Chennai Metco BAINMOUNT Mounting Press - P User manual

BAINMOUNT

Mounting Press - P Manual

Instruction Manual

Pneumatic Mounting Press

Chennai Metco

Bainmount Pneumatic Page 2

Intended usage

When sectioned samples or components are irregular in shape,

mounting is an essential step for further processing. Based on the

requirement of quality and characteristics of the mould, proper

mounting material should be selected. With the appropriate mounting

material, and right mounting parameters high quality mounts can be

obtained with Bainmount mounting machine.

Bainmount Pneumatic Pag3

Contents

1. Safety -------------------------------------------------------------------------------------- 5

2. Transport ----------------------------------------------------------------------------------- 6

3. System Features and Principles of Operation ---------------------------------------- 7

4. Machine Layout ----------------------------------------------------------------------- 8

5. Installation ---------------------------------------------------------------------------------- 9

6. Operation --------------------------------------------------------------------------------- 10

7. Maintenance and Inspection ------------------------------------------------------------- 11

8. Dismantling ------------------------------------------------------------------------------- 13

9. Technical Specification ---------------------------------------------------------------------- 14

10. Electrical Circuit ---------------------------------------------------------------------- 16

11. Warranty certificate ---------------------------------------------------------------------- 20

12. Contact us ---------------------------------------------------------------------------------- 21

Bainmount Pneumatic Pag4

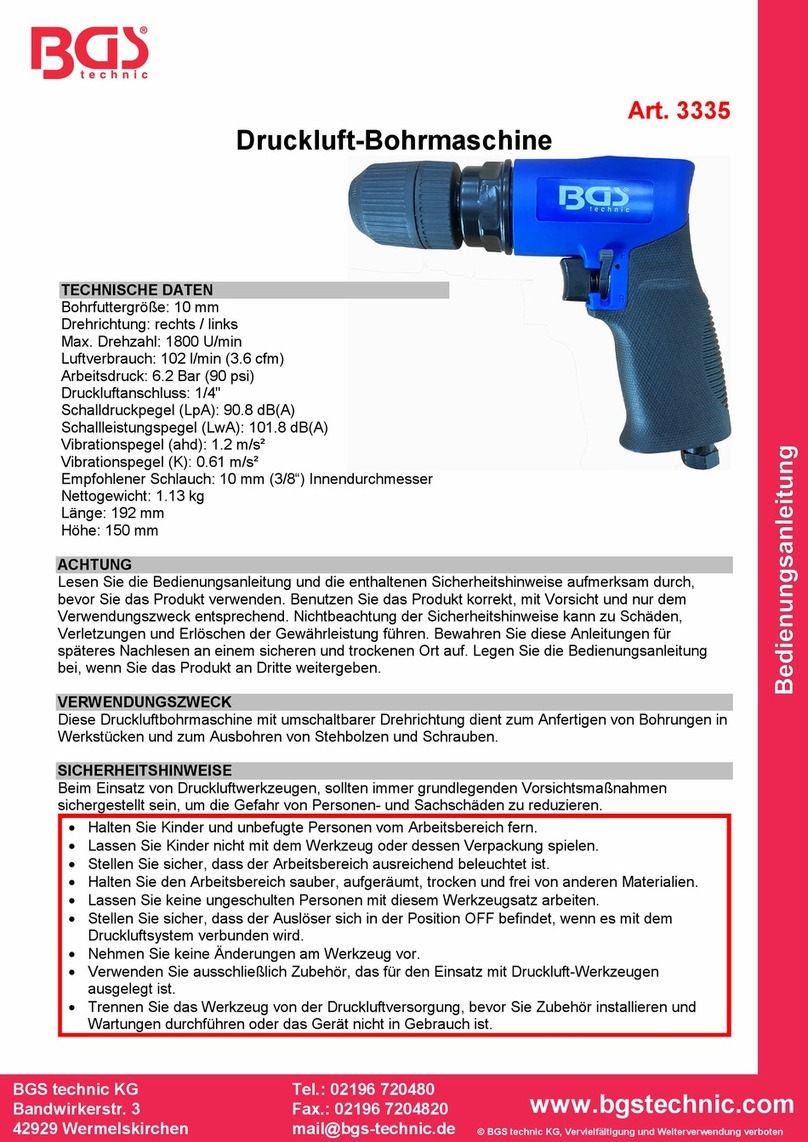

Take a Moment to familiarize yourself with the location and names

of the MP Pneumatic components.

1. Mould closure, 2.Mould Chamber, 3. Heater cover, 4. Display, 5.Parameter Selection

6. Parameter Increase/Ram Up, 7.Parameter Decrease/Ram Down, 8.Cycle Start/Stop

9.Power on/off

Bainmount Pneumatic Pag5

1. SAFETY

1 Safety

1.1 Proper Use

1.1.1 Principle

The Bainmount mounting press is state of the art and designed in accordance with recognized

technical research and experience and safety regulation. Failure or neglect to properly install, operate

and maintain the machine/system may be risk of serious or fatal injury to users or third parties or result

in unnecessary damage of the system or other equipment.

1.1.2 Permissible Operation

The machine/system is a technical working appliance, designed exclusively to Mount the materials

using polymers for easy handling during subsequent operations. Any other usage is regarded as

improper. Any liability on the part of the customer for damages resulting from an improper machine

usage is excluded. The risk has to be borne entirely by the user. The following are the example of the

machine/system misuse:

Using incorrect parameters resulting in damage of the holder..

Using on other industry or application.

Using other than recommended mounting polymers on the machine.

Untrained and unaccomplished this instruction manual personnel operated this machine/system

Proper usage also includes compliance with operating, servicing and maintenance requirement

specified by the manufacturer.

1.1.3 Safe operation of machine

The machine must only be used in a technically error – free condition and according to proper operating

practice in a safety and risk conscious manner while observing and heeding all caution or danger tags

attached to the machine or included in this manual

Malfunction that can impair safety must be remedied immediately.

1.2 Level of hazard

This symbol is used to call attention to hazards or unsafe practices which could result in an injury or

property damage. The signal words, defined below, indicate the level of the hazards. The message after the

signal word provides information for preventing or avoiding the hazards. While reading your manual pay

close attention to areas labeled the signal words.

Bainmount Pneumatic Pag6

1.3 Safety information

Read and understand all the instruction and safety information in this manual. Everyone who works on or

around this equipment including, but not limited to, operator, maintenance personnel, and supervisory

personnel must read and understand the information in this chapter prior to commencing work on or around

this equipment. Failure to conform to the information in this chapter could lead to property damage or

serious personal injury including possible loss of body parts or death. This chapter only describes proper

safety procedures to follow when working with this equipment. Please refer to the instruction manuals

delivered together with the installation of your equipment.

Please ensure that all work described in this manual is carried out in a good environment / workshop using

proper tools and equipment.

1.4 Protection for Installation, Operation and Maintenance Personnel

In addition to the safety information included in this section, always observe all specific safety information

included with the instructions in balance of this manual. As manufactured this equipment has been equipped

with safety devices which correspond to current technology standard in accordance with the prescribed

applications of this equipment. However, residual risks remain to which attention is drawn individually

within this machine manual.

Instruction obligation: The operating company must verify that:

Personnel have the necessary technical, equipment-specific, and safety knowledge or that is

achieved by means of relevant training before the equipment is installed, operated, or

maintained.

Personnel have the necessary competence to be able to work on accordance with the regulations

and instruction.

Indicates an imminently hazardous situation

that, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation that,

if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous that, if not

avoided, might result in minor or moderate

injury. It can also indicate possible loss of

materials or damage to the equipment.

Bainmount Pneumatic Pag7

Before initial startup, personnel have to read and understand all instructions contained within the

supplied documentation.

Equipment obligation: The operating company is required to equip personnel with the necessary protective

clothing as follow:

Safety shoes.

Safety goggles

Safety gloves

1.5 Protection for Third parties

The operating company must also make persons who are not charged with the operating or maintenance of

the equipment aware of the dangers.

1.6 Common Sense safety

Accidents frequently occur due to carelessness or lack of knowledge. To avoid potential problems, review

the information in the section before attempting to install, setup, operate, or maintain this equipment. Think

safety at all the times. Do not let familiarity with the equipment lead to unsafe short cuts. The following

common sense safety practices must be observed at all times.

1. Follow all procedures and precautions in the manual carefully and completely.

2. Only attempt repair or adjustments for which proper training has been completed.

3. Always observe all safety warnings and notices on the machine and in the manual.

4. Do not remove or otherwise alter any guards or panel unless the machine is completely shut

down and has been made inoperable. Be sure to replace these items before restarting the

machine.

5. Never operate the equipment without guards and safety mechanisms in place and functional.

6. Do not allow foreign object to fall into machine.

7. Always use the proper tools for performance of any operation on the machine. Whenever

feasible, use voltage-isolated tools.

8. Do not touch any parts of the machine which may have become hot during operation.

9. Do not wear neck ties, jewelry, loose clothing, and long hair.

10. Wear or use gloves, goggles, safety shields, ear protection, and other employer recommended

safety equipment. Wear protective clothing to prevent burns.

11. Disconnect power and lock out all switches before attempting to adjust or manipulate any

moving parts or mechanism on the equipment.

12. Be aware that there are high voltages in this device when power is connected. Power must be

disconnected when the device is being repaired. However, because there are certain checks and

adjustment that can be made only with any power connected, it is imperative that only trained

personnel, aware of the safety hazards involved and familiar with this type of work and

necessary safety precautions, be permitted to perform this work.

13. Maintain good housekeeping practices to prevent slips, spillage of mounting powders, cuts,

burns, and other possible accidents. Keep the area all necessary items properly organized.

Bainmount Pneumatic Pag8

14. Even though the plant may be equipped with automatic sprinklers or other means of the fire

protection, portable fire extinguishers should be available to the machine operator. To be

effective, portable extinguishers must be reliable, the proper type for each class of fire that may

occur in the area, in sufficient quantity to protect against the exposure in the area, located where

they are readily accessible for immediate use, and maintained in perfect operating condition.

They must be inspected frequently, checked against tampering, recharged as required, and

operable by are personnel who are trained to use them effectively and promptly.

1.7 Hazard Warning Label

Hazard warning labels are applied on the machine where potential hazards are potential hazards are

potentially present during operation and maintenance activities.

Hazard warning labels are in appropriate sizes and colors that catch attention of personnel’s eyes and have

symbols that show hazard types, in addition to descriptions of warning contents.

1.7.1 Types of Hazards Warning Label

The following safety warning labels appear on the system.

HOT

Personnel are requested to confirm the location

of, read and thoroughly understand contents of

all of hazard warning labels applied to this

machine prior to work.

“Warning of Dangerous Electric Voltage”

“Earth (Ground) Protective Conductor Terminal “

“Disconnect the power before open”

“Temperature can reach above 200

®

C ”

Bainmount Pneumatic Pag9

1.7.2 Location of Hazard Warning Label

.

1.8 Safety devices

1.8.1 Insulating chamber lock nut The handle of the mounting press is equipped with a insulating material that helps

to protect the operator from the heat during operation. Figure shows the insulating in the handle of the mounting

press.

1.9 Disposing Individual Component

Users are

NOT

allowed to change the location

of hazard

warning labels. Make sure to apply new labels upon

replacement of the peeled off or worn out labels

Reusable raw

material and problem material.

Environmental pollution.

Protect the environment by correctly disposing

of a recycling raw materials and problem

materials

Bainmount Pneumatic Pag10

Machine frame and all mechanical machine components are made of steel, light metal and plastics.

These materials are recyclable.

Take non-reusable difficult waste, lubricant and batteries, to the appropriate waste disposal point.

Seal any used parts possibly exposed to toxic or corrosive material prior, in inside of vinyl bags. Apply

certain marking to all of the disposal bags to identify possible contamination.

Be careful wh

ile handling waste fluid, which

may corrode

skin and clothing upon contact.

Bainmount Pneumatic Pag11

2. Transport

2.1 Unpacking and Inspection

Inspect equipment and shipping crate immediately upon receipt. Check the packing slip carefully and make sure

all the materials have been received as indicated on the packing ticket. If any damage apparent, you should both

report it to the trucking delivery person and contact the transportation company immediately. When submitting

a claim for shipping damage, request that the carrier inspect the shipping container and equipment.

2.2 Unpacking Location Environment /Cautions

Do not unpack in a location where any of the following conditions apply.

• Unbalanced

• Location with direct humidity (including rain and fog) intrusion

• Location with possible acute temperature change

• Location with strong vibration; also, do not place any product on such location

• Dusty

This symbol is used to call your attention to hazards or unsafe practices which could result in an injury or

property damage. The signal words, defined below, indicate the level of the hazards. The message after the

signal word provides information for preventing or avoiding the hazards.

While reading your manual, please pay close attention to areas labeled the signal words.

2.3 Transporting Machine with Box/Crate

Equipment and tools to be used:

Parallel jack

The forklift or lift truck employed must fulfill the following minimum requirements:

• Carrying capacity according to the total weight (machine/system and transport packing), see shipping papers.

• Length of the forks should be at least 920 mm

Interrupt the unpacking procedure and contact the

responsible forwarder once any obvious abnormality such

as abnormal noise/odor is found during unpacking.

Risk of falling transport items.

Risk of death or severe crushing of limbs

Careful lifting of the mounting press crate with parallel jack

Bainmount Pneumatic Pag12

i. Insert the fork carefully so that the centre of gravity of the box lies in the middle of the forks

ii. Lift it to a safe level so that the box can be moved to the required place

2.4 Unload Distribution Box

Equipment and tools to be used:

Forklift

Lift truck

Pallet Jack (figure )

The forklift or lift truck employed must fulfill the following minimum requirements:

• Carrying capacity according to the total weight (machine/system and transport packing), see shipping papers.

• Length of the forks should be at least 920 mm

• Distance between forks should be about 820 mm

Note: The centre of gravity of Distribution Box is not in the center and depends on the outfitting of the unit.

Risk of falling items.

Risk of death or severe crushing of limbs

Lift truck or forklift according to the total weight to be

transported

Fork length min . 920 mm fork spacing about 820 mm

Do not stand under the transport item during transport

Proper size of pallet shall be use or transportation

Lifting

equipment must be level with floor

during lifting occurrence

Bainmount Pneumatic Pag13

i. Place the Distribution Box into proper size of empty pallet.

ii. Place the fork lift insertion position on the pallet.

iii. Lift the pallet and transport to the installation site.

iv. Place Distribution Box according to installation plan.

2.5 Unload the Bainmount Mounting Machines

Equipment and tools to be used:

Forklift

Lift stand

i. Insert two lifting stand into the bottom four side of the Mounting Machine

ii. Place the fork arm into hollow section of lifting stand

iii. Lift the machine approx. 10 m and check the centre of gravity

iv. Transport the machine to the installation plan

v. Unload the fork lift to place the mounting machine on the floor

Risk of falling transport items.

Risk of death or severe crushing of limbs

Lift truck or forklift according to the total weight to be transported

Fork length min . 1250 mm fork spacing about 1000 mm

Position the forklift at the corresponding marked places of the crate

Do not stand under transport item during transport

Lifting equipment must be level with floor

during lifting occurrence

Bainmount Pneumatic Pag14

2.6 Relocating the Mounting Machine

2.6.1 Preparing for repositioning

Turn off the Main Switch of Electrical Control Panel and remove attachment of the main power

supply to system.

Remove the connecting pipe between Oil Tank and Distribution Box.

Secure all the parts on the Mounting machine

2.6.2 Repositioning of unit

Repeat the step on Section 2.4

Bainmount Pneumatic Pag15

3. System Features and Principles of Operation

3.1 Introduction

The Bainmount Mounting Press is exclusively designed for mounting the materials for metallographic

analysis. The machine offers that, mounting techniques can be programmed through a Programmable Logic

Unit (PLC) for various mounting materials. For this reason, the user can increase the quality and quantity of the

mount.

A user friendly Liquid Crystal Display (LCD) touch screen panel is provided on this system. Not much of

parameters required to determine before operation. User can choose the pre – existing recipes’ for the best

outputs.

3.2 Machine Description

Bainmount Mounting presses are exclusively designed for the metallurgical sample mounting. The machine

consists of a hydraulic motor that applies the pressure while a heater unit surrounds the mould wall which

increases temperature.

One of the advantages of the machine is the programmable mounting modes that facilitate mounting of various

polymers for increased edge retention and abrasion resistance. The advanced touch screen option allows the

user to enter and store the mounting parameters for easy storage and retrieval of mounting data.

3.3 Machine Content

The Bainmount Machines consists of the following assemblies

Electrical Control Panel assembly

Pressure control assembly

Temperature control Assembly

3.3.1 Electrical Control Assembly

The Electrical Control Panel consists of PLC, LCD display, 1-phase AC contactors, switches and etc. The

function of control panel is used to program the mounting cycle. The electrical assembly consists of pressure

indicator, temperature indicator, time and coolant on and off. The safety feature in electrical assembly includes

automatic cut off of pressure and temperature to limit the maximum pressure and temperature that can be

reached.

3.3.2 Pressure Control Assembly

The pressure control assembly includes the items of motors, tranducers, voltage indicator etc. Main function of

the pressure control assembly is not only increase and decrease pressure but also to maintain and limit the

applied pressure.

Bainmount Pneumatic Pag16

3.3.2 Temperature Control Assembly

The temperature control assembly consists of the thermocouple, temperature indicator, tube heater unit etc. The

temperature control assembly is used to monitor the working temperature inside the mold cylinder.

3.4 Working principle of the Bainmount Mounting presses

Initially when the mounting press is switched on, workpiece is placed with the surface of interest facing

downwards and the moulding powder is filled in the moulding chamber. With simultaneous application of

pressure and heat , the moulding powders melt and compact around the workpiece. Then the coolant is turned

on to cool the sample through water cooling tubes around mould cylinder to cool the mounted sample

Bainmount Pneumatic Pag17

4. Machine Layout

Bainmount Pneumatic Pag18

5. Installation

5.1 Installation Environment

Temperature : 5 to 40°C2

Humidity : 20 to 80% RH (no condensation)

5.2 Installation Space

Machine external dimensions (refer to Section 10.9) + working space (1000 mm)of footprint space

Machine height (refer to Section 10.9)

5.3 Environment and Operating Conditions

Ambient Temperature : 2 to 40º C when system is operational

Ambient humidity : 10 to 80% RH (no condensation) when system is operational.

Vibration : 2m/s or less at 10 to 50 Hz

Air cleanliness : An air dust volume of 0.2 mg/m3 or less is preferred.

In addition, there should be very little corrosive Such as hydrogen sulfide, zincate gas and

Chloride In addition, user should aware of following operating condition and

environment for the system:

• The unit should be installed in an area where is a good ventilation. Do not locate unit in area of wide

ambient temperature variation, such as near vent or outdoor entrances.

• Do not place the unit near combustible material or hazardous fumes or vapor.

• Make sure the unit is leveled when operation.

• Do not position the unit in a manner that would make it difficult to operate the Main Switch and

Emergency Stop button (at Electrical Control Panel).

Do not install the unit at the location as potentially

flammable and/or explosive atmosphere

Do not install the unit in a corrosive environment. A

corrosive environment may lead to poor performance and

deterioration of unit.

The system is not designed to be used at the location as

potentially flammable and /or explosive atmosphere

Bainmount Pneumatic Pag19

5.4 Making pipe connection

5.4.1 Connecting between Coolant tank and Machine

The recirculation coolant system connects pipe to and from the coolant tank which must be secured properly

without leakage. The pipe whose diameter is 7 mm fitted with the inlet to allow the coolant which is water to

enter the machine and hot water hose cable is connected to the outlet valve of the mounting press into the

coolant tank for recirculation.

5.5 Making Wiring connection

• The connection data can be seen from the wiring diagrams ( the wiring diagrams are sullied with

machine )

• The electrical connections require a Single phase connector cable

• Check the main voltage present against the voltage identified on the name plate to see if they match

• User must connect the incoming power supply to the terminal block as shown.

5.6 Connecting the compressor

The compressor is connected to the air pressure regulating unit in the mounting press via a 5 mm

diameter air pipe

Ensure sealed connection at the end to prevent

Do not loosen fitting to arrive at proper position or leak

may occur.

Over tightening may cause piper fitting to deform and

damage to the joining fitting

Remove all foreign matter from inside the piping

Work

ing on the electrical equipment must b entrusted

only to a trained and qualified electrician. The work has to

be carried ou according to the rules for electrical

engineering

Careful while handling the pressurized equipments and

only trained personnel should handle the machine

Bainmount Pneumatic Pag20

6. Operation

6.1

Machine Start up

6.1.1 Preliminary work before start – up system

The water to be used as coolant is to be filled in the tank.

The Main Switch and the coolant motor is switched on which is on the rear of the machine.

Ensure the Bainmount Press is set up before operation to be run.

6.1.2 Start up

The following steps must be obeyed and aware during start – up:

Step 1: Turn On the Main Switch on the rear of the mounting press

Step 2: Turn On the Coolant motor

Step 3: Once the mounting press software boots up, press the up option to raise the ram

Step 4: Spray mould release spray over the inside of the chamber of lock nut and on the ram surface for easy

removal of mould after mounting

Step 5: Keep the workpiece with the surface of interest facing downwards

Step 6: Press the down option to lower the ram

Step 7: Fill the mould cylinder with required amount of mounting polymer and close the chamber lock nut.

Ensure to clean the sides of the mould cylinder.

Step 8: Specify the temperature, pressure and time of heating and cooling to specify the mounting cycle

Step 9: Press the cycle start to start the mounting action

Step 10: After the mounting cycle has finished, open the chamber lock nut

Step 11: Press the Up option to raise the ram which brings the moulded workpiece to the surface.

Step 12: Remove the moulded workpiece and close the chamber lock nut. Ensure cleanliness of the machine

after use.

Ensure the coolant motor is running

before mounting operation starts

Table of contents

Popular Power Tools manuals by other brands

Porter-Cable

Porter-Cable US58 instruction manual

Metabo

Metabo W 17-150 Original instructions

Renfert

Renfert Vibrax 1830-000 Series instruction manual

Powermatic

Powermatic PF3-JR Operating instructions and parts manual

Universal Tool

Universal Tool UT1520C operating instructions

DeWalt

DeWalt DCF880-XE instruction manual