Chemical Concepts KDM110 User manual

Ventilated Facades Under-mount Sink Anchor

Panel and Ceiling Hanging Faucet Hole Drilling

KEEP-NUT™

KDM110

SKU NUMBER

CCH-KN-KDM110

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

DRILLING

MACHINE

MANUAL

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 1 9/17/19 2:01 PM

• 2 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

TABLE OF CONTENTS

PRODUCT INFORMATION ............................................................................................3

PART DRAWING ...............................................................................................................5

OVERVIEW .....................................................................................................................7-9

SPECIFICATIONS ......................................................................................................................... 7

EQUIPMENT INCLUDED ............................................................................................................ 7

SPECIAL FEATURES ................................................................................................................... 7

AIR PRESSURE AND VOLUME ............................................................................................... 8

TOOL SET-UP INFORMATION ................................................................................................. 8

DRILL BITS ..................................................................................................................................... 9

TROUBLE SHOOTING ..............................................................................................10-11

LOSS OF SUCTION ................................................................................................................... 10

INSUFFICIENT SUCTION ......................................................................................................... 11

HOLE DIAMETER ........................................................................................................................ 11

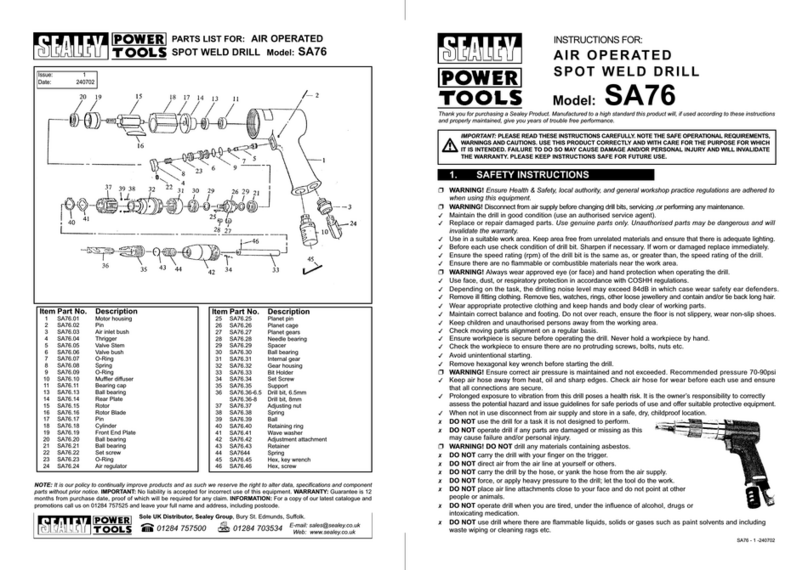

AIR-680C INSTRUCTION MANUAL ..................................................................12-27

INTRODUCTION TO AIR-680C ..............................................................................................13

ABOUT THE SYMBOLS .............................................................................................................13

SAFETY INSTRUCTIONS FOR POWER TOOLS ........................................................ 13-15

DECLARATION ............................................................................................................................16

AIR-680C OVERVIEW ...............................................................................................................17

SPECIFICATIONS ........................................................................................................................ 17

EQUIPMENT INCLUDED ...........................................................................................................18

OPTIONAL ACCESSORIES ......................................................................................................18

SPECIAL FEATURES ..................................................................................................................18

TOOL SET-UP INFORMATION ................................................................................................18

CONNECTION FITTINGS ..........................................................................................................19

AIR PRESSURE & VOLUME ....................................................................................................20

RUST PROTECTION ..................................................................................................................20

HOW TO ADD THE RUST INHIBITOR OIL .........................................................................21

SPINDLE SIZE ..............................................................................................................................22

AIR VALVE LEVER .....................................................................................................................22

WATER CONTROL VALVE ...................................................................................................... 22

SILENCER/MUFFLER ...............................................................................................................23

REVERSIBLE SIDE HANDLE ..................................................................................................23

AIR SUPPLY HOSE ASSEMBLY .............................................................................................23

WATER SUPPLY HOSE ASSEMBLY .....................................................................................23

AIR-680C SCHEMATIC ............................................................................................................24

AIR-680C PARTS LIST ...................................................................................................... 25-27

ACCESSORIES AND FACTORY SERVICE ......................................................................... 27

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 2 9/17/19 2:01 PM

• 3 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

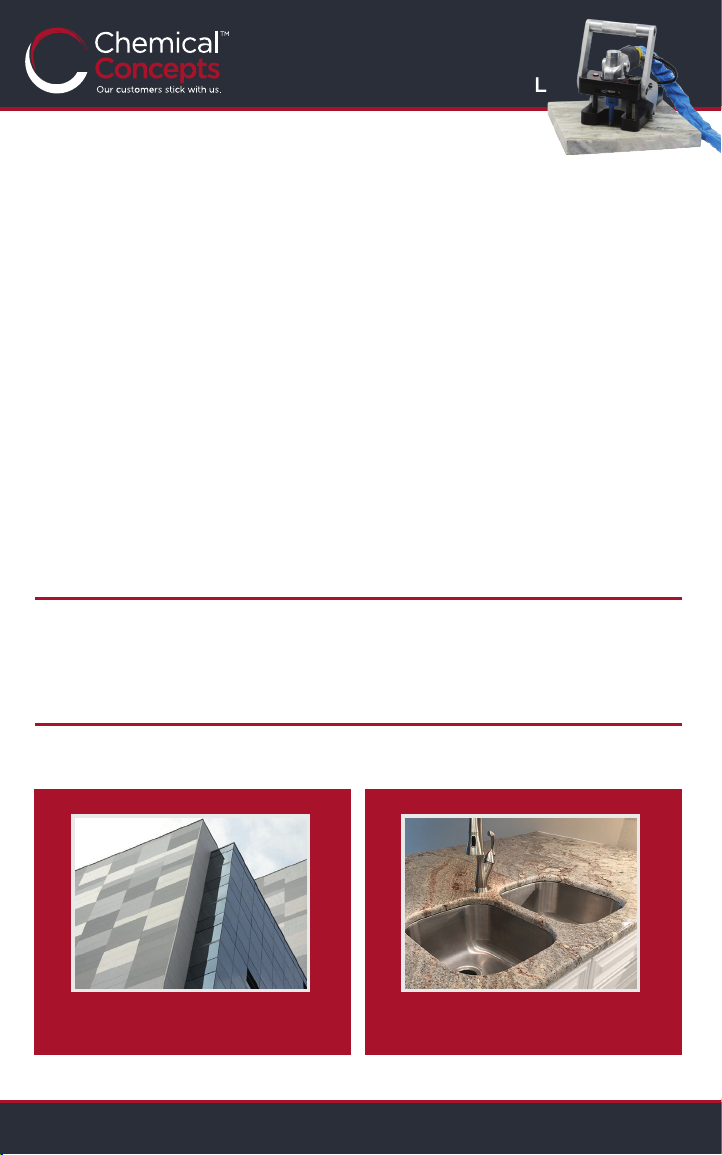

Ventilated Facades Under-mount

Sink Anchor

The KDM110 KEEP-NUT™ DRILLING MACHINE from

Chemical Concepts™, is a lightweight, precision tool for drilling

panels and countertops. This machine will enable any operator

to repeatedly and efficiently drill holes with the correct dimen-

sions for use with the Keep-nut anchoring system. This machine

can also be used to as a general-purpose, portable drill press for

many otherapplications.

Using an array of compatible bits, the machine can prepare holes

in a variety of hard surfaces including granite, marble, engineered

stone, UHPC, ceramics, glass, and composites. The vacuum-foot

allows secure attachment to rough surfaces including unpolished

granite and textured materials. This water-cooled, pneumatic

machine requires only a single airline and a water feed to operate.

Use with thin-wall core bits to drill faucet holes in record time

without a CNC.

KEEP-NUT™ DRILLING MACHINE works on:

PRODUCT INFORMATION:

• Vacuum-foot for secure attachment

to rough or even vertical surfaces

• Built in depth stop for precise,

repeatable results

• Fast, efficient drilling of anchor holes

for KEEP-NUT™ Anchoring System

• Lightweight and easy to operate

• Water cooled and air-operated

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 3 9/17/19 2:01 PM

• 4 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

KEEP-NUT™ is a press-in self-anchoring insert that provides a

permanent threaded fixing in panels or countertops made of

marble, granite, composites, carbon,

Corian®, HPL, glass and others

hard surface materials.

The KEEP-NUT™ insert is

specifically developed to

fasten ventilated façades,

wall-coverings, décor,

furniture, under-mount sinks,

as well as a variety of other applications.

The Keep-Nut is made of stainless steel

for durability and performance in exterior applications.

Available in different lengths to fit several different panel

thicknesses, KEEP-NUT™ can be installed quickly by drilling the

material to the correct hole diameter and pressing in the insert.

KEEP-NUT™ inserts have several advantages. The preparation

needed is just a cylindrical hole drilled by CNC or the KDM series

manual tools. In addition, assembly by pressure is quick and easy

and does not require use of adhesives.

PRODUCT USED WITH:

Two Crown

Four Crown

Panel and

Ceiling Hanging

Faucet Hole Drilling

KEEP-NUT™ DRILLING MACHINE works on:

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 4 9/17/19 2:01 PM

• 5 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

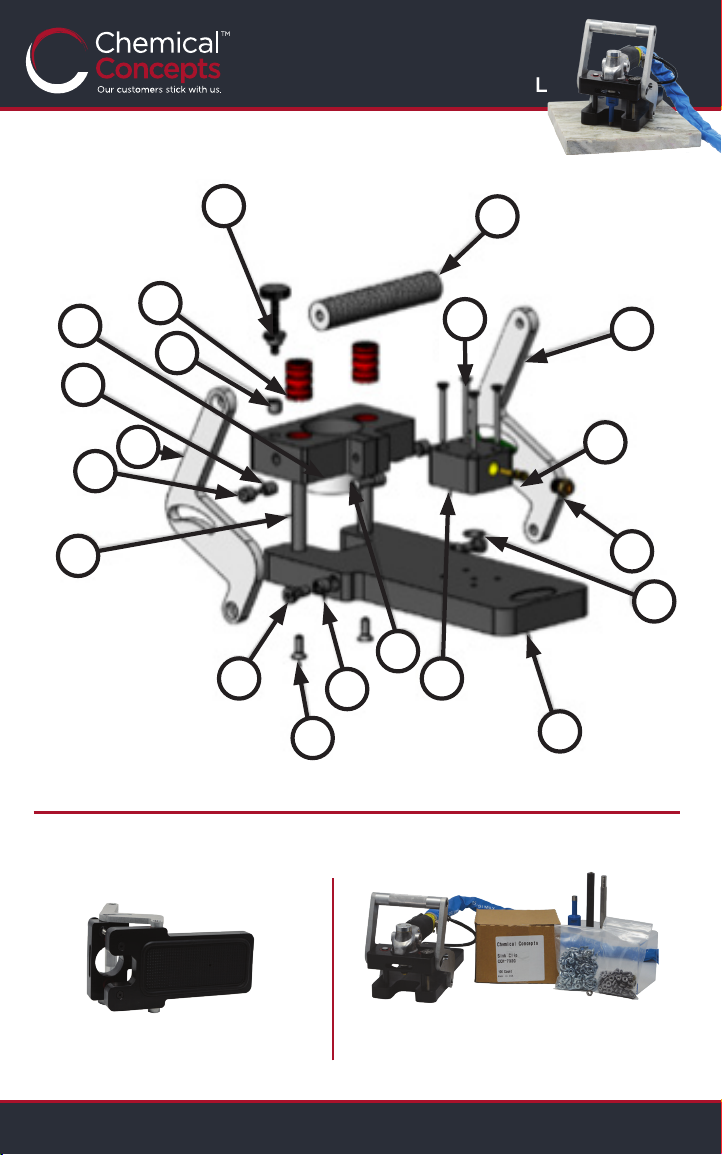

INDIVIDUAL PART PHOTOS

16

15

1

10

3

6

19

14

9

12

13

8

2

2

11

7

17

18

4

PART DRAWING

Use only with

11.8mm ⅝”x 11

diamond bit

5

Keep-Nut-Alpha-Air-Polisher

KEEP-NUT™ Machine

with accessories

Base with bottom view

(See chart on page 6)

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 5 9/17/19 2:01 PM

• 6 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

KEEP-NUT™ Machine

ITEM NO. DESCRIPTION QTY.

1 Cam Follower 2

2 Thread Insert 1/4” - 20 to 7/16” - 14 4

3 Thread Insert 5/16” - 18 to 1/2” - 13 3

4 FHCS #10-24 x 2” 4

5 FCHS 1/4” - 20 x 3/4” 2

6 BHCS 1/4” - 20 x 1 1/4” 1

7 Adjustment Screw 1

8 SHSS 5/16” - 18 x 3/8” 2

9 O Ring 1

10 Ceramic Shaft 2

11 Linear Bushing 2

12 Hex Union 1/4” to 1/4” NPT 1

13 Venturi Valve 1

14 Fixture Base 1

15 Clamping Block 1

16 Handle 1

17 Arm 1

18 Arm 1

19 Venturi Block 1

INDIVIDUAL PART PHOTOS

Full

side view

KEEP-NUT™

Machine

front with

11.8mm ⅝” x 11

diamond bit

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 6 9/17/19 2:01 PM

• 7 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

Specifications

Air Pressure..................................................85 PSI

Air Consumption.....................................16 CFM

Weight........................................................4.84 lbs

OVERVIEW:

Special Features

The KDM110 has a number of special features. The unit is

designed to power both the pneumatic drill/polisher and the

vacuum base using a single airline. The Venturi vacuum base

was designed to deliver powerful suction to hold the unit

securely in place even on rough and textured materials such

as the underside of granite and ceramic surfaces in wet or

dry conditions. The vacuum base allows the unit to be

operated in a vertical or horizontal positions, provided

sufficient air pressure and volume is available. The vacuum

base also has a convenient quick release system to allow the

user to quickly reposition the unit without shutting off the

air line. Simply cover the small circular opening located on

the front of the Venturi block (19) with your finger and the

suction will be temporarily disengaged. The front of the unit

has a slot to accept a wrench allowing the user to change

drill bits without removing the polisher from the base. Simply

slide the included wrench into the slide and engage the

spindle on the Alpha Air-680C. This will prevent the spindle

from rotating. You can then use the appropriate wrench to

attach/remove your drill bit. Lastly the KDM110 has an

integrated depth stop that allows a predetermined depth

to be set for repeatable, accurate drilling.

Equipment Included

Alpha Air680C........................................................................1 pc

Non-coring Drill Bit ( 11.8mm) (CCH-KNBITGRI-11.8MM)...…1 pc

Split Stop Collar (½”)...........................................................1 pc

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 7 9/17/19 2:01 PM

• 8 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

Air Pressure & Volume

The recommended air pressure for this tool is 85 PSI. The most

important factor in running this tool is the volume of air being

supplied to the tool. The volume is the air consumption needed

to run this tool at a constant speed under light downward hand

pressure. The volume is measured in CFM (cubic foot per

minute (ft3/min). You need a minimum of 16 CFM per tool to

power both the tool and the vacuum base effectively.

When choosing a compressor to run an KDM110 we recommend

a rotary screw type with a minimum of a 5 hp motor/15-20 CFM

and a 60-gallon tank, per tool. (I.E. if you want to run four tools,

you will need a compressor with a 20 hp motor capability of

80+ CFM and an 80 to 100-gallon storage tank.) It is also very

important to keep your air cool, dry, and clean, so look for a

compressor with a refrigerated dryer and high-efficiency filter

built in or purchase a separate air dryer and filter unit rated for

your compressors CFM. Also ensure that the hose feeding the

KDM110 is of sufficient diameter to provide the required volume.

½” Hose is recommended.

Tool Set-up Information

Unpack the tool carefully and study the manual. Set the tool on a

level surface and inspect for damage.

Before use, ensure that the Alpha AIR-680C is securely clamped

into the clamping block (15), using a ⁵/₃₂” Allen wrench. If the

drill is not clamped securely in the clamping block the drill

may come loose during use. Excessive force and/or insufficient

air pressure/volume may also force the polisher from the

clamping block.

OVERVIEW: (cont)

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 8 9/17/19 2:01 PM

• 9 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

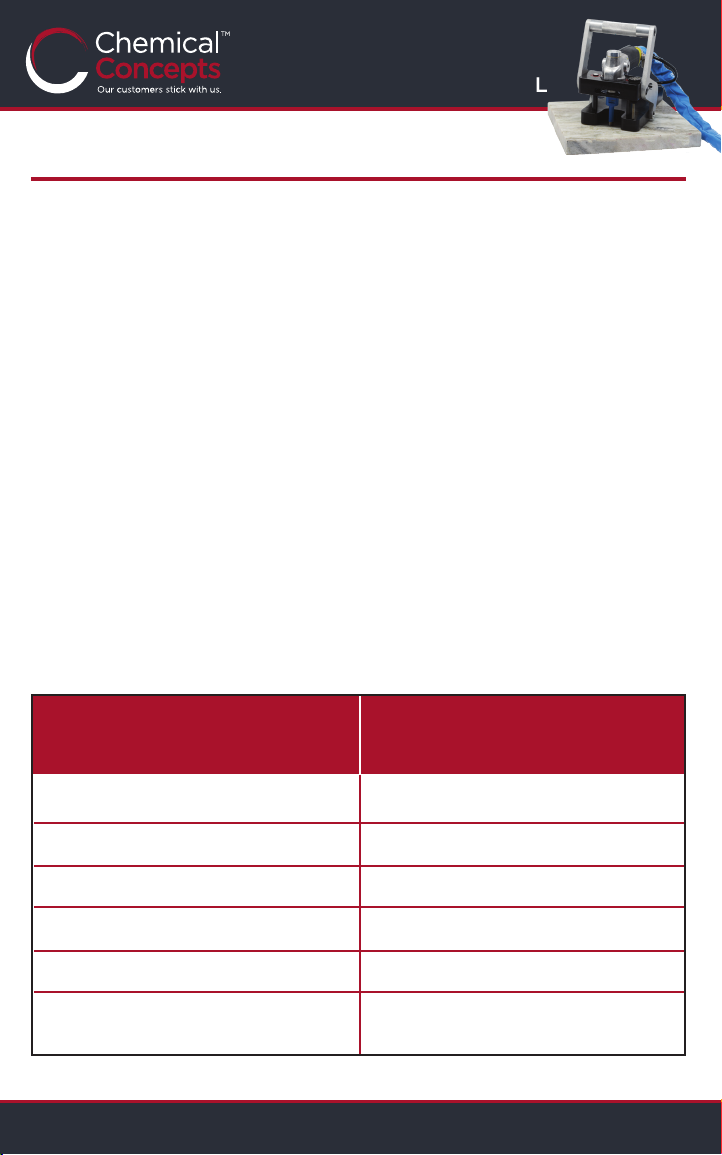

Drill Bits

This machine is compatible with a variety of ⅝” x 11 threaded

drill bits. Specially designed drill compatible with the Keep-nut

anchoring system are available for this unit. The standard bit

included in the box is recommended for marble, granite, quartzite

and other natural stone surfaces. We recommend specialized bits

for drilling ceramic/porcelain and specialized drill bits for glass.

A variety of core bits are available for this machine as well for

drilling faucet holes and other applications where core-bits are

used. The max drilling depth on this unit is approximately 1¼” (3CM).

See below for a chart showing average drilling time to drill a ¼”

depth hole using the included drill bit.

For optimum drilling of porcelain, sintered and ceramic materials,

a higher RPM tool is recommended. The KDM110 can be used to

drill accurate holes in these surfaces when using a bit designed

for these materials, but drilling times will be considerably longer

compared to granite and marble.

OVERVIEW: (cont)

Marble (Carrara) 4.70

Soft Granite (Terra Bianc) 3.67

Hard Granite (Blue Pearl) 12.25

Quartzite (Taj Mahal) 13.00

Engineered Stone 5.67

Sintered/Porcelain

(Neolith) 53.50

Stone Average Drilling Time;

¼” Depth (seconds)

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 9 9/17/19 2:01 PM

• 10 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

If the unit looses suction and the vacuum is

unable to securely adhere to the surface the

most likely cause is a blockage in the venturi.

Debris can become lodged in the venturi

which prevents the unit from creating enough

suction. To correct this, the venturi needs to be

disassembled and the blockage removed.

Once the obstruction is removed the unit

should return to full functionality.

Follow the steps below:

1. Using a hex key loosen the screws (4) that

secure the venturi block (19), and remove

the venturi block from the base.

2. Using the appropriately sized wrench

remove the ¼” NPT fitting (12) on the

venturi block.

3. Remove the value (13) inside the

Venturi block.

4. Visually inspect for any debris

trapped in the Venturi block; Use a

blow gun to clear out any debris

lodged in the cavity.

5. Reassemble parts as shown in the

parts diagram on page 5 & 6; Check

for proper suction.

LOSS OF

SUCTION:

TROUBLE SHOOTING

Q

&

A

Use only with

11.8mm ⅝”x 1 1

diamond bit

SKU NUMBER

CCH-KN-KDM110

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 10 9/17/19 2:01 PM

• 11 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

If the vacuum is unable to securely adhere to

the surface while drilling it is likely that the

Venturi has insufficient air pressure/volume.

With proper air flow the vacuum base should

have plenty of suction to stay in position during

use even while applying moderate force to the

handle while drilling. Check your air supply for

pressure and volume and make sure your airlines

are of sufficient diameter to supply the machine.

If proper air pressure is being supplied make

sure that the bit is properly dressed and cutting

freely. Do not apply excess pressure to the

handle during use. Excess pressure can damage

the Alpha Air-680C polisher and cause the

vacuum base to lose suction.

If the KDM110 is drilling holes that are too large

for the keep-nut anchors, ensure the correct

bit is being used. If the correct bit is in use, you

may need to add a ⅝” washer between the

drill bit and the polisher to insure that the bit is

seated exactly 90° from the polisher. If the bit

has insufficient thread depth this can cause a

misalignment which will affect the final diameter

of the hole produced.

TROUBLE SHOOTING

Q

&

A

INSUFFICIENT

SUCTION:

HOLE

DIAMETER:

Use only with

11.8mm ⅝”x 1 1

diamond bit

SKU NUMBER

CCH-KN-KDM110

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 11 9/17/19 2:01 PM

• 12 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

Part No: AIR-680C

Version 1

103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114

www.alpha-tools.com

Alpha

®

Pneumatic

Air Polisher

Instruction Manual

MANUAL

Part No: AIR-680C

Version 1

103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114

www.alpha-tools.com

Alpha®Pneumatic

Air Polisher

Instruction Manual

MANUAL

Keep-Nut-Alpha-Air-Polisher

Base with bottom view

Part No: AIR-680C

Version 1

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 12 9/17/19 2:01 PM

• 13 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

3

Thank you for purchasing an Alpha® Air Polisher. Please read this

instruction manual thoroughly to ensure safe and correct use of the

pneumatic polisher. Keep this manual in a place where operators

can access it easily whenever necessary.

According to the hazard level, all safety notes in this manual are

classiedinto“DANGER”,“WARNING”,and“CAUTION”.

DANGER! Deathorseriouspersonalinjuryisimminentwhen

handling this polisher incorrectly.

WARNING! Thereisapossibilityofdeathorseriouspersonal

injurywhenhandlingthispolisherincorrectly.

CAUTION! Thereisapossibilityofpersonalinjuryorproperty

damage when handling this polisher incorrectly.

Note:Insomesituations,failingtoobserveWARNINGnotescould

resultindeathorseriouspersonalinjury.Besuretoread

and observe the safety notes to ensure safety and correct

use of the polisher.

1. KNOW YOUR POWERTOOL. Read owner’s manual carefully.

Learnitsapplications and limitationsaswellasspecicpotential

hazards particular to this tool.

2. KEEPWORKAREACLEAN.Clutteredareas and benchesinvite

accidents.

Headquarters,Oakland,NJ—(800)648-7229ext.505

Due to specially designed components this machine must be serviced only

with genuine ALPHA® parts.

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 13 9/17/19 2:01 PM

• 14 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

4

3. AVOIDDANGEROUSENVIRONMENTS.Keepworkareasasdry

aspossible. Donotusetoolinpresence ofammableliquidsor

gases. Keep the area well lit.

4. KEEPCHILDRENANDVISITORSAWAY.Allvisitorsshouldbekept

a safe distance from the work area. Keep out of reach of children.

5. DON’TFORCETOOL.Itwilldothejobbetterandsaferattherate

for which it was designed.

6. WEARPROPERAPPAREL.Donotwearlooseclothingorjewelry

as it can get caught in moving parts. Rubber gloves and insulated

non-skid footwear are recommended. Wear protective covering to

contain long hair.

7. WEAR PROPER EYE PROTECTION. All users and bystanders

must always wear proper personal eye protection which conform with

ANSI/ISEAZ87.1(CAN/CSAZ94.3).Alsouseafaceordustmaskif

operationisdusty.Alwayswearcertiedsafetyequipment.

8. WEAR PROPER EAR PROTECTION. All users and bystanders

mustwearproperpersonalearprotectionwhichconformswithANSI

S12.6(S3.19)hearingprotection.

9. WEAR PROPER RESPIRATORY PROTECTION.All users and

bystanders must wear proper personal respiratory protection. Always

useNIOSH/OSHAapprovedrespiratoryprotectionappropriateforthe

dustexposure.

Warning: Some dust created by power sanding, sawing, grinding, drilling,

polishing and other construction activities contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

- Lead from lead-based paints

- Crystalline silica from bricks, cement and other masonry products, and

- Arsenic and chromium from chemically-treated lumber.

Yourriskfromtheseexposuresvaries,dependingonhowoftenyoudothis

typeofwork.Toreduceyourexposure,workinawellventilatedarea,and

work with approved safety equipment, such as dust masks that are specially

designedtolteroutmicroscopicparticles.

To familiarize with the risks associated with a material, consult with your

employer, manufacturer/supplier and government agencies regarding the

hazards of the materials and their recommendations to protect yourself.

10. DON’TABUSEWATERSUPPLYHOSE.Don’tcarrytoolbysupply

hoseorexposetotrafcareaswhereitcanbecrushed.

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 14 9/17/19 2:01 PM

• 15 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

5

11. ALWAYSSECUREWORKPIECE.Useclampsoravisetoholdwork.

It’ssaferthanusingyourhandanditfreesbothhandstooperatetool.

12. DON’TOVERREACH.Keepproperfootingandbalanceatalltimes.

13. DISCONNECTTOOLS WHEN NOT IN USE. Always disconnect

tool before servicing; when changing accessories such as grinding

wheels, backer pads, etc.

14. REMOVEADJUSTINGKEYSANDWRENCHES. Form a habit of

checkingtoseethatkeysandadjustingwrenchesareremovedfrom

tool before turning it on.

15. MAINTAINTOOLSWITHCARE.Keeptoolscleanatalltimesfor

best and safest performance. Follow instructions for lubricating and

changing accessories. Keep handles dry, clean and free of oil or

grease. Inspect moving parts for alignment and binding as well as

for breakage and improper mounting.

16. AVOIDACCIDENTALSTARTING.Donotcarrya“connected”tool,

ormakeadjustments,orchangediscswithoutmakingsurethetool

is disconnected from the air supply.

17. USE ONLY RECOMMENDEDACCESSORIES. The use of any

accessories other than what is listed or recommended for this

particular tool may be hazardous.

18. KEEPHANDSAWAYFROMALLMOVINGPARTS.

19. USESIDEHANDLES.Suppliedwithtoolforcontrolandsafety.

20. STAYALERT.Watchwhatyouaredoingandusecommonsense.

Donotoperatetoolwhenyou aretired,orundertheinuence of

medication or alcohol.

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 15 9/17/19 2:01 PM

• 16 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

6

deClARATIoN

DECLARED DUAL-NUMBER NOISE EMISSION VALUES IN

ACCOREDANCEWITHISO4871

Measured A-weighted sound power level, LWA, in decibels

Uncertainty, KWA, in decibels

Measured A-weighted emission sound pressure level LpA at

theoperator’sposition,indecibels

Uncertainty, KpA, in decibels

96.9

0.73

85.9

0.73

Values determined to noise test code given in ISO 15744.

Note-Thesumofameasurednoiseemissionvalueanditsassociateduncer-

tainty represents an upper boundary of the range of values which is likely to

occur in measurements

DECLARED VIBRATION EMISSION VALUE IN ACCORDANCE WITH

EN12096

Measured vibration emission total value a

Uncertainty K

Values determined according to ISO 8662-8.

1.48m/s2

0.32m/s2

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 16 9/17/19 2:01 PM

• 17 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

7

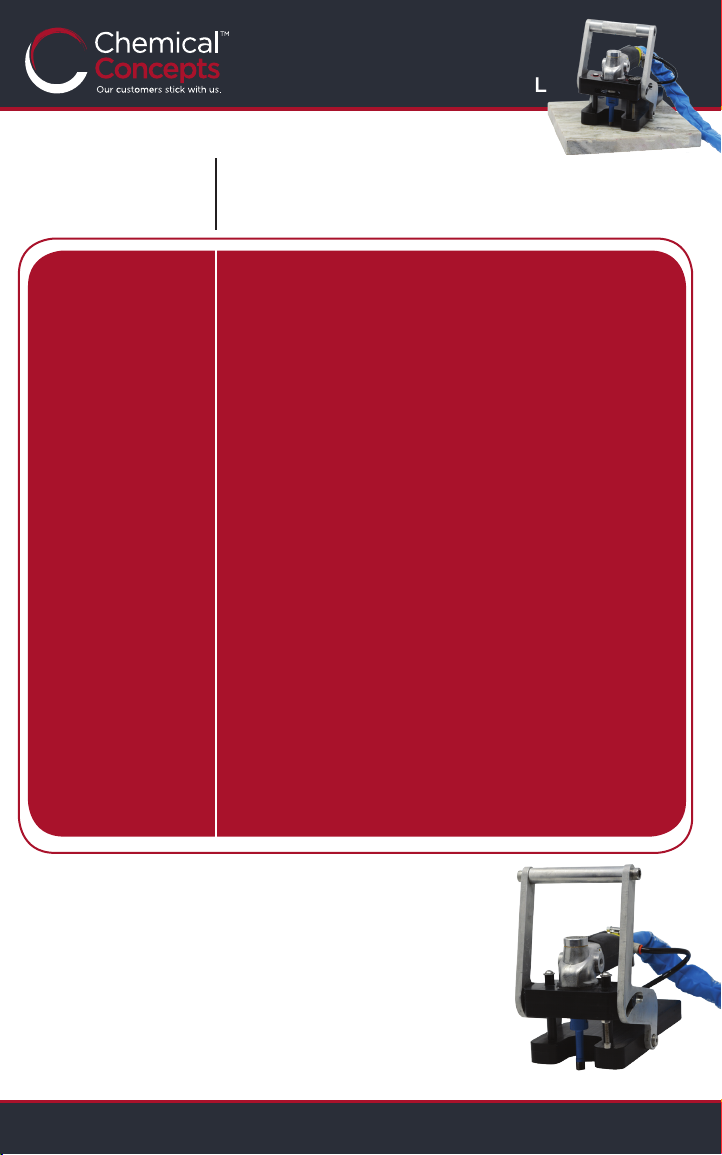

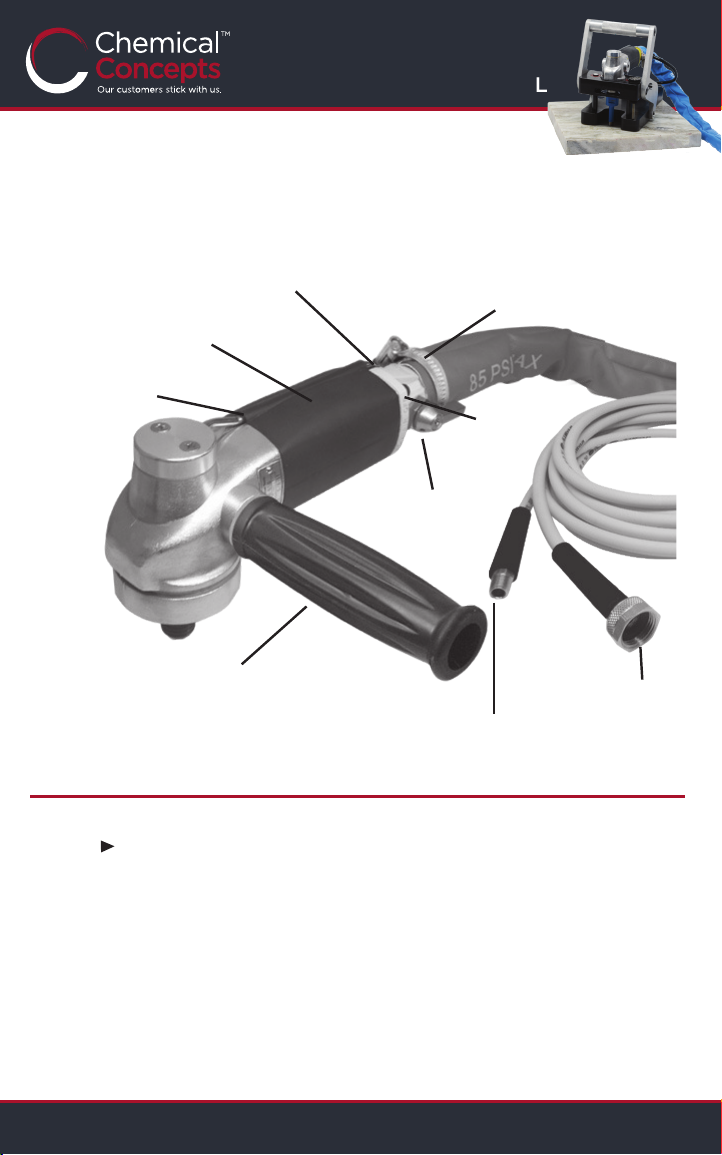

AIR-680C oVeRVIeW

Reversible Handle

15 ft Air Hose

15 ft Water Hose

Adjustable Air Valve

Adjustable Water Valve

Rubber Body Cover

Internal Water

Line Oil Port

Screw

Exhaust Hose With Clamp

sPeCIfICATIoNs

Air Pressure .............................................................. 85 PSI

Air Consumption ..................................................... 15 CFM

NoLoadRPM .............................................................4,000

Weight ........................................................... 2.64lbs/1.2kg

Air Inlet ............................................................... 1/4”BSPP

Water Inlet .......................................................... 1/8”BSPP

Spindle......................................................................5/8”-11

7

AIR-680C oVeRVIeW

Reversible Handle

15 ft Air Hose

15 ft Water Hose

Adjustable Air Valve

Adjustable Water Valve

Rubber Body Cover

Internal Water

Line Oil Port

Screw

Exhaust Hose With Clamp

sPeCIfICATIoNs

Air Pressure .............................................................. 85 PSI

Air Consumption .....................................................15 CFM

NoLoadRPM .............................................................4,000

Weight ........................................................... 2.64lbs/1.2kg

Air Inlet ............................................................... 1/4”BSPP

Water Inlet .......................................................... 1/8”BSPP

Spindle......................................................................5/8”-11

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 17 9/17/19 2:01 PM

• 18 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

8

eQuIPmeNT INCluded

Airhose(15ft/4.5m).........................................1pc

Waterhose(15ft/4.5m) ...................................1pc

SideHandle(reversible).....................................1pc

DoubleEndWrench(19mm/22mm) ...................1pc

RustInhibitorOil(8oz/237ml)(AIR-008) ..........1pc

Screw(w/O-RingSealforOilPort) ...................1pc

ExhaustHoseWithClamp .................................1pc

oPTIoNAl ACCessoRIes

SplashGuard(AWP-01) ....................................1pc

C-ShapedHandle(AWP-21A) ...........................1pc

sPeCIAl feATuRes

The Alpha® AIR-680C polisher was designed with user comfort in

mind, for a full day of use. The silencer system will reduce the noise

volumebelow80dBAandtherubberbodycoverwillinsulatethe

userfromthecoldandfatigue.Theblueexhausthoseisdesigned

toguidethecoldexhaustairandrustinhibitoroilawayfromtheuser

and the work area.

Tool seT-uP INfoRmATIoN

Unpack the tool carefully and study the helpful hints and warnings

contained in this manual. Please take time to familiarize yourself

withthefeaturesofthetool.Besuretollouttheregistrationcard

enclosed, and mail it back to the distribution center today.

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 18 9/17/19 2:01 PM

• 19 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

9

Parallel Thread Tapered Thread NPT

CoNNeCTIoN fITTINGs

TheairandwaterhosettingsonthebackofthistoolareBSPP

(Britishstandard parallelpipeor “G”thread).Thesettings have

parallelthreadsand sealoffonthe atsurfaceonthebottom of

thethread.Thistypeofttingisusuallysuppliedwithan“O”ringor

sealing ring which we replaced with the silencer.

Exhaust

Hose

Hose Clamp

Air Valve

Poly Tubing

Water Valve

Water Hose Fitting

Water Hose

Assembly Hook &

Loop Strap

Air Hose

Assembly

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 19 9/17/19 2:01 PM

• 20 •

Chemical Concepts | 410 Pike Road, Huntingdon Valley, PA 19006 | Made in USA

www.chemical-concepts.com | 800.220.1966 | sales@chemical-concepts.com

KEEP-NUT™

DRILLING MACHINE MANUAL

10

The recommended air pressure for this tool is 85 PSI. The most

important factor in running this tool is the volume of air being sup-

plied to the tool. The volume is the air consumption needed to run

this tool at a constant speed under light downward hand pressure.

ThevolumeismeasuredinCFM(cubicfootperminute(ft3/min).You

need a minimum of 15 CFM per tool.

When choosing a compressor to run an AIR-680C polisher, we rec-

ommend a rotary screw type with a minimum of a 5hp motor/15-20

CFManda60gallontank,pertool.(I.E. if you want to run four tools,

you will need a compressor with a 20hp motor capability of 80+ CFM

and an 80 to 100 gallon storage tank.)

It is also very important to keep your air cool, dry, and clean, so look for a

compressorwitharefrigerateddryerandhigh-efciencylterbuiltinor

purchaseaseparateairdryerandlterunitratedforyourcompressors

CFM.

Attheendofeachworkday,place2-3dropsofrustinhibitoroil(in-

cludedwitheachpolisher)directlyintotheOILPORTofthepneumatic

tool. After applying the rust inhibitor oil, turn the air valve slightly so

that the oil atomizes into a mist and coats the internal components

ofthepolisher.Iftheprocessisexecutedcorrectly,youshouldsee

a mist coming out of the end of the polisher. The Exhaust Hose

(PartNo.658-95C)andHoseClamp(PartNo.1030-1104)needto

beremovedtoseethemisteffect.Seethedetailedstepsonthenext

page for adding the oil to the pneumatic polisher.

KEEP-NUT™ 5 x 8_Drill Manual AV.indd 20 9/17/19 2:01 PM

Table of contents