5

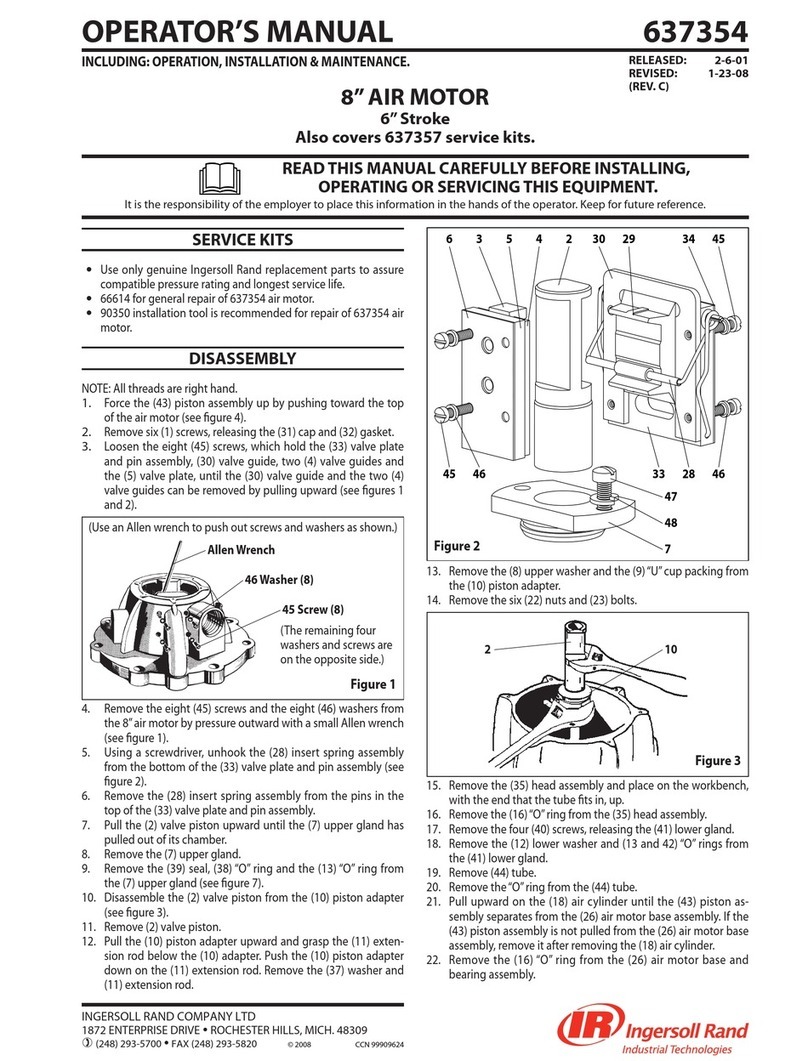

GENERAL REPAIR INSTRUCTIONS

1. Before performing any service operation with the engine mounted, disconnect the grounding cable

from the battery.

This will reduce the chance of cable damage and burning due to short circuiting.

2. Always use the proper tool or tools for the job at hand.

Where specified, use the specially designed tool or tools.

3. Use genuine INGERSOLL-RAND parts.

4. Never reuse cotter pins, gaskets, O-rings, lock washers, and self locking nuts. Discard them as you

remove them. Replace them with new ones.

5. Always keep disassembled parts neatly in groups. This will ensure a smooth reassembly operation.

It is especially important to keep fastening parts separate. These parts vary in hardness and design,

depending on their installation position.

6. All parts should be carefully cleaned before inspection or reassembly.

Oil ports and other openings should be cleaned with compressed air to make sure that they are

completely free of obstructions.

7. Rotating and sliding part surfaces should be lubricated with oil or grease before reassembly.

8. If necessary, use a sealer on gaskets to prevent leakage.

9. Nut and bolt torque specifications should be carefully followed.

10. Always release the air pressure from any machine-mounted air tank(s) before dismounting the engine

or disconnecting pipes and hoses. To not do so is extremely dangerous.

11. Always check and recheck your work. No service operation is complete until you have done this.

NOTES ON THE FORMAT OF THIS MANUAL

This workshop manual is applicable to the Ingersoll Rand L series 3 and 4 cylinder industrial engines, namely

the 3IRL2N, 3IRL4N & 4IRL5N models.

A large majority of components, parts and data specifications are common within the L series, and for

simplicity, the illustrations are based on the 4IRL5N engine. Where there are differences or exceptions for

individual models, the relevant illustrations and / or data tables are clearly identified with the appropriate engine

model to which they apply.

1. Find the applicable section by referring to the Table of Contents at the beginning of the Manual.

2. Common technical data such as general maintenance items, service specifications, and tightening

torques are included in the General Information section.

3. Each section is divided into sub-sections dealing with disassembly, inspection and repair, and

reassembly.

4. When the same servicing operation is applicable to several different units, the manual will direct you to the

appropriate page.

5. For the sake of brevity, self-explanatory removal and installation procedures are omitted.

More complex procedures are covered in detail.

GENERAL INFORMATION