4

differential circuit breaker or GFCI. Please refer to the specific characteristics

of the circuit breaker.

•For security reasons, the system’s PE or Ground terminal must be connected

to the installation’s earth ground (green/yellow wire in the cable section).

Please refer to the wiring diagram.

•To prevent overheating, ensure the correct connection and size of cables.

•The input cable must not exceed 10’ (3m) and the output cable 5’ (1.5 m).

•All cable connections and connectors must be maintained in good condition.

Once the connection of the AC cable has been completed, it is imperative to fit

the Winsta Wago plug snap on security cover. See “Assembling the Shore

Power Connector”

Start up precautions.

In order to avoid all risk of electric shock or irreversible damage to the device, please

follow very carefully the following recommendations.

•Do not dismantle the device. The housing (protection against fire) must be

correctly mounted.

•This device complies with enforced standards; regarding emitted interference,

protection against disturbances of external origins (refer to the paragraph on

EMC –Technical Specifications.)

•When in use, avoid submitting the device to levels of interference, in particular

electromagnetic and conducted, exceeding those legally permitted (for

example, the devise installed too close to an emitter) as this may cause

irreversible damage.

•This device emits interference (electromagnetic and conducted) which complies

with legal standards. Ensure that materials used are compatible i.e. susceptible,

with this device in order to avoid irreversible damage.

Device serial number

The serial number appears on the data plate label on one side of the device. This

number is aligned vertically and comprises a first number indicating the year of

manufacture (e.g.: 12 for 2012), a letter indicating the month of manufacture (e.g.: C for

the month of March).

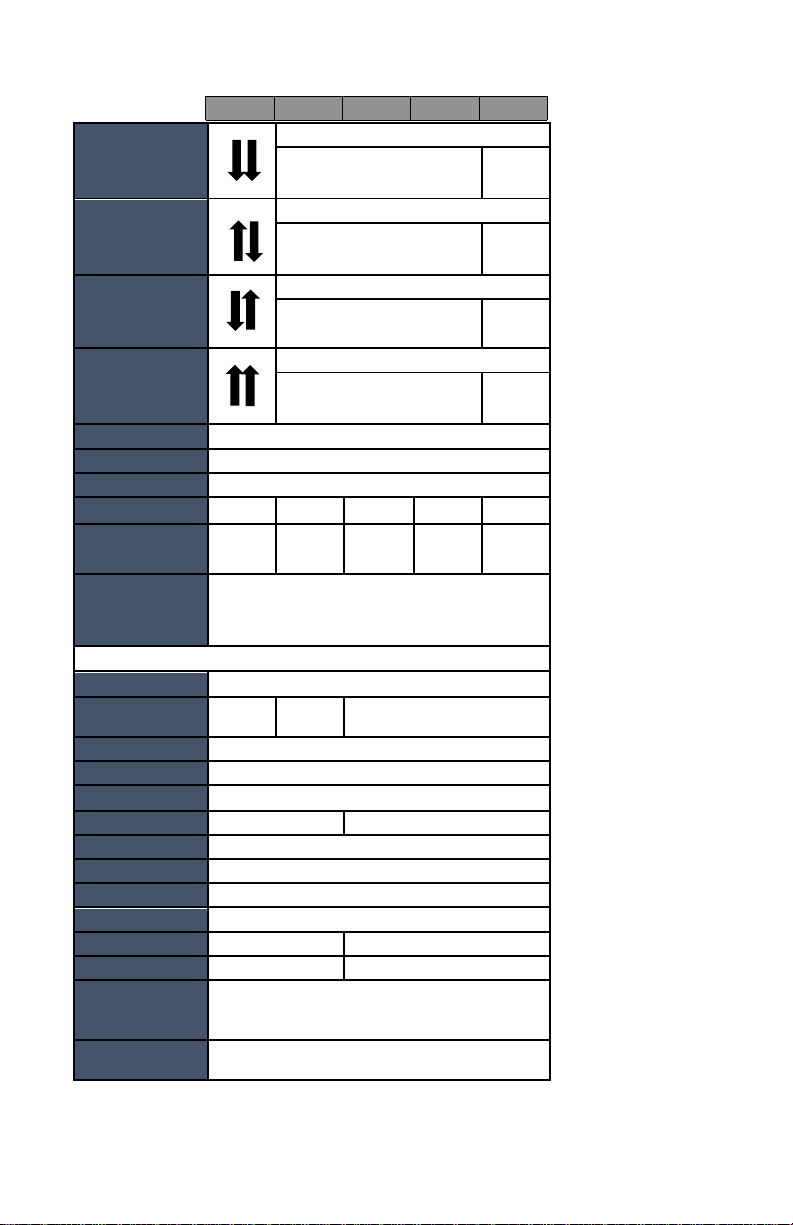

Model Number

SV = Sentry Voyager series

12 or 24 = DC Voltage Output

20, 40, 60… = DC Amp Output

/3 = 3 battery banks

X = 115/230vac, C = 230vac only, B = 115vac

J = 50/60 Hz, No Letter = 60 Hz only