KENT INDUSTRIAL (USA) INC.

1231 Edinger ave.,Tustin,CA.92780 U.S.A.

Tel:(714)258-8526 Fax : (714)258-8530

1-2.Safety prevention

Safety prevention instruction:

This machine is equipped with many safety devices in order to prevent the injury of

the operator and the damage of machine parts. Therefore, the operator must

completely understand the safety prevention instruction below:

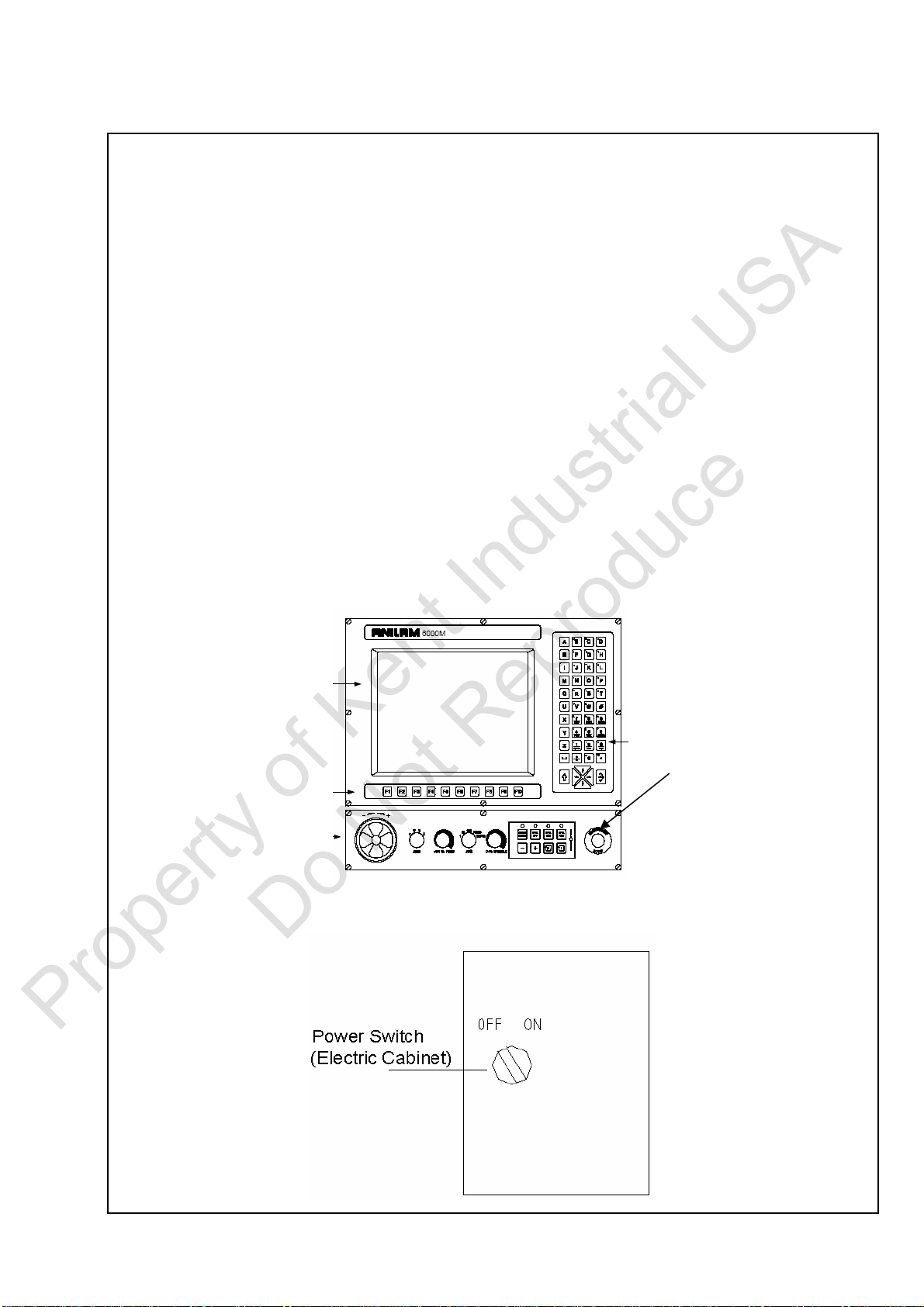

1-2-1. The basic operation practice

Our milling machine possess the potential danger as follows: specific control

buttons, transformer, motor, circuit combination box, high-voltage connector ……

etc. Please do not touch the dangerous objects.

1.【Warning 】

1. Please do not touch the control button with wet hand.

2. The operator must be familiar with the position of Emergency Stop button in

case of the emergent situation happens.

3. When replacing the fuse, the main power must be turned off.

4. Please preserve enough working space, and prevent the falling of tool and

work-piece.

5. Please keep the cleaning of the working field. The coolant, oil, chips must

be cleaned any time in order to prevent the slip.

6. When operating, please make sure the button is what you’re going to push.

7. If there are two or more than two people operating the machine in the same

time, these people have to be will-trained, and these people have to build

good communication before operating the machine in case of the accident

happened.

2.【Attention 】

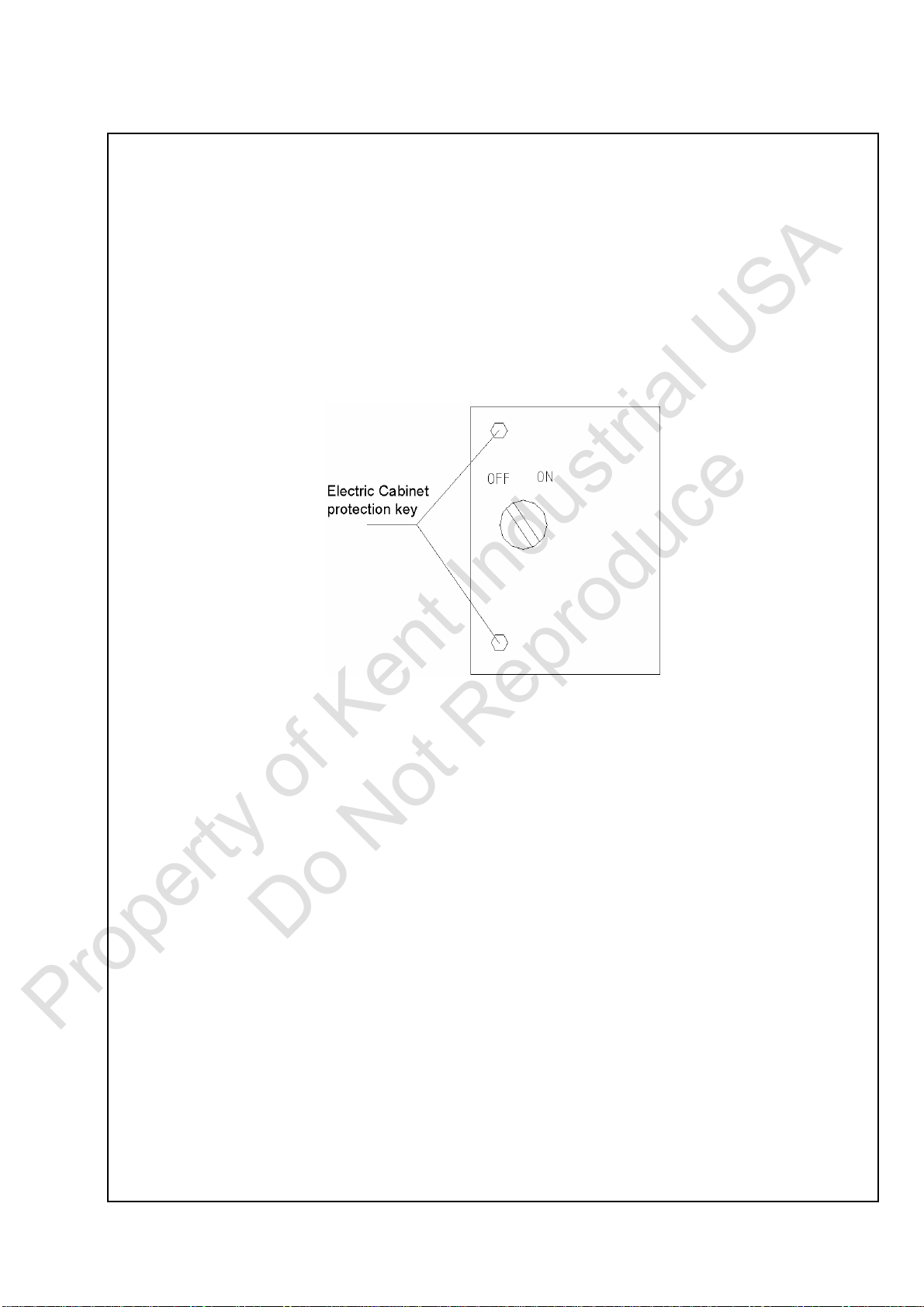

1. When the power of this machine is malfunction, please turn off the main

power immediately.

2. Please use the recommended lubricating oil.

3. The fuse should be replaced with the general, and common fuse.

4. Preventing the NC unit, control box, electro box … etc from leak of

electricity in case of the malfunction.

5. Do not modify the computer setting, and storage capacity arbitrarily. Please

save the original data as a back up file before making a modification.

6. The warning plate must be kept clean, when it is not clear enough, please

replace the plate. Remember to make a mark below of the warning plate in

order to avoid the wrong installation.

1 - 3

Property of Kent Industrial USA

Do Not Reproduce