not face flammable materials to avoid danger.

4. Regularly check the tightness of the fastening bolts of the diesel engine connection, and tighten them

in time when they become loose.

5. Pay attention to the oil pressure and cooling water status of the diesel engine in time during

operation to prevent malfunction.

6. It is strictly forbidden to stop the engine suddenly at high speed and under large load, and stop it

after idling for (3-5) minutes. Otherwise, it will damage the zero part (supercharger, etc.) and other

moving parts, thus shortening the service life of the diesel engine.

⊙Maintenance:

1. The air filter should be cleaned and maintained in time, and should be cleaned and maintained daily

in harsh environment.

2. Replace the lubricating oil regularly according to the specification, and clean the diesel engine filter

and oil filter screen regularly.

⊙If you purchase a diesel engine with after-treatment device, please note the following to avoid

unnecessary damage to you.

If non-compliant diesel fuel is used, the following failures and risks may result.

(1) Injector carbon accumulation, gumming, deterioration of engine performance, resulting in higher

fuel consumption and frequent DPF regeneration.

(2) After-treatment poisoning failure, leading to frequent regeneration.

(3) DPF regeneration, the internal temperature is too high, leading to DPF cracking, burning melt and

other damage, which may lead to fire in serious cases.

If non-compliant oils are used, the following failures and risks may result.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

(1) Engine exhaust back pressure increases, performance deteriorates, and fuel consumption increases

(2) DPF regeneration cycle is shortened and regeneration is frequent.

(3) DPF regeneration, the internal temperature is too high, resulting in DPF cracking, burning melt and

other damage, which may lead to fire in serious cases.

▪Users are requested to buy diesel and oil from regular gas stations and keep relevant supporting

documents, such as gasoline invoices, etc.

▪We do not assume warranty obligations for engine related failures caused by the use of

non-compliant diesel or engine oil!

▪Users are recommended to contact Changchai after-sales service department for after-treatment

desulfurization, ash cleaning maintenance and other paid services every 1500 hours of use.

Special Note: Be sure to use the diesel engine safely!

To prevent entanglement, scalding and fire, pay attention to the safety signs pasted on or near the

relevant parts of the diesel engine!

Caution.

1. The user must add safety protection devices at the corresponding dangerous hazards for the content

of the diesel engine safety warning decal before use.

2. Users need to pay special attention to check that the hose and pipe connections are not damaged by

heat and vibration; when filling flammable liquids, do not allow flammable liquids to come into contact

with high temperature surfaces, electrical components or rotating parts.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

Warning Markers

This instruction manual and the safety warning marks used on the product and their meanings are as

follows.

Danger Dangerous means that the situation is critical and, if not avoided, could result in serious

personal injury or casualty.

Warning Warning means that there is a potential hazard which, if not avoided, could result in serious

personal injury or death.

Caution Caution means that there are potential hazards which, if not avoided, could result in minor

or moderate personal injury.

The descriptions beginning with "CAUTION" are particularly important safety precautions, and if you

ignore them, the performance of the diesel engine may deteriorate or even lead to failure.

Safety Precautions

(1) For your safety, please observe the following precautions regarding operation.

Warning Failure to follow the instructions in this manual for proper operation may result in serious

equipment damage, personal injury or casualty.

▪Check for fuel leaks or spills. If so, stop the engine and scrub it clean or make repairs.

▪Do not put other oils and objects that can easily catch fire near the diesel engine.

Warning Do not touch the electrolyte of the battery

▪Be careful not to expose your eyes and skin to the electrolyte. The electrolyte of the battery is dilute

sulfuric acid, which can burn the skin. If you accidentally come into contact with the electrolyte, rinse

immediately with plenty of water.

▪Proper ventilation of the battery area and the area around the battery must be well ventilated. Take

care to keep the battery away from ignition sources, as the battery will volatilize flammable hydrogen

gas during charging.

▪Fires from fuel fires: Place fire signs near fueling outlets.

▪If the use of gasoline or other similar products can cause fuel fire.

▪Be sure to shut down first, then refuel.

▪Do not put fuel or other flammable items near the diesel engine, as this may cause them to catch fire.

▪Stay away from moving parts: When the diesel engine is running, be especially careful not to touch the

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

moving parts. If other parts of the body or clothing near the moving parts, once the cooling fan,

flywheel or output shaft hooked, may cause personal injury. Users of diesel engines exposed moving

parts should be equipped with protective devices.

▪Avoid contact with hot parts of the diesel engine when operating to avoid scalding.

Warning Exhaust gas is toxic

▪Good ventilation must be ensured when the diesel engine is running. Do not close windows, vents or

other ventilation facilities. Inhalation of exhaust is hazardous to health.

▪Never operate a diesel engine in a narrow room, in a passage, in a basement or in a boat cabin.

Exhaust is difficult to remove in these places and is very harmful to personal health.

▪When users use the exhaust port or the exhaust pipe, they should install a protection device. When

the diesel engine is running or just after the diesel engine is shut down, be careful not to let your body,

hands or clothes touch the muffler, exhaust pipe and the body of the diesel engine. Because at this time

the whole diesel engine is hot, once contact can cause burns.

Warning Do not operate diesel engines after drinking

▪Do not operate the diesel engine after drinking or when you are unwell, otherwise accidents are likely

to occur.

(2) Safety precautions regarding inspections

▪Before checking the electrical system, be sure to turn off the battery switch or disconnect the negative

lead. Otherwise, it will cause a short circuit and fire.

▪Be sure to shut down the diesel engine before servicing it.

Warning Avoid scalding when changing oil and hot water

▪If you must drain the oil while the engine is hot, be careful not to splash the oil on people to prevent

burns.

▪An anti-scald sign should be placed near the overflow of the water tank. Be sure to wait for the water

temperature to drop before discharging the cooling water, otherwise the hot water may splash on

people and cause scalding accidents.

Warning Beware of the dirt brought by blowing

▪When using compressed gas, you must wear protective equipment: such as wind goggles to protect

your eyes, because dust or flying debris can hurt your eyes.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

Warning

(3) Disposal of waste

▪Put the used oil into a suitable container. Do not pour used oil directly outdoors, into sewers, rivers or

the sea.

▪Disposal of waste must comply with the relevant legal regulations. Hand over the waste to a

professional waste recycling company for centralized disposal.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

1 Main technical specifications and technical data of

diesel engines

1.1 Main technical specifications of diesel engines

Model V402 3M78 M403TCI

Type Inline, water-cooled, four-stroke, direct injection

Air intake method Naturally aspirated Pressurized

intercooling

Number of cylinders

2 3

3

Cylinder diameter×piston

stroke(mm) 80×79 78×85 78×85

Total Displacement(L)0.794 1.218 1.218

Rated net power/speed

(kW/ r/min)

7.5

~ 16

/

1500

~ 3600

9.5

~

18.5/

1500

~ 3600

18.5

~

35/

1500

~ 3200

Maximum torque(N.m)55 80 145

Compression ratio 19:1 17.5:1

Firing order 1-2 1-2-3

Valve

clearance

(cold)

Intake valve(mm)

0.18~0.22 0.15~0.20 0.20~0.25

Exhaust valve(mm)

0.23~0.27 0.15~0.20 0.20~0.25

Minimum adjustable no-load

s

p

eed

(

r

/

min

)

1200±50 850±50 900±50

Lubrication method Pressure, splash compound

Crankshaft rotation direction Counterclockwise (facing the power output)

Calibration speed oil

pressure(kPa)

200~400

Oil pressure at idle(kPa) ≥100

Oil temperature(℃) ≤110

Exhaust temperature(℃) ≤650

Starting method Electric start

Net Quality (kg)

60 115 125

Note: According to different matching needs, some technical parameters, net

quality, etc. may be changed. The detailed model and power speed parameters

of diesel engine are shown on the nameplate.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

1.2 Tightening torque of main bolts and nuts

V402 3M78 M403TCI

Cylinder head bolts(N·m) 55

~

60 80

~

90

Main bearing cover bolts(N·m) /45

~

50

Connecting rod bolt(N·m) 26

~

30 50

~

55

Flywheel bolts(N·m) 75

~

85 80

~

90

Belt pulley bolts(N·m) /110

~

130

Injector end high pressure fuel

line(N·m) 25

~

30

Injection pump end high pressure oil

pipe(N·m) 25

~

30

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

2 Notes on the use of electronically controlled fuel systems

2.1 Electronically Controlled Common Rail System

The structural components and operating principles of the common rail fuel injection

system.

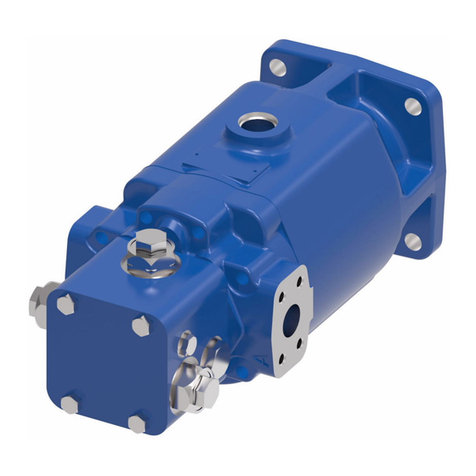

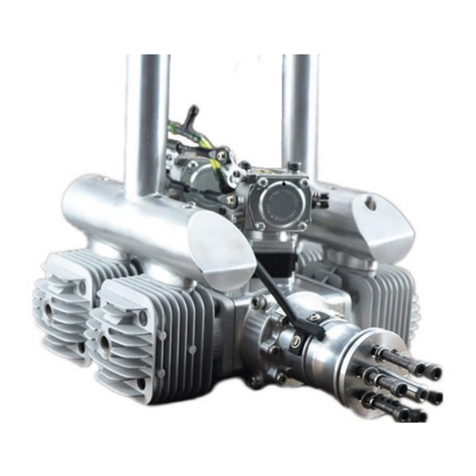

2.1.1 Structure and composition of common rail fuel injection system

The following figure shows the structural composition of the high pressure common rail

fuel injection system. The high pressure common rail fuel injection system consists of a low

pressure fuel supply section, a high pressure fuel supply section, a high pressure common rail

section, a fuel injection section and an electronic control section. Any replacement or

adjustment work must be carried out by professional personnel.

Diagram of the structural components of the common rail fuel injection system

(1) Low pressure fuel supply section

The low pressure fuel supply part consists of fuel tank, fuel pump, oil-water separator, fuel

pipeline and return pipeline. The role of this part is mainly to suck out and filter the fuel from

the tank and deliver it to the high pressure fuel pump.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

(2) High-pressure fuel supply section

The high-pressure fuel supply part consists of high-pressure fuel pump, pressure control

valve, fuel metering valve, etc. The role of this system is to further pressurize the fuel sent from

the fuel pump and deliver it to the high-pressure fuel pipe, and the fuel pressure at the outlet

of the high-pressure fuel pump can reach 160-200MPa.

(3) High pressure common rail section

The high-pressure common rail part consists of high-pressure fuel pipe, common rail pipe

and rail pressure sensor, pressure regulator and flow restriction valve installed on the common

rail pipe. Its function is to accumulate the high-pressure fuel from the high-pressure pump,

eliminate the pressure fluctuation in the fuel, and deliver the fuel to each injector.

(4) Fuel injection section

The fuel injection part consists of the injector and the control solenoid valve integrated in

the injector. This part controls the injection timing and injection volume by controlling the

opening and closing time of the solenoid valve.

(5) Electronic control section

The electronic control part consists of electronic control unit, sensors and actuators. This

part controls the actuator action according to the working condition signal of the diesel engine.

The main role of diesel engine electronic control is to control the injection volume, control the

injection advance angle and injection pressure. In order to improve the power, economy and

exhaust performance of the diesel engine, the electronic control system also includes the

electronic control of the intake and exhaust system.

2.1.2 Principle of operation of common rail fuel injection system

As shown in the figure below, the injector is connected to the common rail tube through

the high pressure fuel line, and the rail pressure sensor on the common rail tube reflects the

current oil pressure value. The common rail tube is connected to the high pressure oil pump

through the high pressure fuel line, and the high pressure oil pump is responsible for providing

high pressure oil to the common rail tube (injector). In front of the high-pressure oil pump

plunger there is a solenoid valve that controls the amount of oil entering the plunger. The

opening of the solenoid valve determines the amount of oil entering the plunger, thus indirectly

controlling the common rail pressure.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

Principle of operation of common rail fuel injection system

When the ignition switch is turned on, the starter motor drives the diesel engine to rotate

and the low-pressure fuel pump starts to pump fuel to the high-pressure fuel pump. When the

pumping pressure of the oil delivery pump is greater than the spring force of the regulator

installed on the high-pressure oil pump, the regulator will be opened and the low-pressure fuel

will enter the oil channel of the high-pressure oil pump and connect to the plunger chamber of

the oil pump through the oil channel in the high-pressure oil pump. When the camshaft of the

high-pressure oil pump rotates, the plunger moves up and down reciprocally to pressurize the

low-pressure fuel. The pressurized fuel enters the high-pressure fuel line, at which time the ECU

adjusts the opening of the solenoid valve according to the internal setting data and the current

rail pressure value from the rail pressure sensor, so that the current rail pressure value is equal

to the pre-set value, thus independently controlling the injection pressure. The solenoid valve

on the common rail injector controls the start and stop of fuel injection. the ECU gives the

solenoid valve power, the injector starts to inject fuel, the ECU gives the solenoid valve power

off, the injector fuel injection stop, the length of time the solenoid valve is energized

determines the amount of fuel injection.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

Common Rail Fuel Injection System Control Strategy.

Schematic diagram of ECU function structure

The common rail system uses an electronic control unit (ECU) for optimal injection control

and related diesel engine and vehicle functions based on various sensor signals monitored in

real time and dynamically optimized calculations by the built-in diesel engine management

system program.

The ECU uses the signals provided by the sensors to be informed of the requirements of

the motorist (as determined by the gas pedal position) and the instantaneous operating

conditions of the diesel engine and the vehicle as a whole. Based on these inputs and the

stored characteristic profiles, the duration and start point of the injection are calculated. The

injection start point, injection duration and injection pressure are calculated by the ECU and

with the help of output signals trigger the drive stage, which provides the appropriate power to

the actuators for controlling the common rail pressure, injector elements. the ECU also has a

complete calibration, testing and fault diagnosis system, fully meeting the OBD regulatory

requirements, supporting post-processing control, in addition to other control functions (air

conditioning, fan, electric heating plugs, etc.). The common rail system diesel engine has the

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

advantages of low fuel consumption, low emission and high power, meeting the requirements

of customers and emission regulations for diesel engines. the ECU supports diesel engine

management modules such as intake system, exhaust after-treatment system, as well as vehicle

speed, gears and other functions, realizing the integrated management of diesel EFI control

system.

The ECU of common rail system mainly consists of input signal processing module, CPU,

output control module, communication module and so on. As shown above is the schematic

diagram of ECU function structure.

2.2 Electrical control system wiring harness

The wiring harness is the link between the ECU and the fuel supply system, once it fails,

the whole system will work in abnormal or stop working condition. Therefore, it is forbidden to

make any modification to the diesel engine wiring harness. All consequences caused by the

user's own transformation of the wiring harness will be borne by the user.

2.3 In order to ensure the normal operation of the electronic control system, the following

matters should be noted when using.

(1) The system is strictly calibrated and there is no part for the user to adjust, and the user is

not allowed to change the system status at will to cause deterioration of emissions.

(2) The system needs to use a DC power supply that matches the system, do not use other

specifications of power supply, so as not to damage the electronic control components.

(3) Ensure that all electric control components and connectors are dry and clean.

(4) Do not plug and unplug the electrical control components harness connectors at will to

avoid loosening or poor contact causing abnormal work. Do not change the direction of the

wiring harness, the fixed policy and the diameter of the wires inside the harness without

permission.

(5) If the user needs to remove the parts in the injection system because of adjusting other

parts of the diesel engine, please go to the professional maintenance unit to deal with it.

(6) When users have questions about the state of the electronic control and maintenance,

please go to the professional maintenance unit to deal with.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

(7) When it comes to the failure of oil supply system parts or electronic control system parts,

please go to the professional maintenance unit to deal with it.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

3 Use and operation of diesel engines

3.1 Precautions for use

(1) Use should be adjusted and maintained in accordance with the maintenance methods and

regulations introduced in this manual.

(2) Not allowed to start immediately after full load work at high speed, must be gradually

transition from low-speed no-load to high-speed full load.

(3) The fuel used by the diesel engine must be clean and should be left to settle for more than

72 hours.

(4) Maintain the normal water temperature (75 ℃~95 ℃). release the cooling water must first

open the radiator cap (must wait for the water temperature to reduce before opening.

To avoid scalding), and then unscrew the water release switch on the cylinder block.

(5) Medium speed when the normal oil pressure should be 0.25 ~ 0.55MPa.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

(6) Must strictly control the weight of the load, do not allow overload, otherwise it will affect

the reliability and service life of the diesel engine.

(7) Newly installed or replaced injectors should be medium-speed low-load break-in, the

break-in time should not be less than 30 minutes.

(8) In the process of operation, such as the discovery of abnormal phenomena, to stop in time.

(9) The new machine or after overhaul, the diesel engine needs to be broken in.

3.2 Fuel, oil and cooling water

3.2.1 Fuel

Users should select the diesel fuel grade used according to the season and ambient

temperature of the region.

The selection of fuel type should be in accordance with the regulations of motor diesel (VI)

in GB19147.(See the following table)

Diesel fuel grade 0# -10# -20# -35# -50#

Minimum Operating

Temperature(℃)

4 -5 -5~-14 -14~-29 -29~-44

Diesel refilling and precautions

Diesel fuel must be left to settle for more than 72 hours before injecting into the diesel

engine, and then take off the upper layer of clean diesel fuel without water and impurities or

filter with silk cloth.

Warning:

(1) When the engine is running, do not fill the tank with fuel.

(2) Do not smoke when filling the tank with diesel fuel, no open fire in the surrounding area.

(3)Use a clean fuel pipe when refueling, do not spill the diesel fuel outside.

(4)Wipe off the spilled fuel, and the material with fuel must be moved to a safe place.

3.2.2 Lubricants

Motor oil should be CJ-4 grade and above.

The viscosity of the oil is greatly affected by the temperature, so the user should choose

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

the correct viscosity of the oil according to the ambient temperature, see the following chart.

In order to keep your engine in good condition, users should try to use high quality diesel

engine oil.

Warning: Different brands of engine oil should not be mixed at the same time.

3.2.3 Cooling water

If you use well water, spring water or other mineral hard water, you should add the right

amount of softening agent, such as sodium carbonate (soda ash), sodium hydroxide (caustic

soda), etc. The easiest way to deal with the water is to boil it after precipitation to remove

impurities and then use it.

The most commonly used antifreeze is ethylene glycol (glycol) aqueous solution or

alcohol.

The use of antifreeze should be noted:

△Since antifreeze has the characteristic of increasing in volume with the increase in

temperature, when adding cooling media, the amount added should be 5% to 6% less than the

total capacity of the cooling system.

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

△The boiling point of ethylene glycol is 194.4℃, so the water in the antifreeze is easy to

evaporate, so it should be filled with clean water after using for a period of time.

△If it is not rust-proof antifreeze, the scale should be removed frequently.

When the diesel engine used for a long time, the surface of the cooling water cavity will

form scale, affecting the heat dissipation of the diesel engine, for this reason should be

regularly cleaned up the scale, the removal method is as follows:

(1) Remove, will process the surface coated with butter to prevent corrosion. 25% of

hydrochloric acid solution can be injected into the water cavity, after 10 minutes of standstill,

the solution will be released, wash with water. if the scale is not removed, can be repeated

again.

(2) According to each liter of water plus 75 ~ 80 grams of caustic soda (NaOH) weight ratio

of the solution, injected into the water cavity, then start the diesel engine, running at medium

speed for 10 minutes, the solution in the water cavity for 10 ~ 12 hours, and then start the

diesel engine, running at medium speed for 10 minutes, release the solution, wash with water.

if the scale is not clean, can be repeated.

Note: The above description is for reference only, please consult with the supplier for the

specific antifreeze to be filled.

Coolant refilling and precautions:

Fill the cooling water to the mark of the fill port.

Take care to close the drain valve after cooling water flows from the drain valve.

Tighten the filler cap.

Start the engine and run it to normal temperature until the thermostat opens (the cooling

water pipe becomes visibly warmer at high cycle).

After the first run, stop cooling and check the level of the liquid.

3.3 Pre-start inspection and preparation

(1) Before starting the new engine for the first time, check carefully whether the fastening

connection of each part is loose, whether the accessories are complete, and whether the

operating mechanism is flexible.

(2) Check the oil level of the oil sump, it should be between the upper limit mark and the

lower limit mark of the oil dipstick, please refer to the main technical data of the diesel engine

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

for the oil sump storage quantity.

(3) Check the amount of oil stored in the fuel tank, open the fuel tank switch, make the

diesel oil flow to the diesel pump, and eliminate the air in the fuel system.

(4) Check the battery and connection line.

(5) Check the cooling system and add enough water.

(6) In case of cold and freezing weather, the diesel engine should be placed in the

anti-freezing and cold site, and when working in the field, the oil pan should be baked before

starting and hot water should be added two or three times to make the diesel engine warm.

(7) The diesel engine should be started so that the load is in the disconnected state.

3.4 Startup

The starting procedure is as follows:

(1) Turn the lock switch to start the diesel engine, each start time should not exceed 15

seconds to protect the starter and battery. If the diesel engine fails to start for 3 times in a row,

the cause should be identified and eliminated before starting again.

(2) After starting should immediately check the oil pressure. diesel engine at idle, the oil

pressure can not be less than 0.05MPa. newly assembled diesel engine 5 minutes after starting,

stop to check the oil sump oil surface, add oil if necessary, so that the oil surface between the

upper and lower mark on the dipstick.

(3) Within one minute after the diesel engine starts, should immediately check the water

temperature table to confirm the normal operation of the cooling system.

3.5 Operation

(1) After the diesel engine start, should not be immediately full load operation, should

make the diesel engine in low speed and no-load operation at medium speed in turn heating.

(2) When running, should always pay attention to the oil pressure and cooling water

temperature. calibration speed, oil pressure should be in 0.25 ~ 0.55MPa, cooling water outlet

temperature control in 75 ~ 95 ℃or less.

(3) The diesel engine running should always pay attention to observe the instrument panel

readings are normal, there is no abnormal sound, such as found, should immediately stop to

check, find out the reasons for allowing the start and run again.

(4) Often pay attention to the oil circuit, the water circuit connection sealing, such as

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

版权归常柴股份有限公司所有

This manual suits for next models

2

Table of contents

Other Changchai Engine manuals