PLANING MODE

With the machine set up in planing mode:

Use the Cutter Guard Height Adjuster to adjust the height of the Cutter Guard, so that the work

piece can fit underneath.

Set the Planing Depth Adjuster to the desired setting, reading off the Planing Depth Scale. If in

doubt, set the depth to 0.5mm

Connect a dust extractor to the 100mm diameter outlet.

Start the machine, wait for it to get up to full speed.

Lay the work piece flat on the Infeed Table and push it over the cutter block. Use a push stick or

push pad to ensure hands are kept well away from the cutters.

Pick up the work piece and return it to the starting position. Make as many passes as necessary to

achieve a flat planed finish.

When planing taller pieces, over 60mm, undo the Cutter Guard Lock and slide the Cutter Guard

away from the Side Fence just enough to provide clearance for the workpiece.

SWITCHING MODES

To move from planing mode to thicknessing mode:

Engage the drive rollers by moving the Drive Rollers Lever into the upper position.

Release the tables using the 2 Planing Bed Locks, one at each end: Rotate the handle towards

the centre of the machine, pull out away from the cutter block and then lower the handle.

Use the Lifting Handle to move the tables into a vertical position. This process is spring assisted,

but take care as the tables are heavy. The tables are automatically locked in the vertical position.

Swing the Extractor Hood up and over the cutter block, until it clicks into place.

THICKNESSING MODE

With the machine set up in Thicknessing mode:

Measure the thickness of the work piece.

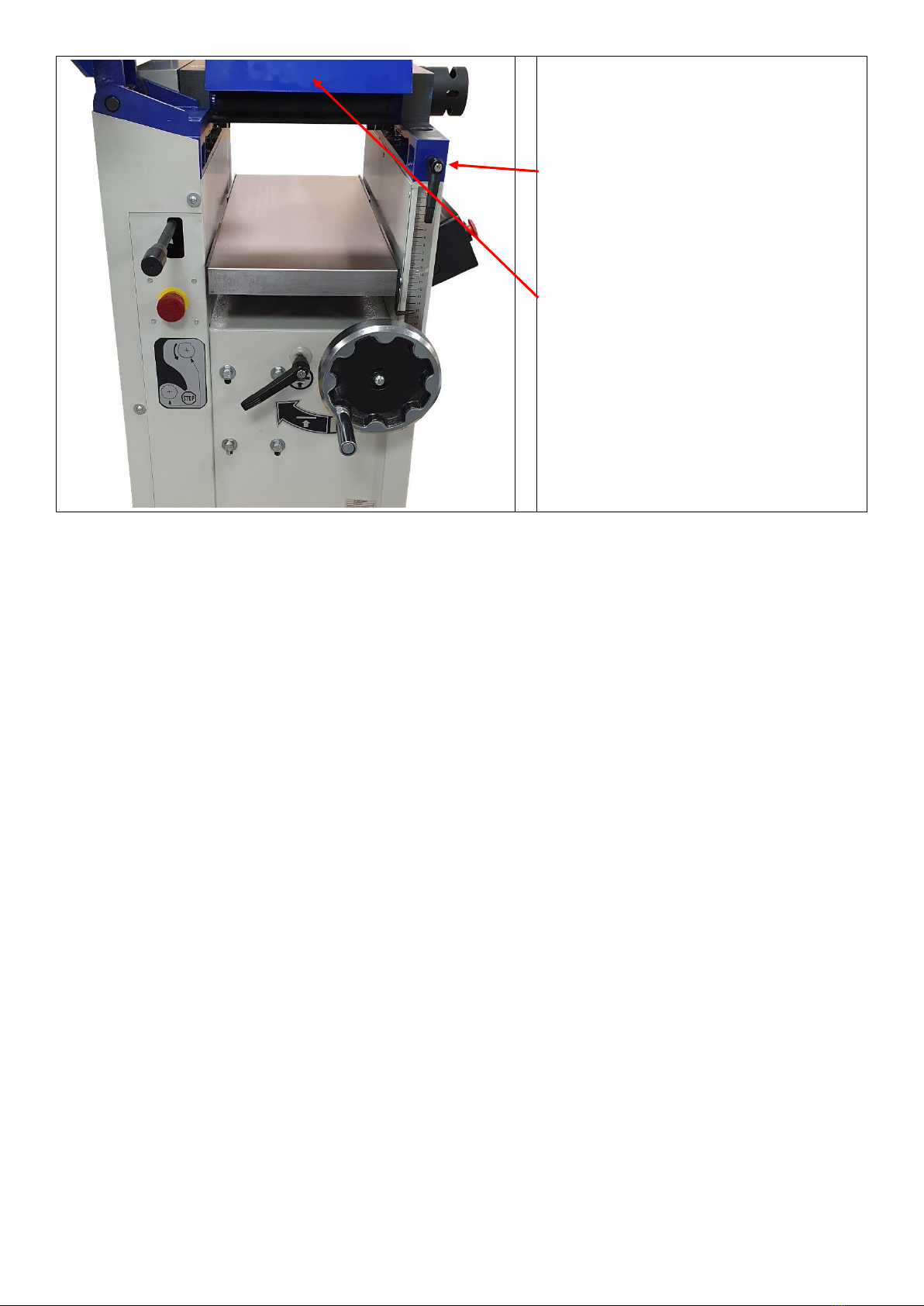

Rotate the Thicknessing Bed Height Adjuster anti-clockwise to unlock the thicknessing bed.

Wind the Thicknessing Bed Height Adjuster handwheel clockwise to raise the thicknessing bed.

1 rotation is equal to 2mm adjustment.

Read off the scale or use the Digital Position Indicator, with accuracy down to 0.1mm, to set the

bed at the starting thickness. Then raise the bed another 1 –2.5mm, depending on how much

stock is to be removed.

Tighten the Thicknessing Bed Height Lock.

The feed direction is the opposite direction to planing mode.

Start the machine, wait for it to get up to full speed.

Lay the work piece flat on the end of the table. Slide it forward until you feel the drive rollers take it

from you. Let go of the work piece and walk to the other end of the machine to support the work

piece as it is fed out of the thicknesser.

A safety bar will prevent you from trying to make too big a cut. If the timber hits the safety bar,

lower the table to take a smaller cut.

Make as many passes as necessary to get the desired finished dimension.

If making multiple components, consistency is best achieved by feeding them all through at one

depth, before adjusting the table height and feeding them all through again.