Assembly Sequence –Wall Mounting

Before installing the cabinet, ensure that the wall or mounting surface has

sufficient strength to support the cabinet and the expected cabinet payload.

The mounting surface must also be flat and extend beyond the top, bottom,

left, and right edges of the cabinet.

RECOMMENDED: Use RMR Quick Wall-Mounting Kit (ordered separately)

for quick and easy mounting of RMR Wall-Mount Enclosures.

See IIS-737045-001 for details.

Jump to “Assembly Sequence – Equipment Rails” (page 4) if using RMR

Quick Wall-Mounting Kit

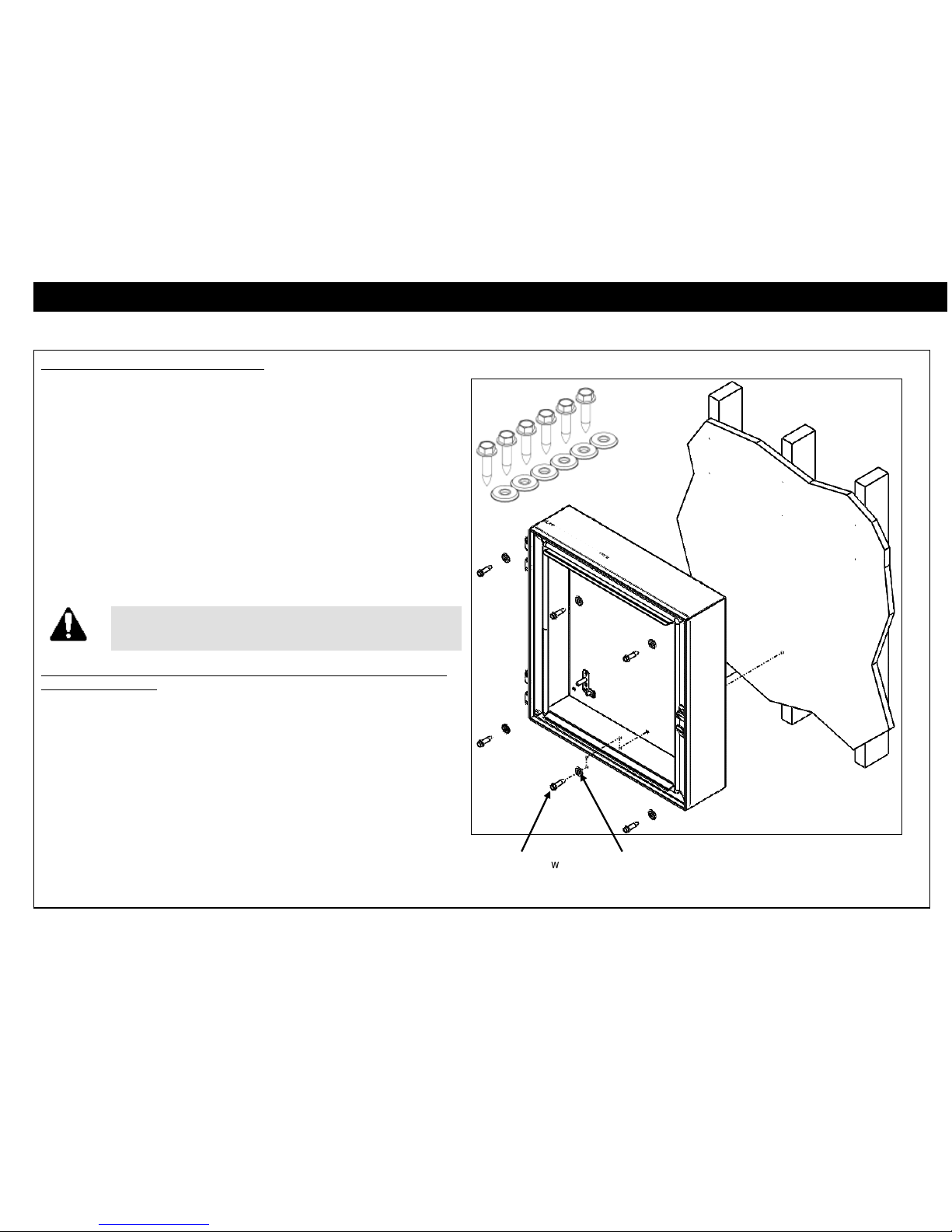

Assembly Sequence –Standard Mounting Kit

Tools Required

M13 Socket Driver

Included Hardware

(6) Sealing Washer

(6) M8x40 Lag Screw

Note: For A2 model RMR Fixed Wall-Mount - Start on step 2. Skip thesesteps and

jump to “Assembly Sequence – Equipment Rails” (page 4) if using RMR Quick Wall-

Mounting Kit.

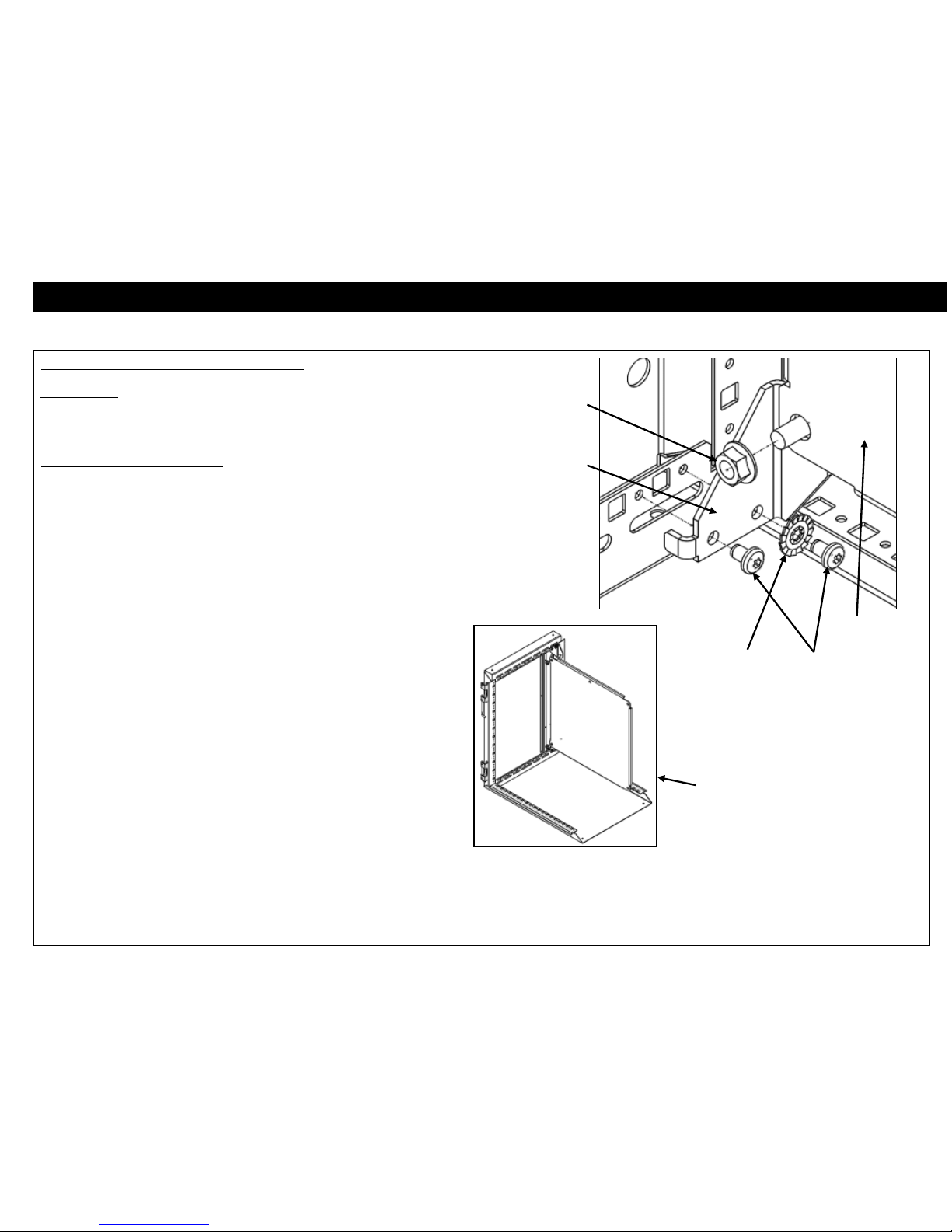

Step 1: Separate Center Chassis from Rear Chassis-

For A3 models, RMR Swing Wall-Mount Enclosure only

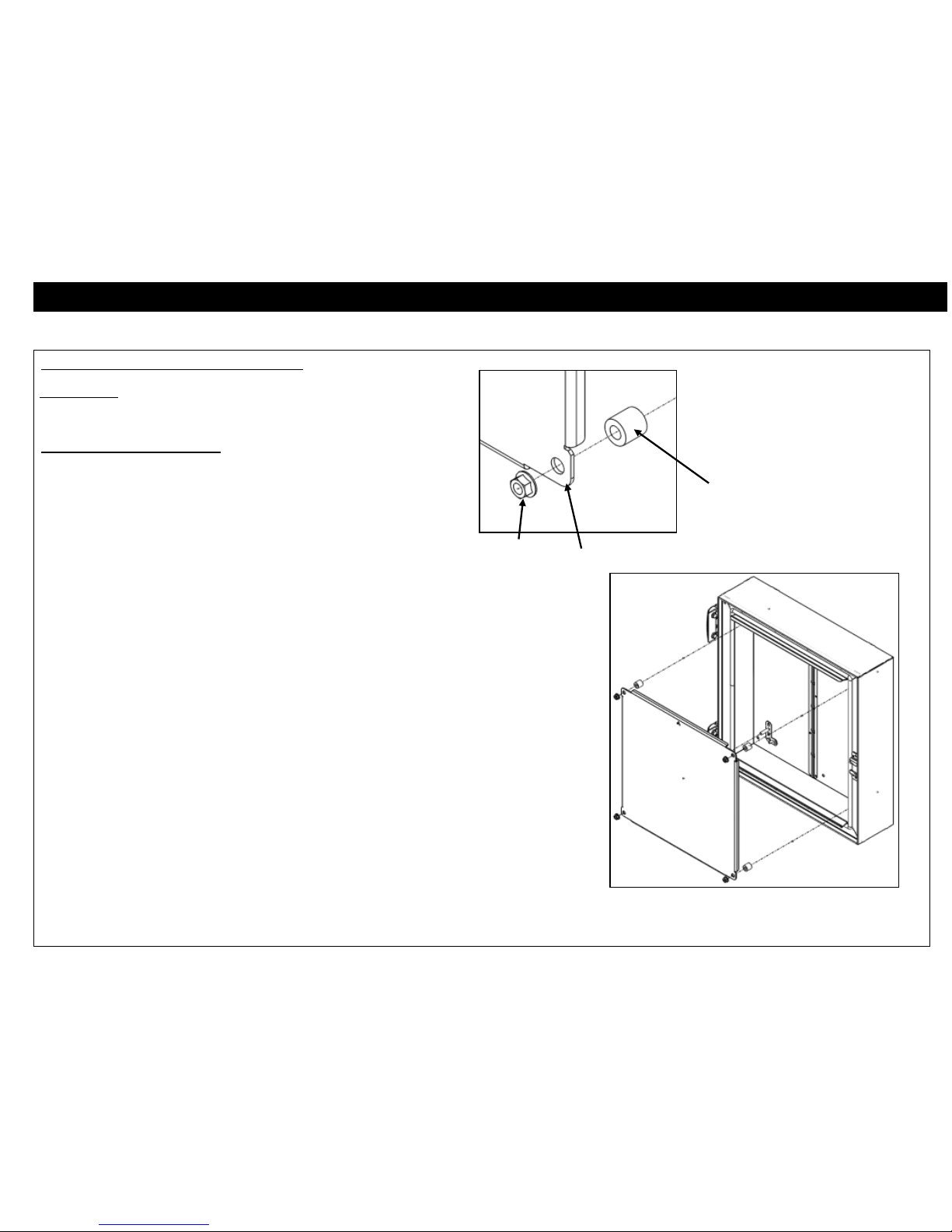

1. Determine which side the cabinet will hinge from. The cabinet is

shown with the hinge on the left side. Invert the cabinet to position

the hinge on the right side.

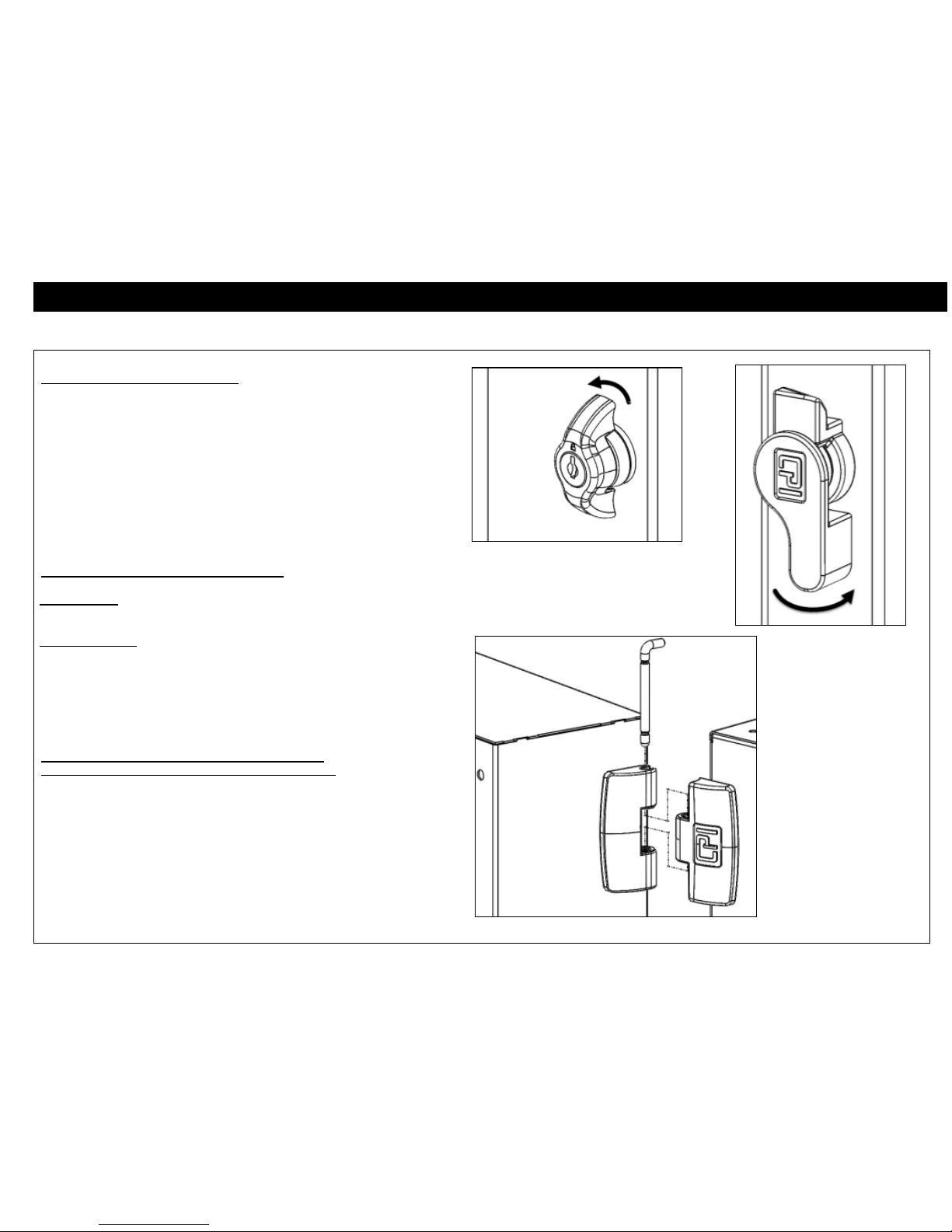

2. Rotate front door latch counterclockwise to open Front Door to gain

access to center chassis latch.

3. Rotate center chassis latch(es) counter-clockwise and swing open

center chassis 120 degrees.

4. Pull out hinge pins to separate center chassis from rear chassis.