Changchai L26 User manual

L26/L28/L30/L32

DIESEL

ENGINE

-changchai

OPERATION

MANUAL

CONTENTS

~reface(To

the Customers)

Overall and Mounting Dimensions of L26/L28/L30/L32 Diesel Engines

Overall and Mounting Dimensions of L26M/L28M/L30MIL32M Diesel Engines

Schematic Drawing of Lubrication System

Section IPrincipal Technical Specifications and

Data·····················

(1)

Section II Mounting of the Engine and Coupling of the Driven Machine with

the Engine ··········································································· (3)

Section mOperation of the

Engine·············································

(4)

Section WAdjustment and Maintenance of the

Engine············

(7)

Section VElectrical Starting

System··········································

(12)

Section

VI

Defects and

Elimination·············································

(14)

PREFACE

(To the Customers)

Many

thanks for your purchasing our CHANGCHAI brand L261L281L301L32 diesel engines.lt is

recommended that the operator,before operating the engine,reads the manual carefully.

CHANGCHAI brand L261L281L30/L32 diesel is of single cylinder,horizontal,four -stroke,water

coolded,direct injection engine.The L261L28/L30/L32 diesel engines have the advantage of more

powerful output,higher torque reserve,lower fueVwater consumption,easy starting,high safety coefficient,

reliable operation,convenient maintenance and wide applications.

L261L281L30/L32 diesel engines have the same dimensions,power take-off and operation method as

the predecessor ZS1125.They are suitable

for

powering small sized

4-wheel

tractors,boats,engineering

machinery,they can also be used as aprime mover

for

transportation vehicles,small electric generators

and agricultural processing machines.

For noraml,reliable and safe operation of the engine,it is hope that the operator,when operating the

engine,pays close attention

to

the following:

l.1t is forbidden

to

touch high temperature parts such as water hopper and silencer,and moving parts

such as flywheel and starting shaft

to

prevent being scalded and injured.Keep the fuel tank

away

from

fire and never direct the exhaust towards inflammables such as straws,haystacks and cotton

to'

avoid

dangers.

2.Children,the aged

who

acts slowly and the person

who

has abnormal behaviors are not allowed

to

enter the working site.

3.When coupled with driven machines,the engine should develop its rated output at rated speed as

specified on the name plate,avoid running the engine with overload and at overspeed or with underload

and at

low

speed for along time.lt is forbidden

to

run the engine in the absence of watchers.

4.A fuel and alubricating oil of specified grade is

to

be used,and before being used,they should be

completely precipitated and thoroughly filtered.Any utensils used herein should be kept clean.And the

used lubricating oil should be periodically changed.The element of fuel filter and the screen of sump

strainer should be periodically cleaned.

5.Fill the air filter with oil up

to

the oil level line.Regular clean,maintenance and change of oil

should be done.Especially when the engine is used

for

powering tricycles and small sized 4-wheel

tractors,operating in very windy and dusty condition,clean,maintenance should

be

done every day.

6.Clean soft water is used for cooling water.The engine is

to

operate under boiling condition of the

cooling water in the hopper.The quantity of water should always be kept in such a

way

that the red ball

of the float must not

go

down below the mouth of the funnel of the hopper.

7.Regularly check the mounting connection and fastening bolts of the engine parts for looseness.lf

any looseness is found,tighten it at once.

8.The fuel,controller fitted on the gear casing has been adjusted and sealed before engine shipment.

Do

not take off or adjust it

at

random.

9.The users must drain out completely the cooling water of the engine in winter.While the cooling

water can not be

to

drain out completely,it is necessary to screw off the

water-drain

cock or cylinder

head and must clean all the dirt.

It is hope that the operator make acorrect operation and maintenance of the engine,do not allow the

engine

to

run under abnormal condition.Then high quality Changchai brand L26/L28/L30/L32 eilgines

will certainly build up your family fortunes.

Since improvements on products and broadening of applications are made from time

to

time,your

engine may be slightly different from instructions and statements contained within this manual.They

won",!

be altered until the new revised edition is published.The users are requested to pay attention

to

this.

58'

l.:-~1..!~..LBrt!lL

\l>Qi!ndt!Cat!11_

r

I

I

I

~l

\

~

-,

~

~

1,10

1

1

I

-\

j ,

--

---t

!

II1

~

11----------..

..Jj1L

_L"=--.J

i

~-i+-J::I

!=-..m-__

r

!

l--_H~----J

J

!.

916

______.

Overall

and

mounting

dimensions

of

L261L281L301L32diesel

engines

Overall

and

mounting

dimensions

of

L26MIL28MIL30MIL32M

diesel engines

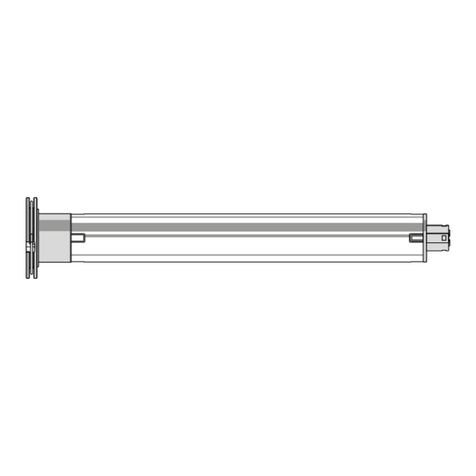

Schematic drawing of lubrication system

I.Pipe connection seat

5.Pipe connection bolt

2.Pipe connection 3.Connecting pipe 4.Sump strainer

6.Washer

7.0il

pump

8.0il

pressure indicating float

Section IPrincipal Technical Specifications

A.Technical Specifications

Items Specifications

Engine Model L26

L2S

ju6M

L28M

L30 I.J2

L30M

I.32M

Type Single cylinder.four stroke,horizontal type

Combustion Chamber Direct injection

Cylinder bore(mm) 120 125 120 125 125 130 125 130

Piston stroke(mm) 120

Piston displacement

(L

)1.357 1.473 1.357 1.473 1.534 1.659 1.534 1.659

Rated. output/Rated speed

18.51

201

18.51

201

211

23/ 21/ 23/

(kW/r/min)

2200 2200 2200 2200 2200 2200 2200 2200

Specific fuel consumption 244.8

(g/kW-h)

Specific lube oil consumption 2.04

(g/kW·h)

Cooling method Water cooled,evaporative

Starting inethod hand cranking Electrical hand cranking Electrical

Fuel injection pressure(MPa) 19.13

Net weight(kg) 205 208 217 220 210 212 222 224

Overall dimensions

(LxWxH) 916x475x709978x475x709916x475x709978x475x709

(mm)

B.Principal Technical

Data

Intake valve(mm) 0.35±O.05

Valve clearance(cold) Exhaust valve(mm)

O.45±0.O5

Fuel injection

~iming

20

o-23°before T.D.C.

Cylinder head nut(N

·m)

385-415

Connecting rod bolts(Nem) 100-120

Tightening torque of

main bolts and nuts Flywheel nut

320-370

Balancing block

100-120

bolts of crankshaft

- 1 -

C.Models

and

Specifications

of

Main Fitting Components(L26JL28)

Items Models/Specifications

Fuel injector PF68S125

Nozzle couple ZCK154S530A

Fuel injection pump B139-1

Lube oil pump Rotor type

Fuel filter C0506C

Models

and

Specifications

of

Main Fitting Components(L301L32)

Items Models/Specifications

Fuel injector PF68S125

Nozzle couple ZCK154S530A

Fuel injection pump BFIAWI05Z01

Lube oil pump Rotor type

Fuel filter C0506C

- 2 -

Section II Mounting of the Engine and

Coupling of Driven Machine with the Engine

A.Mounting

of

the Engine

The engine should be bolted

down

to

arigid base with the same mounting dimemsions as

the diesel engines of its kind(see the drawing of overall and mounting dimensions of the enigne).

The axial dimensions of the pulley of the driven machine should coincide with that of the engine

to

avoid torsion of the V-belts.

The engine and driven machine should be in

good

coupling.Protection measures of the

flywheel and belt pulley should be taken

to

avoid danger.

B.Selection

of

the Size of the Pulleys

When the engine

IS

used

to

drive working machines,the user should make acorrect selection

of the size of pulleys

to

ensure normal operation of the engine and driven machines.The size of

pulleys

may

be calculated according the following formulas:

Where Dhis the diameter of the pulley on the engine shaft(use pitch diameter in case V-belt is

used) ;

D2

,the diameter of the pulley on the shaft of the driven machine(use pitch diameter in

case V

-belt

is

used);

nl

,the rotative speed of the engine;

n2,

the rotative speed of the driven machine.

One piece of

V-belt

pulley,148mm in outer diameter,is attached

to

the engine on its delivery

from

the maker's works.Pulleys of special specifications

may

be provided through negotiation when

customer place an order.(Don't increase the diameter

to

get more efficiency and higher speed.Our

company will not .bear three guarantees responsibility for this)

- 3 -

Section

ill

Operation of the Engine

A.Preparation before Operation

1.Lubricating oil

1.1 Lubricating oil for the engine should conforln

to

the standard of GB11122-1997.Use

lubricating oil of CC20W/40 grade in summer,CC10W/30 grade

in

winter.

1.2 Lubricating oil should be stored in aclean and tight container to prevent dirt from

getting in.Before adding oil,draw out the dipstick and pour clean oil into the crankcase.The

quantity of oil added is about 4.5 litre so that the oil level in the crankcase will lie between the

two

marked lines on the dipstick.Caution:The oil level must not

go

over the upper line,nor fall

down below the lower one.

2.Diesel Fuel

2.1 Fuel for the engine should conform

to

the standard of GB252-2000.Use light diesel fuel

NO.O

in summer,No.-lO or

No.-20

in winter.

2.2 Open the fuel tank,pour into it clean diesel fuel already thoroughly precipitated and

filtered.Any utensils used herein should

be

kept clean.

2.3 Open the fuel cock.Then fuel will

flow

through the fuel filter to the injection pump.

2.4 Loosen the vent screw on the fuel injection

pUUlp

or loosen the fuel pipe connections,in

order that air,if any,in the fuel

pipe

line rnay get out.When it is noted that fuel without air

hubbIes flows out,re-tighten the vent screw

or

connections.

3.Cooling water

Clean soft water such as faIn water,snow water or river water is used.Pour it into the hopper

until the red ball of the float rises upto its top position.N·ever

use

foul water or hard water such

as well water.In case hard water has

to

be used under particular condition,a soften treatment

should be made by asimple

way

of boiling and precipitating before use.Otherwise,the blockage of

water passages or erosion of hopper Inay occur.The cooling water in the hopper should be

changed regularly and

be

free from foreign Inatter and dirt.

B.Starting the Engine

Acareful check should

be

made after preparations mentioned above have been done.Then

start the engine according to the following procedure.

1.Set the speed-control knob

at

"START'

position indicated

on

the panel.

2.Insert the starting crank into the starting shaft hole.Push down the decompression lever and

crank the engine,until anormal fuel injecting sound is noted

..

3.Speed up the cranking of the engine to tnake the flywheel gain enough inertia,then

suddenly release the decompression lever,but continue

to

crank the engine with efforts.Then the

engine will start running itself.

- 4 -

4.0nce

the

engine starts

up

running,the starting crank,because of

the

action of the spiral

jaws on its clutching end,will

jerk

out

of

itself,and therefore the operator must

keep

on holding it

firmly

and

gently

take

it

off from the starting shaft hole to prevent any incident.

C.Running

of

the engine

Caution:While running the engine,take precautions against winding,scalding·

and

fire.

It

is hope that

the

operator pays attention

to

the safety marks nearby

the

filler of fuel tank,

water tank

cap

of the radiator,flywheel,gear casing starting shaft

and

silencer.

I.After starting the engine,check

the

red float

in

the oil indicator

and

see

if

it

rises up.In

case it fails to rise

up

or

suddenly drops down,stop the engine

and

fill

it

with sufficient quantity

of oil or remedy the trouble.

2.Allow the engine to

run

idle

at

low speed for

3-5

minutes after its being started.When the

temperature of cooling water becomes relatively high,gradually increase the engine speed and

lo~d.

Never

run

the engine

at

high speed

and

with full load immediately after starting.

3.The water

in

the

hopper keeps boiling during the operation of the engine.Sufficient quantity

of fresh water must

be

fed

in

at

once when

the

red ball of

the

float goes down to the mouths of

the funnel of the hopper.

4.The engine

is

not allowed to

run

under

black smoke exhausting conditions.During the

operation of the engine,the operator should pay close attention to the color of the exhaust.!n case

black smoke

in

the exhaust is found,if everything else

is

normal,the load on

the

engine should"

be

reduced or remedy the trouble.

5.If any abnormal noise is noted during the operation of the engine,stop it immediately for

check.

6.A

new engine

IS

not

allowed to operate with full load

In

its first 50 hours of operation.

After aperiod of

40-50

hours,it

is

necessary to check and

retighte~

all

the

loosened bolts and

nuts.

De.Stopping the Engine

I.Gradually unload the engine

and

then slow down the speed of

the

engine

and

let

it run

idle for several munites.Shift the speed-control lever knob

to

"STOP" position,the engine will then

stop running.

2.Under particular conditions vihere emergency stop is necessary,it is advisable to loosen any

of the connections of the high pressure fuel pipe or use clothes or towels

at

hand

to block the

inlet of the

air

filter.

The

engine

can

also

be

stopped

by

putting the decompression device into

action.

E.Precautions After Stopping the Engine

I.Close the fuel tank cock.

- 5 -

2.If the engine is

to

be put out of service

for

along period of time,it is necessary

to

drain

out the cooling water by opening the draining cock

on

the cylinder head.Especially in winter,the

cooling water must be drained out immediately after the engine has been stopped in order

to

prevent subsequent cracking of the cylinder blcok and other parts as well because

.of

freezing.

3.Turn the flywheel until fail

to

turn it.Then push down the decompression lever and

continue

to

turn the flywheel until the marked line

on

the flywheel matches with the marked line

on

the hopper,

so

that both the intake and exhaust valves are set under closed condition and the

piston is set at the top dead centre position in the compression stroke in order

to

prevent any

dust

from

getting into the cylinder.

4.Periodically dismantle the draining cock,clean the water passages and remove the scale.

5.Check the connection between the engine and its support often.Check and retighten all the

loosened bolts and nuts.

- 6 -

Section NAdjustment and Maintenance of the Engine

A.Adjustment of Valve Clearance

I.Remove the cylinder head cover.

2.Turn the flywheel until the mark Ton its periphery coincides with the marked line on the

hopper in order

to

set the piston at its top dead centre position in the compression stroke.

3.Loosen the locking nut and turn the adjusting screw on the rocker arm with ascrew driver

to

set the valve clearance

to

the specified value (the intake valve clearance is O.35mm,and the

exhaust O.45mm)by means of afeeler gauge inserted between the valve stem and the rocker arm.

4.In the course of adjustment,screw in the adjusting screw

to

such an extent that the' push

rod is just free to turn but not

too

100se.When this is done,tighten the locking nuts in order

to

prevent any loosening afterwards.

5.Draw out the feeler gauge,and re-check the valve clearance.

B.Adjustment of Injection Timing

I.Disconnect the high pressure fuel pipe

from

the injector.

2.Loosen the nut which connects the high pressure fuel pipe

to

the injection pump,turn the

pipe around

so

that the open end of the pipe is upwards,and re-tighten the nut.Then prime the

injection pump until the high pressure fuel pipe is full of fuel.

3.Tum the flywheel slowly until the fuel just begins

to

flow

out of the end of the pipe.Stop

turning and check whether the injection timing mark line on the periphery of the flywheel

coincides with the mark line on the hopper.In case the injection timing is

too

advanced or

too

lagging behind,adjustment is then necessary and should be made according

to

the following

procedure.

(I )Shut off the fuel filter cock.

(2)Set

the speed-control lever knob at the middle position.

(3)Disconnect the high pressure fuel pipe

from

the fuel pump.

(4)Screw off the pump fixing bolts and take off the pump.

(5)Increase or decrease the number of shims

for

adjustment.Increase the number of shims if

injection timing is advanced.Decrease the

nu~er

of shims if lagging.

(6)Mount back the injection pump and tighten the fixing bolts.While doing so,it is necessary

to

pay special attention

to

that the ball of the plunger adjusting arm must be engaged with the

slot in the speed-governing fork inside the gear casing.This should be checked again through the

inspection hole after the pump has been mounted back in order

to

prevent the engine

from"

mnning away"resulting

from

possible mis-mounting.

After adjustment,it is advisable

to

check again according

to

the above -mentioned item 3.

Readjustment is necessary if something is found incorrect.Caution:The adjustment of injection

- 7 -

timing of each engine has already been made carefully by the engine manufacturer.Therefore it is

not recommended that the engine operator increases or decreases the number of shims at option,

which would aftect the normal operation of the engine.

C.Adjustment of Decompression Device

The good function

of,

the decompression device

may

be tested by hand feeling in the

floolwing way:Tum the decompression lever clockwise with your left hand,and at the same time,

crank the engine with your right hand by means of the starting handle.If your left hand feels

heavy while your right hand feels light,then the decompression device works correctly.However,

attention should be paid to that the decompression shaft must not touch the rocker arm while

cranking the engine,after the decompression lever has been released back.

If the contrary is the case,adjustment must be made as follows:

I.Remove the deecompression cover on the cylinder head cover.

2.0ne

hand hold the decompression lever,the other hand loosen the locking nut,tum the

adjusting screw by adriver.After the adjustment,tighten the locking nut again.

3.Mount back the decompression cover.

D.Maintenance of the Engine

The maintenance of the engine should be conducted as the following items and requirements.

- 8

-'

Item

1.Cooling water

2.Lubricating

oil

3.Lubricating

oil stariner

4.Air filter

5.Fuel filter

element

6.Main bolts

and nuts

Maintenance of the Engine

Maintenance

As soon as the red ball of the float in the hopper goes down

near the mouth of the funnel,replenish water.

As soon as the oil level in the sump drops down near the

lower marked line on the dipstick,replenish oil.

After the first 50 hours of operation of anew engine,it is

necessary

to

clean the crankcase and the oil sump,and

renew the oil.

Hereafter,. the oil must be changed once every 100 hours of

operation.

After the first 50 hours of operation of anew engine,it is

necessary

to

dismantle the strainer and clean it.

Hereafter,the strainer must be cleaned once every 100

hours of operation.

Ordinarily,the filter is

to

be

cl~aned

once every 100 hours

of engine operation.

But when the engine is used

to

power awalking tractor,the

cleaning of the filter is

to

be done every

50

hours of

operation.

In

case the engine is operating in adusty atmosphere,it is

necessary

to

clean the filter every shift of work.

Clean the paper element of the filter with clean fuel or

kerosene and

blow

it

from

inside out,replace it

if

damaged.

Retighten main bolts and nuts.with required torques after

first

40-50

hours operation of a

new

engine.

Retighten them every 300 hours of operation after this.

- 9 -

Period

as required

-Everyday

First 50 hours

100 hours

First

50

hours

100 hours

100 hours

50

hours

Every shift

100 hours

First

40-50

hours

300 hours

filling screen

7.Fuel

Item

tank

and

Maintenance

Remove the

screen

from the inlet of the fuel

tank

and

clean

I

it

in

fresh fuel.

Clean

the

inside of the fuel tank with

clean

fuel.

-'r---

Period

50

hours

500 hours

8.Lapping

of

valve

9.Valve

clearance

10.Cylinder head,

cylinder

liner

and

piston-

connecting rod

assembly

II.Oil ducts

in

the crankshaft

12.Cooling water

passages

Smear

the valve seat with alittle

bit

of lapping

paste

and

lap

it together with the valves carefully (Caution:

do

not

let

the

lapping

paste

get into the valve

guides).

After lapping,wash the valves

and

the

valve seats with fresh

fuel

and

wipe them dry.Checking

the

valve for tightness

may

be

done by pouring into the intake

and

exhaust ports a

slnall quantity of fuel

and

ubserve whether it

leaks

out

around

the

valve seats.

Adjust according to the recommended procedure.

Remove carbon deposit

if

any,and

clean

them

~?ith

fresh

fuel.!t may not

be

necessary to dismantle them for

cleaning

if

the

engine operates normally.

Clean

the

center

hole of the

crankpin

and

oil passages

in

the

crankshaft ,vith fresh fuel.

Pour

into

the

water passages asolution of hydrochloric

acid

(HCI)

of

25%

concentration,keep

it

for about

10

minutes

and

then

blow

-wash

with fresh ,vater.

Repeat

it

if

not

thoroughly cleaned.

Note:

the

hopper

must be removed fronl the engine before

cleaning.

-10

-

500

hours

100

hours

1000

hours

200

hours

500

hours

Item

13.Fuel injt?ctor

Maintenance

ICheek fuel injection pressure

and

sprayablility of the

injector.Normally the spray is in 4concentrated

jets

pattern

and

no fuel dribbing or non -atmozied

jet

IS

found.!f

necessary,clean the nozzle couple

and

remove carbon

deposits inside the injection orifices with a

00.30mm

needle.!n

case

fuel dribbling

IS

found

and

no clear"

chattering"is heard when spraying it is necessary to

lap

the

fitting surfaces of nozzle couple with alittle bit of lapping

paste.After washing and reassembly.Readjust fuel injection

pressure again.

-:-

11

-

Period

as

required

Section VElectrical Starting System

A.Wiring diagram

of

Electrical Starting System

KZT-12D

Flywheel generator

B.Main Elements of Electrical Starting System

The maIn elements of electrical starting system is composed of starting motor,flywheel

generator,voltage regulator,starting switch and battery.

I.Starting motor

Model QD139G motor is used,with arated power of 3kW and avoltage of 12V.lt is of

shorttime rating design with abattery as its power supply.The motor is fitted with asolenoid

operated switch and

an

one

way

clutch.When it is connected to power supply,since the action of

the solenoid-operated switch,its pinion will be pushed out and engage with the ring gear on the

flywheel,thus the engine will start mnning up.The clearance between the end surface of the motor

pinion and the end surface of flywheel is 3.5-5mm,which can

be

adjusted with insulating shims.

2.F1ywheel generator

Flywheel type charging generator is used,with arated capacity of

150-300W

at

user~s

option,

and avoltage of 12V.It is used together with regulator.It is also used for charging the battery for

electrical starting operation and lighting power source.!f generator be used or not may customer

option.

3.Voltage regulator

Model KZT

-12D

regulator is used.It rectifies

AC

produced by the generator,regulates its

voltage to 14V and charges the battery.And it has the function of .automatic limitation of voltage.

4.High capacity battery for starting use,self-provided by the users,with arated capacity of

noless than 150Ah and arated voltage of 12V.

5.Circuit key switch

-12

-

Model JK424 ignition key switch is used,with four positions:

5.1 Initial position

"0"

(Circuit is disconnected)

5.2 Position" I

"(Tum

the key clockwise)

5.3 Position"

n"

(Continue

to

turn the key clockwise)The key can

tum

back

to

position"

I"

automatically.

5.4 Position"m"(Tum the key counterclockwise

from

position"O")

C.Operation Procedure of Electrical Starting

1.Preparation before starting

1.1

Check all the wiring connections for tightness.

1.2 Check

to

see if there is adistance of 3.5-5mm between the

two

end surfaces of the

pinion of the starting motor and the ring gear.

1.3 Check

to

see if the key switch is at position"O".

2.Starting

Insert the key into the JK424 switch and tum it

to

position" I",then the battery will be put

in the main circuit of the starting motor.After that,tum the key

to

the position" n"then the pinion

of the starting motor will come out and engage with the ring gear

to

rotate the flywheel.In most

cases the engine will start up running and the charge-indicating lamp will light up.After starting,

turn the key back

to

the position" I"immediately,and the pinion of the starting motor will draw

back of itself and disengage with the ring gear.Once the engine starts running normally,turn the

key

to

the position"

m"

to

put the starting motor and the battery in the circuit,then the current

pointer will shift in"

+"

direction,which indicates that the charging of the battery is under

way

normally.

3.Precautions

3.1 Each starting operation must not last over 5seconds,and the maximum duration must not

over

15

seconds.The interval between the

two

consecutive starting operation shall be at least 2

minutes.Otherwise the starting motor will be burnt out and damaged.

3.2 Never turn the key

to

the position"

II

"during the running of the engine

to

prevent the

pinion of the starting motor and the ring gear

from

being damaged due

to

their collision.

3.3 Tum the key back

to

position"

0"

and take it out after stopping the engine.H the engine

is

to

be put out of service for along time,it is advisable.

to

disconnect the wires

from

the battery

to

prevent the generator

from

being burnt out.

3.4 In case of failing

to

starting the engine on several consecutive times,it is recommended

to

refer

to

the related operation manual and check the electrical system of the engine or consult

the professional for maintenance.

3.5 Wiring connections of starting motor.

All the conducting wires must as short as possible.Sectional area of the copper wlnng with

the battery must no-less than

25

mm

2,and sectional area of the wire with the starting switch must

no-less than 4mm2also.

-13

-

Section

VI

Defects

and

Elimination

A.Engine Fails to

Start

Cause

l.In

cold weather,lube oil

becomes too viscous,difficult

to

crank the engine

2.Faults in fuel system

2.1 Unsteady fuel

flow

2.2 Freezen fuel

2.3 Air in fuel pipe line

2.4 Fuel injection timing

incorrect

2.5 Insufficient fuel injection

pressure,ne~dle

valve seized,

injection orifices choked with

carbon deposits

2.6 Pumping element (Plunger

and barrel of the injection pump

worn out)

3.Insufficient compression in the

cylinder

Remedy

---

Fill the hopper with hot water.Use lube oil of specified grade or

preheat lube oil before pouring it into the oil sump,but

do

not

heat the oil sump with external fire.If necessary,disconnect the

engine from the driven machine by pulling off the belt,then start

the engine.Stop it after the engine has been warmed up,reput the

belt on and start the engine again.

Check-the fuel tank and the element of the fuel filter whether

there is any water or dirt.Clean the element in clean fuel if it is

choked with dirt,or clean the fuel tank and fill it with clean fuel

of recommended grade if any water is found

in

the tank.

Use fuel of specified grade and heat it.

Release air and tighten all of fuel pipe connections.

Adjust according

to

recommended procedure.

Clean,lap or renew the_injector nozzle,adjust injection pressure to

specified value.

Renew pUlnping element(Plunger and barrel)

-14

-

This manual suits for next models

3

Table of contents

Other Changchai Engine manuals

Popular Engine manuals by other brands

Bartec Varnost

Bartec Varnost 4KTC 250 manual

GEIGER

GEIGER SOLIDline Original assembly and operating instructions

ABB

ABB HT575363 Operation manual

Lenze

Lenze g500-B Project planning manual

Briggs & Stratton

Briggs & Stratton 260700 Operating and maintenance instructions

Textron

Textron MPE 850 MARINE Service manual

Nord Drivesystems

Nord Drivesystems B 1000 Operating and maintenance instructions

Desert Aircraft

Desert Aircraft DA170 owner's manual

Oriental motor

Oriental motor PKP Series operating manual

Rotax

Rotax 125 MAX DD2 evo Installation instructions and operators manual

Kohler

Kohler 4EF Operation

Yanmar

Yanmar 1GM10 Operation manual