Chase Research CC4 User manual

CRC Ltd, Cool Works, Unit 2 Neepsend Ind. Est., Parkwood Rd, Sheffield S3 8AG, UK.

Tel: +44 114 278 0711

Director: Dr. S.T. Chase Secretary: Dr. L.C. Kenny

Registered in England & Wales, No. 4643351 VAT registration No. GB 763 8558 84

CONTINUOUS 4He SORPTION COOLER

TYPE CC4

GENERIC INSTALLATION AND OPERATING INSTRUCTIONS

Photo shows a typical CRC CC4 sorption cooler

2

Contents

1. GENERAL HANDLING.....................................................................................................................3

2. SAFETY OF CHASE RESEARCH CRYOGENICS PRODUCTS...............................................................3

2.1. Pressure Equipment Directive 97/23/EC (Pressure Equipment Regulations 1999)..............3

2.2. Pressure Systems Safety Regulations 2000...........................................................................3

2.3. Safe Operation.......................................................................................................................4

2.4. Risk Assessment ....................................................................................................................4

3. A BRIEF DESCRIPTION OF THE SORPTION COOLER UNIT..............................................................6

4. INSTALLATION...............................................................................................................................7

4.1. Mechanical ............................................................................................................................7

4.3. Electrical ................................................................................................................................8

5. ATTACHING YOUR EXPERIMENT TO THE SORPTION COOLER......................................................9

5.1. Radiation shielding................................................................................................................9

6. OPERATION: quick-start guide....................................................................................................10

6.1. Cooldown and commence continuous operation...............................................................10

7. OPTIMISING THE PERFORMANCE OF YOUR SORPTION COOLER ...............................................11

7.1. Varying the cycle time.........................................................................................................11

7.2. Varying the cycle steps........................................................................................................12

7.3. PID stabilisation of the CC4 .................................................................................................13

9. STANDARD Pin-Out Assignments ...............................................................................................14

10. cc4 OPERATIONAL SEQUENCE FOR INITIAL COOLDOWN AND EXTENDED OPERATION ........15

THIS GENERIC OPERATING MANUAL describes how to install and operate a CRC CC4 sorption cooler.

It is accompanied by an Excel file that contains the validation test data and the calibration files that

are specific to the sorption cooler unit that you have purchased.

You are advised to make a note of the location of the Excel file specific to your sorption cooler unit.

CRC can provide another copy on request if you send us the Serial Number engraved around the rim

of your cooler’s main plate.

This manual was last updated in January 2022.

3

1. GENERAL HANDLING

WARNING!

CRC SORPTION COOLERS CONTAIN HELIUM GAS AT HIGH PRESSURE.

Do not crush, twist or bend the unit. Avoid applying mechanical stresses. Do not

heat the unit above room temperature. Keep in a sealed cryostat, or in the

shipping box and brace in which it came.

Do not hold or lift the unit by means of the cold heads.

Do not tamper with the copper capillary fill tubes.

Avoid the use of acid fluxes when soldering in the vicinity of the cooler. Chloride

based fluxes will corrode stainless steel and could damage your cooler.

Always allow the unit to warm to room temperature before allowing air into your

cryostat. Opening the air valve of a cold cryostat is likely to damage the unit.

After unpacking the sorption cooler according to the instructions supplied, the sorption cooler

should be immediately transferred into the host cryostat. The shipping brace doubles as a stand for

the sorption cooler, though when used as a stand, the screws through the top aluminium plate into

the cold heads should NOT be in place. When picking the sorption cooler up, it should be firmly

grasped by the main plate.

2. SAFETY OF CHASE RESEARCH CRYOGENICS PRODUCTS

2.1. Pressure Equipment Directive 97/23/EC (Pressure Equipment Regulations 1999)

This CRC sorption cooler unit is manufactured in accordance with Sound Engineering Practice. The

volume and gas pressure within the sorption cooler are such that the equipment falls below the

lower classification limit in Annex II of the Pressure Equipment Directive. Hence the requirements

for Conformity Assessment do not apply and no Declaration of Conformity can be made, or CE

marking applied.

The sorption cooler is covered by Article 3 Paragraph 3 of the Pressure Equipment Directive, which

states: “Pressure equipment and/or assemblies below or equal to the limits in sections 1.1, 1.2 and

1.3 and section 2 respectively must be designed and manufactured in accordance with the sound

engineering practice of a Member State in order to ensure safe use. Pressure equipment and/or

assemblies must be accompanied by adequate instructions for use and must bear markings to

permit identification of the manufacturer or of his authorized representative established within the

Community. Such equipment and/or assemblies must not bear the CE marking referred to in Article

15.”

2.2. Pressure Systems Safety Regulations 2000

This sorption cooler unit does not contain a pressure x volume product exceeding 250 bar-litres

hence PSSR regulations 5(4), 8-10 and 14 do not apply. This means that the system does not require

a written scheme of examination. The sorption cooler is not ‘mobile’ in the sense intended in the

PSSR hence the owner has duties under these regulations to ensure that a) the safe operating limits

are not exceeded; b) the unit is operated in accordance with these instructions; c) the unit is

4

returned to Chase Research Cryogenics Ltd in the event that any maintenance is required. The

sorption cooler contains no user-serviceable parts.

2.3. Safe Operation

The safe operating temperature range of this sorption cooler is 0 to 320 K.

2.4. Risk Assessment

CRC sorption coolers contain Helium gas under pressure. The stored energy of the system is less

than 50 bar litres. All system components are integrity tested during manufacture; the slightest leak

will make the sorption cooler lose its stored gas and cease to function. A unit that has leaked

presents no risks whatever to the user; the following risk assessment applies therefore only to

functional units.

Hazards and consequences

Accidental damage to the sorption cooler unit could result in the sudden release of pressurised

gases, causing mechanical failure of the unit and potential injury (or damage to surrounding

instruments) from ejected debris.

Possible events leading to failure are: overheating of the unit, for example in a fire; dropping or

crushing of the unit; twisting or bending of the gas tubes. Mechanical damage to the unit is most

likely to occur during assembly of the instrument of which the sorption cooler forms part.

Risks without controls in place

It is extremely unlikely that the above events will lead to danger. Chase Research Cryogenics Ltd has

produced more than two hundred sorption cooler units of various designs, which are in use for a

range of applications worldwide. To date there has never been a sudden failure of a sorption cooler

unit –indicating that with normal use (including inevitable handling mishaps) the units have an

excellent safety record. User experience to date shows that accidental mechanical damage to

sorption cooler units is likely to result in slow leaks, not sudden failures.

Controls in place

The controls that are in place to eliminate (as far as reasonably practicable) the risks arising from

mechanical damage to a sorption cooler unit are:

•This written instruction manual, containing warnings about the potential risks arising from

damage to the unit and alerting the user to more risky operations;

•Instructions that the unit should not be used if it has been subjected to overheating,

dropping, crushing, bending or twisting;

•A warning label on the transit box that the instructions should be read prior to handling the

unit.

The applications for which sorption cooler units are intended make it impossible to place warning

labels on the unit itself. However if the sorption cooler is incorporated into another instrument, that

instrument should carry a warning label to alert the user that the sorption cooler contains no user-

serviceable parts and should not be disassembled.

Risks with controls in place

Providing users read and follow this instruction manual the risks are negligible.

5

2.5. Safe Transportation

The unit must be correctly re-installed in its shipping brace before transportation either by road or

air. Follow the unpacking instructions provided in reverse order and contact CRC for advice if

needed. The cooler+brace should be securely packed into the cooler’s rigid shipping box, which

contains polystyrene or similar cushioning material to firmly hold the unit and prevent any

movement within the box. Add extra pieces of packing foam to ensure that the heavy pumps cannot

move in transit. Place the rigid shipping box into a much larger outer carton surrounded by at least

5-10 cm soft fill on all sides, this should ensure that if dropped the impact shock will be absorbed by

the overpack, and not transmitted to the cooler itself.

For transportation purposes CRC sorption coolers are classified under UN 2857, Class 6A (6=Other

articles containing gas under pressure; A=asphyxiant gas). Special Provision 119 applies:

Refrigerating machines include machines or other appliances which have been designed for the

specific purpose of keeping food or other items at a low temperature in an internal compartment,

and air conditioning units. Refrigerating machines and refrigerating machine components are not

subject to the provisions of ADR if they contain less than 12 kg of gas in Class 2, group A or O

according to 2.2.2.1.3, or if they contain less than 12 litres ammonia solution (UN No. 2672).

This special provision means that the cooler does not need to be either labelled or shipped as

hazardous or dangerous goods, whether transported by road or by air, provided that it is

appropriately packed.

Ensure that the outer carton is clearly labelled as fragile with ‘This Way Up’ labels and add Shock

Indicators if you are handing the consignment to third-party couriers, as these should deter rough

handling.

6

3. A BRIEF DESCRIPTION OF THE SORPTION COOLER UNIT

The CC4 sorption cooler is shown in the figure below. Continuous cooling of the 1K cold head is

achieved by alternately cycling the two 4He module at intervals, such that the 1K cold head is always

being cooled by one of the modules. In use, the sorption cooler is inverted, i.e. the cold head will be

at the bottom. The main plate needs to be thermally sunk to the cold head of a cryocooler at 4K or

below, see section 4.1 for more information. The 1K-head is used to extract heat from the

experiment, see section 5 for more information. The pumps and heat switches can reach up to 50K

during operation, these need to be radiation shielded from the head, for more information see

section 5.1. All electrical connections are mounted on the main plate on a stack of MDM connectors,

see section 4.2 for more information.

The following short names for the various parts of the sorption cooler are used throughout this user

manual:

Short name used in this manual

Refers to the sorption cooler part

1K-head

The cold head of the split condenser module

4-head

4He module head

4-Pump

4He module pump

4-Switch

Heat Switch for the 4He pump

The two 4He modules (which are identical) will be referred to as Module A and Module B.

He4 module

He4 Pump

1K cold head

Electrical

connector

Split

condenser

module

Not visible: heat switches

and heat straps

Main plate

Head Support

structure

7

4. INSTALLATION

4.1. Mechanical

Before installing the unit in your cryostat, be sure to carefully remove any pieces

of foam packing from around the pumps, as mentioned in the unpacking

instructions.

There should be no need to touch the heat switches or heat straps during

installation or normal operation of the sorption cooler. The heat switches can be

easily damaged, and if bent or twisted are likely to fail.

This sorption cooler is designed to be pre-cooled using a mechanical cryocooler such as a GM or

pulse tube operating at 4K or below. The thermal link to the cryocooler should be made from gold

plated copper to ensure excellent thermal contact between the sorption cooler and the cryocooler.

Mounting holes are provided on the main plate for attaching the sorption cooler to your cryostat

cold plate. To attach the sorption cooler to the 4K stage of the cryocooler there are twelve M4

clearance holes distributed around the periphery of the circular main plate (note: UNC6 clearance

holes can be substituted at customer request). A CAD file of your sorption cooler can be provided

on request to aid with interfacing.

Because the cooling down of the heads depends upon gas convection, and on

liquid helium collecting in the heads fed by gravity, the sorption cooler mustbe

kept close to vertical with the heads downwards.

Ensure spring washers are

under every bolt head, these

will take out differential

thermal contraction that

might otherwise cause

loosening of the bolts, and

thus compromise thermal

contact.

8

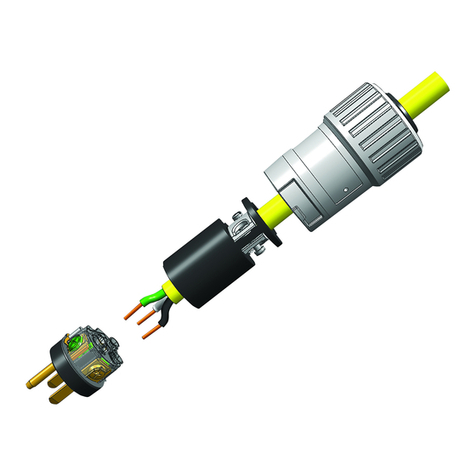

4.3. Electrical

All electrical connections are brought out to stack of three MDM-SSP connectors (2 x 15 pin, 1 x 9

pin) mounted onto the main plate. Pin-outs are listed at the end of this instruction manual. The

table below summarises the temperature sensors installed on the CC4.

ITEM

Calibration

Options

1K-head RuO2

Generic Lakeshore Cryotronics or

Scientific Instruments Inc.

Individually calibrated

sensors available on request

4-head RuO2

Generic housekeeping sensors,

calibration supplied by CRC

Lakeshore sensors available

on request

Switch diode

Generic –supplied by CRC Ltd

Pump diode

Generic –supplied by CRC Ltd

Voltage / current requirements for driving the heater and thermometers are summarised in the

table below:

ITEM

NUMBER

IMPEDANCE/

JUNCTION VOLTAGE

VOLTAGE/

CURRENT

4-pump heater

1

300approx.

20 to 25 V

Heat switch heater

1

10k

5 V

Diode thermometers

3 or 4

0.5 to 1.8V

10µA DC

4-head RuO2thermometer

1

1kto 3k

1µA max.

Generic (i.e. standard calibration) RuO2sensors from Lakeshore Cryotronics or Scientific Instruments

Inc. are the default option on the head of all CRC sorption coolers. Individually calibrated ‘CERNOX’

or RuO2 sensors are only fitted (at additional cost) at the customer’s request. The thermometer on

the 1K-head is operated as a 4-wire device and should ideally be driven by an AC current no greater

than 1µA. Calibration tables for all thermometer sensors are in the Excel data file that accompanies

each unit. Generic diode calibration curves for the pump diode and heat switch diode are supplied

as standard. The diode thermometers require excitation with currents of 10A DC.

The heat switch heater typically requires about 5V to keep the switch in the ‘ON’ state with the

absorber pod at greater than ~20K, and it will cool to the off state (T < 10 K) in ten to fifteen minutes.

The pump heater impedance is typically 300. To operate the sorption cooler it is necessary to

periodically warm the 4-pumps to between 40 and 45k. A heater current of up to 100 to 130mA will

heat the 4-pump rapidly; lower heater currents will result in slower heating. Try to ensure that the

lead-in wiring to the pump heater is not unduly dissipative and is appropriately heat-sunk.

9

5. ATTACHING YOUR EXPERIMENT TO THE SORPTION COOLER.

This model of sorption cooler provides just one point at which heat may be extracted from a user’s

experiment mounted on a separate cold table, which is the 1K-head. There are several M3 holes

tapped in this surface for thermal connections between your experiment and the sorption cooler

(note UNC4 holes can be substituted at customer request).

While fixing experimental equipment to the cold head, extreme care should be

taken not to torque or bend the gas pipes. Always support the cold head against

the applied torque.

Under no load, and with the main plate at ~4K, the cold head will run at an average temperature of

about 900mK. The temperature fluctuates periodically due to the antiphase cycling of the 4-

modules; the average temperature and the amplitude of the fluctuations will depend on the

software used to control the CC4 and there are different optimisation strategies that are possible,

depending on whether low temperature or temperature stability is more important. This is

discussed further in Section 7. When the 1K-head is loaded the temperature increases, typical data

are given in Figure 1 below. Load data for your specific sorption cooler are supplied in the Excel data

file that accompanies your unit.

5.1. Radiation shielding

The 1K-head, and any cold table/experimental equipment/detector assembly you attach, must be

properly radiation shielded at around 4K to achieve satisfactory operation. The cold table should be

thermally connected to the 1K-head with a copper heat strap. No other mechanical attachments to

the sorption cooler unit are necessary for satisfactory operation. If your sorption cooler

performance is not meeting the specification, this is likely to be due to a radiation load. Check your

radiation shielding and consider adding extra multi-layered insulation around your radiation shields,

or around the pump side (“warm side”) of the CC4.

10

6. OPERATION: QUICK-START GUIDE

6.1. Cooldown and commence continuous operation

The basic cooldown steps for the CC4 are as follows:

•Turn on the GM cryocooler and wait unit both heat switches have turned off.

•Turn on the pump heaters to keep both pumps warm (around 45K) until both 4-heads

and the 1K-head are cold (4K or below)

•Turn the heat off pump A, turn on heat switch A to cool 4-head A to

~1K. The 1K-head will also cool to ~1K at this point.

•15 minutes later: Turn the heat off pump B, turn on heat switch B to cool 4-head B to

below 1K.

•With all heads now below 1K the periodic re-cycling can begin.

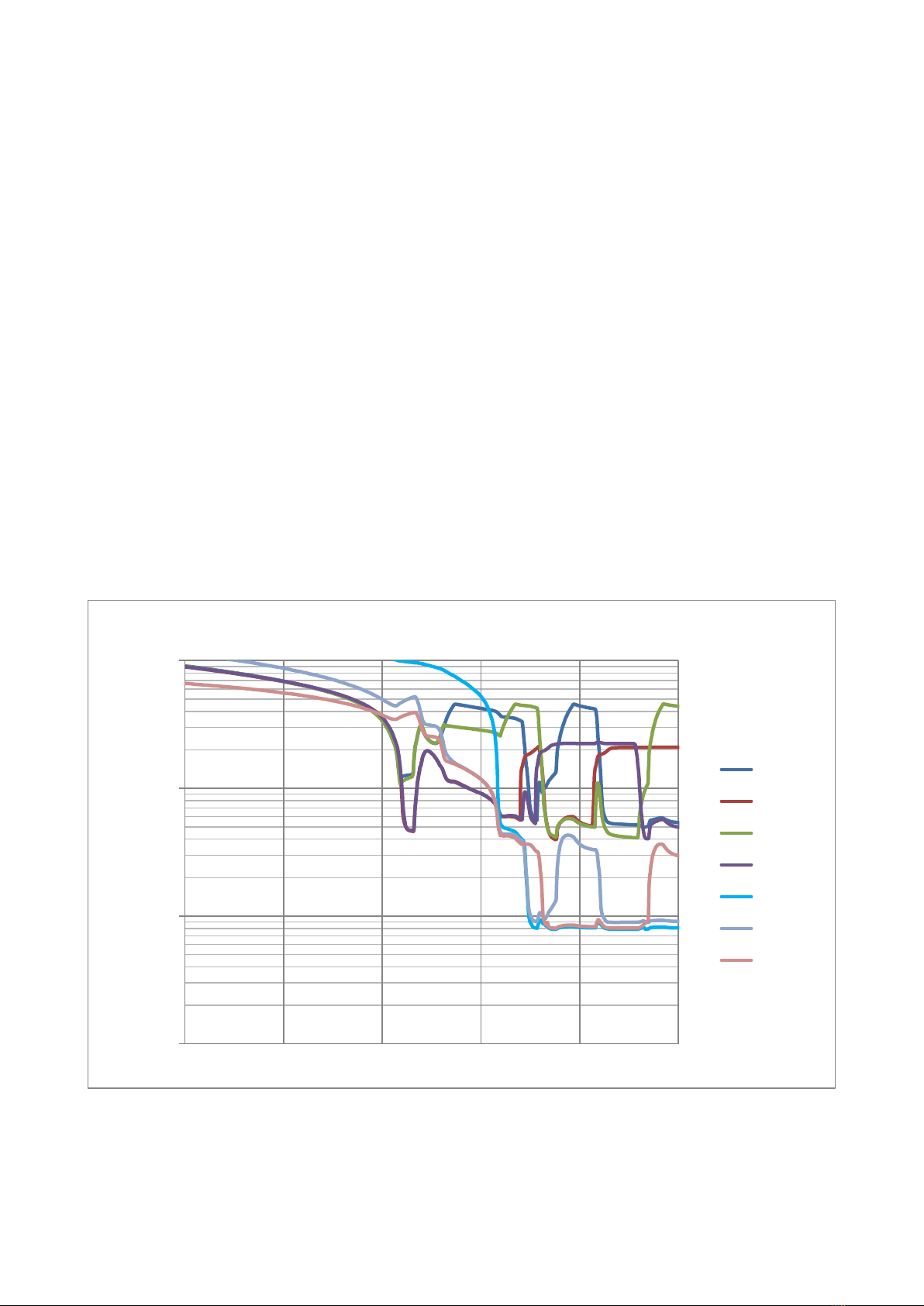

This cooldown sequence is illustrated in Figure 2 below, which shows a typical cooldown from room

temperature to 1K (at ~1350 minutes). The key steps to observe are:

-Heat switches turn off just after t=1200

-Pump heaters are turned on shortly after this

-All heads are at ~4K around t=1340

-Switch A turned on just before t=1350 for final cooldown of 4-head A and 1K-head

-Switch B turned on 15 minutes after for final cooldown of 4-head B

-Ready to begin cycling at t=1350

Figure 2

0.1

1

10

100

1000 1100 1200 1300 1400 1500

Temperature K

Time Mins

CC4 initial cooldown and establish cycling

Pump A

Switch A

Pump B

Switch B

1K-head

4head A

4head B

11

6.2 Established alternate cycling for continuous operation.

The cycle time that is optimum for your CC4 will depend on your cryocooler’s power and the heat

load that your experiment imposes, but is likely to be in the range 30-100 minutes. The examples in

this manual use 100 minutes cycle time.

The cycling steps are explained more fully in Section 8 and can be summarised as follows:

•Switch A off

•Heat pump A (the 1K-head is being cooled by 4-head B)

•Keep pump A warm while 4-head A cools

•Switch A on

•Switch B off

•Heat pump B (the 1K-head is being cooled by 4-head A)

•Keep pump B warm while 4-head B cools

•Switch B on

This sequence can be repeated for as long as required.

7. OPTIMISING THE PERFORMANCE OF YOUR SORPTION COOLER

Running the CC4 with programmable power supplies under software control enables a range of

options to tailor the CC4 performance to the user’s own set-up and application. Options include:

•Varying the cycle time;

•Varying the timing of individual cycle steps;

•Varying the rates at which pumps and/or heat switches are heated.

You are recommended to experiment with your own system to optimise its performance in your

setup, for your application.

7.1. Varying the cycle time

The cycle time cannot be reduced below the time taken to heat and cool the pumps and the heat

switches. Very rapid heating cycles are only possible if the CC4 is run using a powerful GM/PT

cryocooler that is able to rapidly remove the heat dumped by the pump when the heat switch is

turned on. This heat pulse temporarily increases the temperature of the main plate, and if it gets

too warm (above ~10K) there is a danger that the other heat switch (the ‘off’ switch) will also turn

on. Disrupting the cycle. In general, for better temperature stability and low running temperature,

we advise gentle turn-on of pump and heat switch heaters (see below).

The cycle time cannot be lengthened beyond the expiry time of either He4 module in the CC4, i.e.

the time taken to evaporate all of the Helium 4 liquid in the 4-head. When a module expires it will

start to warm up, and will warm the 1K-head before the other module takes over the cooling. The

expiry time will depend on the load imposed on the head, both by parasitic loads internal to the

CC4, and by external loads due to the user’s experiment. Your CC4’s technical datafile will specify

a recommended cycle time for your specific unit, when working under a specified applied external

load. If you find that your experiment causes the modules to expire, you should seek to reduce the

load (i.e. improve radiation shielding and heat sinking), and then try reducing the cycle time.

12

7.2. Varying the cycle steps

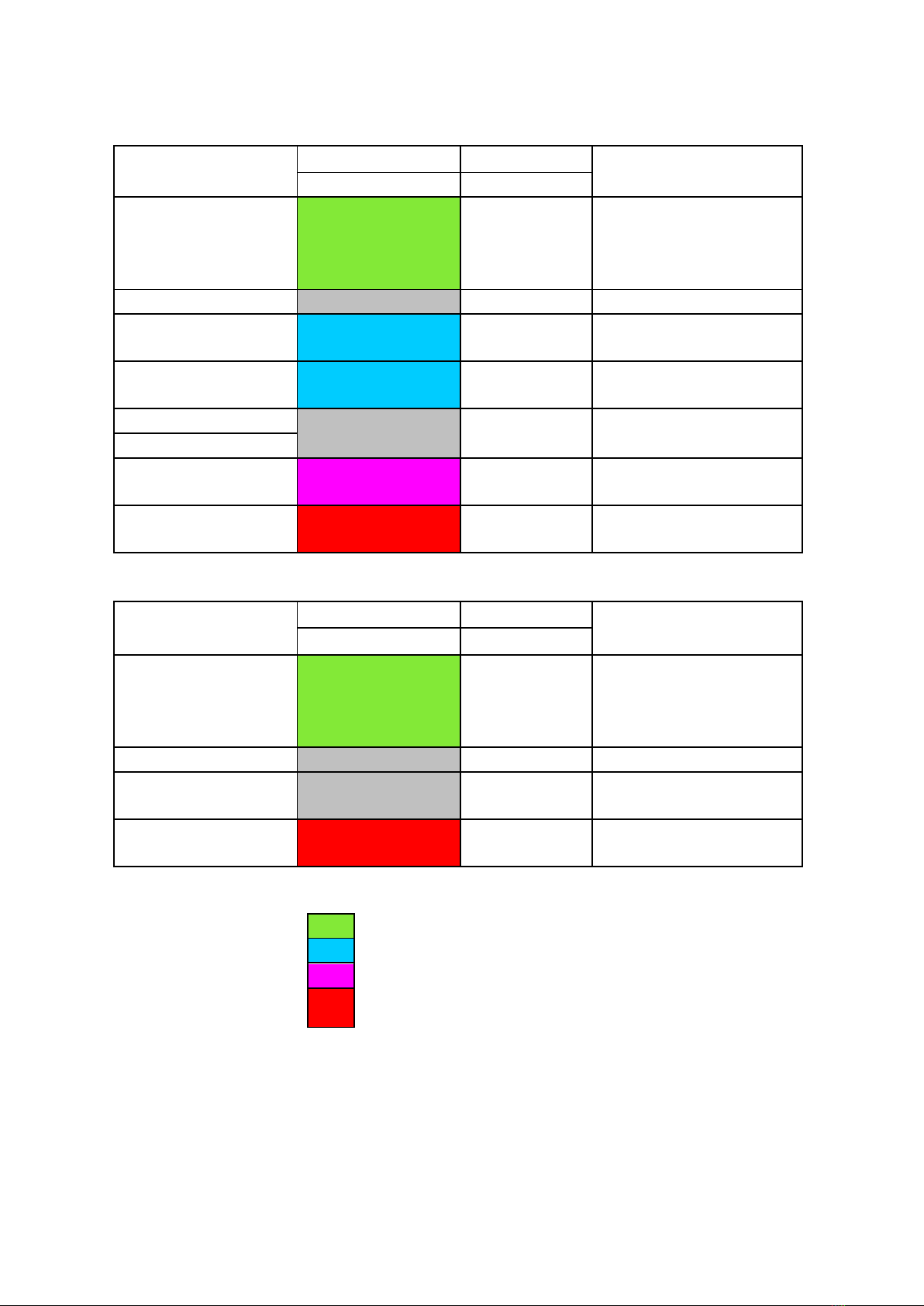

Figure 3 shows an example of a cycling sequence (100 minute cycle time) optimised to give a low

base temperature for the CC4. In this example the pump heaters are turned on gently at first, and

they are turned off as soon as the 4-heads stop cooling rapidly. This minimises the heat loading on

the CC4.

Figure 3

In the second example shown in Figure 4 the cycling sequence is optimised to reduce temperature

fluctuations at the 1K-head.

Figure 4

13

The cycling time in Figure 4 is again 100 minutes, but here, the heat switches are turned on gently

at first, and the pumps are kept warm for a longer portion of each cycle. This means that the heat

loading on the CC4 is greater overall, however the rate of heat transfer to the main plate when the

cycle is switched is reduced, meaning that the temperature fluctuations transmitted to the 1K-

head are also reduced.

7.3. PID stabilisation of the CC4

Finally, the CC4 wiring is configured to enable PID stabilisation of the temperature through

the application of a varying external load via a feedback loop to compensate the inbuilt

fluctuations. Many different PID optimisation schemes are possible and the user is

encouraged to experiment to find the one that best suits their own set-up.

PID optimisation does require the application of loads to the 1K-head and so the CC4 will

run at a higher, though more stable, temperature when it is used.

14

9. STANDARD PIN-OUT ASSIGNMENTS

He4 modules

Function

female 15 pin

Drive current

TYPE

PIN #

or voltage

RTD THERMOMETER V+

1

100nA AC

RTD THERMOMETER V-

generic 6951

9

Or low voltage

RTD THERMOMETER I+

2

Driver

RTD THERMOMETER I-

10

e.g. V<0.5mV

not used

3

PUMP DIODE I+

DC2018

4

10A

PUMP DIODE I-

11

SWITCH DIODE I+

DC2018

5

10A

SWITCH DIODE I-

12

not used

6

not used

13

SWITCH HEATER I+

10kOhm

7

2.5 to 3 Volts

SWITCH HEATER I-

14

PUMP HEATER I+

300 Ohm

8

50 to 100 mA

PUMP HEATER I-

15

13 to 15 V

Function

female 9 pin

Drive current

TYPE

PIN #

or voltage

RTD THERMOMETER V+

Lakeshore

1

100nA AC

RTD THERMOMETER V-

or Scientific

6

Or low voltage

RTD THERMOMETER I+

Instruments

2

Driver

RTD THERMOMETER I-

7

e.g. V<0.5mV

nc

3

nc

4

nc

8

PID heater

100 kOhm

5

50 to 100 mA

9

0 to 5 V

Resistance thermometer

Diode thermometer

Low power heater (a few mW)

High power heater (up to about

2W)

15

10. CC4 OPERATIONAL SEQUENCE FOR INITIAL COOLDOWN AND EXTENDED OPERATION

Step

Pump

A

Pump

B

A

B

Working status

Notes

heater

heater

Heat

switch

Heat

switch

1

OFF

OFF

OFF

OFF

Wait for both heat

switches to turn off

Pre-cooling with GM/PT

2

ON

ON

OFF

OFF

Wait until both 4-

head temperatures

are less than 4K

Heat both pumps to ~45 K, turn

power down (or off) to keep them at

40-45K

3

OFF

OFF

ON

OFF

Turn on heat switch

A, 4-head A and 1K-

head cool down

heads should cool to ~1K fairly

rapidly

4

OFF

OFF

ON

ON

Turn on heat switch

B, 4-head B cools

down

All heads should now be at ~1K

Begin alternate cycling for extended operation. Repeat steps 5 to 11 at your chosen cycle interval

5

OFF

OFF

OFF

ON

Turn off heat switch

A,4-head A

temperature rises to

~4K

The 1K-head is being cooled by

Module B

6

ON

OFF

OFF

ON

Turn on Pump A and

Heat to 45K,4

head A desorption

A more gradual heat will reduce

temperature fluctuations but raise

the average temperature

7

OFF

OFF

OFF

ON

Turn off Pump A

heater,Wait for

thermal relaxation

time

The time taken for this step will

depend on the cryocooler power.

Typically ~10 minutes

8

OFF

OFF

ON

ON

Turn on heat switch

A,4 head A starts

to cool down

A gradual heat switch turn on will

reduce temperature fluctuations

9

OFF

OFF

ON

OFF

Turn off heat switch

B,4head B

temperature rises

to~ 4K

The 1K-head is being cooled by

Module A

10

OFF

ON

ON

OFF

Turn on Pump B and

Heat to 45K,4head

B desorption

See step 6

11

OFF

OFF

ON

OFF

Turn off Pump B

heater,Wait for

thermal relaxation

time

See step 7

Table of contents

Popular Accessories manuals by other brands

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS 51874 instruction manual

TFK

TFK mamaboard operating manual

ACTON

ACTON R10 ROCKETSKATES owner's manual

ThunderDog

ThunderDog TH6000BB instruction manual

IPVideo Corporation

IPVideo Corporation Halo Training guide

Hubbell

Hubbell KILLARK ACCEPTOR UGP Series INSTALLATION, OPERATION & MAINTENANCE DATA SHEET