Changchai CC170FB User manual

www.changchai.com.cn

CHANGCHAI AIR-COOLING

DIESEL ENGINE

OWNER’S MANUAL

2014/CHANGCHAI

CONTENTS

PREFACE

SAFETY PRECAUTIONS

1.Principal Technical Specifications ............................................................................................ - 1 -

2. Position of Caution Mark......................................................................................................... - 1 -

3.Installation................................................................................................................................. - 2 -

4. Operation of the Engine........................................................................................................... - 2 -

5. Starting of the Engine............................................................................................................... - 5 -

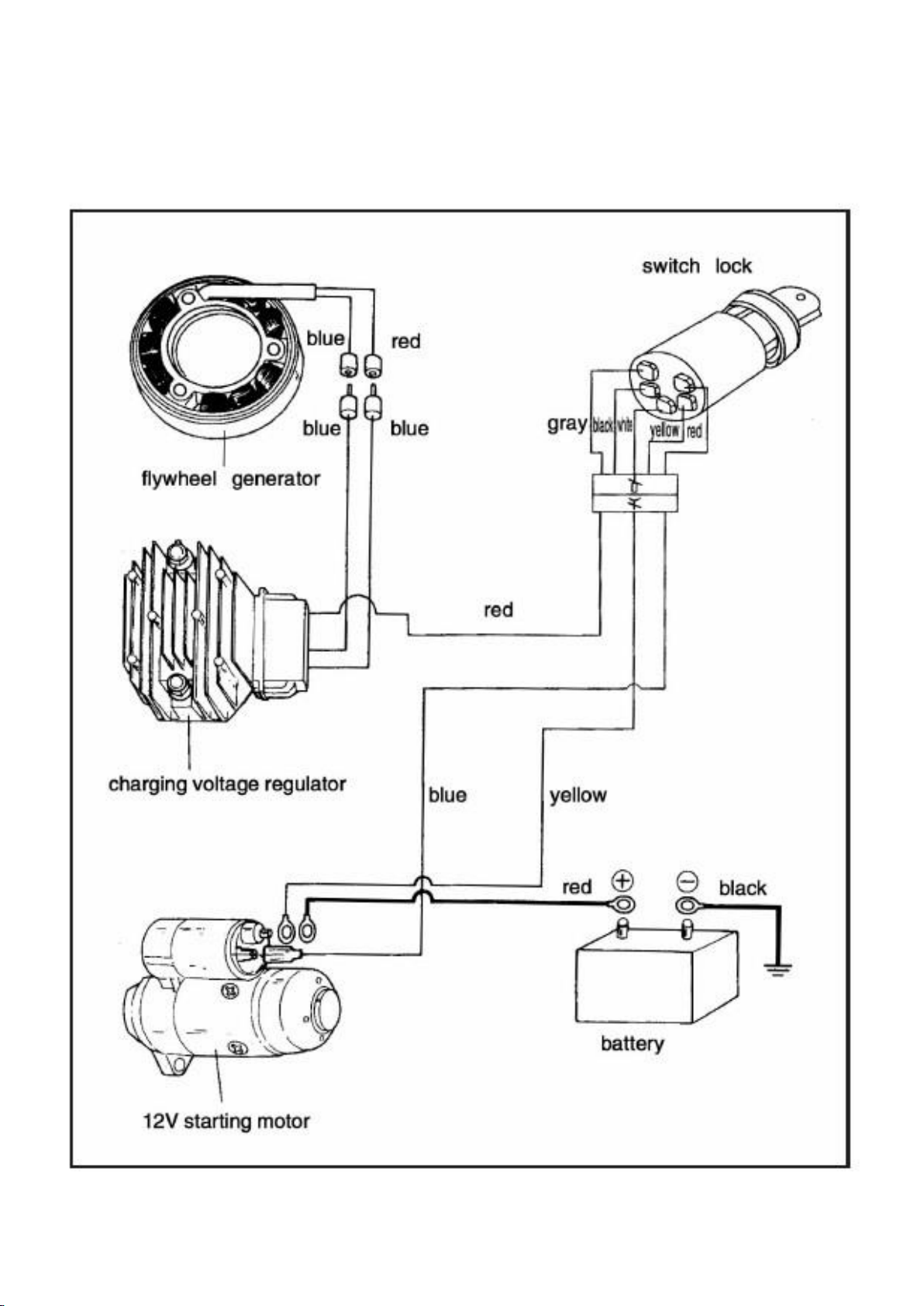

Circuit Diagram of Electrical Starting Engine......................................................................... - 9 -

6.Running of the engine............................................................................................................. - 11 -

7. Stopping of the engine ........................................................................................................... - 12 -

8. Periodic checks and maintenance........................................................................................... - 13 -

9. long-term Storage of the Engine............................................................................................ - 15 -

APPENDIX I Overall and Mounting Dimensional drawing...................................................... - 16 -

HYPERLINK \l _Toc20145 APPENDIX III Performance Curves and Connection Dimensions- 18 -

APPENDIX III Output Dimensions of the Crankshaft.............................................................. - 18 -

PREFACE

Thank you very much for you purchasing CHANGCHAI brand air-cooled

diesel engine.

In order to operate the engine safely and correctly, read this manual

carefully. Otherwise the mistake is operated may lead to the accident.

If you find any unclear points or have any suggestions, please do not

hesitate to consult your nearest dealer.

This Operation Manual tells you how to operate and service your

CHANGCHAI brand air-cooled diesel engine. Please read it before using the

engine to insure proper handling and operation. Follow the instructions

carefully to keep your engine in the best running condition. If there are

unidentified items, please consult your dealer.

WARNING:

Indicates a strong possibility of severe personal injury or loss of life if

instructions are not followed.

CAUTION:

Indicates a possibility of severe personal injury or loss of life if

instructions are not followed.

NOTE:

Indicates a possibility of personal injury or equipment damage if

instructions are not followed.

SAFETY PRECAUTIONS

(In order to let you use safely, please strictly observe)

▲DANGER:

FIRE PREVENTION

1.If put the petrol into wrongly, it will cause the, so please confirm not to make mistake while

adding the fuel.

2.Be sure to stop the engine before refueling.

3.If fuel is spilled, please wipe it away.

4.Keep other oil and inflammable away from the engine.

Attention on CHARGINGTHE BATTERY

1.Batteries generate hydrogen gas, which can highly explosive. Do not smoke or allow

flames or sparks, especially during charging.

2.Battery electrolyte contains sulphuric acid. Protect your eyes, skin and clothing.In case of

contact, flash thoroughly with water and get prompt medical attention, especially if your eyes are

affected.

▲WARNING

A.EXHAUSTATTENTION

The waste gas sucks the human body harmfully. So never operate the engine in a poorly

ventilated place. Such as airtight room or corridor, etc. If operate the engine indoors, it is must set

up the ventilator, the vent indoors, shutter, etc. In order to keep ventilating it well while running.

B.PREVENT BEING INVOLVED IN

Please not to touch the rotating parts such as the driving pulley while running the engine.In

addition, after connecting with working machinery, the dangerous part such as the belt and coupler,

should be covered properly with the protection cover.

C.BE CAREFUL OF SCALD

The cylinder, the muffler and its cover can become very hot while the engine is running or

after the engine is just stopped. Please not to keep in touch with hands, the body clothes, etc.

D.OTHERATTENTIONS

1.Please don’t operate the engine after drinking.

2.While starting, please confirm fist whether it is safe around or not

3.Always wear safety shoes( non-skid soles) and proper clothes.

- 1 -

1.Principal Technical Specifications

Model

CC170FB

173F

178FA

186FA

188FA

192FA

Type

Single-cylinder, vertical, four-stroke, air-cooled, direct injection

Bore×Stroke

70×59

73×59

78×64

86×72

88×75

92×75

Displacement(L)

0.227

0.247

0.305

0.418

0.456

0.499

Rated power/rated speed

(kW/r/min)

3.0/3000

3.5/3600

3.5/3000

4.0/3600

3.7/3000

4.0/3600

5.7/3000

6.3/3600

6.8/3000

7.5/3600

7.5/3000

8.2/3600

Maximum idle speed r/min

No more than 108% of rated speed

Minimum idle speed r/min

≤1300

Fuel consumption/rated speed

g/(kW▪h)r/min

310/3000

330/3600

280/3000

310/3600

280/3000

310/3600

300/3000

320/3600

300/3000

320/3600

Oil consumption g/(kW▪h)

≤4.0

Grade of fuel

NO.0, NO.-10, NO.-20

Grade of oil

CD Grade or SAE10W—30,SAE15W—40

Injection timing (Before T.D.C)

20°±1°

21°±1°

24°±1°

Direction of rotation

Counterclockwise (face the output shaft)

Valve clearance (cold) mm

0.10~0.15

Starting method

Recoil start or electric start

Lubrication method

Pressure and splash

Lubricating oil capacity (L)

0.75

1.1

1.65

Fuel tank capacity (L)

2.5

3.5

5.5

Overall dimension

(L×W×H) mm

335×380×415

383×421

×450

420×440×495

Net weight kg

≤27

≤33

≤53

NOTE:The specification will be changed as the improvement of engine, so this is only a

reference not an acceptance basis.

2.Position of Caution Mark

In order to ensure a safe operation, the company affixes a caution mark on the diesel engine.

Please keep the mark in good condition, if there’s any damage, change a new mark. The mark

could be purchased from the agents.

- 2 -

3.Installation

Note:

If the running engine is too great in vibration, it will damage the engine and the driven

machine, so the engine must be fixed.

If the belt pulley is too tight, it will cause the accident. Please choose the belt pulley of the

suitable size.

(1)There muse be a tight stationary foundation for the engine to avoid vibrations or

movement when the engine is running.

(2)Make sure that the centering position of the output shaft is properly aligned.

(3)If use the belt the pulley drive the engine, the size of the belt pulley should be in

accordance with the request for load.

The diameter of the belt pulley can be obtained by the following formula:

(rated)speedEngine speedmachineryDrivendia.pulleymachineryDriven

dia.pulleyEngine

(4)Please confirm whether the shaft hole of the belt pulley and the size of keyway match the

output shaft. Make sure not pack the keyway in to key by force. Otherwise may cause the accident.

Tighten the bolt of output shaft correctly. If the engine emits the black smoke in running, you must

reselect the diameter of the belt pulley.

(5)It is important to guarrantee that the belt tightness is moderate. If the belt is passed tight, it

will cause the engine starting difficult, still will arouse the premature worn out of the belt, even

will curve the output shaft thus cause the accident.

(6)Fixed type and quantity of the V-belt.

Model

Type×Quantity

If there are unidentified places to the

installation of the diesel engine and connection

with road. Please consult your nearest Changchai

dealer.

CC170FA(B)

A×2

178F(A)

B×3

186F(A)

B×3

188FA

B×3

192FA

B×3

4.Operation of the Engine

While your engine is still new, every part does not undergo breaking in, improperly using

may shorten the life of the engine. Follow the breaking-in procedures during the first 20 hours.

The operator must follow the following items:

a.Operate the engine for 5 minutes after starting for the first time. Keep the low load and low

speed until the engine hot, make sure not to operate the engine neither in no load of the low speed

nor in full load of the high speed.

b.Avoid overload

The engine can’t be full load running during breaking-in period. It can carry on breaking-in

according to 3000r/min,about 50% of load.

c.Change the lube oil regularly

- 3 -

If there are unidentified places to the

installation of the diesel engine and connection

with road, Please consult your nearest

Changchai dealer.

4.1 Choice and use of the fuel

(1)Please use light diesel fuel which is most suitable for the engine.

(2)Use of the fuel

a.When filling the fuel tank from container, make sure that no

dust or water are mixed in the fuel. This may cause the engine to

operate abnormally.

b.If the fuel has already been put for several hours, water and

dust in the fuel will precipitate the bottom of the container and

then you can collect the clean fuel at the top of the container with

the pump.

(3)Supply the fuel

Note:

a.It is very dangerous to fill the petrol to the engine, you must

confirm the type and trade mark of the fuel at first before refuling.

b.Must stop the engine before refueling.

c.If the fuel over flow carelessly, clean the excessive fuel.

d.The dust remains in the bottom of the container, then take

clean fuel at the top of the container out with the pump.

e.Don’t let the fuel lever go beyond red line position.

4.2 Lube oil

(1)The lube oil choice method.

a.It is very important to choose the suitable lube oil. If the lube oil grade used is not fit for the

engine, it will cause the risk of piston seizure, piston ring sticking and accelerated wear of the

cylinder liner, bearing and other moving parts increases significantly. Your engine life may

seriously shortened.

b.All the year round must use the special-purpose lube oil above CC grade.

Temperature(℃)

Above 20℃(summer)

10~20℃

(spring,autumn)

Below 10℃(winter)

grade

SAE 30

SAE 20

SAE 10W—30

(2)Check the lube oil lever and supply.

a.Must check the lube oil lever before starting the engine.

b.The lube oil can’t exceed the upper limit mark

- 4 -

c.See the form in capacity of lube oil.

Caution:

1.Put the diesel engine in horizontal and check the lube oil lever, if necessary, supply the lube

oil.

2.Check the lube oil lever before tighten

the filler cap.

3.Check the oil lever by the dipstick to see

whether it between upper and lower limit

marks.

4.Clean the excessive oil.

5.Tighten the dipstick after the lube oil is checked.

Engine model

CC170F(B)

178F(A)

186F(A)

188FA

192FA

Oil capacity(L)

0.75

1.10

1.65

1.65

1.65

4.3 Change the air filter element

(1)The element must be replaced when the output decreases or bad exhaust color is noticed.

Loosen the wing nut, remove the cover of the air filter and take the element.

(2)Remount the cover of the air filter, and tighten the wing nut after change the element.

4.4 Direction of the exhaust vent

The exhaust elbow is installed on the muffler

cover to prevent exhaust entering the air filler.

Note:

Prevent the water gathered on the exhaust

elbow to flow into the muffler.

- 5 -

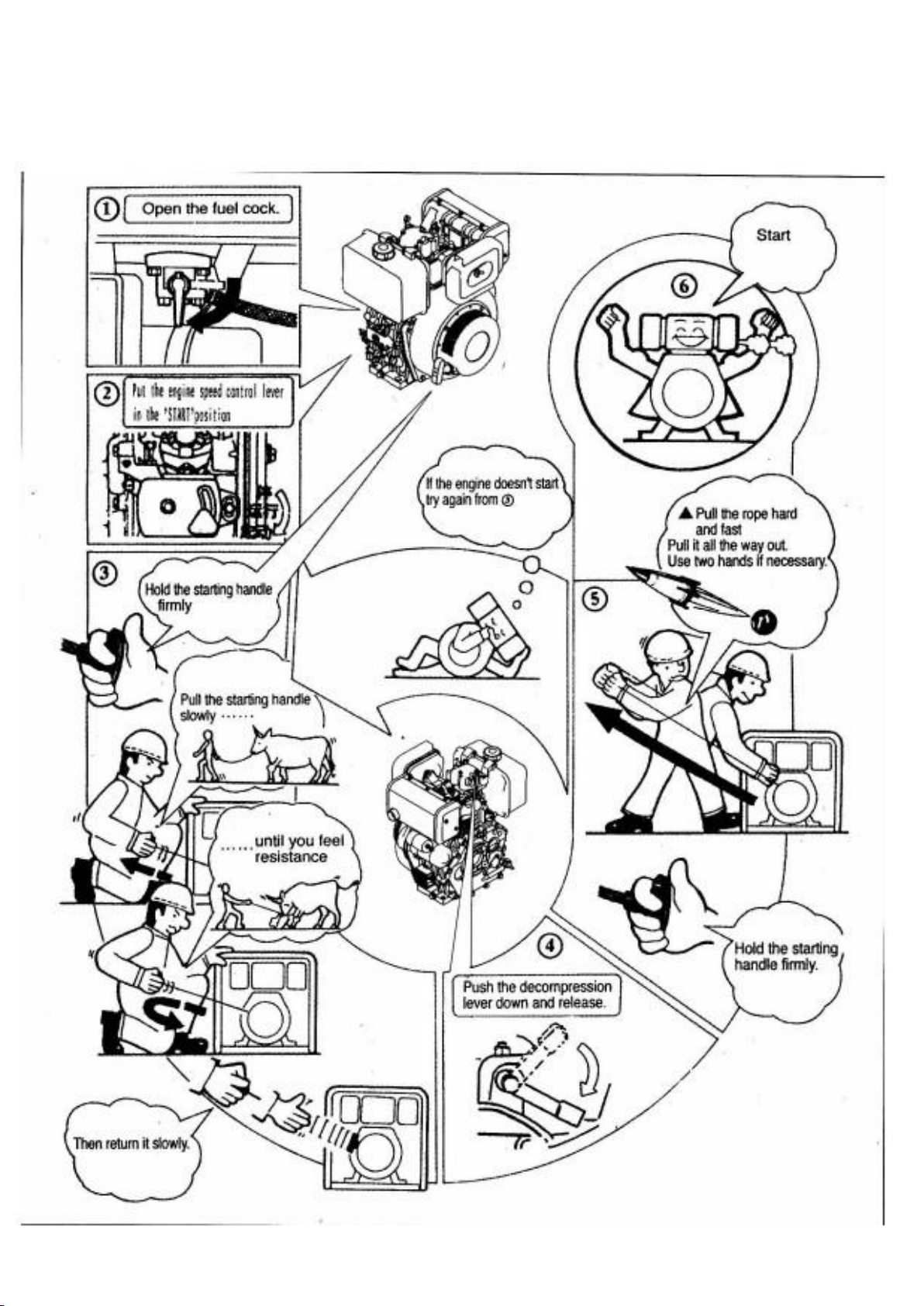

5.Starting of the Engine

5.1 Recoil starting

(1)Open the fuel cock.

(2)Set the speed control lever to “START”position.

(3)Hold the recoil starting handle.

A.Pull out the handle to the position where you feel strong resistance, and then return it to the

initial position.

B.Push down the decompression lever. It will return

automatically when the engine start.

C.Start: Pull on the recoil starting handle use two hand

until you feel resistance, pull the rope hard and fast.

D.In cold weather, when your engine is hard to start,

remove the rubber plug of the cylinder head cover and add

2ml of lube oil before starting.

Note:

It is important to tighten the rubber plug of the cylinder head cover except when adding oil. If

the plug is not in place, rain dirt and dust may enter the engine, and cause accelerated wear of

internal parts, then it can cause serious problems.

- 6 -

Start main points

- 7 -

Start main points

- 8 -

5.2 Electric starting

A.Start the engine according to the following

sequence.

(1)Open the fuel cock.

(2)Set the speed control lever to “START”

position.

(3)Turn the electric starting switch to

“START”position in clockwise.

(4)Remove your hand from the switch as

soon as the engine starts.

(5)If the starting motor doesn’t start after 10

seconds, wait for about 15 seconds before restart.

(If the starting motor is turned for too long, the

battery will go flat and motor seizure will occur.)

B.Maintenance of the battery

Check the battery once a mouth. If the

electrolyte lever has dropped to the lower mark,

replenish with the distilled water up to the upper

limit mark.

The battery capacity of stipulation:

Engine model

Capacity

CC170F(B)

12V 24AH~36AH

178F(A)

186F(A)

188FA

192FA

12V above 36AH

- 9 -

Circuit Diagram of Electrical Starting Engine

- 10 -

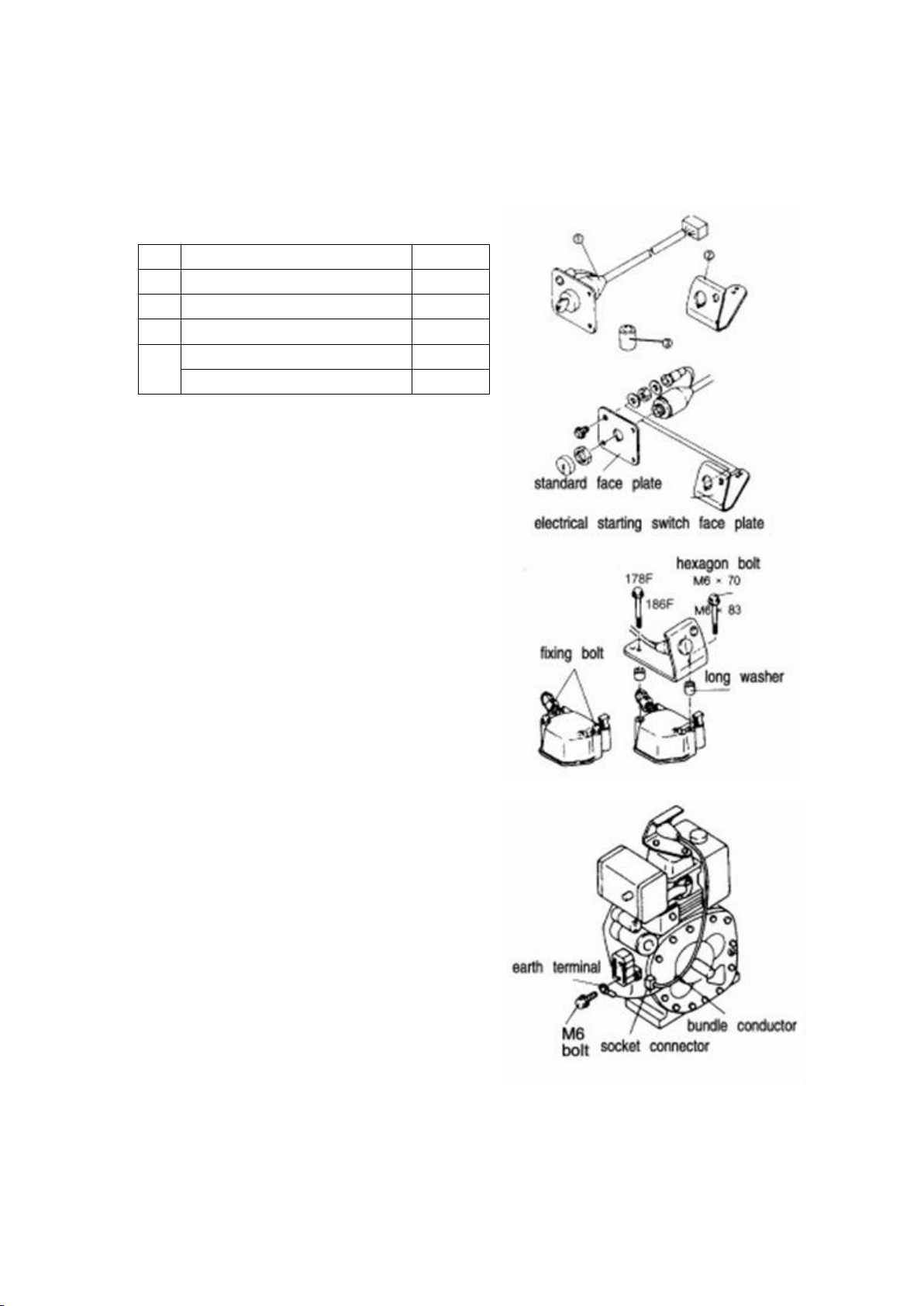

5.3 Mounting of the Electrical Starting Switch Assembly

If the electrical starting switch face plate is mounted on the upper of the cylinder head cover,

please according to the following parts and sequence of operation for mounting.

A.Parts:

B.Sequence of operation

(1)Refit the electrical starting switch assembly

from the standard face plate to the electrical starting

switch face plate of the cylinder head cover.

(2)Remove the two fixing bolt of the cylinder

head cover.

(3)Clamp down the face plate with long washer,

and fix by the hexagon bolt.

(4)Screw the earth terminal of the bundle

conductor in the way of the M6 bolt.

Note:

If the bundle contacts against muffler or output

shaft, the mishaps such as fire will be initiated.

No.

Name of part

Quantity

1

Electrical starting switch assembly

1

2

Electrical starting switch face plate

1

3

Long washer

2

4

Hexagon bolt M6×70( 170F/178F)

2

Hexagon bolt M6×83( 186F)

2

- 11 -

6.Running of the engine

Caution:

a.To prevent exhaust poisoning. The engine must operate in ventilation.

b.Avert hand, body and clothes to be involved in the moving parts such as the output-shaft,

the belt, v-belt pulley and so on, in order to prevent injured.

c.First close the engine, then repair the moving parts and its surrounding parts. Before start

the engine, it must be sure there is no tools and anything else in the cylinder.

Note:

a.If the engine has been running, the muffler

will be very hot. Be careful not to touch it.

b.When the engine operate the air filter

breathe in the surrounding airflow. Do not let hand,

body and clothes near by it in order to prevent

injured.

c.Speed must be adjusted by speed control

lever.

d.Do not loosen either the speed limit bolt or

fuel control, otherwise the speed and out put of the

engine will abnormal.

(1)Warm up the engine without load for 5 minutes.

(2)If the engine is still warm, set the speed control lever to the desired speed position.

(3)During operation, continuous black exhaust smoke indicate that the engine running

overload. So you must adjust the engine or the pulley of the driven machine.

(4)Checks on the engine while the engine is running.

a.Check to see whether there are abnormal noise and vibration.

b.Check to make sure there is good exhaust noise.

c.Check to see the color of the exhaust gases to see if it is white or black.

d.If any of abnormal phenomena are detected, stop the engine immediately and consult

nearest Changchai dealer.

- 12 -

7.Stopping of the engine

Caution:

Do not stop the engine suddenly since it may causer the temperature to rise abnormally and

shorten the service life of the engine.

(1)Move the speed control lever to low speed position, and run the engine for about 5

minutes with no load.

(2)Set the speed control lever to the “STOP”position, and never stop the engine with the

decompression lever.

(3)Return the fuel cock to “S”(closed)position.

(4)Slowly pull out the recoil handle until pressure is felt, this means the piston is on the

compression stroke where the intake and exhaust valves are closed. This prevents rust from

forming while the engine is not in use.

(5)In electric-start models, set the starter key to the “OFF”position directly.

Preparations for using the engine next time

(1)Replenish the fuel tank with fuel.

(2)Check whether the bolts, nuts of every parts become loose. If become loose and must

tighten.

(3)Remove the dust and dirty on the surface of the cylinder.

- 13 -

8.Periodic checks and maintenance

Periodic check and maintenance are very important for keeping the engine in good condition

and service life. The chart below indicates which checks to make and when to make them. The

mark(●)indicates that special tools and skills are required.Please consult your Changchai dealer.

Periodic check and maintenance schedule

Item

Regular service period

Daily

20

hours

50

hours

100

hours

200

hours

500

hours

1000

hours

Check bolt and nuts of

engine parts for tightness

○

Check and replenish lube oil

○

Replace lube oil

○

1st time

○

2nd time

Clean oil filter

○

○

Check for oil leakage

○

Replace air filter element

○

Clean and replace fuel filter

○

1st time

○

clean

○

replace

Check fuel injection nozzle

●

Check fuel injection pump

●

Adjust clearance of intake

and exhaust valves

●

Check clearance of intake

and exhaust valves

●

Replace piston rings

●

Check battery electrolyte

Monthly checked and if necessary replenished with distilled water

(1)Replacing the lube oil

Drain off the old oil while the engine is still warm,

and refill with the recommended oil.

Temperature

Lube oil

specification

Lube oil type

Over 20 ℃

(summer)

Over CC

No.SAE30

10℃~20℃

(spring,autumn)

No.SAE20

Below 10℃

(winter)

No.SAE10W-30

- 14 -

(2)Cleaning the oil filter

Loosen off the bolt and then pull out the oil filter

(3)Replacing the air filter element.

A.Paper element

Replace the air filter element after every

200 hours of operation.

Note:

A clogged element hinders the flow of air

to the combustion chamber. This makes starting

difficult, reduces engine output, smokes black,

increases lube oil and fuel consumption. Never

run the engine without the element or with a

defective element.

B.oil bath element

Check the oil lever before running the

engine. Fill the lube oil to the upper mark. If the

oil is dirty, replace it.Clean the element with

kerosene frequently, then immerse it in lube oil,

push out of the surplus lube oil.

(4)Cleaning and replacing the fuel filter.

The fuel filter also has to be cleaned

regularly to insure maximum engine output.

First drain off the fuel from the fuel tank, then

loosen two nuts of the fuel cock and pull out the

fuel filter from the fuel tank.

(5)Tightening cylinder head bolts

Tightening the cylinder head bolts requires a

special tool. Don’t try it yourself. Please consult

your nearest Changchai dealer.

(6)Adjusting the injector and the injection pump,

replacing the piston ring of the valve seat.

All these require special tools and skills,

please consult your nearest Changchai dealer.

- 15 -

(7)Checking and replenishing battery electrolyte.

Battery electrolyte will be lost through

continuous charging and discharging(Much more

electrolyte is lost during summer than in winter.).

Before starting, check for the electrolyte levels, and

replenish with distilled water up to the upper mark if

necessary.Check the battery electrolyte every mouth.

9.long-term Storage of the Engine

Please follow the instructions below if you plan on storing the engine for long periods of

time.

(1)Run the engine at low speed for five minutes.

(2)Quickly drain off the lubricating oil while the engine is still warm and refill it with new oil.

(3)Take the rubber plug off the cylinder head cover and add about 2ml of the lubricating oil

into it.

(4)Push the decompression lever down and hold it while your pull the recoil starting handle 2

or 3 times.(Do not start the engine)

(5)Pull the decompression lever up and pull om the compression stroke where the intake and

exhaust valves are closed. It is also the point that will prevent moisture from entering the chamber

to cause rust.

(6)Wipe the dirt on the surface of the cylinder and store the engine in a dry place.

- 16 -

APPENDIX I Overall and Mounting Dimensional drawing

CC170FA(B) 178F(A) 186F(A)/188FA/192FA

This manual suits for next models

5

Table of contents

Other Changchai Engine manuals