Chell TP9000CI User manual

Page1

Please read thismanual carefullybefore using the instrument.

Use of this equipment in a manner not specified in this

manual may impair the user’s protection.

Chell Document No. : 900255Issue 1.0

ECO : ---- Date:15th August 2023

Chell’s policyof continuously updating andimproving productsmeans that

this manual maycontain minor differencesin specification, components and

software design fromthe actualinstrument supplied.

Page2

CONTENTS

1Description ..............................................................................................................................3

1.1 Introduction........................................................................................................................ 3

Specification...................................................................................................................................4

2.1 Power Supply:.................................................................................................................... 4

2.2 Package:............................................................................................................................ 4

2.3 Ethernet Specifications:..................................................................................................... 4

2.4 Operating conditions:......................................................................................................... 4

2.5 Dimensions ........................................................................................................................ 5

3Installation and Interconnections......................................................................................... 6

3.1 Wiring – Power & comms .................................................................................................. 6

3.1.1 TP9000 Power Supply................................................................................................ 6

3.1.2 MIL-DTL-26482 Series I Mating Connector (PT06A14-15S)..................................... 6

3.1.3 OptionalM12 Mating Connector (recommended cable of type 'Harting 09478411002

or equivalent)............................................................................................................................ 6

3.2 Mounting Holes.................................................................................................................. 7

4TP9000 Webserver..................................................................................................................8

4.1 Introduction. ....................................................................................................................... 8

4.2 Common Controls Sidebar................................................................................................ 9

4.3 The 'Setup'Page............................................................................................................... 9

4.3.1 Introduction................................................................................................................. 9

4.3.2 Data Streaming........................................................................................................... 9

4.3.3 GeneralEthernet Comms......................................................................................... 10

4.3.4 NetScanner Comms ................................................................................................. 11

4.3.5 UDP Specific Comms............................................................................................... 11

4.4 'Live Data' Page............................................................................................................... 12

4.5 ‘Channel Info’ Page......................................................................................................... 12

4.6 ‘Advanced’ Page.............................................................................................................. 13

4.6.1 Time Stamping......................................................................................................... 13

4.6.2 Live Health Check .................................................................................................... 13

5Service and Calibration ........................................................................................................14

5.1 Service............................................................................................................................. 14

5.2 Calibration........................................................................................................................ 14

5.3 Adjustment....................................................................................................................... 14

5.4 Cleaning........................................................................................................................... 14

Page3

1Description

1.1Introduction

The Chell TP9000CIis atranslator designed tobeusedwith Measurement

Specialties NetScanner9x16 devices, whichhave Ethernet communications but

do notnativelysupporttheChell and IENA streamingprotocols.Itis basedaround

the original TP9000that wasdesignedfor adding theDDS protocol to NetScanner

devices.

The TP9000CI is asmall device thatis designedto attach totheside of the

NetScanner and communicate directly with it, providingan Ethernet interface to

command the NetScanner to streamdata and switch valves andread back the

data from the NetScanner, converting it toaChell or IENA formatteddatastream

that is transmitted over TCP/UDP as appropriate.

Configuration is provided via an embeddedwebserver whichcanalsobeusedas

an information/debugtool tocheck that thedevice is correctly communicating with

the NetScanner.

Page4

Specification

2.1Power Supply:

DC Supply

18 to 48VDC

Maximumcurrent consumption:18 VDC supply: 1400mA

48 VDC supply: 520mA

PoE : See section3.1.1

2.2Package:

Dimensions

128

x

60

x

36

mm

Weight

380g

2.3Ethernet Specifications:

TCP/IP 10Mb/s & 100Mb/s viaAuto Negotiation

TCP

andUDP

protocols supported

2.4Operating conditions:

Operating temperaturerange: -55°C to +90°C

Storage temperature range: -55°C to +90°C

MaximumRelative humidity: 95% at 50°C (non condensing)

MIL-DTL-26482

PT06A14-15S

Page5

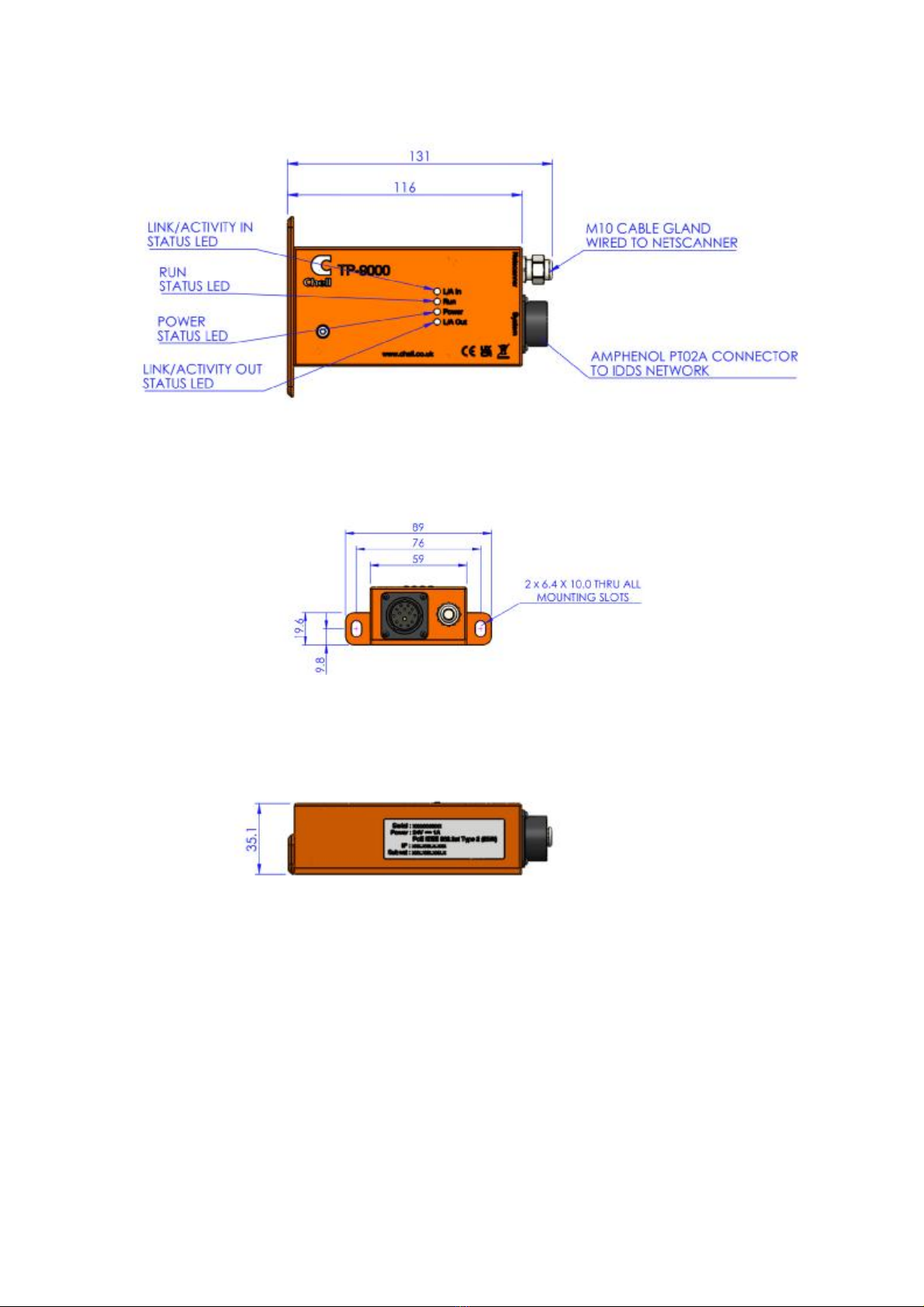

2.5Dimensions

Page6

3Installation and Interconnections

3.1Wiring – Power & comms

3.1.1 TP9000 Power Supply

The TP9000 is equipped with anauxiliary DCpower supply and aPower-over-

Ethernet supply. TheDCsupplywill takepriority soaTP9000poweredupover DC

will not negotiatewith aPoEswitch.IftheDCsupply is removed, thentheTP9000

will establish a power supply froma PoE switch if it is present.

If however theTP9000is poweredvia PoEand aDC supply thembecomes

available,theTP9000 will switch all its powerconsumption over to the DC supply.

The power supply source detectedatstart-up is displayedonthe embedded

webserver for information purposes.

3.1.2 MIL-DTL-26482 Series I Mating Connector (PT06A14-15S)

Recommend use :DC supply and PoEType 1, 2.

Pin Number

Designation

A Ethernet RX+

B Ethernet TX+

C Ethernet TX-

D Trigger IN

E Trigger REF

N Ethernet RX-

P Power Supply +Vdc

R Power Supply Return(0V)

3.1.3 Optional M12 Mating Connector (recommended cable of type 'Harting

09478411002 orequivalent)

Recommend use :PoE Type 1, 2.

Pin Number

Colour Code

1 1 DA+ (TX+)

2 2 DA- (TX-)

3 3 DB+ (RX+)

4 4 DB- (RX-)

5 5 DD+

6 6 DD-

7 7 DC-

8 8 DC+

Page7

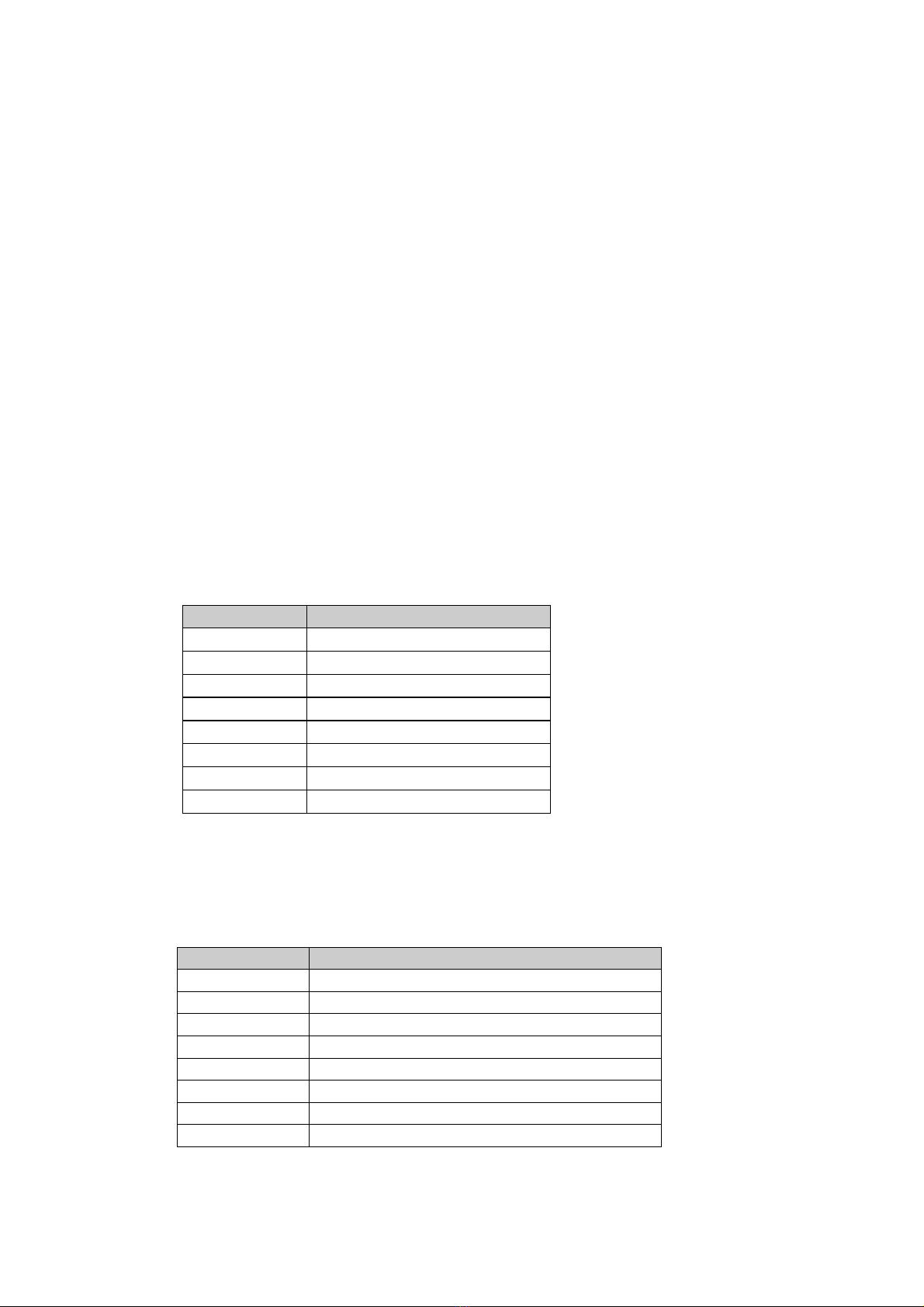

3.2Mounting Holes.

The TP9000 has 2 slotted mounting holes that line up with theouter mounting

holes on the NetScanner. The TP9000 is designed tofit on either side of the

NetScanner product and has an optional mounting bracket whichcan be used in

high vibration environments. This bracketis fitted to the TP9000 with two M3 hex

bolts asshownbelow. To mount the bracket to the NetScanner, two of the bolts

must be removedfrom the topplate of the scanner. These bolts arethen passed

through the mountingbracket as shown below.

NOTE : It is important that the sealing‘O’ which is present on the NetScanner top

plate bolts is moved to below the TP9000mounting bracket to maintain the

sealing integrity of the NetScanner.

Page8

4TP9000Webserver

4.1Introduction.

In keepingwith other devices fromChell containing an embeddedwebserver, the

TP9000includes some pages thatcontainconfigurationparameters as well as

information/debugpages.

The webserver is divided by tabs intofive areas of functionality,namely 'Setup’,

'Live Data', 'Channel Info', ‘Advanced’ and ‘Factory Tools’.

'Setup’ provides the means tosee the currentstreamingrate and commssetupfor

boththeTP9000unit and theconnectedNetScanner device. The unit's function

may bechecked and demonstrated using 'LiveData' toshow the current pressure

and temperature readings fromthe attachedNetScanner. ‘Channel Info’ shows the

configuredrangeofeachtransducer ofthe connectedNetScanner device.

‘Advanced’ has extra functions &informationthatmost users probably do not need

butmightbenecessary for other users. ‘Factory Tools’ ispassword protected,but

simply provides accessto theserial number and manufacture dateof theTP9000.

Figure 4.1, Main Setup page

Page9

4.2Common Controls Sidebar

4.3The 'Setup' Page

4.3.1 Introduction

The 'Setup’ pageshowsall of theTP9000’s main operatingparameters. Setup is

divided into differentcategories by function, and eachcategory is detailed

separately in the following.

4.3.2 Data Streaming

The ‘DataStreaming’sectionshowstherateconfiguredfor datastreamingfrom

the attachedNetScanner. For timingsynchronisation purposes,in general usethis

is always ahardwaretriggereddatastream,with thetrigger internally generated

by the TP9000. TheCommsProtocol dictatesthe transport layer protocol used for

the datastreamingoutput.If IENA specification is required, this must beset to

UDP. Theprotocol shows theendianness formatsettingfor thedatastreamed

output.

Figure 4.2, Data SteamingSetup section

Figure 4.1 above shows the first page viewed when

navigating to the webserver. The menu at thetop allows the

user to choosewhat is visible in the central window, and the

sidebar (shown left) shows information andalso provides a

means to reset the unit.

Ahard reset will restart the oprerating system within the

TP9000 and is requiredwhen changing theIPaddress of the

unit. Asoftreset simply restarts the application andis

therefore significantly quicker and best used to actually use

other applied settings after they have been changed.

There are also two command functions provided to operate

the valving within theNetScanner to performaZero orPurge

function acccordingly.

Page10

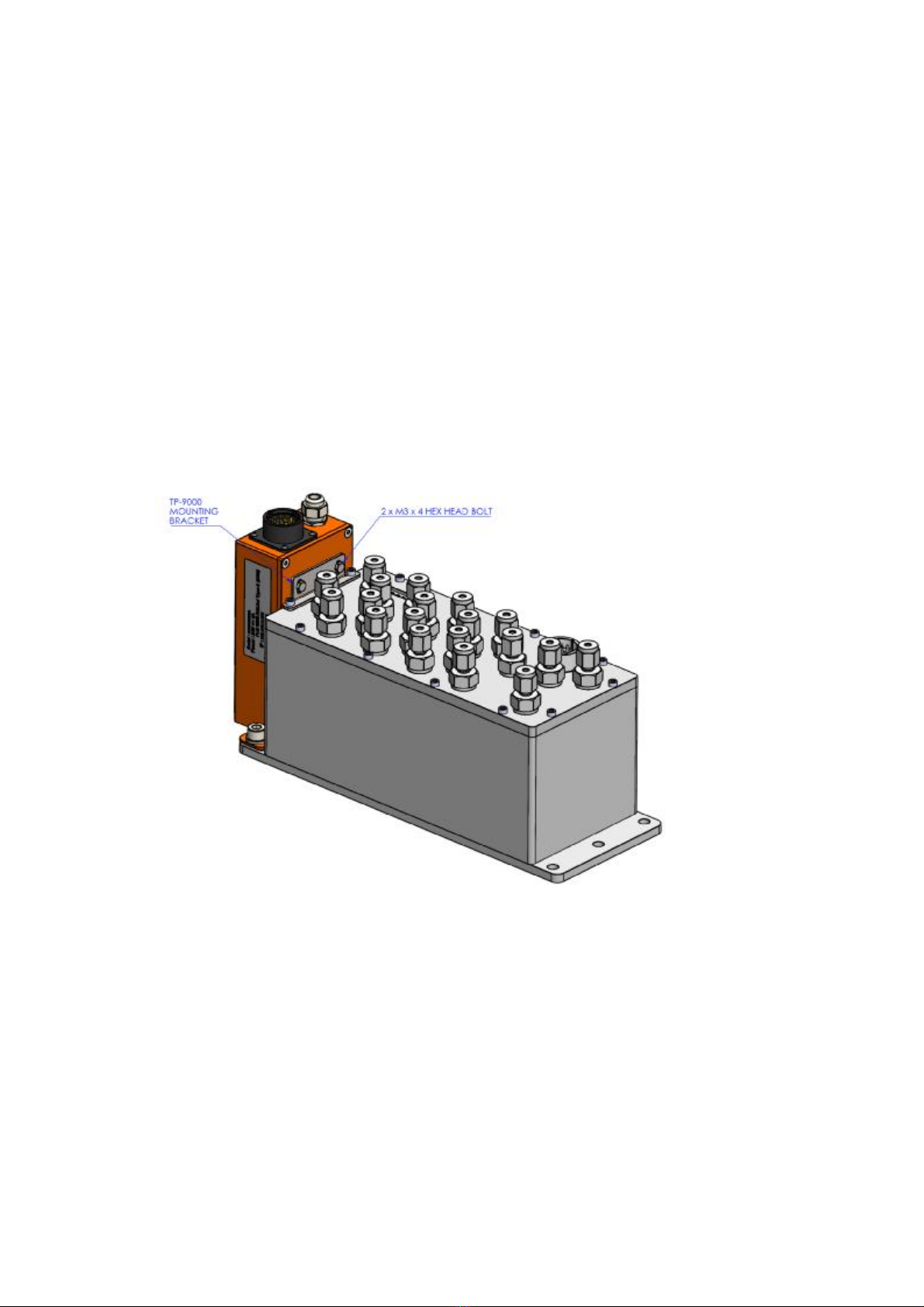

4.3.3 General Ethernet Comms

The General Ethernet Commsparameters areshown in Figure 4.3. The options in

this section control the TP9000’s IP address, subnet mask andLocal port.

Figure 4.3a, TCP Commsgroup

‘Static’& ‘DHCP’ radio

buttons

Toggle between a statically set IP address (using the text boxes

below), or adynamically assigned IPaddress (from an external

DHCP server)

'IP Address' IP address allocated to TP9000on the user's network.

'Subnet' Subnet mask as set on theuser's network.

‘Local port’ Local port of the device (fixed to101).

‘Apply’ Applies the settings tothelocal memory

Table 3.1, TCP Commsgroup settings

When DHCP is selected by clicking theradio button, thei/p address and subnet

address cannot be edited, as shown below.

Figure 4.3b, DHCP Comms

Page11

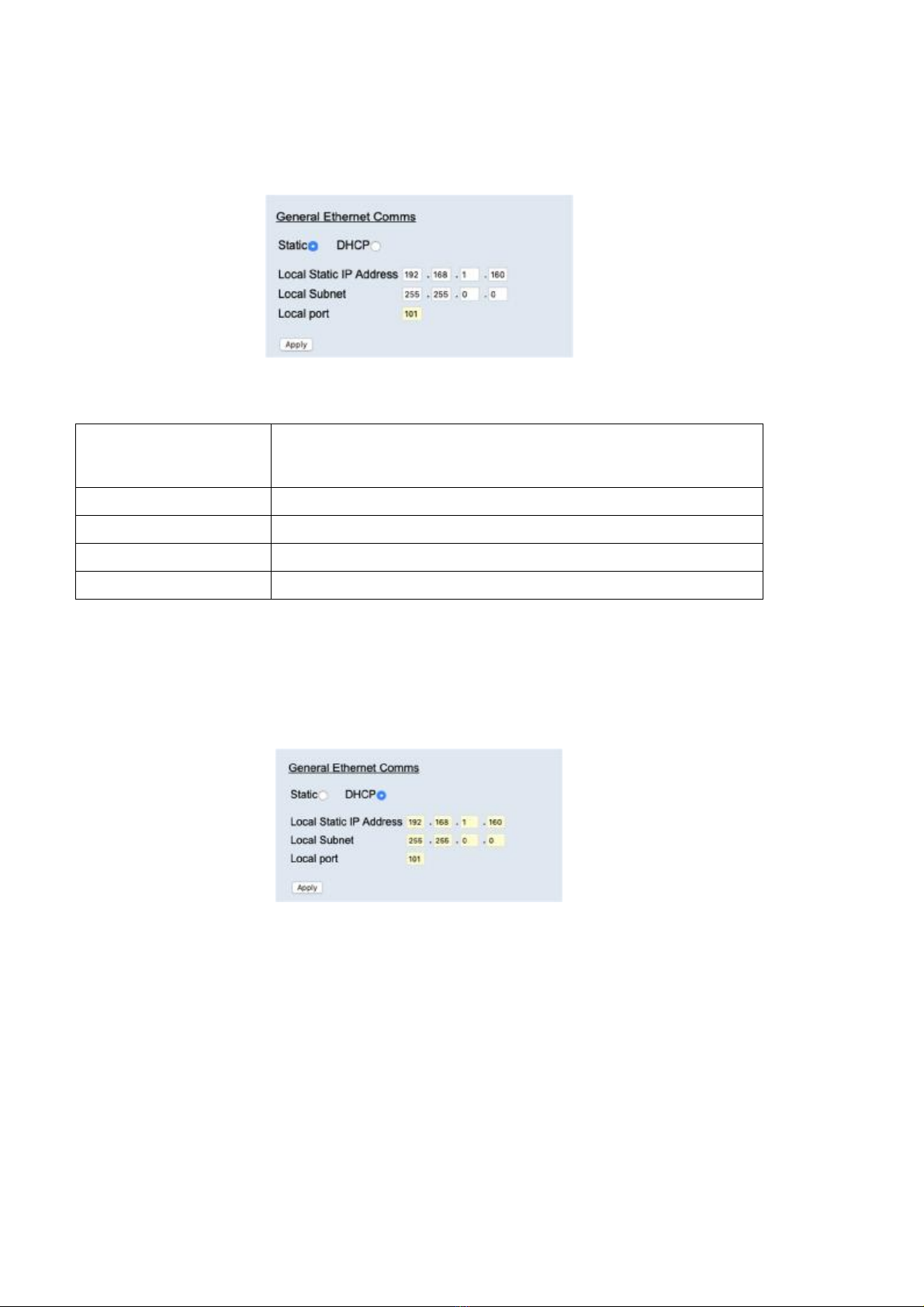

4.3.4 NetScanner Comms

The NetScanner Commssection shows the IP address and Subnet of the

connected NetScannerunit (as shown in Figure 4.4). This is set by the factory

initially when the TP9000 is connected to the NetScanner and should not be

changed unlessthe TP9000 unitis moved to a different NetScanner.

Figure 4.4, NetScanner Comms section

4.3.5 UDP Specific Comms

This section allows for configuration of the remotehost’s UDP address andport so

thattheTP9000knowswheretoautomatically startstreamingdatato onpower up

(assumingthe data rateis not set to ‘Off’). Thisis also thesectionwhere the IENA

specification can be selected for the datastreamoutput.

Figure 4.5, UDPSpecificComms section

Page12

4.4'LiveData' Page

Figure 4.6 shows the 'Live Data' page of the webserver.

Figure 4.6, Live Data Page

The livedatapageisameans todemonstrating thecorrect operation of TP9000

and essentially confirms communicationwith the attachedNetScanner. The page

shows boththepressure (in psi) and temperature (indegreesC) for eachchannel

as reported by the NetScanner.

4.5‘Channel Info’ Page

The 'Channel Info' page shows asummaryof the range configured for each

transducer ofthe connectedNetScanner, as reported at systeminitialisation.

Figure 4.7, ‘Channel Info’ Page

Page13

4.6‘Advanced’Page

The advancedpagecontains informationontimestampingandsystem health

check readings.

4.6.1 Time Stamping

This section shows thesettings for thetimestampingwithin theTP9000. This

timestamp will allow theuser to get microsecond level accuracytimestamps onthe

datapackets.

Figure 4.8, Timestampingsection

‘PTP synchronisation on’

checkbox

This shows whether timestamps arePTP synchronised or

not. Please note this will only work if there is a PTP

grandmaster clock on the same network as the TP9000.

‘Time format’ This setting allows the for the time stamps to be

represented as UTCor TAI(atomic time).

‘Apply’ This button will apply the settings chosenon this page.

‘Refresh’ This allows the user to refresh thedisplayed value of the

last read timestamp from the TP9000.

‘last read Translator UNIX

time’

The top lineshows the current UNIX time in the TP9000.

The bottom lineshows a human readable equivalent time.

4.6.2 Live Health Check

The TP9000providesaliveupdateof itsinternaltemperatureand barometric

pressure as read by anonboardbarometric pressure transducer. This is updated

continuously at around 2Hz.

Figure 4.9, Live Health Check section

Page14

5Service and Calibration

5.1Service

There are no user serviceable parts inside the instruments.Should any difficulties

be encountered intheuse ofthe TP9000,it is recommendedthatyoucontact Chell

Instruments Ltd for advice and instructions.

5.2Calibration

Calibration is not required for the TP9000.

5.3Adjustment

There are nouser adjustments in theinstrument. The user is strictly forbiddenfrom

removing the covers without invalidatingChell’s obligations under warranty.

5.4Cleaning

Adirty instrument may be wiped clean withasoft cloththat has beensprayedwith

a proprietary ‘foamingcleaner’, then wipeddry immediately.

Underno circumstances should the instrument be wetted

directly orleft damp.

Table of contents

Popular Electronic Dictionary manuals by other brands

Cross Technologies

Cross Technologies 4116-21T23 instruction manual

Franklin

Franklin Talking Spanish-English Dictionary BES-1240 user guide

Cross Technologies

Cross Technologies 2083-914A instruction manual

Franklin

Franklin Talking Children's Dictionary CDS-240 user guide

Ectaco

Ectaco TL-2B&FreeML320 - Bulgarian - Talking Electronic... user manual

Franklin Explorer

Franklin Explorer EST-7014 user guide