Charles H. Callies Inc SC-II User manual

CompleteBuildingInstructions

For the SC-II

Society of Wireless Pioneers - California Historical Radio Society

How to Build

the

SC~II Receiver

Authoritative Data on the 5-Tube Shielded Receiver

Designed by McMurdo Silver and

Laurence M. Cockaday

Containing Full Description, List of Parts, Wiring Instruc,

tions, Photographs and Detail,s of Assembly and Proper

Operation of This Remarkable Radio Receiver

l l I

TABLE OF CONTENTS

Section 1

What the S-C II Receiver Is ........ .. .............. ... .... Page 4

Parts Specified for the S-C Receiver . . ........ .. .. . ..... . .. Page 6

Inspecting and Testing Individual Parts .... .. ........... . .. Page 7

Assembling the Receiver .. .......... ... .. .. .. .. . .. . . ....... Page 11

Wiring .. . . . ... ..... . ...... .. ... . .. . .. ..... .... . . .. ..... . . .Page 15

Checking Connections . .. . .... .. ...... .. .............. . .... Page 20

Attaching Link Motion ...... . ... .. . ... . . . . .... . . . .. . ... . ... Page 22

Mounting Front Panel .. . .... .. . .. ... ..... ..... . ...... .. .... Page 23

Attaching Dials .. ..... . ... . ... . . .. ... . ... .. . . .... . . .. ... . .. Page 23

Coil Placement .. .. . . .. .. . ........... . ... ... . .. . . ... .... .. .. Page 24

Preliminary Testing .. .. .. .. .. ••... .. . ....... . .. . . ... ... . . . .Page 26

Connecting Batteries ............ . ......... . .. . ... . ......... .Page 27

Antenna and Ground System ..... .. ... .. ... . .. ... .. . .. . . ••.Page 27

Loud Speaker .. .. .... .. . . .... . . . . .. .. . . . .. ..... . .. .... . . ... Page 30

Operation .. . . ... . .. ••. . . ...... . ......... .. . . . .. ........... Page 30

Most Sensitive Operating Condition . . . .. . . . . .............. .Page 32

Tuning for Distant Stations . . .... .... .. ............ . .. . ••. .Page 32

Loggin;; .. . ... .. .... ..... . . . ..... . .. .. ...... . ... . . .. ... .. .. Page 33

Preliminary Selectivity Adjustment .. .... ... . ••. ............ .Page 33

Balancing ........ . . . .... . . . .... . . .. .... . .. . . . . .. . .. .. . . .... Page 34

Battery Eliminators .. ... . .... . .. . .. .... . . .. .. . . ••. .. . .. . ... Page 36

Section 2

Trouble-Shooting

Failure to Receive Signals, Lack of Volume , Lack of

Sensitivity , Poor Tone Quality . . ... ... . .......... . ..... Page 37

Noisy Reception, Blocking or Motor Boating, Humming ... .Page 38

Batteries, Current Consumption , Loud Speaker, Fitting

Shields in Place, Coil Placement .... . ..... . . .. ... . ...... Page 39

Tubes, Use of UX200A Detector Tube, Potentiometer

Switch , Coil Socket Contact . ..... . ... . . .... ...... .. .. .. Page 42

Selectivity Adjustment , Loop Operation Short and

Long Wave Reception, Condenser Adjustment . ... ...... Page 43

Automatic Control of Power Equipment ........... . ... . . ... Page 45

Copyright 1927

Charles H. Callies Inc.

846 W. Jackson Blvd.

Chicago

[ 2 l

THE S-C II receiver has been designed by Lauran ce M. Cock-

aday and M cMurdo Silver with the idea of providing a radio

receiver possessed of practically all the mechanic al and electrical

detail s of the finest factor y-built receiver plus a quality of reproduc-

tion not obtainabl e in any except the most expensive of factory products.

The S-C II receiver will provide sufficient volume for home enter-

tainment purpo ses, and even for a small auditorium upon local sta-

tions. If reception conditions are favorable, stations several hundred

or more miles away may be received with ample loud speaker volume.

The quality of reproduction obtainable is believed to be superior to

that of practicall y all other receivers with the exception of a very few

of the highest class receivers price at from $250.00 up.

The sensitivity of the receiver is sufficient to allow the reception

of out-of-town stations with pleasing regularity and its selectivity is

sufficient to permit of separation between powerful local stations in

such crowded areas as those encountered about New York or Chi-

cago. At the same time, the operation of the receiver is simplicity

itself, for only two tuning controls need be manipulated together

with a single small knob used to turn the receiver on and off and

adjust volume.

The receiver itself is easy to assemble since every detail of its con-

struction has been planned with the utmost care, with the thought

in mind that it would be assembled by an absolute novice, totally

unfamiliar with radio. At the same time, investment value has been

considered most carefully and it is believed that the S-C II receiver

will not become antiquated for some years to come since its design

is in accordance with best engineering practices and there seem to

be few ways in which it could be practically improved upon. Never-

theless, should broadcasting conditions change, as in the matter of

wavelengths employed, the S-C II receiver is so flexible that by a

simple alteration of the coils used, or the substitution of a new set

of coils, its wavelength range may be adapted to any particular class

of broadca sting service that might be anticipated within the next

few years. ·

While it is very true that many five-tube factory-built receivers

may be obtained upon the open market for figures as low as $25.00,

the purchaser should always remember that in radio, as in other

fields, he only too frequently receives exactly what he pays for

(often less) , and it is hardly to be believed that a factor y-built

receiver, bearing as it must factory overhead and labor, can contain

[ 3 l

the same value either in material or engineering design that is obtain-

able in a receiver constructed by the user and costing 110 more than

many of the more reasonably priced commercial receivers. Thus ,

were the S-C II receiver to be supplied as a completely assembled

outfit , and were it to be priced on a level with average factory-built

sets, it would cost approximately $120.00; whereas by virtue of a

few hours of enjoyable work in building it himself , the purchaser is

able to save approximately $60.00. To state this in another way, he

is able to obtain approximately double value for an expenditure of

about $60.00 for the S-C II receiver that he would receive m a

factory-built set.

What the S-CII Receiver Is

THE S-C II receiver is a five tube set of standard design, incor-

porating two stages of tuned ~adio fr~quency. amplifi<:atioI?, a

detector, and two stages of high quality audio amplification.

The design of the radio frequency amplifier is such that it may be

adjusted to peak efficiency for each wavelength received , no endeavor

being made to provide semi-automatic means of holding it at a point

just below peak efficiency for all wavelengths. (It is a well-known

fact that this could not be accomplished practically due to variations

in receivers, and to obtain stability it would be necessary in an auto-

matically stabilized system to accept something less than peak sen-

sitivity. In the S-C II receiver no compromise has been made, and by

means of one small volume control knob, the set may be adjusted

to the absolute limit of sensitivity and, literally, nothing in the way

of performance be sacrificed as a result.)

The first radio frequency amplifier consists of an antenna coil,

"0,"tuned by a variable condenser "I-1," and so designed that it

will cover the wavelength range of 200 to 550 meters, and allow for

the use of either a long or short antenna. This first RF stage includes

a UX201A tube, the plate circuit of which is connected to the sec-

ond radio frequency transformer "P-1," the secondary of which

(similar to that of the antenna coil "O"), is tuned by a second

variable condenser "I-2." This second RF stage, consisting of trans-

former "P-1" with its socket "L-2," condenser "I-2" and tube "M-2"

is housed in a complete aluminum box "Q-1" which effectually pre-

vents the transfer of undesired energy between this stage and any

other portion of the receiver and also eliminates the pick~up of

extraneous interference upon the coils, condensers, and wiring of the

stage itself. This second stage, incorporating also a UX201A tube,

leads into the detector stage, similarly designed and constructed, and

housed in the second aluminum shield "Q-2."

[ 4 l

r

~

" •

'

~

1

~

~

I>

' '

' 0

" . @

'(~@

The sensitivity of the radio frequency amplifier as well as the

volume, is controlled by means of a 200-ohm potentiometer "B,"

integral with which is an on-off switch which completely turns the

receiver on and off.

The detector tube employs a negative grid bias to permit rectifica-

tion, for it is well known that a grid bias will allow of the handling

of stronger signals without distortion than will a grid condenser

and leak.

The output of the detector tube is fed into an audio amplifier

consisting of two audio transformers "N-1" and "N-2," a CX301A

and a CX371 tube. The audio amplifier is extremely interesting and,

in a sense, original, for its frequency range is from 30 to approximately

5,000 cycles, above which frequency it provides practically no ampli-

fication. This is desirable since the radio frequency portion of the

receiver preceding the audio amplifier is designed to pass a 10 kilo-

cycle band, which means that after rectification only frequencies up

to 5,000 cycles (the range of frequencies employed in music and

speech is from about 27 to 4,192 cycles), will be fed from the detec-

tor to the audio amplifier. However, the very sharp cut-off above

5,000 cycles of the audio amplifier results in the elimination of back-

ground hiss, and possibly more important, heterodyne squeals fre-

quently heard in present-day broadcasting when some 600 stations

are simultaneously operating in channels which will accommodate,

at the most, only one-third this number of stations without pro-

nounced interference.

The S-C II receiver is designed for operation with either batteries

or battery eliminators and will be found quite satisfactory when so

used. It may not satisfactorily be used with dry cell tubes, for the

vQlume obtained, as well as the quality, will not be comparable with

that obtained with standard CX301A and CX371 tubes. (It must

eeunderstood that the receiver will operate satisfactorily with CX299

and 220 tubes but that the volume and quality will suffer as a result

of their use.)

Parts Specified for the S-C II Receiver

LIST

A

B

C-1-C-2

D

E-l-E-10

1 Carter H ¾ resistor ..................... $0.25

1 Carter M-200-S potentiometer. . . . . . . . . . . . 1.25

2 Carter tipjacks @ 10c................... .20

1 Benjamin No. 9040 UX spring socket...... .75

10 Eby binding posts (Ant., Ant., Gnd., A+,

[ 6 ]

F-1-F-2

G-1-G-2

H

I-1-I-2

J

K

L-1-L-3

M-1-M-4

N-1-N-2

0

P-1-P-2

Q-1-Q-2

R-1-R-2

A- C-, C-, 45+, 90+, Amp.+) @15c. 1.50

2 National B vernier dials, clockwise @ $2.50. 5.00

2 Polymet 1 mf. condensers @ $1.00. . . . . . . . 2.00

1 Polymet .002 condenser. . . . . . . . . . . . . . . . . . .40

2 Silver-Marshall 316B condensers @ $4.50 .. 9.00

1 Silver-Marshall 316A condenser ........... 4.50

1 Silver-Marshall 637 _linkmotion ........... 2.00

3 Silver-Marshall 515 coil sockets@ $1.00 ... 3.00

4 Silver-Marshall 511 tube sockets@ 50c .... 2.00

2 Silver-Marshall 220 transformers @ $6.00 .. 12.00

1 Silver-Marshall 116A coil . . . . . . . . . . . . . . . 2.50

2 Silver-Marshall 118A coils @ $2.50 ....... 5.00

2 Silver-Marshall 631 stage shields @ $2.00. . 4.00

1 Van Doorn* S-C chassis unit (including

pierced formed steel panel, chassis and nuts,

screws and insulators) ................... 5.00

$60.35

*With the panel and chassis will be found an envelope containing:

31 6/32 nuts

22 6/32 x ¾" RHN P screws

9 6/32 x 1¾" RHN P screws

9 collars ¾ x ¾"

20 Belden soldering lugs

20 binding post insulating washers

4 tipjack insulating washers

3 potentiometer-switch insulating washers

Inspecting and Testing Individual Parts

FROM the foregoing general description of the parts used in

the S-C II receiver, the builder should have become sufficiently

familiar with them so that he may be able to intelligently inspect

each part before attempting to assemble the receiver.

Resistor "A" is a small strip of fibre wound with a flat resistance

wire, connections to which are made through two mounting lugs on

either end. Unless it appears to be physically broken or damaged, no

trouble may be anticipated.

Potentiometer-switch "B" should be examined very carefully. It

will be seen to consist of a fibre strip wound with fine resistance

wire held in a metal frame. As the knob is turned a contact arm

moves over this wire-wound resistance strip and it is necessary that

this contact be so bent that it presses firmly against the resistance

sector at all points throughout its arc of rotation. The on-off switch

[ 7 l

simply consists of two contacts carried on a metal frame attached to

the potentiometer. The under or inside contact is actuated by a fibre

cam attached to the potentiometer contact arm shaft. An angular

bend in this inner arm will be seen to fall into the bakelite cam at

one setting of the potentiometer adjustment. This is corr ect, and at

this point the under switch spring should not press against the out-

side switch spring. As the shaft is rotated, the angular bend in the

spring will be forced out of the slot in the bakelite cam and as this

occurs it will be seen that the cam forces the inner conta ct of the

switch against the outer contact blade and this condition of the two

springs pressing against each other should persist throughout the bal-

ance of rotary movement of the potentiometer shaft. (Wh en the

angular bend of the under contact arm is allowed to fall into the

slot ia the bakelite cam, the on-off switch is open-at other positions

it is closed.) Should the springs not make proper contact, they should

be bent with the fingers so that they make firm solid contact, and care

should be taken to see that the actual points of contact are clean,

and free of dirt or dust.

Tip jacks "C-1" and "C-2" may be ignored until the receiver is

completely assembled, at which time they should tightlv hold the tips

of lou·d speaker or phone cord inserted in them. If they do not, the

springs may be bent so that they will do so.

Detector tube socket "D" should be examined to see that the four

terminal screws and nuts are quite tight and a tube tried in it to make

sure that proper contact is effected and that the socket springs hold

the tube tightly in place.

Binding posts "E-1, E-2, E-3, E-4, E-5, E-6, E-7, E-8, E-9, E-10"

should be examined to see that they have the proper markings, that

they are equipped with fastening nuts , and that their tops unscrew

and screw up properly so that a wire may be held between the top

and base of each binding post.

Dials "F-1", and "F-2" should be examined to see that the indi-

cator plates rotate as the control knobs are turned and that each one

is accompanied by the three small studs and nuts necessary to fasten

it to the panel.

Fixed condensers "G-1" and "G-2" should be examined for signs of

physical damage and should preferably be tested with a B battery.

If a B battery is available, and two wires from it are connected to

the two terminals of the condenser, a spark should be noticed. With

battery leads removed, the two contacts of the condenser should be

short-circuited with another piece of wire , when it will ,be noticed

that the charge given to the condenser by the battery will discharge

with a slight spark. [ s J

Gz

Q,

"'

.J

L3

lz

...

Lz

d

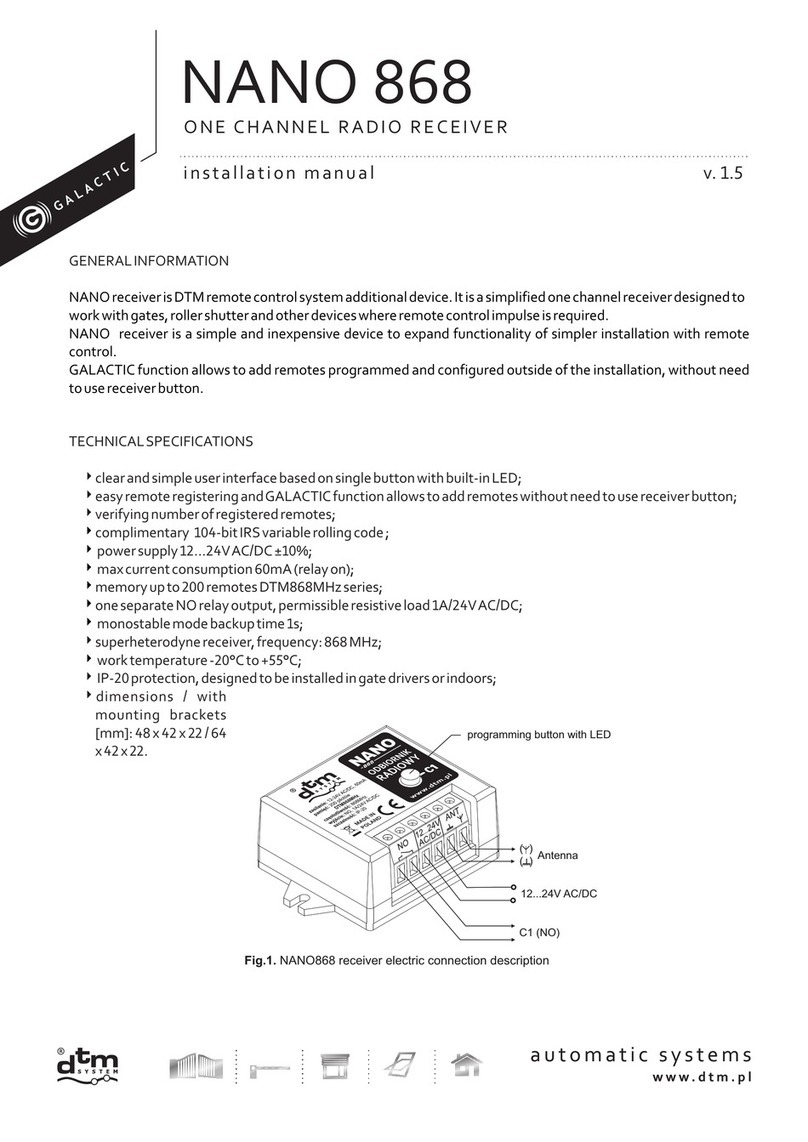

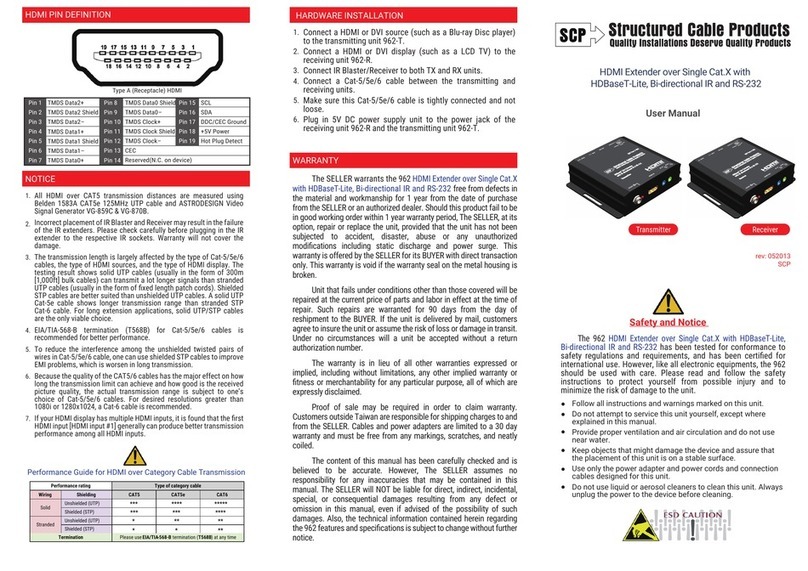

Fig 2.

[ 9 l

Condenser "H" should be tested in the same fashion except that

being very small it will not retain a charge and will simply show no

spark as connections from the battery are made to it.

The variable condensers "I-1," "I-2" and "J" should be examined

to see that they rotate properly and that the rotor plates do not touch

the fixed or stator plates at any point thruout their arc. Should the

condensers have been damaged in transit, they may be adjusted ac-

cording to instructions appearing elsewhere in this booklet.

Mechanical link motion "K," unless it shows obvious signs of

being bent, can be ignored until the time comes to assemble it on the

condensers.

Coil sockets "L-1," "L-2" and "L-3" should be tested in connect ion

with the RF transformers "O," "P-1 " and "P-2." Each transformer

should be inserted in a coil socket and the following test for con-

tinuity of winding made. Taking RF transformer "O" in its coil

socket, one lead from the B battery should be touched to terminal No.

6 and held there. The other lead from the B ,battery should be

touched successively to terminals Nos. 3, 4, and 5, from which a spark

should be obtained. In the case of transformer "P-1" and "P-2" a

spark should be obtained between contacts 3 and 6, and 4 and 5, but

not between 3 and 4 or 5. If a spark is not perceived in this test,

the coil sockets should be examined to make sure that the spring fin-

gers touch the buttons on the coil forms.

Tube sockets "M-1, M-2, M-3, M-4" should be tested as was

detector tube socket "D."

The two large transformers "N-1" and "N-2" should be tested

with a B battery. A spark should be obtained between terminals 1

and 2, and 3 and 4, but not between terminals 1 and 3 or 4. No spark

should be obtained between any terminals an_d the metal cases of the

instruments.

Unless the shields "Q-1" and "Q-2" appear to be bent or crushed,

they are OK; assuming the base pans to be pierced and the front

ends of each shield to be slotted with a long U-shaped slot.

The steel panel and chassis "R-f' and "R-2" should be examined

to see that they are not scratched and that they appear to be properly

pierced and formed, but not bent thru damage in transit.

[ 10 l

Assembling the Receiver

j\ LL parts for the receiver having been procured, and tested in

f"l..accordance with the foregoing paragraphs, the assembly may be

started by mounting all parts upon the steel chassis "R-2" in ac-

cordance with the photograph of Fig. 2. The first step is to put all

binding posts and tipjacks in place. In the small package of assorted

screws, washers, etc., accompanying the chassis, there will be found

ten small flat insulating washers of fibre with holes in them just large

enough to slip over the binding post screws. There will be found

ten more similar washers with small projections on one side which

are designed to be put into the over-size holes at the rear of the steel

chassis for the binding posts. The nuts having been removed from the

binding posts, they should be placed on the chassis in position shown

with the extruded washers on top of the chassis and the flat washers

beneath, with the extrusions of the upper washers falling inside the

holes of the chassis. If this is done, it will be seen that when the nuts

are screwed up upon the binding post shanks with a pair of pinchers,

none of the metal of binding post shanks will come in contact with

the chassis, but will be held away from it by the insulating washers.

Under each binding post nut should be placed one of the small solder-

ing lugs, exactly as seen in the photograph of Fig. 3.

The two tipjacks should be attached to the chassis in the same

fashion as the binding posts, using the set of four (two plain and

two extruded) insulating washers that appear to be slightly larger

than those used for the binding posts. The details of attaching these

tipjacks will be seen from the photograph. (Being of metal, they

must not actually touch the metal chassis.)

The on-off switch and potentiometer, "B," should be fastened to

the front of the chassis with its various contacts projecting upward,

as seen in the different photographs. The knob having been removed

from this instrument, the lock nut on the shaft bushing should also

be unscrewed. Three large insulating washers will be found accom-

panying the chassis screw assortment. The two plain ones should be

placed over the shaft bushing and pushed back. The shaft bushing

should then be pushed thru the hole in the half-round projection at

the front of the chassis, the extruded washer placed over the bushing

so that the extrusion falls in the hole of the chassis, and the lock nut

screwed up on the whole assembly. When this operation is per-

formed properly a test should be made with a B battery . One wire

from the B battery should be touched to the chassis and the other

touched to all contacts of the switch and potentiomett>r. If the in-

[ 11 l

sulating washers are properly arranged and there is no metallic con-

tact between the chassis and unit "B," no spark will be obser~ed,

which is the correct condition. (The same test should be given the

binding posts and tipjacks, for there must be no metallic contact be-

tween any of these instruments and the chassis at this stage of the

assembly.)

The next step is to mount the two stage assemblies in shield pans

at the right-hand end of the chassis. By placing the shield pans in the

approximate positions shown in the photographs, it will be found

that certain holes will coincide-notably, the large round lead hole

to the rear of each shield pan, plainly visible in Fig. 2, as

well as the two mounting holes for the tube socket, the three holes

for the coil sockets, and those for the condensers "I-2" and "J."

In the screw assortment will be found a total of nine hollow studs

and nine long screws. Taking coil socket "L-3" three long screws

should be pushed thru the mounting holes in it and over these screws

on the under side of the coil sockets the three hollow studs for this

socket should be slipped. The socket should then be placed in posi-

tion in shield pan "Q-2" as seen in the various photographs. On the

under side of the chassis, nuts should be tightened up on these mount-

ing screws with a pair of pinchers. When the operation is com-

pleted, the coil socket will be held in place ¾ of an inch above the

shield pan "Q-2" by means of the three mounting screws and the

three hollow studs on the mounting screws. The actual arrange-

ment of these studs may possibly be most dearly perceived from the

photograph of Fig. 4. The same operation should be performed with

coil socket "L-1" and "L-2" (the shield pan "0-1" being held to the

chassis "R-2" under coil socket "L-2.") Caution should be observed

in every case to make sure that the small indentation in the bakelite

coil socket ring falls in the position visible in photograph of Fig. 2

and that terminal No. 3 of the coil socket is in every case the extreme

right-hand terminal, viewing the chassis from the front.

The next step is to mount the detector socket "D." The details of

this operation are evident in Fig. 2. A single screw is pushed thru

the mounting hole located close to terminal "G" of this coil socket.

Under the screw head is placed one of the small lugs and a nut is

tightened up with a pair of pinchers on the end of the screw pro-

jecting thru the under side of the chassis. Socket "D" is held in

place by this single screw and in order that contact be made by means

of the wire shown connecting the minus terminal of this socket to

[ 12 J

Fig. 3

[ 13 l

H

E,o

Ee

a,

E,

E~

A

Es

Ea

E,

c,

c,

the lug under the mounting screw head it is necessary that the bot-

tom of the chassis be cleaned of enamel where the fastening nut

makes contact with it.

The four tube sockets "M-1, M-2, M-3, M-4," may be mounted

using two screws and two nuts each. Under the mounting screw

heads, falling between the minus and plus terminals of these sockets a

soldering lug should be placed, turned toward the minus terminal.

Another soldering lug fastened under the "minus" terminal screw

of each socket is pointed toward the first lug , as can be seen from

Fig. 2, so that both lugs touch. (They are later soldered together

and make the minus connection between each tube filament and the

chassis which actually forms the negative A and negative B battery

wiring for the receiver.) It is needless to say that the under side of

the chassis should be scraped where the nuts for these mounting

screws come in contact with it.

Referring to Fig. 3, it will be seen that some of these mounting

screws serve to hold the condensers and fixed resistances on the bot-

tom of the chassis. Thus on the mounting screw holding tube socket

"D" condenser "H" is fastened by means of another nut tightened

up on this screw to hold the condenser firmly in position. It is very

important that this procedure be followed out exactly-one nut must

serve to hold the condenser away from the actual chassis while

another holds it tightly to the screw. (To rephrase, it is necessary

that the metal contact clamps of condenser "H" do not actually

touch the ohassis at any point but that thru the eyelet holding one

of these clamps in place the mounting screw of coil socket "D" is

passed with a nut on either side of the condenser.) Upon the mount-

ing screws of sockets "M-1" and "M-2" are fastened to two bypass

condensers "G-1" and "G-2." In this instance it is desirable that

the metal cases of the condensers make contact with the chassis, and

they are clamped directly to it by the fastening nuts on the tube

socket mounting screws. Upon the rear mounting screw of coil

socket "L-2'' one end of the half ohm resistance "A" is held in the

same fashion as was condenser "H": that is, as the screw comes

thru the bottom of the chassis "R-2" one nut is placed over it and

screwed up tightly; then one end of the resistance "A" is dropped

over the screw and a second nut tightened up on top of this, so that

at no point does any of the metal structure of resistance "A" come

in contact with chassis "R-2."

The two audio transformers "N-1" and "N-2" should be fastened

on the chassis at the left-hand end as shown in Fig. 2. The exact

position of these transformers is evident from the photograph, and it

[ 14 ]

will be seen that the terminal strip of the rear transformer is toward

the right while that of the front transformer is toward the left.

The three variable condensers "I-2," "I-1" and "J" should be

fastened to the chassis. In the postions shown in Fig. 2 "l-1" (which

is identical actually to "I-2") falls at the left of the chassis exactly

in front of coil socket "L-1." Two mounting holes will be found in

the chassis, the position of which coincides with the two threaded

holes in the mounting feet of each condenser. Screws should be

pushed up thru the chassis and screwed up tight into the mounting

lugs of the condensers. (The screw-heads may be s~en in Fig. 3)

Condenser J,with the shortest shaft, mounts at the nght end of the

chassis, in shield pan "Q-2."

The assembly is now completed, and should be carefully examined

and checked, making sure that all instruments are mounted exactly

as seen in the photographs.

Wiring

THE wiring of the S-C II may be done entirely without solde~-

ing, if desired, although it is strongl_y ~ecommende~ ~hat certam

connections be soldered. (No descnpt10n of the wmng method

where soldering is not employed will be given; for any prospectiv:c

builder not familiar with the use of a soldering iron had best take his

parts to a service station, where he may have his receiver assembled

and tested at a very nominal cost.)

All wiring on top of the chassis should first be put in place start-

ing as follows: One end of the fabri~ insulated ~ellogg hook::-~p

wire should be bared for about half an mch by pushmg back the m-

sulation and this end twisted around terminal "G" of the coil socket

"D." The nut on thi~ terminal is tightened up with a pair of pinchers,

clamping the wire tightly to the terminal. The _wire i? then pulle~

straight forward on the chassis, scraped free of msulat10n so that 1t

may ,be twisted around terminal screw N?·3 _ofcoil. socket ''.L-3."

This screw being tightened upon the wire, 1s continued directly

forward t~ a soldering lug found under a nut on condenser "J."

The end of the wire is pushed thru this lug, twisted around it, and

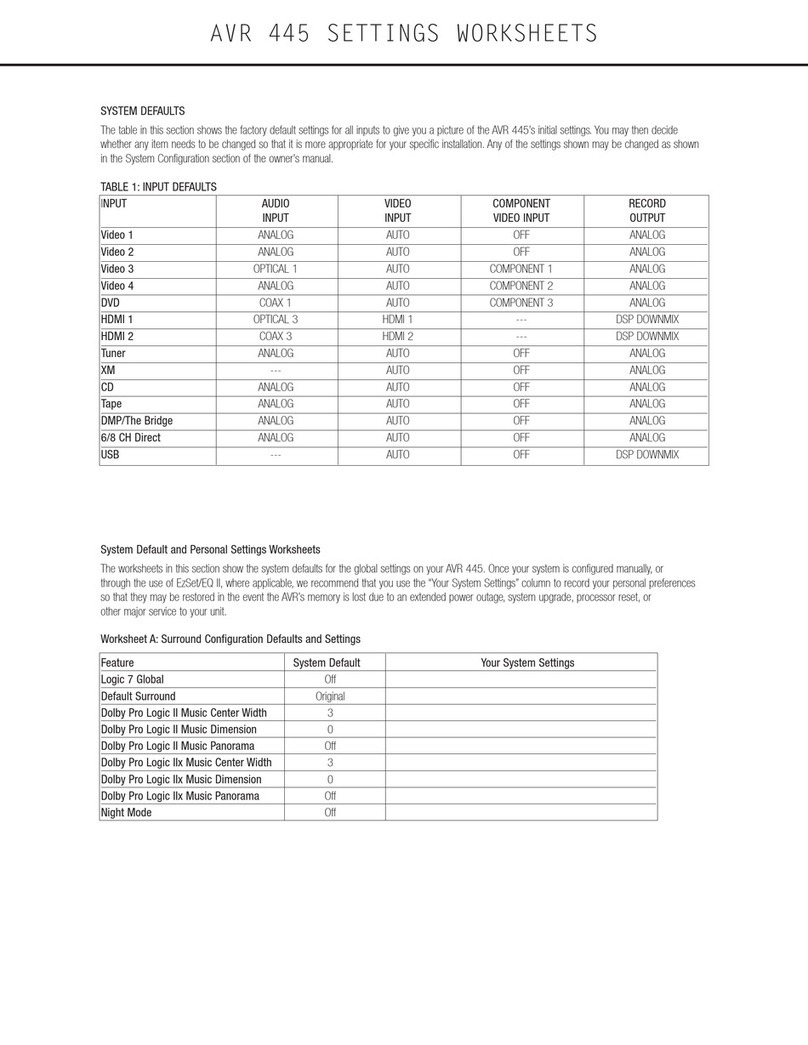

soldered to the lug. This connection is plainly illustrated in Fig. 5,

where the wire joining these three terminals can be seen.

A similar connection is made joining terminal ."Q" of tube socket

"M-2," to terminal No. 3 of coil socket "L-2," to th_e soldering lug on

condenser "I-2."

An exactly similar connection is made between terminal "G" of

[ 15 J

tube socket "M-1 ," terminal No. 3 of coil socket "L-1 ," and the

soldering lug on condenser "I-1."

These three exactly similar leads are plainly visible in Fig. 5

and should be as short and direct as possible.

A small wire should now be used to connect the minus terminal

of coil socket "D" to the lug under the mounting screw head of this

socket, exactly as seen in Figs. 2 and 5.

The two overlapping soldering lugs on the "minus" terminals and

the mounting screws adjacent to these terminals in the case of tube

sockets "M-1, M-2 , M-3 , M-4" should be soldered together exactly

as illustrated in Fig. 2.

Starting now at the left end of the chassis, terminal "G" of tube

socket "M-4" should be connected to terminal No. 3 of audio trans-

former "N-2." Terminal No. 2 of audio transformer "N-2" should

be connected to terminal "P" of tube socket "M-3." Terminal "G"

of tube socket "M-3" should be connected to terminal No. 3 of audio

transformer "N-1."

One end of a long wire should be fastened under the plus

terminal of tube socket "M-3," then carried over, kitty-cornered,

9Crapedand fastened under terminal "plus" of tube socket "M-4." In

the chassis adjacent to this terminal will be found a hole thru which

the long end of this connecting wire should now be pulled. Turning

to Fig. 3, it is practically impossible to see where this wire comes

thru the chassis (the approximate point is marked at "X"), comes

out underneath and follows the path of other connecting wires (which

will later be put in place) . This wire is pulled taut on the under side

of the chassis and up thru the large hole adjacent to the "plus"

terminal of socket "M-1" at which point the wire is scraped , wrapped

around and fastened under terminal screw "plus" of the tube socket

"M-1," and finally pulled back down under the chassis thru the same

large hole thru which it come up. It is then drawn slightly to the

rear of the chassis around the corner of condenser "G-2," scraped and

soldered to the lug of binding post "E-4" and then carried straight

along to a similar large hole in shield pan "Q-1" adjacent to terminal

"plus" of tube sock:et"M-2." At this point it is scraped exactly as in

the case of the previous tube socket, fastened under terminal "plus"

of socket "M-2" and pulled back down thru the hole in the chassis

thru which it came up. Again it is carried along the back: of the

chassis, this time behind condenser "G-2" and up thru the last of the

large holes, this time found in shield pan "Q-2" just under the

"plus" contacts of tube socket "D." The wire is here clipped, the

l 16 I

J

D

L_.----

L,

IZz

----<t ,

[ 17 l

end scraped , and fastened under the plus binding post nut of tube

socket "D." This is the positive A battery lead.

A second wire is now soldered to the lug of binding post "E-4,"

pulled straight forward across the chassis to potentiometer switch

"B," and soldered to the extreme right-hand lug of "B," viewed from

the front. (This lug, like another opposite it, forms the connection

to one end of the resistor segment of the potentiometer wound with

fine wire.)

A wire is soldered to the left-hand lug of the potentiometer (di-

rectly opposite the one previously connected to), carried down be-

neath the sub-base along the path of its predecessor and is terminated

by being soldered to the rear lug of condenser "G-1." A wire is now

soldered to the lug of the potentiometer switch arm stamped "carter,"

pulled down and carried along the under side of the sub-base to the

rear of condenser "G-1" and then pulled over and terminated by

beingsoldered to the rear, free, end of resistance "A." Still another

wire is soldered to the other contact of the switch. (The blade with

the angular bend.) This wire is also carried down beneath the

chassis and directly back to the lug of binding post "E-5" to which

it is soldered.

There is now only one connection on potentiometer-switch "B"

which has not been used. This is the small soldering lug fastened

under the screw head holding the assembly of the two switch springs

and their bakelite insulators to the frame of the instrument. To

this lug a long wire is soldered, which is carried along the path

of predecessors to the nearest terminal of condenser "G-1" to which

it is soldered. It is then carried back and around the case of con-

denser "G-1" and finally up thru the large hole in the chassis adja-

cent to the "plus" terminal of tube socket "M-1." It is now pulled

directly forward on the chassis under coil socket "L-1" and finally

terminates by having its scraped end fastened under terminal screw

No. 6 of coil socket "L-1."

A new length of wire is also soldered to the same contact of con-

denser "G-1" and carried along the chassis and up thru the large hole

adjacent to the plus terminal of tube socket "M-2" after which it is

pulled straight forward along the chassis under coil socket "L-2" and

terminates with its scraped end being fastened under terminal No. 6

of coil socket "L-2." The remaining or rear contact of condenser

"G-1" has a short length of wire soldered to it which is carried back

around the condenser case and terminates by being soldered to a lug

under the rear mounting screw of tube socket "M-1," which serves

to connect one side of condenser "G-1" directly to the metal chassis

of the receiver. [ 18 l

A wire soldered to the lug of binding post "E-1" is carried along

the chassis and up thru the hole adjacent to terminal No. 5 of coil

socket "L-1" under which terminal screw the bared end of this wire

is terminated. A second wire similarly joins binding post "E-2" to

terminal No. 4 of coil socket "L-1," coming up thru the hole in the

chassis adjacent to this terminal, visible in photograph "X."

A wire is connected to terminal "P" of tube socket "L-1," carried

down thru the adjacent hole in the chassis, along the under side of

the chassis, and up thru the hole in shield pan "Q-1" adjacent to

terminal No. 4 of coil socket "L-2" under which terminal the scraped

end of this wire terminates. Care should be taken to see that where

this wire runs under the chassis it is at least ¼ inch away from the

chassis. A second wire, similarly held away from the chassis, is used

to connect terminal "P" of tube socket "M-2" to terminal No. 4 of

coil socket "L-3." Both of the a;bovewires can be seen in photograph

"3" coming down thru the chassis and running parallel to it and ¼

inch below it.

A wire is connected to terminal "P" of tube socket "D," carried

back and down under the chassis thru the large hole found under

the "plus" terminal of this tube socket and then over to the free

lug of condenser "H" (see Fig. 3). It is soldered to this lug

and then carried back and under a lug fastened to the rear

mounting screw of coil socket "L-3" straight along the chassis, and

under another lug, fastened to the rear mounting screw of coil socket

"L-2," then up thru under a similar fastening lug on the rear mount-

ing screw of said socket "L-1," the hole adjacent to terminal No. 2

of audio transformer "N-1," under which terminal the bared end of

the wire is terminated. The three lugs on the mounting screws of

coil sockets "L-1," "L-2" and "L-3" serve simply to hold this long

wire definitely in position close to the chassis, but they at no point

make metallic contact with this wire itself.

A wire is attached to terminal No. 1 of audio transformer "N-1"

pulled down thru the hole in the chassis back around the rear side of

condenser "G-1" and is terminated by being soldered to the lug of

binding post "E-8." A wire soldered to the lug of binding post "E-10"

is carried back along the rear of the chassis, around condenser "G-1"

and over to the left front corner of the chassis, along the back:of the

chassis by condenser "G-1" and terminates in tipjack "C-2." A wire

soldered to tipjack "C-1" is carried diagonally across the chassis and

comes up thru the hole adjacent to terminal "P" of tube socket "M-4"

under which terminal screw it~ bared end terminates.

[ 19 l

A second wire is soldered to the free end of resistance A, carried

along the rear of the chassis, around corner of condenser "G-1"

and diagonally across the chassis up to the hole adjacent to terminal

No. 4 of audio transformer "N-1" under which terminal screw its

bared end is terminated. A wire is soldered to the lug of binding

post "E-7" carried back along the chassis around the corner of con-

denser "G-1" and up thru the hole adjacent to terminal No. 4 of

audio transformer "N-2" under which terminal screw its bared end is

terminated. One end of a wire, pulled up thru the hole in the

chassis is now fastened under terminal No. 1 of audio transformer

"N-2." It is then pulled back diagonally along the chassis around the

corner of condenser "G-1" and up thru the large hole in shield pan

"Q-1" adjacent to the plus terminal of tube socket "M-2." It is then

carried forward to terminal No. 5 of coil socket "L-2," scraped,

wrapped around this terminal which is tightened upon it, and carried

back and down thru the same hole in the chassis. It then continues

under the chassis, comes up thru the similar large hole in shield pan

"Q-2," is pulled forward and is scraped and fastened under terminal

No. 5 of coil sockiet "L-3." It now turns back on itself, goes back

down thru the large hole in the rear of the shield pan, and terminates

in the soldering lug of binding post "E-9."

A wire is fastened to terminal No. 6 of coil socket "L-3," carried

back and down thru the same large lead hole in the rear of the shield

pan "Q-2," scraped, and soldered to the rear contact of condenser

"G-2." From here it is then pulled back along the rear of the chassis,

around the corner of condenser "G-2," and terminates by being

soldered to the lug of binding post "E-6." The final connection is

put in by soldering one end of a length of wire to the lug of binding

post "E-3," then continuing it to the front contact of condenser

"G-2," and to which it is soldered , and the end terminat es in lug on

the rear mounting screw of coil socket "L-3" which also serves to

hold the long detector plate lead in position on the under side of the

chassis. Checking Connections

The wiring, now completed should be examined with the utmost

care. Every connection should be traced back in accordance with the

above instructions and, if possible, compared with the diagrams

in the booklet, and with all photographs for the actual positions

of wires. While the builder may not be able to interpret the symbols

of the diagrams at first sight he should be able to do so upon a care-

ful examination, since every instrument in them which is repre-

sented by symbols also bears the designating letters used in the

[ 20 l

12, K Rz lz J Q, P, L3 P, Lz Nlz D 02

F g. 5

[ 21 l

photographs and parts list, and, in addition, has every terminal num-

bered exactly as on the instrument itself. These terminal numbers

have also been used thruout the foregoing wiring instructions. (It

is much simpler in case any error has been made to find it and cor-

rect it by an immediate check than to do so later possibly as the re-

sult of blowing out one or more tubes or damaging batteries , for

such damage could very easily result if a mistake were made in wir-

ing the receiver.)

Attaching Link Motion

THE receiver having been completely wired but without the

front panel mounted, the next step is to attach the link motion.

With the front edge of the chassis toward the builder, the two

right hand variable condensers "I-2" and "J" should be turned to the

right so that their plates entirely interleave (and are stopped from

turning farther only by contact with the round tie bar connecting

the condenser end plates). The link motion should then be taken

in the fingers in such a position that the two parallel bars are above

the lock collars and that these collars, with their set screws, project

to the rear. The two lock collars should then be slipped gradually

over the shafts of condensers "I-2" and "J" back to a point where

there is a space of only about .½of an inch between the link motion

lock collars and the lock collars on the condenser shafts. In this

space of .½of an inch between the link and condenser lock collars

the front edges of the shields "Q-1" and "Q-2" fit.

The two variable condensers "I-2" and "J" should now have their

rotor plate sections entirely disengaged from the stator plates by

turning the shafts in a counter-clockwi se direction. The link "K"

should also be turned as far to the left as it will go so that on each

condenser shaft one arm of the link points straight to the left and

one arm straight upward. In this position the set screws in the link

motion lock collars will be visible when looking straight down upon

the chassis and they should be tightened up upon the condenser shafts

with a screw driver. If this is done, it will be found that if one con-

denser is now rotated, the other condenser will rotate with it due to

the mechanical linkage provided thru the link "K."

It is very important that the linking of the two condensers be

done with the condensers adjusted to exactly the right positions. This

may be determined either in actual operating tests of the receiver, or

before it is ever tested. (The proper position mechanically is with

the two condensers so adjusted that as the rotor plates of one just

start to interleave with the stator plates , the rotor plates of the other

condenser will be in exactly the same position.)

[ 22 l

Mounting Front Panel

TH E receiver , now completely wired and with the link motion

attached, is ready to receive the front panel. The knob, front

lock nut, and the insulating bushing on the shaft of the potenti-

ometer switch "B," should be removed so that the unit hangs loosely

in its hole in the chassis. With the entire chassis assembly in such a

position that the condenser shafts point directly forward, the builder

may simply slip the panel in place against the chassis in such a fashion

that the shafts of condensers "I-1" and "I-2" project thru the two

large centrally located holes in the panel and the bushing of the

potentiometer switch "B" projects thru the hole falling within the

circular arrow marked "VOLUME" at the center bottom edge of

the panel. The panel should be fastened to the chassis by means of

two machine screws and nuts, one of which goes thru the panel and

front edge of the chassis at each end of the assembly. These screws

should be tightened up, with the nuts on the under side of the chassis,

the screw heads being upon the front panel.

With the fingers of the left hand , the potentiometer switch should

have its shaft bushing lined up centrally in the holes in the chassis

and panel. The remaining extruded insulating washer should be

pushed over the bushing of unit "B" in such a fashion that it

serves to hold the potentiometer switch shaft away from the panel

and chassis. The lock nuts should be tightened down upon the

threaded shaft bushing using a pair of pinchers so that the

potentiometer switch is firmly held in place and yet so that at no

point does any of its metal assembly touch the panel or chassis (the

extruded washer serves to insulate unit "B" from the panel and

chassis at all points). The shaft of the potentiometer switch should

be turned entirely to the left as far as it will go and the control knob

pushed over this shaft with the arrow-head pointing to the word

"OFF" upon the front panel. The set screw in this knob should

then be tightened up using a small screw driver, which completes

this operation . Attaching Dials

IT NOW remains only necessary to attach the two National dials,

"F-1" and "F-2" to the receiver to complete it. The small nickel

center caps, serving to conceal the central bushings of the dials,

should be pulled off with the fingers, the set screws in the bushings

found underneath these caps loosened, and the dials pressed down

over the shafts of condensers "I-1" and "1-2" so that they come up

flush against the panels. Before actually putting the dials in place,

[ 23 l

however, the three small threaded studs found accompanying each dial

should be screwed into the holes in the dial intended to receive them.

Thus as the dials are pressed over the shafts of condensers "I-1" and

"I-2" the three studs on each dial will go thru holes in the panel

intended to receive them. The three small nuts accompanying each

dial are then screwed up on these threaded fastening studs on the rear

of the panel. Two of them can be seen in the photographs toward

the top of each dial, while one projects thru panel and chassis and

will be found on the under side of the front edge of the chassis.

It will be noticed that as condensers "I-2" and "J" are rotated,

the link motion will strike the upper right threaded mounting stud

of dial "F-2" and this one should be twisted off just behind its nut

with the pliers. (This may be accomplished by simply twisting the

stud back and forth, when it will snap off almost flush with the rear

side of the fastening nut.)

Both dials "F-1" and "F-2" should be adjusted to read zero against

their indicating marks and all variable condensers "I-1," "I-2" and

"J" turned in so that their rotor and stator plates are entirely inter-

leaved. The dial bushings should then be fastened tightly to the con-

.denser shafts by tightening up the set screws previously loosened to

allow these bushings to slip over the condenser shafts. This being

done, the small nickel mounting caps, removed with the fingers, may

be replaced on the center of each dial to conceal the bushings and set

screws.

Care should be exercised in operating the receiver never to strain

the dials and condensers by turning the dials too far to the left or

right. If this is done, the points of the dial-bushing set screws will

score grooves in the condenser shafts, possibly at an angle, with re-

sultant strain and possible damage to the condensers 1-1 and I-2. (If

this occurs, the trouble may be remedied by realigning the dials as

suggested above, and tightening up the dial-bushing set-screws very

tightly.)

Coil Placement

THE actual placement of the three coils "O," "P-1" and "P-2"

in the receiver is very important, for, if "O" is misplaced, a

short circuit will result which may burn out all tubes and will

certainly result in damage to the coil and to the batteries if allowed to

continue. Coil "O" may be told from coils "P-1" and "P-2," which

are alike, by the fact that in a slot at its base are contained a few

turns of green silk covered wire, while in coils "P-1" and "P-2"

this same winding consists of white silk covered wire.

[ 24 l

",

...

0

B

... N,

M3

c,

c,

E,

E,

c,

E•

E,

o,

E•

E,

Ea

E•

E,o

Oz

Fig. 7

[ 25 J

Coil "O" should be inserted in coil socket "L-1" while coils "P-1"

and "I'-2" should be inserted in coil sockets "L-2" and "L-3." It

will be found that the coils can be inserted only one way due to a

small round guiding key of bakelite on the bottom of each coil from

which fits in a similar recess on the coil socket rings. When the coils

are first inserted it will be found that the coil socket springs are very

stiff, which is correct, and the coils will go in very hard; and, in fact,

may have to be worked in gradually by twisting them from side to

side, at the same time exerting a downward pressure.

Preliminary Testing

ELSEWHERE in this booklet (see index) will be found a

list of the accessories required to operate the S-C II receiver

and it is therefore assumed that the builder has all of these

accessories available.

The first step is by means of two wires which may be either bell

wire, flexible hook-up wire (or two wires of a standard Belden 7-

lead battery cable), to connect the A battery to binding posts "E-4"

and "E-5." The plus or red terminal of the six volt storage bat-

tery should be connected to the binding post "E-4," marked "A BAT.

+"; while the black, or negative terminal, of the storage battery

should be connected to the binding post "E-5," marked "A BAT.

-." A single tube should then be inserted in tube socket "M-4"

and the volume control knob turned from the "OFF" position all the

way to the right. Just as it leaves the "OFF" position, the tube in

socket "M-4" should light and should remain at exactly the same

brilliancy thruout the entire arc of movement of the volume control

knob (if the brilliancy of tube "M-4" varies, the volume control is ad-

justed, it indicates that the switch on unit "B" is not functioning sat-

isfactorily and it should be inspected in accordance with paragraphs

devoted to inspection of this switch).

The tube should then be moved successively to all sockets, starting

with "M-3" and progressing thru "M-1," "M-2," and "D." In

each socket it should light and it should be extinguished when the

volume control knob is turned to the "OFF" position.

This test made, the remaining four tubes may be inserted in the

sockets in the receiver, making sure to place the CX371 power tube

in socket "M-4" while UX201A tubes should go in all other sockets.

The same condition should now exist in that if the volume control

knob "B" is turned up from the "OFF" position, all tubes should

light and their brilliancy should remain constant at all adjustments

of the volume control knob other than the "OFF" position.

[ 26 l

It is very important that the wire from the storage battery con-

nected to binding post "E-4," marked "A BAT. +," should now be

removed and connected successively to binding post "E-8," "E-9,"

and "E-10," marked respectively "45+," "90+," and "AMP+."

THE TUBES ABSOLUTELY SHOULD NOT LIGHT

WITH ANY OF THESE CONNECTIONS. If they do, it in-

dicates that the receiver has either been incorrectly wired or a tem-

porary, short-circuit has developed which must be located in accord-

ance with the trouble-shooting data. If they do not light, the lead

from the positive post of the storage battery may be re-connected to

its proper binding post, "E-4."

Connecting Batterie s

THE above tests having been very carefully gone thru, the bal-

ance of batteries may be connected to the receiver. One 45

volt B battery should have its minus terminal connected directly

to the minus, or black, terminal of the 6 volt storage battery. A wire

from binding post "E-8," marked "45+," should be connected to the

positive terminal of this first B battery and also to the negative

terminal of a second 45 volt B battery. A wire from binding post

"E-9," marked "90+," should be connected to the positive terminal

of this second B battery and also to the negative terminal of the

third B battery. A wire from binding post "E-10," marked "AMP+,"

should be connected to the positive terminal of the third and last B

battery. (If four B batteries, giving a tota:l of 180 volts, are used,

the wire from binding post "E-10" should connect to the positive

terminal of the last or fourth B battery while the negative terminal

of this B battery should connect to the positive post of the third B

battery, and to nothing else.)

Assuming a 171 tube to be used with 135 volts maximum B volt-

age, the positive side of a 22¼ volt C battery should be connected

to the black, or minus, terminal of the storage battery. A binding post

upon this battery marked "-4¼" should be connected to binding

post "E-6" marked "C -." The binding post marked "- 22¼"

upon this same B battery should be connected to post "E-7," marked

"C -," of the receiver.

Antenna and Ground System

THE builder of the S-C II receiver had best consult with his

local dealer or service man in order to find out the most suitable

type of antenna for use in his particular location, since in many

locations close to large powerful broadcasting stations, it is necessary

[ 27 l

What They Say of the SC-II

Arthur H. Lynch, former editor of "RADIO BROAD-

CAST," wires:

S-C second receiver sent me for test is proving more

than satisfactory. Mechanically and electrically it is

a perfectly fine job. I congratulate you.

Volney D. Hurd, radio editor of the CHRISTIAN SCI-

ENCE MONITOR writes of the remarkably sensitivity

of the S-C IL Here's what he says:

The ability to obtain maximum sensitivity with sim-

plicity of operation is a fundamental need of pres-

ent day radio receivers and our test with the new

Silver-Cockaday II gives just these results. One of

the interesting points is the uniform degree of sen-

sitivity at all wavelengths. Stations from 200 up to

545 meters are brought in with equal volume and

clarity.

A word from an internationally famous acoustical

engineer on the S-C II means a lot, for such a man

knows tone quality. Here's what Francis H. Early ,

who designed the K Y W (Westinghouse, Chicago)

studios and the practise hall of the Chicago Philharmonic

orchestra to mention but 'tiV-0 :.of his accomplishments, '-says

of the S-C II : ;

... the S-C II Receiver that I am now using in ~y

acoustical work, far surpasses the claims that ·-~ou

make for it.

In checking up on ' 1he acoustical properties of dis-

tant radio stations, I find that this receiver gives

results that I have heretofore been unable to ob-

tain from several high-priced instruments. This is

particularly true over the sho rter wave-lengths and

you will probably be glad to know that I have found

absolutely no distortion over the entire range.

It cuts through the maze of local stations very nicely

and has such tremendous natural volume that it will

operate my loud speaker on coast stations .

Kenneth A. Hathaway of the technical staff of the CHI-

CAGO DAILY NEWS, acutely aware of broadcast con-

gestion in the middle west, comments as follows:

I wish to say that I have personally tried out the

S-C II receiver and have found it highly satisfactory

for the Chicago territory where conditions are worse

than at any other point in the county. The repro-

duction keeps pace with the best and the clarity is

remarkable, under conditions naturally favorable to

radio reception.

A radio writer and authority known to almost every

newspaper reader is Carlton E. Butler, radio editor of

the CHICAGO EVENING AMERICAN. He finds the

performance of the S-C II quite satisfying:

The S-C II is what I would call an ideal home re-

ceiver. It has beautiful tone quality, volume suf-

ficient for any needs, and selectivity to cope with

present broadcasting congestion.

[ 28 l

After the S-C II had been per-

fecte9 to its final form, the com-

ments of man prominent au-

thorities were ~solicited. Each

was asked to t~y the set under

any conditions he cared to

choose, and then, after his test,

to express his full and unbiased

opm10n. Read what these au-

thorities have to say:

Frank L. Brittin, radio editor of POPULAR MECHAN-

ICS, and designer of the famo us POPULAR MECHAN-

ICS super-heterodyne comments:

The S-C II looks good, sounds good, and tunes

sharp.

Ernest R. Pfaff, radio designer and authority, chief en-

gineer for a large manufacturer, says:

I wish to compliment you on the design of the S-C

II Receiver.

I have found it to possess all of the desirable char-

acteristics that make up a good receiver; namely

simp licity, efficiency and excellent tone quality.

In addit ion to being an excellent receiver from

a "radio" standpoint, ~be set is very easy to con-

struct.

Wendell Buck, a writer ."1 authority well known as a

contributor to the NEW YL 1!,KSUN , and designer of the

Varion receiver, writes:

Allow me to congratulate you upon the neat and

compact design of the S-C II receiver which I con-

sider to be one of the best receiver values for the

money in the home constructor field_

To be able to provide a shielded five-tube receiver with

metal panel and chassis at so low a price as $60.35,

for the component parts, and yet to have included

such high quality products throughout is a most note-

worthy accomplishment.

John F. Rider, contributor to many technical magazines,

possessor of an enviable engineering reputation, Writes:

Whenever the names of two known writers and radio

engineers are combined, as in the case of McMurdo

Silver and Lawrence M. Cockaday, it is only natural

that the results of their efforts would be closely

scanned and widely commented upon.

When I heard that the new S-C II receiver was to

make its appearance I was more than interested to

learn the details, both electrica lly and mechanically,

of the new receiver and I can say very frankly that

the design appeals to me very favorably.

You have a circuit here that is quite sufficiently se-

lective for the most congested areas, a simpl e method

of tuning control, and a very attractive ensemble. The

new S-C II appears to have had very careful en-

gineering thought and consideration and should be a

great success.

It is particularly fortunate you have been able to

bring the price of the parts for such a receiver down

to as low a figure as approximately $60.00 and the

receiver should fill a long felt demand.

Charles H. Callies, designer of the Callies Super, and

many popular pieces of apparatus, writer of national

reputation, expresses his opinion:

It has been tried and proven-every statement that

you have made about the new Silver-Cockaday II

receiver is substantiated in detail.

I have tried out the set the last few evenings. It is

beautiful in tone, the volume is adequate and it tunes

sharply_ I think it fills th e long felt want for a re-

liable five-tube receiver.

Needless for me to say the S-C II was tried out in

about as poor a location for broadcast reception as is

to be found anywhere in this city of cluttered up air

lan es (Chicago). In my estimation it is delivering

about 100%.

The opinion of a careful and deliberate engineer, famous

for the design of fine audio amplifying equipment and

such popular receivers as the Radio Broadcast Super-

heterodyne, is worth much. Kendall Clough, after care-

fully operating the S-C II receiver in the Testing De-

partment of the Research Laboratories of Chicago, re-

ports as follows :

We have carefully tested the S-C II receiver and

found it to be an extremely satisfactory receiver .

Electrically, the design is excellent, for the receiver

possesses sufficient sensitivity for present-day require-

ments. The degree of selectivity appears to be ample

for present congested broadcasting conditions. We

can offer no suggestions for materially improving the

quality of reproduction of the receiver. Its mechani-

cal design is most pleasing, particularly when its dur-

ability and structural excellence are compared to that

of many receivers submitted to this laboratory for

test.

[ 29 l

to use comparatively short antennas while other locations will . fre-

quentl y allow different types of antennas more suited to particu lar

conditions.

For general purposes an extremely satisfactory antenna would con-

sist of a single wire approximately 60 to 75 feet long, terminating in

an insulator fastened either to a tree , barn , garage, or other suppor t

approximatel y 60 to 7

5 feet away from the house in which the re-

ceiver is located. The other end of this wire should be fastened to

another insulator , in turn fastened to the buildin g housing the re-

ceiver. This same wire which most simply would merely be pulled

thru the eyelet of an insulator and wrapped back around itself for

several turns , would then be carried down and into the house to the

receiver, either thru a standard lead-in strip, or porcelain tube or

possibly even just held down by a window fram e. This lead-in then

continue thru the house to either binding post "E-1" or "E-2" of the

receiver.

If it is impossible to erect an outdoor antenna, a single wire, 50 to

60 feet long, strung along a picture moulding or placed in an attic

will be entirely satisfactory for local and medium distance reception.

This wire should have an insulated covering, but need have no other

insulation. ·

The ground connection is made by means of a wire connected to

binding post "E-3" of the receiver which terminates in a standard

ground clamp fastened to a scraped and bright portion of a water,

steam, or gas pipe near the receiver.

Loud Speaker

THE loud speaker, a Western Electric cone type, should have the

tips on the end of its cord inserted in two tipjacks "C-1" and

"C-2" on the receiver chassis. The loud speaker should not be

placed directly upon the cabinet containing the receiver as mechanical

hum may develop if this is done. It should preferably be located

several feet from the receiver itself.

Operation

THE above connections having been made as outlined, the re-

ceiver is ready to be operated. With all tubes in place, the two

shield tops "Q-1" and "Q-2" should be dropped down over

the parts contained in the shield pans and their edges allowed to fall

inside the turned up edges of the shield pans so that each shield with

its pan will form a tightly closed aluminum box housing a coil, coil

socket, variable condenser, tube , and tube socket.

[ aol

-.(

z: 0

z z II•·

'" ::,

~

0

z:

~

" /?0

~

E '!i

'1'

Fig. 8

[ 31 l

To operate the receiver the volume control should now be turned

just up from the "OFF' position so that all five tubes light. As this

is done, a slight plunk will be heard in the loud speaker indicating

that the set has been turned on and current is flowing through it. If

the two dials "F- 1" and "F-2" are now adjusted thruout their

scales in such a fashion that they always both read approximately

alike, a local station is sure to be heard if operating. To properly

tune any station in, the two dials "F-1" and "F-2" should be ad-

justed for maximum volume, after which the volume knob should be

turned slowly to the right . As this is done, the volume of the re-

ceived signal will increase up to a point where as the volume knob is

turned further to the right, the signal suddenly becomes distorted,

and if weak to begin with, will turn into a squeal.

Most Sensitive Operating Condition

TH E most sensitive operating condition of the receiver is with

the volume knob turned just as far to the right as it will go

without causing the station received to be heard as a squeal.

This volume adjustment is not critical except on very weak distant

stations, and besides serving as a sensitivity control for the receiver it

also serves the main purpose of reducing volume on powerful stations.

It will be noticed that if the volume control is turned too far to

the right, that as dials "F-1" and "F-2" are rotated, a plunk will

be heard when they arrive at a position relative to each other at

which a signal can be heard if one were broadcasting within range at

the wavelength to which the two dials "F-1" and "F-2" are at that

moment set. With the volume knob just to the left of this position,

the receiver is most sensitive.

Tuning for Distant Stations

IN TUNING for extremely distant weak stations, it is well to

set the dial "F-2" at any setting at which a local station cannot

be heard. Then if the volume knob is turned practically all the

way to the right beyond the point at which the local stations will be

heard as a squeal, and dial "F-1" rotated approximately throut the

range of settings of the dial "F-2," a plunk will be heard. If dial

"F-1" is moved slowly back and forth so that this plunk disappears

and re-appears with each movement and the volume knob is at the

same time slowly turned to the left, the most sensitive condition for

out-of-town stations will be reached just as the volume knob is

turned so far to the left that as dial "F-1" is'rotated about the set-

[ 32 J

ting at which the plunk was heard, it will no longer be heard and in-

stead a slight hissing, due to static or atmospheric noise will be evi-

dent in its place. If, however no distant station i; heard dial

"F-2''. should _be~,e-se~,about one degree either way, followel by a

rese_ttmg of dial F-1 and the volume knob, and this method <'Sf

tumng pursued over the entire range of dial "F-2 " thruout which

operation some stations are certain to be heard. '

Logging

ONCE a station has been heard, if the dial settings of "F-1"

and "F-2" are written down, the station may be tuned in

. again _by~imply resetting the two dials to the same figures

~gain, and adJu_stmgthe volume control as far to the right as possible

m order to obtain the most sensitive condition (just before the "plunk"

is heard). If, however, the antenna should have been moved from

binding post "E-1" to binding post "E-2" the setting of dial "F-1"

will be altered by several degrees and so a record should also be

kept in the log of which binding post the antenna was connected to--

either "E-1" or "E-2 ."

Preliminary Selectivity Adjustment

WHEN the re_cei~eris hoo~ed ~p,the antenna should be tried

first upon b111d111gpost E-1 and then upon binding post

"E-2." In the case of a weak station it will come in much

louder with the antenna connected to one post than when it is con-

ne_ctedto the other end and at the same time the tuning of dial "F-1"

will be broader and less critical. This post should be used for the

reception of out-of-town stations with greatest volume if local inter-

ference is not very great. If local interference is great, however, the

antenna must ,be connected to the binding post which gives the sharpest

tuning of dial "F- 1" (with slightly less volume than on the other

connection) .

If sufficient selectivity to get thru the local stations is not obtained

by this simple change, then the antenna length must be cut down.

As an example of a satisfactory arrangement, many users in Chicago

and New York have two antennas-one about 20 feet long and the

oth~r about 50 to 60 feet long. On silent night (on Monday in

~h~cago) the long ~ntenna is used connected to the binding post

g1v111gthe greatest signal strength on out-of-town stations while on

"'.ee~-day nig~ts_a small antenna is generally used, connected to the

b111d111gpost g1v111gmost satisfactory selectivity.

[ 33 1

Balancing

IN PURCHASING condensers "I-2" and "J" the dealer should

be as_kedfor Silver-Marshall condensers, the boxes of which are

marked with crayon figures of either plus or minus 1, 2, or 3.

These figures represent the percentage deviation from a standard

condenser. For example, if one plus 3 and one minus 3 condenser

were procured as condensers "I-2" and "J" it is doubtful if maximum

satisfaction would be obtained from the S-C II receiver. The builder

should therefore always be sure to get two condensers the boxes of

which are marked within one number of each other; that is, a plus

1 and a plus 2 or a minus 1 and a zero condenser would be entirely

satisfactory together.

Despite this precaution of matching taken at the factory it fre-

quentl y happens that condensers will be slightly damaged in transit

or strained by the builder in the mechanical assembly of the receiver.

Therefore after the receiver has been completely assembled and is in

operation, it may be well to check the ganging of the condensers "I-2"

and "J" by loosening the set screw in the lock collar of link motion

"K" upon the shaft of condenser "I-2." Thus with a station tuned

in, it is possible by means of the dial "F-2" to rotate condenser "I-2"

independently of "J" and by grasping the link motion "K" with the

fingers, condenser "J" may also be moved independently of con-

denser "I-2." This test should be made upon a fairly weak station

on a wavelength somewhere between 300 and 400 meters and the

two condensers set for best signal strength independently of each

other. The set screw locking the link "K" to the shaft of "1-2"

should then be tightened and the receiver tuned in to other wave-

lengths. If this ganging is correct, each station will be tuned in com-

paratively sharply on dial "F-2" (if a short antenna of 10 to 20

feet is used for this test it may be made on local stations). With

the condenser so locked, the shield tops "Q-1" and "Q-2" should be

removed and the condensers carefully examined to see that they

start to interleave at exactly the same point. If, however, they do

not interleave at some points and one leads in ahead of the other,

by more than y3-,/', it may be assumed that they have been slightly

strained at some time and they must be adjusted to compensate for

this strain.

This adjustment is made in accordance with the drawing appear-

ing in this booklet, by means of a wrench accompanying either con-

denser "I-1" or "I-2 ." The adjustment actually consists of loosening

the lock nuts upon the stator plate support bar at the right-hand side

of either condenser "I-2" or "J" and re-adjusting the position of this

[ 34 J

Fig. 9

[ 35]

side of the stator so that as the rotor plates start to interleave they

will interleave absolutely centrally between the stator plates. The

condenser upon which this adjustment should be made (if it is neces-·

sary) will be the one in which the rotor plates do not appear to start

to interleave centrally between the stator plates. When the rotor

plates of both condensers interleave centrally between the stators, the

two condensers will gang properly and the tuning on dial "F-2" will

be quite sharp except on the most powerful local stations.

Battery Eliminators

THE S-C II receiver may be employed with standard A battery

eliminators, if desired, although it will probably be found most

economical to operate it in conjunction with a trickle charger

and storage battery together with a standard relay switch connected

in one of the filament battery leads, which will automatically throw

the battery on charge when the receiver is turned off, and vice versa.

If a B eliminator is to be used, it should be selected most carefully,

for practically all standard B eliminators are provided with adjust-

able voltage controls with obviously no means of allowing the builder

to determine definitely the voltages he is applying to his receiver.

In itself, this may not seem advantageous until it is realized that a

UX201A detector tube will give the same apparent results as a de-

tector on voltages between 20 and 200 in the hands of an inex-

perienced operator, and it is almost certain that the use of B elimi-

nators of unknown voltage output will result in short tube life.

Aside from this fact, the average B eliminator , due to very poor

output voltage regulation, will cause motor-boating when it is used

with receivers employing high quality audio amplifiers. A circuit is

therefore presented herewith, in accordance with which a very satis-

factory B eliminator may be constructed with constant output volt-

ages (suited to the S-C II receiver), and free from troubles such as

motor-boating, humming, or condenser break-down. (This eliminator

may ,be used with any standard receiver and, in fact, will be found

superior to practically all factory-built B eliminators available at

this writing-February, 1927.) Due to the fact that its output volt-

[ 36 l

C'1~ # 4 PLl.l(i

T• Ll fl HT .$0CKCT

110 r.,o era£ A.c.

ages are substantially constant and are those required for proper opera-

tion of the S-C II receiver, normal tube life may be anticipated since

it is impossible to misadjust the eliminator with resultant high

output voltages which would damage tubes and result in poor quality

of reception, due to inability to properly adjust the C biases re-

quired. It is not suggested that any endeavor be made to obtain C

potential from this eliminator since the cost of a C battery is nominal,

its life practically indefinite and such an effort would unduly compli-

cate the situation.

TROUBLE-SHOOTING

Failure to Receive Signal s

WITH the receiver connected for operation, should no signals

be received, the trouble may be traced to an improper antenna

and ground system, improper or defective batteries , improper

or defective tubes, defective speaker, or poor or incorrect connections.

Lack of Volume

Should , in the opinion of the builder, insufficient volume be ob-

tained from the receiver, a direct comparison should be made between