Hitachi DH 24PC User manual

Other Hitachi Drill manuals

Hitachi

Hitachi DS 9DVF3 User manual

Hitachi

Hitachi DB3DL2 User manual

Hitachi

Hitachi DH 24PE (S) Manual

Hitachi

Hitachi FDS 12DV User manual

Hitachi

Hitachi DH 40YB User manual

Hitachi

Hitachi DH 40MR User manual

Hitachi

Hitachi D 10VC2 User manual

Hitachi

Hitachi DS18DVB2 User manual

Hitachi

Hitachi DV 18V User manual

Hitachi

Hitachi DS 9DVB User manual

Hitachi

Hitachi D 13VB3 User manual

Hitachi

Hitachi DB3DL User manual

Hitachi

Hitachi DB3DL2 User manual

Hitachi

Hitachi DC 120VA User manual

Hitachi

Hitachi DS 14DFL User manual

Hitachi

Hitachi DS 14DVB User manual

Hitachi

Hitachi VTP-16A User manual

Hitachi

Hitachi DH 45ME User manual

Hitachi

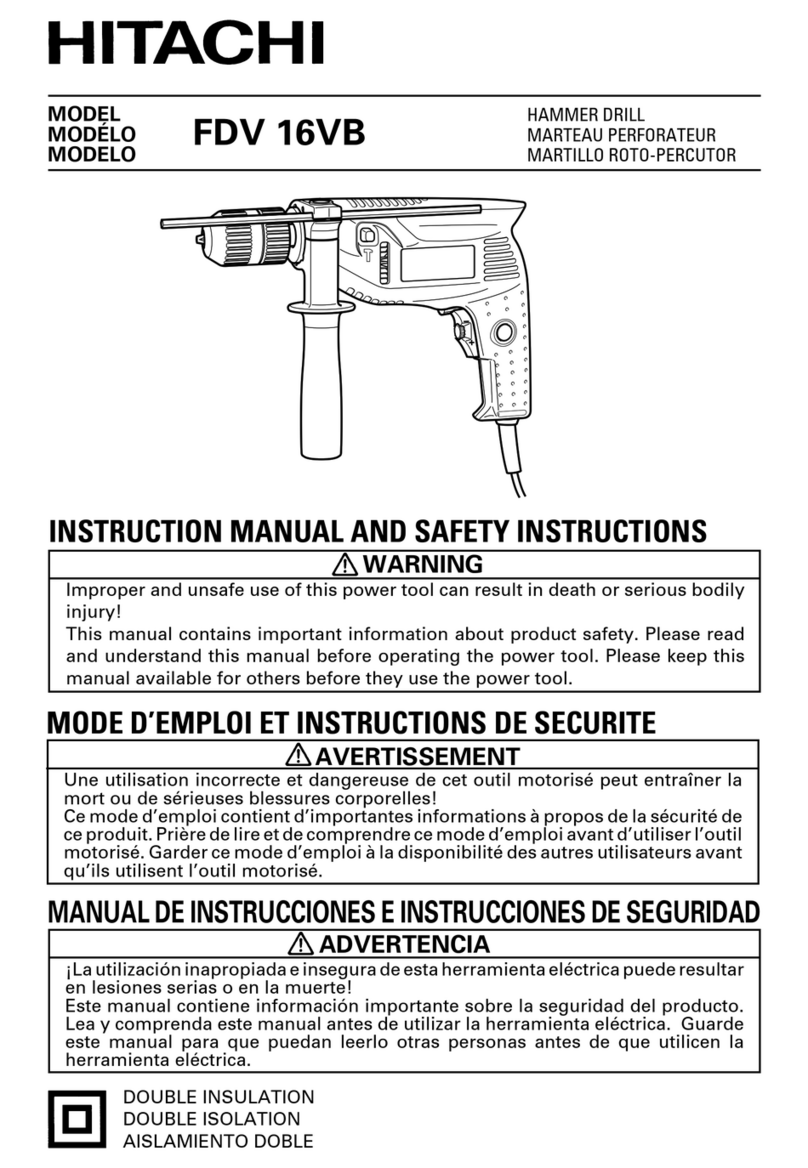

Hitachi FDV 16VB Operator's manual

Hitachi

Hitachi FDV 16VB2 User manual