CHARGETRONIX TP-EVPD-160kW User manual

1

Installation Manual

160 kW DC Charger

Product #TP-EVPD-160kW

2

Please Note

ChargeTronix reserves the right to make changes as necessary in order to comply

with industry changes, to account for any errors or omissions, and to ensure a safe,

reliable installation process.

The operational and programming manuals are separate from this manual, which

covers only electrical and mechanical installation procedures.

Please call our customer support line at +(1)949-649-1644 for questions related to

the installation, operation, or maintenance of this equipment.

Confidentiality

The material contained in this document represents proprietary and confidential

information pertaining to services and methods exclusive to ChargeTronix. By reading

this document, you agree that the information contained herein shall not be disclosed,

duplicated, or used for any purpose other than the installation, operation, and

maintenance of the equipment mentioned herein.

The TP-EVPD-160kW charger is available in several different voltage and connector configurations,

listed below by product number:

TP5-160-480-1

Max Voltage: 1000VDC; Connectors: CCS1 and CHAdeMO

TP5-160-480-2

Max Voltage: 1000VDC; Connectors: CCS1 and CCS1

HPC-160-480-1

Max Voltage: 1000VDC; Connectors: Liquid Cooled CCS1 and CHAdeMO

HPC-160-480-2

Max Voltage: 1000VDC; Connectors: Dual Liquid Cooled CCS1

HPC-160-480-3

Max Voltage: 1000VDC; Connectors: Liquid Cooled CCS1

This manual contains procedural directions and guidance regarding the electrical and mechanical

installation procedure(s) for the ChargeTronix TP-EVPD-160kW charger.

3

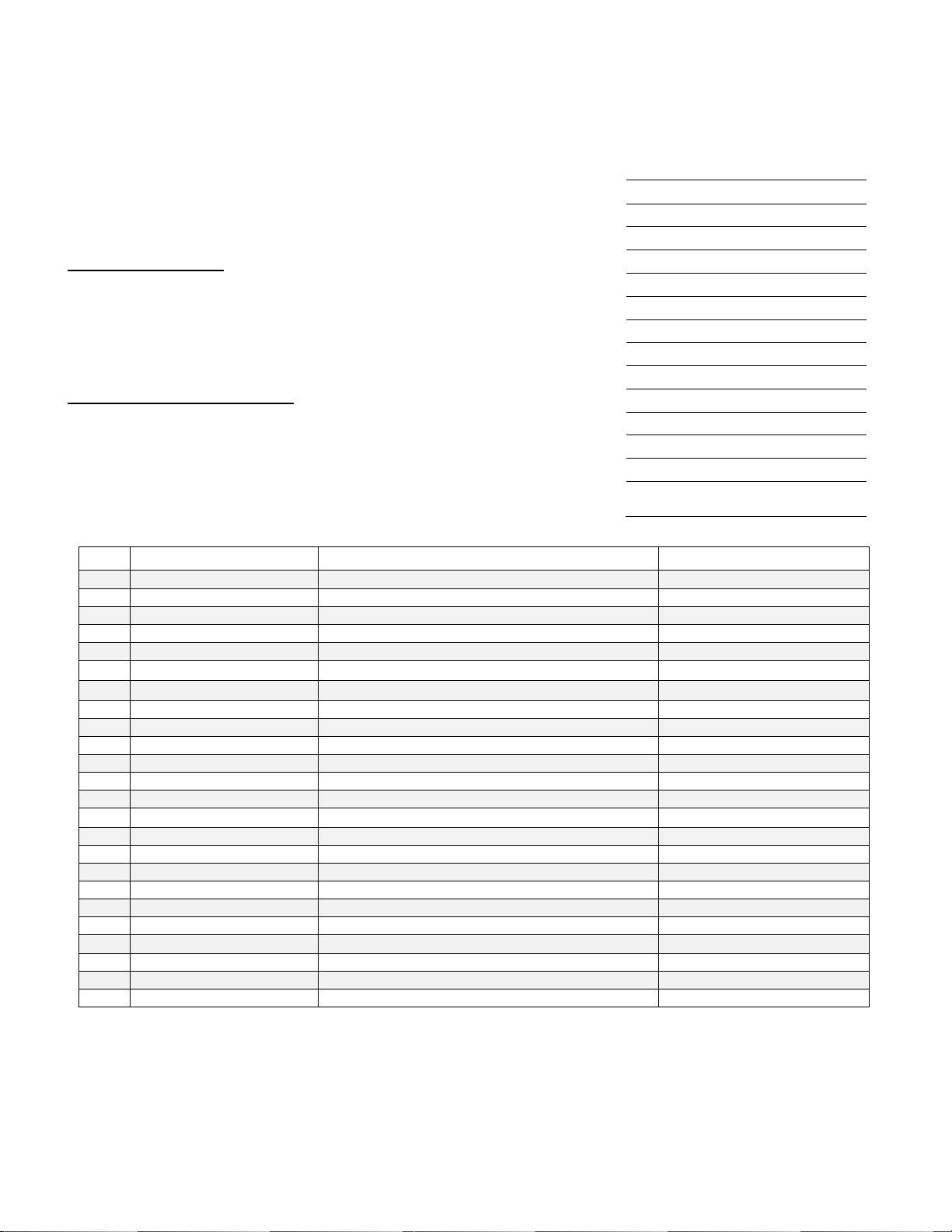

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................................................................... 3

CRITICAL SAFETY ............................................................................................................................................. 4

INSTALLATION OVERVIEW .............................................................................................................................. 7

OUTLINE OF DRAWING - 160kW DCFC ........................................................................................................... 8

CHARGER ANATOMY ........................................................................................................................................ 9

MECHANICAL INSTALLATION ........................................................................................................................ 10

CHARGER INSTALLATION............................................................................................................................... 11

AC Input Power Wiring .........................................................................................................................................................13

AC Input Termination............................................................................................................................................................13

HOW TO START A CHARGING SESSION ...................................................................................................... 14

CHARGER SETTINGS ……………………..........................................................................................................15

MAINTENANCE AND SERVICE ....................................................................................................................... 16

TROUBLESHOOTING ...................................................................................................................................... 17

CUSTOMER RESPONSIBILITIES .................................................................................................................... 19

WARRANTY ...................................................................................................................................................... 20

APPENDIX ........................................................................................................................................... 21

4

CRITICAL SAFETY

READ THE ENTIRE MANUAL BEFORE DESIGNING OR INSTALLING

EQUIPMENT

WARNING

This unit is a high-powered electrical device and can be hazardous if improperly installed,

serviced, or operated. Failure to follow procedures in this manual could result in extreme

hazardto personnel and/ordamage to the equipment and related infrastructure. All installation,

programming, servicing, maintenance, and operation must comply with local codes and the

Authority Having Jurisdiction (hereafter referred to as ‘AHJ’).

IMPORTANT SAFETY INSTRUCTIONS

Symbols contained herein are international icons used to depict the various necessary levels of caution when installing,

servicing, maintaining, or otherwise accessing this equipment. These same symbols will also appear on the equipment

itself for identifying necessary caution levels required when accessing certain components of the charger.

DANGER

Denotes potential high voltage, which carries a risk of electrical

discharge that can result in severe injury and/or death.

WARNING

Denotes a hazard that could result in severe injury and/or death.

GENERAL

CAUTION

Denotes a potential hazard or unsafe practice that could result in

injury.

SERVICE WARNING

There are no serviceable items inside the equipment. There are high-voltage components inside the equipment

which could cause severe injury or death if tampered with, touched, or otherwise accessed. Do not attempt to repair

the charger yourself. Such servicing can only be performed by qualified personnel.

CHARGING CABLE DAMAGE

Do not operate the charger if the charging cable has any exposed wires present or the cable is otherwise damaged.

Shut off power to the charger at the electrical disconnect or at the breaker if suchdamage does occur or is present.

Then, immediately contact ChargeTronix support. If there are any questions regarding this process, please contact

ChargeTronix customer support.

5

SAFETY INSTRUCTIONS

Read the entire installation manual instructions prior to site design and charger installation. This equipment should only be

installed by a journeyman or master level electrician. Compliance with local building codes is required. In most jurisdictions,

the installation of this equipment requires plan checks and building and electrical permits prior to construction or installation.

Verify these and other necessary requirements with the local AHJ prior to starting any construction or installation.

The charger relies on a grounding system for safety. All grounding instructions should be strictly adhered to as prescribed

in this manual, any applicable electrical safety requirements, all local electrical safety codes, and the National Electrical

Code (hereafter referred to as ‘NEC’).

HIGH VOLTAGE EQUIPMENT:

This charging system contains both AC and DC high-voltage circuitry, devices, and components. As such, this

charger equipment should only be installed by a qualified electrician trained to work on high-voltageand high-current

AC and DC systems.

ADDITIONAL CAUTIONARY NOTES

WARNING

Do not have power on while any of the maintenance doors of the charger are open unless proper personnel

protection equipment is worn. Only trained personnel should be working with this equipment while the doors are

open and/or the unit is receiving power.

WARNING

There are high voltage and high-capacity energy storage components in this system. There are components and

circuits that remain charged for some time (1 to 2 minutes) with high-voltage power, even after the main power has

been disconnected. Always test with a voltmeter before any maintenance or service is performed.

This manual offers guidance and instructions on the electrical and mechanical installation procedure(s) for the

ChargeTronix HPC-160-480 charger.

6

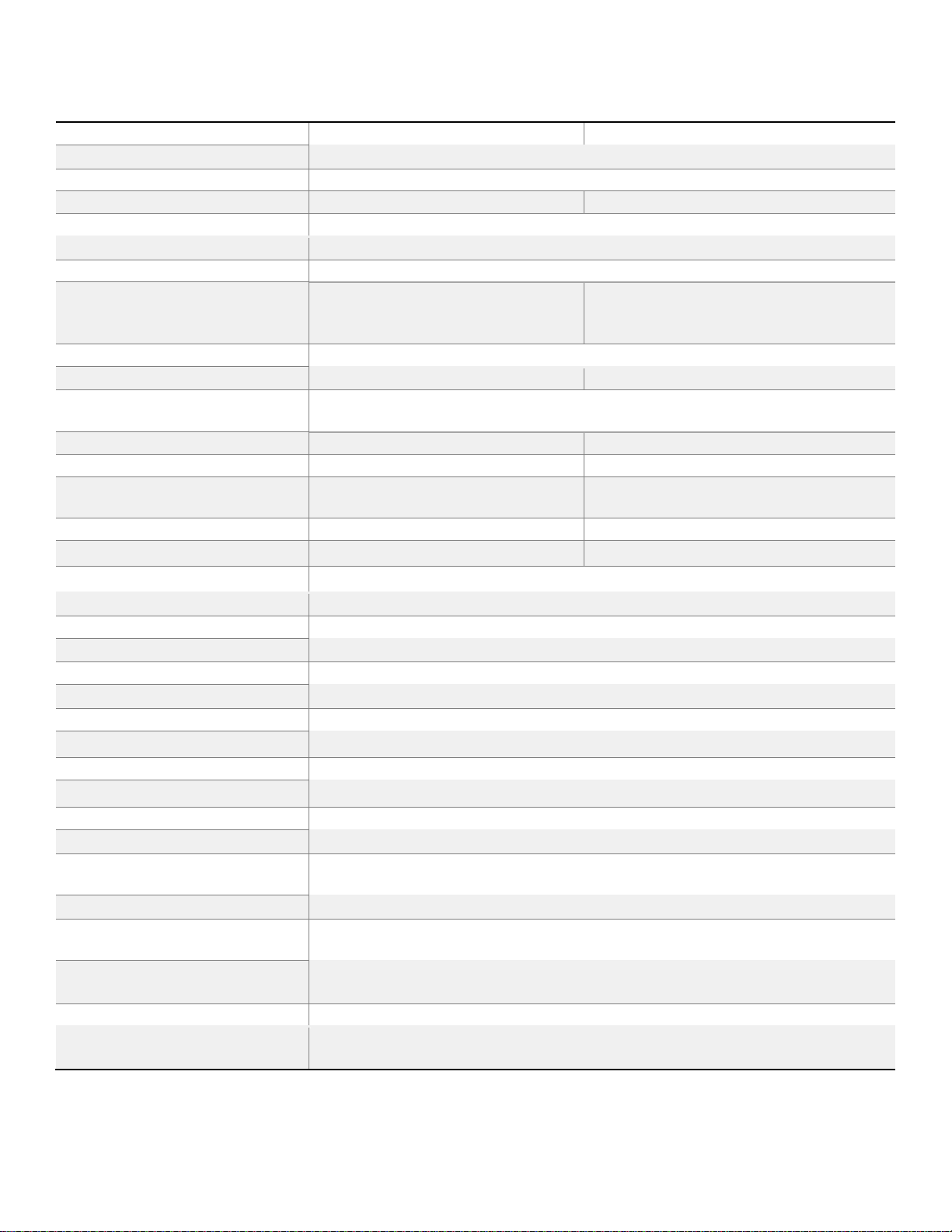

Product Number

TP5-160-480

HPC-160-480

Input Voltage

480V (3P + N + PE), 60Hz

Output Voltage

150–1000 VDC

Max Output Current

Up to 200A per connector

Up to 400A per connector

FLA || Breaker Rating

215A || 300A

Power Factor

>0.98

Efficiency

>94% at nominal output power

Connector Options

CCS1 and CCS1

CCS1 and CHAdeMO

CCS1

CCS1 and CCS1

CCS and CHAdeMO

CHAdeMO Cable

125A (Standard) or 200A

CCS Cable

200A

400A Liquid Cooled

Charging Protocol

Standards

Mode 4, IEC-61851, ISO-15118, DIN 70121 || Mode 4,CHAdeMO 0.9,1.0

Cycle Mode

1 x 160kW (Max: 200A)

1 x 160kW (Max: 400A)

Parallel Mode

2 x 80kW

2 x 80kW

Connector cable length

CCS –16ft (5m)

CHAdeMO –16ft (5m)

CCS –13ft (4m)

CHAdeMO –16ft (5m)

Cable Management

Included

Included

Weight

880 lbs. (400 kg)

1221 lbs. (550 kg)

Dimensions (L x D x H)

29.5”x 26.5’’ x 73’’

Insulation (input –output)

>2.5 kV

Ingress Protection

NEMA 3S (IP54), IK10

Operating Temperature

-22°F to 131°F (-30°C to 55°C)

Altitude

< 6600ft (2000m)

Working || Storage Humidity

≤ 95% RH || ≤ 99% RH (Non-condensing)

Display

10’’ LCD touch screen

Communication || Protocol

Ethernet, 4G/WiFi || OCPP 1.6J

Access Control

RFID: ISO/IEC 14443A/B | Credit Card Reader (Optional)

Metering

DC kWh meter per each connector

Power Electronics Cooling

Air cooling fans

Electrical Safety: GFCI

RCD 20 mA Type A

Electrical Safety: Surge

Protection

20 kA

Electrical Safety General

Over Voltage, Under Voltage, Over Current, Missing Ground

Electrical Safety: Output

Short

Output power disabled when output is short circuited

Electrical Safety

Temperature

Temperature Sensors @ Charge Coupler and Power Electronics

Emergency Stop

Disables output power with emergency stop button

Regulatory Compliance

UL-2202 || EMC: EN 61000-6-1:2007, EN 61000-6-

3:2007/A1:2011/AC:2012

7

INSTALLATION OVERVIEW

Electrical Input

Requirements

Input voltage: 480 VAC (3 Phase + Neutral + Earth), 60Hz

Full Load Amperage: 215 Amps (at rated power)

Breaker Capacity: 300 Amps

Location

These charger have 4 doors (i.e. front, rear, left, and right). Clearances of 30 in. distance on the front and rear

sides, and 24 in. distance on the left and right sides, are to be maintained at all times in order to allow for

proper air circulation and cooling. This clearance also allows the opening of doors for maintenance

procedures.

For relocation or lifting of the charger and mounting pad, a forklift or crane may be used. Provisions for such

an action have been included in this document.

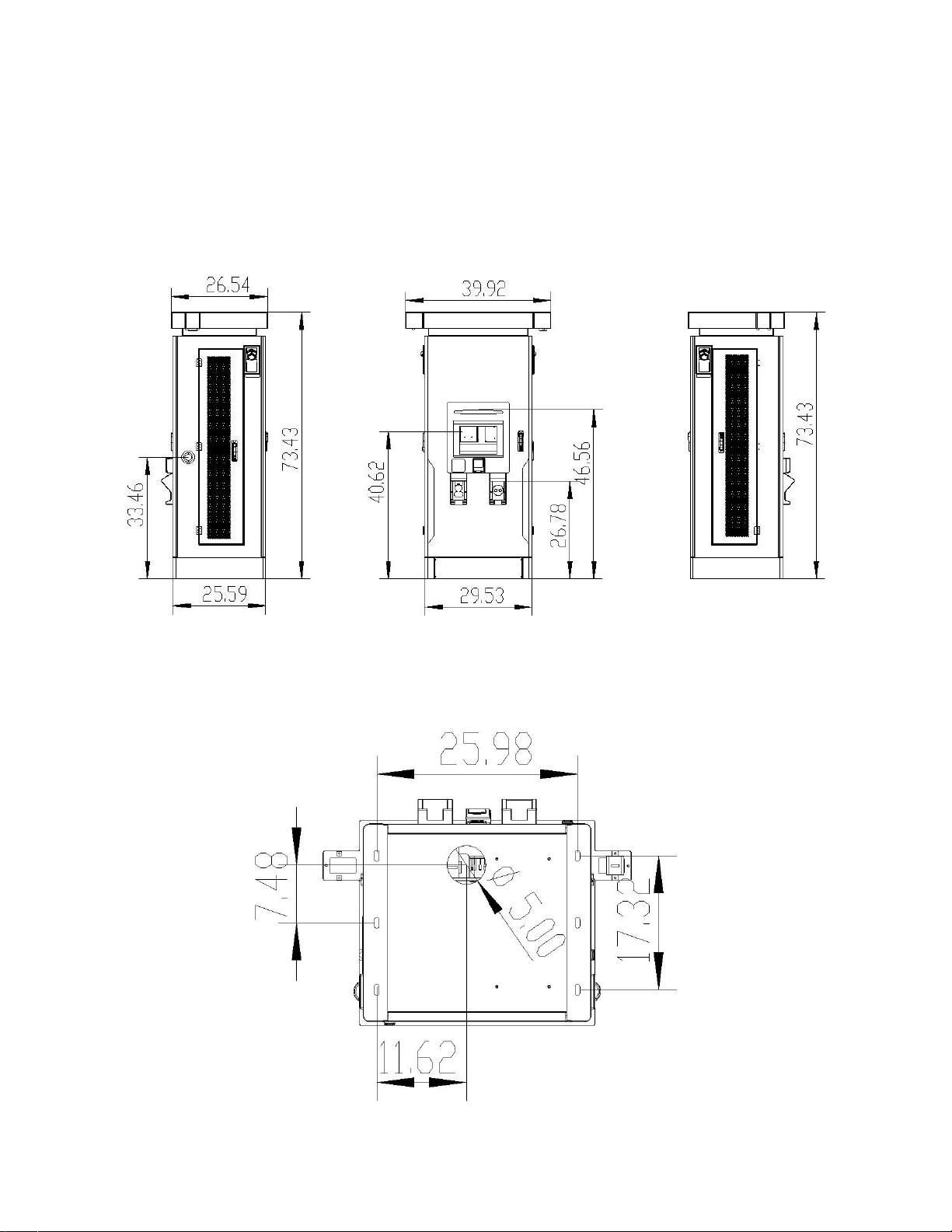

Charger Dimensions (LxDxH): 29.5”x 25.59”x 73.5”

Concrete Base

A flat concrete base with a vertical gradient of no more than 5% will be provided, with a provision for electrical

service wires to exit the concrete pad in the location as defined in this document.

The mounting pad shall be made of concrete cement, with approximate dimensions of 3 ft. wide by 2 ft. deep,

in order to accommodate the weight and dimensions of the base. Place the charger on the concrete mounting

pad with anchor studs using lock washers and nuts.

Mounting Pad

To meet ADA requirements, the concrete mounting pad shall not exceed 6 in. above the place of the parking

lot.

Barricade (Bollards)

Suitable bollards should be outfitted in order to restrict the approach of an electric vehicle (EV) to the charger.

Bollard position shall be in accordance with any applicable local code(s).

Input cables must be copper (3P+N); flexible copper is preferred. Please see the table, listed on the next

page, for cable gauge requirements.

Cables

Depending on the situation and cable type, the cables must be embedded in the ground with the proper cable

ducts.

Grounding

Reliable, protective grounding must be provided at all times. It is recommended to have a separate, dedicated

ground exclusively for the charger in order to ensure the highest degree of safety. The ground resistance

should be less than or equalto 4Ω. Copper cablein accordance withtheNECshallbe used to connect the charger

housingtotheexternal ground.

Breaker

A breaker (3P+N) with suitable current capacity, dependent upon the charger rating provided, is required. This

shall be in accordance with the NEC, typically 1.25 times the full load amperage.

Miscellaneous

Copper lugs (flat type) for the input cable and earth cable should be provided, and shall be sized dependent

on the size of the cable.

Do not let any flammable, explosive or flammable materials, chemicals, flammable vapors, and/or other

dangerous goods within close proximity of the charger.

Additional notes

The charger is rated IP54. In areas which see flooding, heavy rain, storms, snow, or other harsh weather

conditions, ChargeTronix recommends erecting a canopy over and above the charger for the equipment’s

protection.

Confirm beforehand that the intended installation site has a load capacity sufficient to support this equipment.

Charging cable length will vary between 13 ft. and 16 ft., depending on options.

8

OUTLINE OF DRAWING - 160kW DCFC

Figure 1 Charger Outline

Figure 2 - Charger Bottom View

9

CHARGER ANATOMY

10

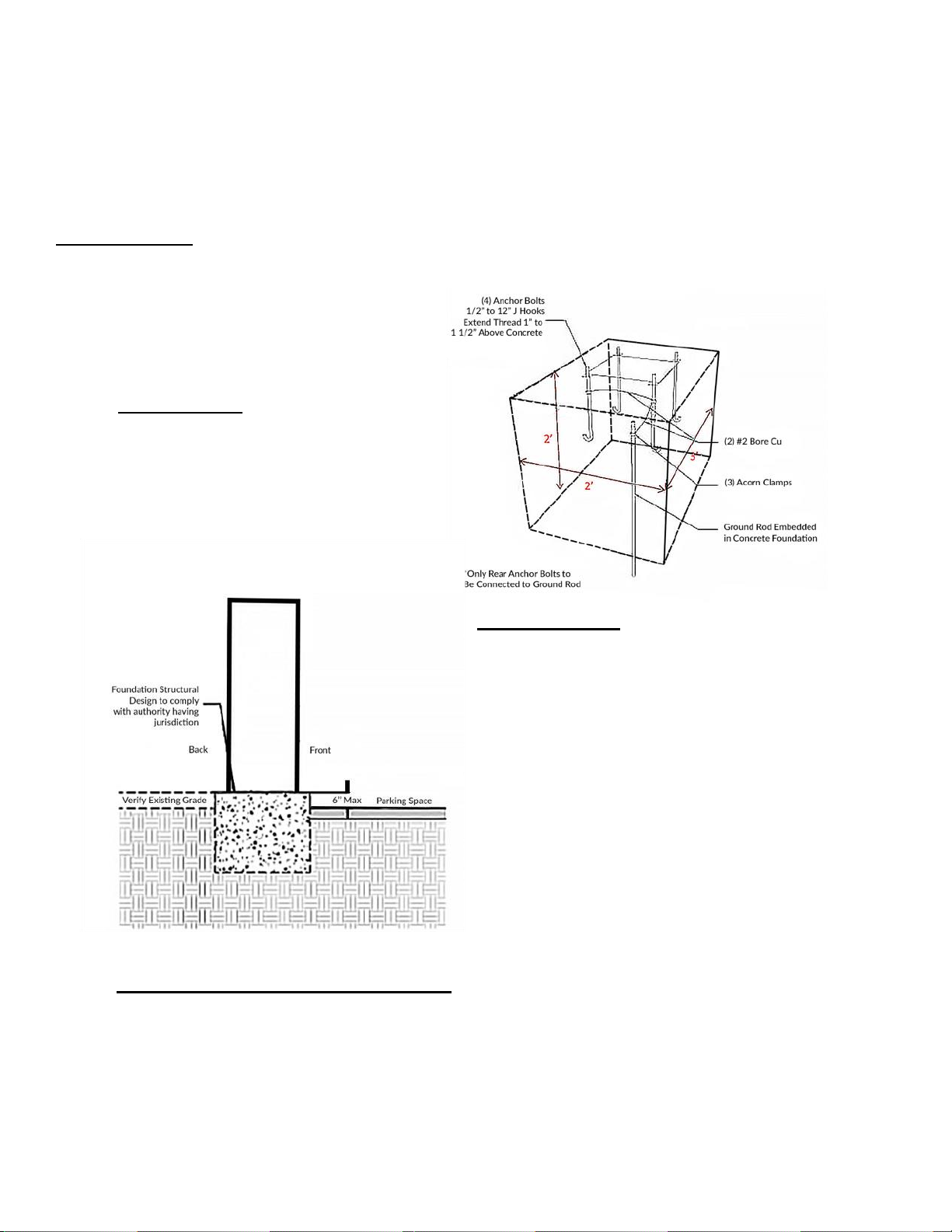

MECHANICAL INSTALLATION

CONCRETE PAD

A concrete pad constructed from 3,000-4,000 psi-concrete should be used. Electrical conduit for AC power

should be positioned such that it exits the concrete pad at the Main AC power line opening (see: Figure 2).

Alternative Anchor Installation –4 places

Use Hilti 1/2” KB-TZ SS 304 anchors (see: Appendix A Hilti Technical Information). Ensure that the

concrete has cured in accordance with the concrete and Hilti requirements. Position of the anchors shall

be in accordance to Figure 3 and installed per Hilti instructions. A ground rod will be needed and

installed.

PREPARATION

Ground Rod Connection: Use acorn

clamps to two #2 bare copper wire from

the ground rod to the first rear anchor bolt,

as shown on the diagram.

SIDE ELEVATION

▪

The concrete foundation needs to be sized

in accordance with local jurisdiction code(s). The

foundation referenced is 2 ft. deep and contains

rebar, as noted above.

▪

The foundation for the charger should have

a maximum height of 6 in. above finished grade.

‘Finished grade’ is defined as the location where the

user operating the charger will stand. Foundations

that extend higher than 6 in. above finished grade

will cause the charger controls to be above

ADA-compliant maximum standards and could result

in a failed inspection, possibly requiring the foundation

be lowered in order to meet ADA guidelines.

11

CHARGER INSTALLATION

ADA Consideration

There are a range of recommended best practices when installing electric vehicle chargers that incorporate ADA

requirements in the charger installation. Such practices include parking space striping, adequate allowance for wheelchair

movement, and bollards to protect the charger.

This equipment has been designed to meet ADA requirements when installed as prescribed in this manual; the prescribed

installation in this manual is also in accordance to the STANDARDS FOR ACCESSIBLE DESIGN for Americans with

Disabilities document.

2010 ADA Standards for Accessible Design: http://www.ada.gov/2010ADAstandards_index.htm

For information about the ADA, including the revised 2010 ADA regulations, please visit the Department’s website

www.ADA.gov ; or, for answers to specific questions, call the toll-free ADA Information Line at (1)800- 514-0301 (Voice) or

(1)800-514-0383 (TTY).

PLACING CHARGER ON MOUNTING PAD

1. A forklift will be required to move the charger into position. The charger with the crate will

weigh approximately 1050lbs. The charger without the crate weighs approximately 840 lbs.

To lift the charger, use either the forklift cut-out in the lower frame or the lifting eyes at the

top of the charger.

2. Remove the screws that hold the cover plates on the front and back of the base.

3. Before lifting the charger onto the mounting pad, remove the front/back cover plates which

will expose the slotted mounting hole. With the forklift, place the charger in position and

lower it onto the mounting pad while aligning the mounting pad studs with the slotted holes

in the charger base, ensuring that the electrical service also passes through the 4 in. cut-out

in the floor of the charger.

4. Install a large ½ flat washer, followed by a ½ split washer, and then fasten down the

appropriate nut and torque to Hilti specification. Remove the lifting eyes and plug the

threaded holes in the charger enclosure with appropriate fasteners, then seal with silicon.

5. Re-install the side cover plates.

12

INSTALL BASE FASTENERS - 4 PLACES

Install 1/2” x 1” x 1/8” thick washer, then the ½” lock washer and the 1/2-13 UNC nut and torque

to Hilti specification.

13

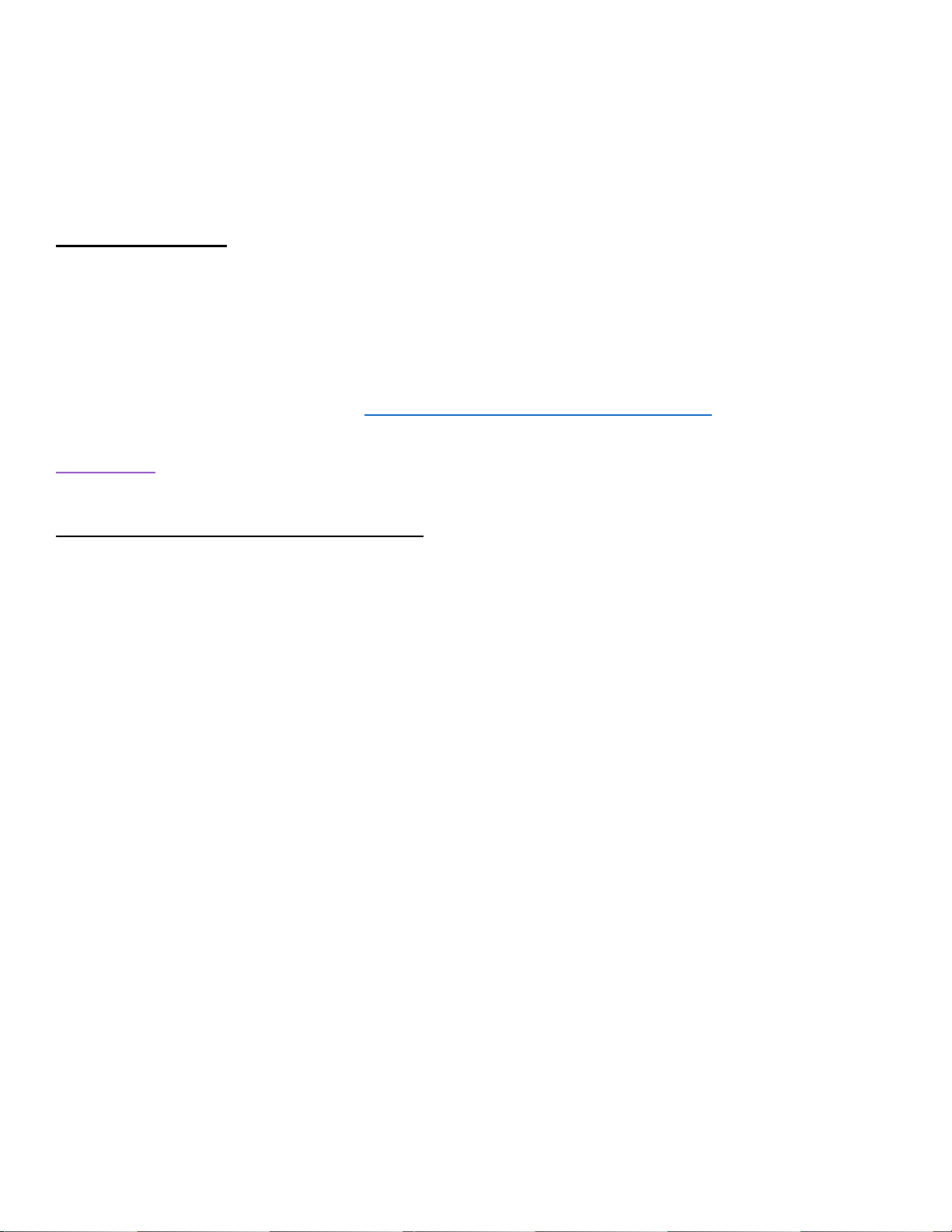

AC Input Power Wiring

INPUT VOLTAGE

AC Input Termination

COMPONENTS

•L1, L2, L3 are the 3 phase lines

•N is the Neutral

•PE is the protective earth or ground

Schematic diagram

of the input

connection of the

charger.

The charger requires an input

voltage of 480 VAC

(3 Phase + Neutral + Earth), 60Hz,

and a current of 215 amps.

Figure 3 –Main Breakers

14

HOW TO START A CHARGING SESSION

RFID CARD

1) Please select the connector compatible with your EV

2) Plug the connector into your EV

3) The display on the charger will provide options to select the authorization/payment method

4) Swiper the RFID card

5) The charging session will begin within 60 seconds

6) To stop charging: swipe the same RFID card again or use the STOP button the screen

QR CODE / MOBILE APP

1) Please select the connector compatible with your EV

2) Plug the connector into your EV

3) The display on the charger will provide options to select the authorization/payment method

4) Scan the QR code at the charger, or use the mobile app to begin the charging session

5) The charging session will begin within 60 seconds

6) To stop charging: Use the mobile app or use the STOP button on the screen

CREDIT CARD

1) Please select the connector compatible with your EV

2) Plug the connector into your EV

3) The charger display will provide options to select the authorization/payment method

4) Authorize your credit card. Make sure you have enough pre-loaded funds to charge

5) The charging session will begin within 60 seconds

6) The charging session will automatically stop after 100% charge is achieved. Or, you can use the

STOP button the charger screen.

15

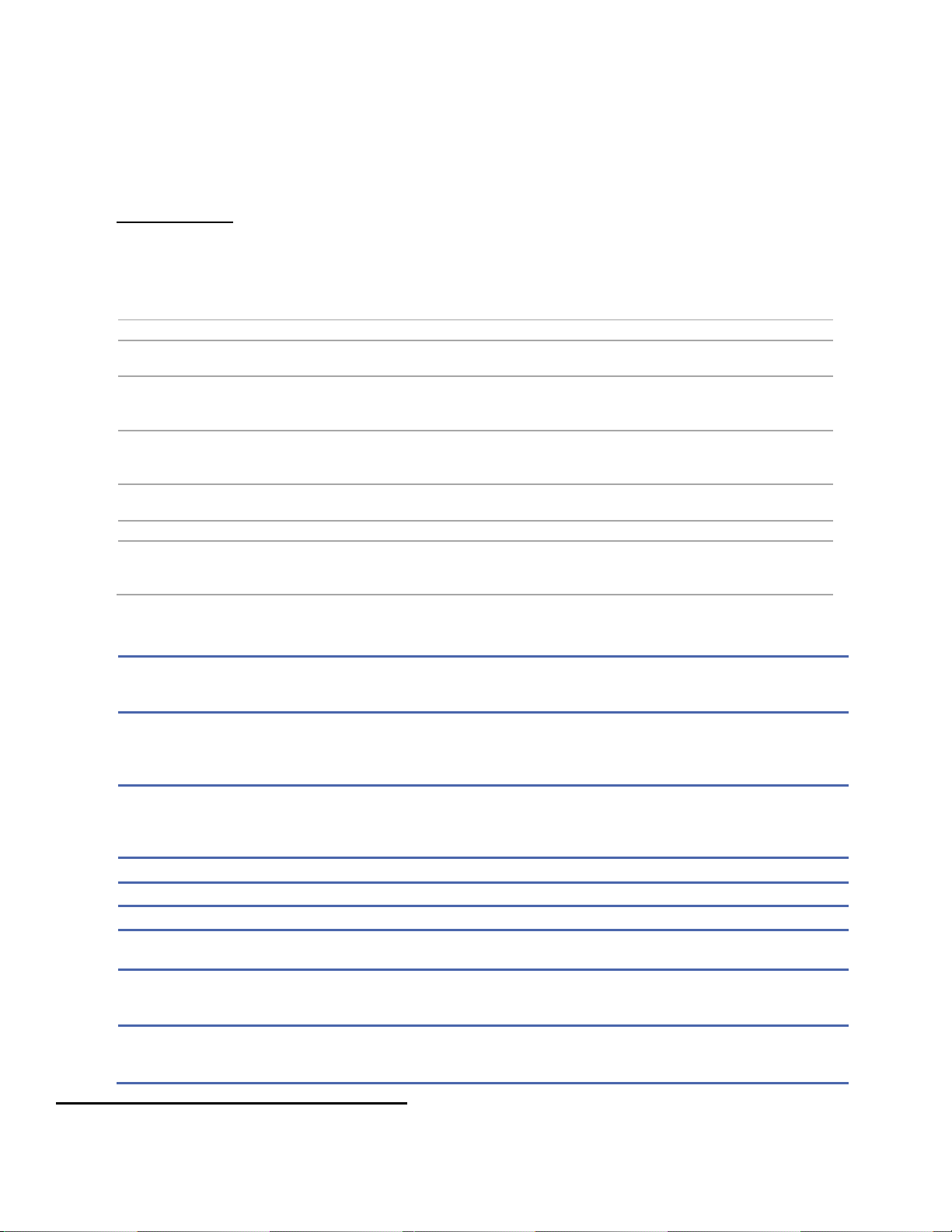

CHARGER SETTINGS

Setting Parameters

During the initial installation, the setting parameters must be set by

the manufacturer, operating partner, or service partner. Changes

may only be made by trained personnel.

To access settings window:

1) Touch the ChargeTronix Logo

2) Provide the password. Password will be shared with the

authorized representative.

3) Select ‘system settings’

PARAMETER

VALUE

TIME ZONE

UTC+HH:MM

PSM QUANTITY

1

POWER OUT MODE

1

OCCUPLIED PLUG

1

PSM MAX VOLTAGE

1000

PSM MAX CURRENT

300

PSM MID VOLTAGE

200

PSM MID CURRENT

80

PSM MIN VOLTAGE

150

PSM MIN CURRENT

1

PMAX

20000

CCS NETWORK 1

ETH1

INSYS PLC MAC 1

00:00:00:00

TIME

2020-08-20

T20:46:25

.

S.NO

PARAMETERS

VALUE

REMARKS

1

NETWORK

ETH

Ethernet - DO NOT CHANGE

2

NETCFGFILE

/etc/network/interfaces

Path - DO NOT CHANGE

3

WLAN CONF

/home/guest/wpa_supplicant.conf

Path - DO NOT CHANGE

4

DEVICE IP

192.168.2.5

IP Address of Device

5

DEVICE GATEWAY

192.168.2.1

IP Address of Gateway

6

DEVICE NET MASK

255.255.255.0

IP Address of Mask

7

SERVICE URL

ws://localhost:8080/ocpp/

OCPP Server URL

8

DEVICE ID

1020180520001001

Device ID (alphanumeric)

9

CHARGE POINT VENDOR

ChargeTronix

Charger OEM - DO NOT CHANGE

10

CHARGE POINT MODEL

DC

Charger Type - DO NOT CHANGE

11

ADPATH

./pic

Path - DO NOT CHANGE

12

QRCODE NAME

NA

13

LANG

en

Path - DO NOT CHANGE

14

MODE

offline/record/upload/debug

Path - DO NOT CHANGE

15

CHARGING PIC

/img/charging_tata.jpg

Path - DO NOT CHANGE

16

IDLE PIC

/img/standby.jpg

Path - DO NOT CHANGE

17

LCM

1cm=/dev/tty54

Path - DO NOT CHANGE

18

LCM ENCODE TYPE

UNICODE

Encode - DO NOT CHANGE

19

LCM PASSWORD

123456

Password for Access

20

RFID

RFID0=/dev/ttyS1

Path - DO NOT CHANGE

21

PLUG1

GBTDC1:2=/dev/ttyS0

Path - DO NOT CHANGE

22

PLUG2

GBTDC2:2=/dev/ttyS0

Path - DO NOT CHANGE

23

DC1QRCODE NAME

NA

24

RFID ORIGINAL NUMBER

0

NA

16

MAINTENANCE AND SERVICE

DANGER: READ AND FOLLOW “SAFETY CONCERNS” AT THE BEGINNING OF THIS MANUAL BEFORE

OPERATING OR INSTALLING THIS DEVICE

EV Chargers require regular maintenance beyond installation to ensure the quality of the vehicle’s charges and

the continued value of your EV. Whether you’re installing a personal EV charger or one for public use, eventually

your device will require repair or maintenance services to keep the system working without issue.

MAINTENANCE PRECAUTIONS

Each of the capacitors in this device has high voltage for a time after shutting off the input power supply. Allow 1

minute after powering down, and then test with a voltmeter, before servicing internal components.

MAINTENANCE ITEMS

Perform periodic checks every 3 to 6 months based on the site conditions and the usage of the charger:

1) Check the input voltage and ensure it is within the acceptable limits

2) Check the ground/earth resistance and ensure it is within the acceptable limits

3) Clean the air filter periodically

4) Make sure that the power module lights are blinking green

5) Ensure that the charging cables are not worn out or showing wiring, and that the connector pins are clean

6) Make sure all of the air-cooling fans are working normally

VISUAL CHECK ITEMS

1) Check for abnormal sounds from running fans and power units

i If there is an abnormal sound present, please contact ChargeTronix at +(1)949-694-1644 for further

assistance

2) Check the device for abnormal odors, changes in inner materials, corrosion, anomalies in appearance, etc.

i If there are any anomalies, please contact a ChargeTronix support representative for further

assistance

3) Check for dust and dirt in this device regularly

i The air filters on the doors can be removed and cleaned using a vacuum cleaner or air blower

ii The cabinet can be cleaned using a vacuum cleaner

1 Please pay extra attention while using the vacuum cleaner, it should not apply pressure on the

control boards or any components

iii The dust on the components can be cleaned using a soft cloth

REPLACEMENT OF FIXED-LIFE COMPONENTS

To prevent the device from failure due to worn out components, it is necessary to replace the components before

they reach the end of their lifespan. Use the following replacement intervals as a guideline for the estimate of the

total running time.

oIntake and exhaust air filters (if present): Approximately three (3) years. The period depends upon the

site conditions.

oPlease keep in mind that the replacement interval of each part can vary depending on the usage

environment of the device.

Please contact a ChargeTronix support representative for further assistance when you replace the parts.

17

TROUBLESHOOTING

ERROR CODES

If an error occurs, check the nature of the error by referring to the following “Error Code List” and take appropriate

actions according to instructions by the manufacturer

ERROR

DESCRIPTION

POSSIBLE SOLUTION

ERROR FLAG 0

Lightning protection device failure

Check the SPD and GFCI circuit

ERROR FLAG 1

Insulation detection abnormal

The insulation check on the EV has failed.

Please try to charge different EV.

ERROR FLAG 2

Abnormal communication between

Insulation Monitor and Main Control Board

(CM)

Please check the connection between the IM

and CM boards. Check the LED lights on the

CM and IM

ERROR FLAG 3

Abnormal communication between TR

board and CM board

Please check the connection between the tr

and cm boards. Check the LED lights on the

CM and TR

ERROR FLAG 4

Electronic lock failure

Possible failure of the connector to lock on the

EV or the 24v supply voltage

ERROR FLAG 5

Internal use

Reserved

ERROR FLAG 6

Abnormal communication between DC

meter and main control board (CM)

Please check connection between the DC and

CM boards. Check the LED lights on the CM

and communication lines of the DC meter

FAULT TYPE SOLUTION

IP address communication failure or Server

Communication Failure

Please check the parameter settings interface IP address

information, such as the corresponding IP address is not correct,

please re-enter the address, restart the charger

AC input over voltage / under voltage

Please check the AC input side if the voltage is too high or too low,

excluding the input exception if there is a fault. Then, check the

parameters, the interface set, and the threshold set to ensure that

are correct

DC output over voltage / over current

Please check whether the output voltage and current are within the

range of parameter settings. If not, please check whether the output

voltage, current is too high, or whether the parameter setting is

reasonable

Card reader failure

The card reader is incorrectly wired, or the card reader is disabled.

Insulation fault

Please check whether the DC bus insulation is normal.

Monitoring board communication failure

Check whether the monitoring board communication line is correct

Charging connector connection failure

Charging connector is disconnected, please check whether the

charging connector is connected properly.

The emergency stop button is pressed

Check whether the emergency stop button is pressed, if it is, inspect

the charger and if everything is normal, release the emergency button

and restore the main breaker

Charging Session shutdown is not successful

MCU board and power module communication failure. Please press

emergency stop button to stop the charging. Check the MCU board

and power module CAN communication bus.

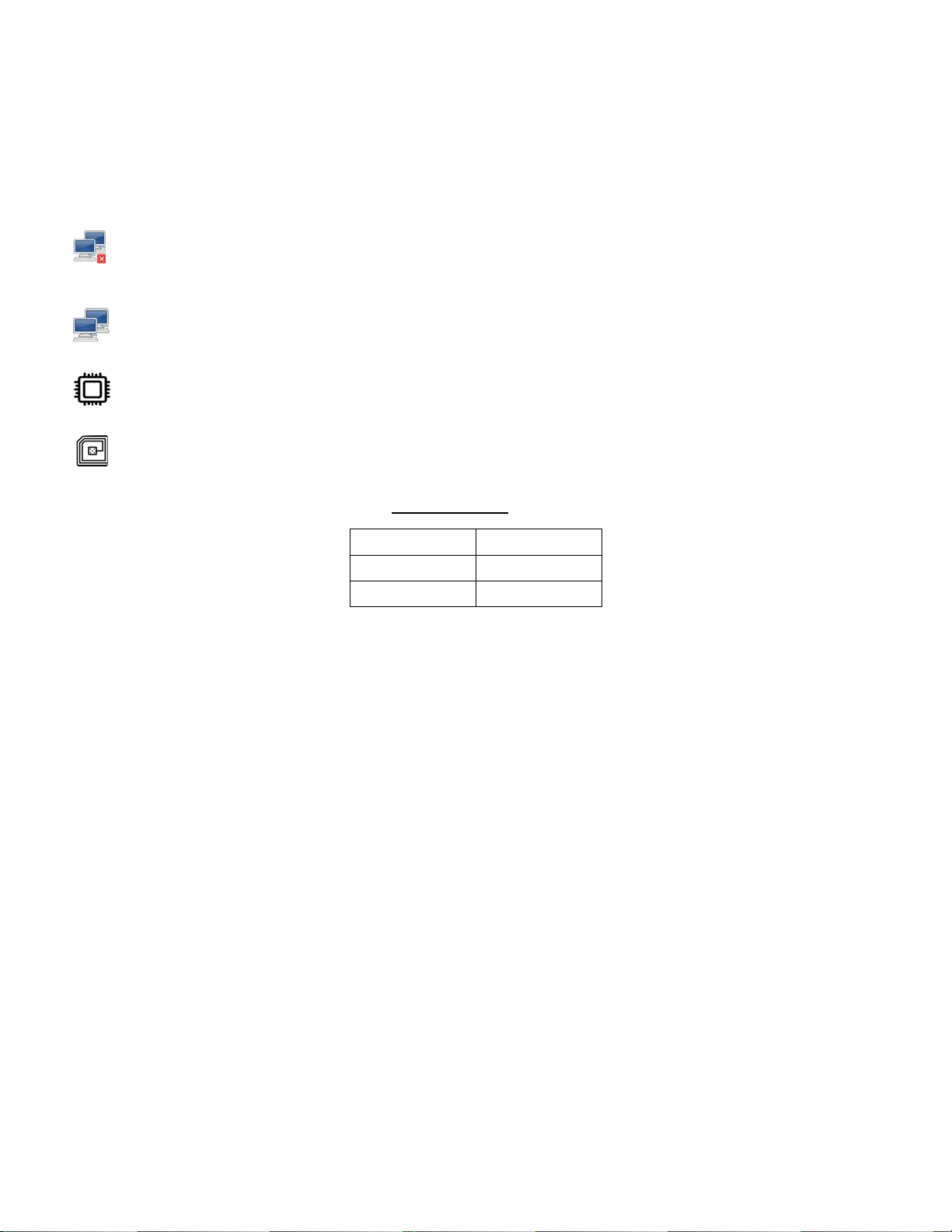

Physical Diagnostics at Charger/On Screen

18

The icons below will be visible in the top-right corner of the charger screen:

This icon indicates that the charger is not connected to a server network. It can also indicate a loss of

internet connectivity. If no network is connected, the charger works as a stand-alone device with

ChargeTronix RFID cards.

This icon indicates that thechargerisconnectedtoa servernetwork; it canbe authorized with registered

RFID cards or the mobile app.

This icon indicatesthe working condition of the charger.If the icon flashes or is not visibleon the screen,

the controller is inactive.

This icon indicates that the RFID card reader is active. If the icon is not visible on the screen, the RFID

reader is inactive.

LED Indicator:

RED / Orange

Fault

Green

Charging

White

Available

19

CUSTOMER RESPONSIBILITIES

1) Operate the charger with the required protective devices, such as miniature circuit breakers

(MCBs), switches and properly installed cables

2) The operator/owner/customer is cautioned that any changes or modifications not approved by

ChargeTronix shall void ChargeTronix warranty policy

3) Write an emergency plan that instructs people what to do in case of emergency with the charger

4) Locate and prepare the site as per the instructions laid out in this document

5) Ensure that there is sufficient space around the charger to carry out any regular maintenance

work

6) Appoint a trained person(s) responsible for the safe maintenance/service of the charger

7) Neither ChargeTronix, nor any of its affiliates, shall be liable to the operator/owner/customer of

this product or third parties for damages, losses, costs, or expenses incurred as a result of an

accident, misuse, or abuse of this product or unauthorized modifications, repairs or alterations

to this product, or failure to strictly comply with ChargeTronix operating and maintenance

instructions

For any support on installation and commissioning, please contact below:

ChargeTronix

3120 Pullman St.

Costa Mesa, California, USA 92626

E: support@chargetronix.com

P: +(1)949-694-1644

20

WARRANTY

Warranty and Service Plan

ChargeTronix DC chargers come with the 2 years parts only standard warranty. However, we offer

service plans which cover parts and labor as well for an additional add-on fee. We can train your

operators or engineers and equip them with a basic understanding of troubleshooting and part

replacement to make sure the equipment downtime as well as the total cost of ownership is minimized.

Warranty Terms

LIMITED WARRANTY: Subject to the exclusions from warranty coverage set forth below, ChargeTronix

warrants that the Product will be free from any defects in materials and/or workmanship (the “Limited

Warranty”) for a period of two years after 30 days from the date of shipment or from date of the initial

installation whichever is earlier (the “Warranty Period”). If the Product becomes defective in breach of

the Limited Warranty, ChargeTronix will, upon written notice of the defect received during the Warranty

Period, either repair or replace, at ChargeTronix’s choice, the Product if it proves to be defective.

ChargeTronix will also pay for shipping charges for the failed part. If the returned part has not failed the

customer will pay for shipping charges for the replacement part and the associated returned part. Under

this guarantee, ChargeTronix liability is limited to repair or replacement of the product with the same or

equivalent, or reconditioned product warranted for the original warranty period. The warranty will not

include removal costs, reinstallation costs, loss of charger revenue, nor loss or damage of any kind

whatsoever, whether incidental, consequential or otherwise.

Exclusions From Limited Warranty

IMPORTANT: The Limited Warranty and on your Product shall not apply to defects, or service repairs,

resulting from any of the following:

•Damages due to normal wear and tear to charging cords, connectors, LCD/LED display, Touch Screen, or any product

alteration or modification, misuse, abuse, accident, vandalism, acts of nature, power surges, or use of software, parts, or

supplies not supplied by ChargeTronix, and causes other than manufacturing defects not covered by the warranty.

•Force Majeure –any occurrence or extraordinary event or circumstance beyond the control of ChargeTronix that is an act

of God or whether that occurrence is caused by war, riot, storm, (such as hurricanes, flooding, earthquake, volcanic

eruption, etc.), or other natural forces, including high input voltage from generators or lightning strikes or acts of nature or

other causes.

•Any Alteration or Modification of the Product in any way not approved in writing by ChargeTronix.

•Abuse, damage or otherwise being subjected to problems caused by negligence (including but not limited to physical

damage from being struck by a vehicle) or misapplication, or misuse of the Products by customers or end users.

•Any damage to the EV charger cord, unless such damage is caused by a manufacturing defect in the cord or connector

assembly.

•Improper site preparation or maintenance. That has been improperly installed, operated, handled, or used, including use

under conditions for which the product was not designed, use in an unsuitable environment, or use in a manner contrary

to the ChargeTronix Installation and Operations Manual or applicable laws or regulations.

•Damage because of accidents, extreme power surge, and extreme electromagnetic field.

•Use of the Product with software, interfacing, parts or supplies not supplied by ChargeTronix.

•ChargeTronix disclaims any liability for damage to product, property, or personal injury resulting in whole or in part, from

improper installation, maintenance or use that is not in accordance with ChargeTronix installation and maintenance

procedures.

•Maintenance or use that is not in accordance with ChargeTronix installation and maintenance procedures.

•That has been subjected to incidental or consequential damage caused by defects of other components of the electrical

system.

This manual suits for next models

5

Table of contents