CHESTER U.K. H80 User manual

IMPORTANT

SAFETYFIRST

ALLMACHINESAREDANGEROUS

1.Usethecorrecttoolforthejobathandnevermakeamachinedoajobitwasnotdesignedfor.

2.Neverforcethetoolinthemachineitwilldothequickerandsaferatthecorrectrate.

3.Alwaysuseclampsorvicestosecurework– yourhandisnotstrongenough!

4.Whenchangingtoolsorworkpiecesalwaysdisconnectthemachinefirst.

5.Servicethemachineregularly;acorrectlyoperatingmachineisasafermachine.

6.Alwaysreplacebeltcoversbeforestartingthemachine.

7.Understandthemachinefullybeforeoperationandalwaysreadthemanual.

8.Gettoknowthemachineslimitationsandapplications.

9.Ensurethatthemachineissecurelyboltedtothebenchandthatthebenchissecurelyboltedtothe

ground.

TAKEGREATCAREWHENOPERATINGTHISMACHINETOPROTECTYOURBODY

1.Alwayswearsafetyglasses–everydayglassesarenotsuitable.

2.Dustcanbecausedwhenmachiningcertainmaterials,alwayswearamask.

3.Makesureyouarenotwearinganylooseclothingsuchasties,rings,braceletsthatmaygetcaughtin

themovingpartsofthemachine.

4.Keepaproperfootingandbalancewhilstoperatingthemachine.

5.Neverleavecleaningrags,etconornearthemachine.

ChesterUKH80Bandsaw

1

SAFETYFIRST

ELECTRICS

1.Allelectricaltoolsmustbeearthed.

2.Neveruseelectricaltoolsindamporwetenvironment.

3.Makesurethemachineisintheoffpositionbeforeswitchingonatthemains.

4.Alwaysimmobilisethemachinebeforeservicingorsettingupworkinthemachine.

5.Greatcareshouldbetakenwhenusingcoolantfluidwithmachinetools.

6.Ensurethemachineiscorrectlyconnectedandafuseoftheproperratingisused.

CHILDREN

1.Keepchildrenawayfrommachines,ifnecessaryfitsafetylockstothemachineandmainsswitches.

2.Neverusemachinerywhilsttalkingtovisitors,alwaysconcentrateonthejobinhand!

REMEMBERALLMACHINESARE

DANGEROUSIFNOTUSED

CORRECTLY!

ChesterUKH80Bandsaw

2

CONTENTS

1. MachineSpecifications......................................................................................................................4

2. RecommendedSpeedsforCuttingofVariousMaterials...................................................................4

3. MachineAdjustments........................................................................................................................5

4. Maintenance.......................................................................................................................................7

5. Troubleshooting.................................................................................................................................7

6. ElectricalConnection&Operation....................................................................................................8

7. Installation&Adjustments................................................................................................................8

8. PartList..............................................................................................................................................9

9. PartDiagram....................................................................................................................................10

10. StandDiagram..................................................................................................................................11

11. CircuitDiagram................................................................................................................................12

12. ElectricalPartList............................................................................................................................12

ChesterUKH80Bandsaw

3

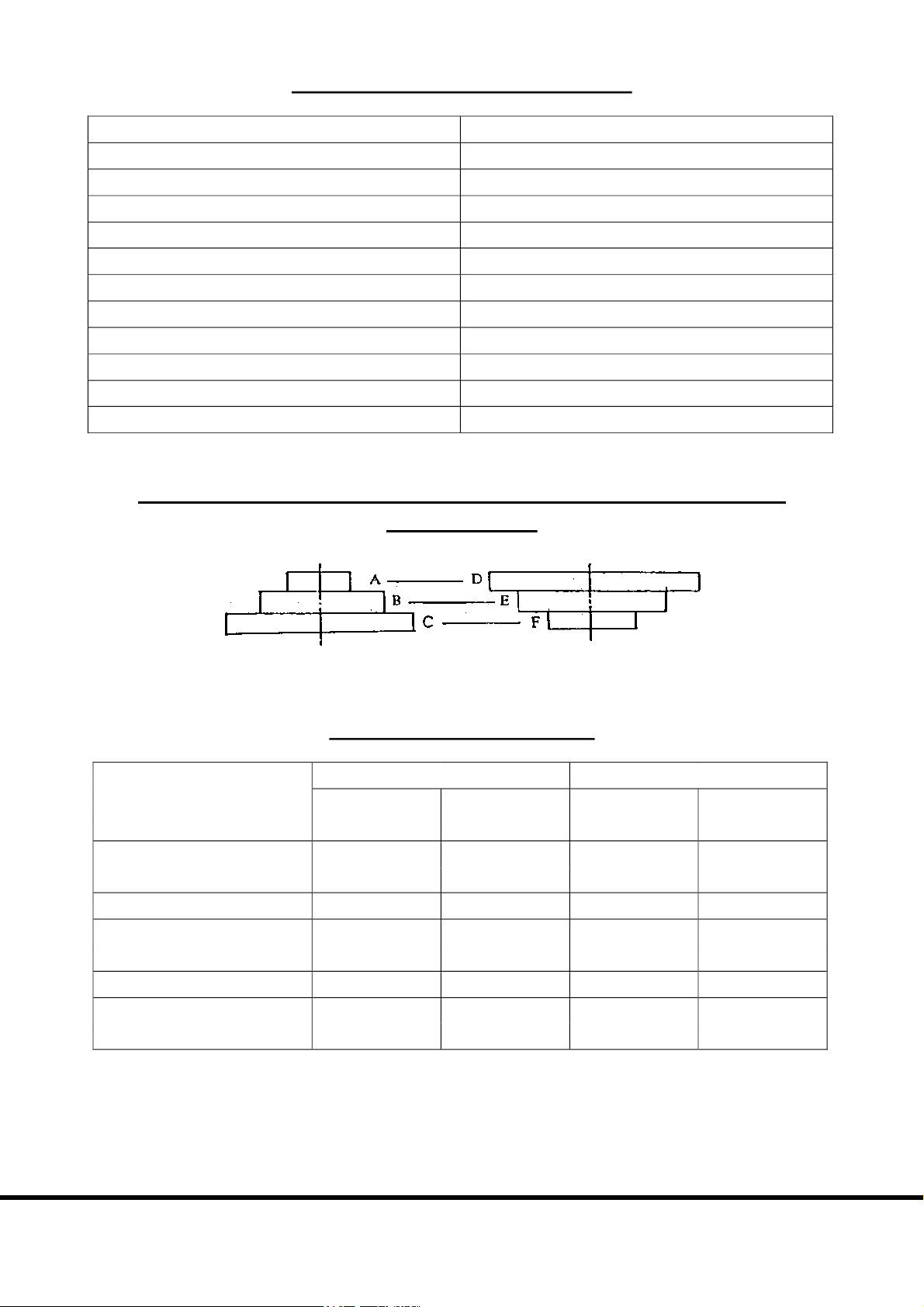

MACHINESPECIFICATIONS

Motor 230V/50Hz420W

BladeSpeed 20,29,50m/min

Max.CuttingCapacity(@90°) Rounddeg90mm

Square90x120mm

Max.CuttingCapacity(@45°) Rounddeg60mm

Square70x65mm

BladeSizeLength 511/8”

Teeth 14tpi(asstandard)

Thickness 0.025"

Width 1/2"

SawBodyTiltingRange 0° 45°

PackingSize 760x295x465mm

RECOMMENDEDSPEEDSFORCUTTINGOFVARIOUS

MATERIALS

MOTORPULLEY SAWPULLEY

MATERIALCUTTINGCHART

Material Speed (SFM) BeltGrooveUsed

50Hz 60Hz MotorPulley SawPulley

Tool,Stainless 20MPM 24MPM SmallA LargeD

orAlloySteel (65FPM) (80FPM)

BearingBronzes,MildSteel, 30MPM 36MPM MediumB MediumE

HardBrassorBronze (95FPM) (120FPM)

SoftBrass,Aluminium 50MPM 61MPM LargeC SmallF

orOtherLightMaterials (165FPM) (200FPM)

ChesterUKH80Bandsaw

4

MACHINEADJUSTMENTS

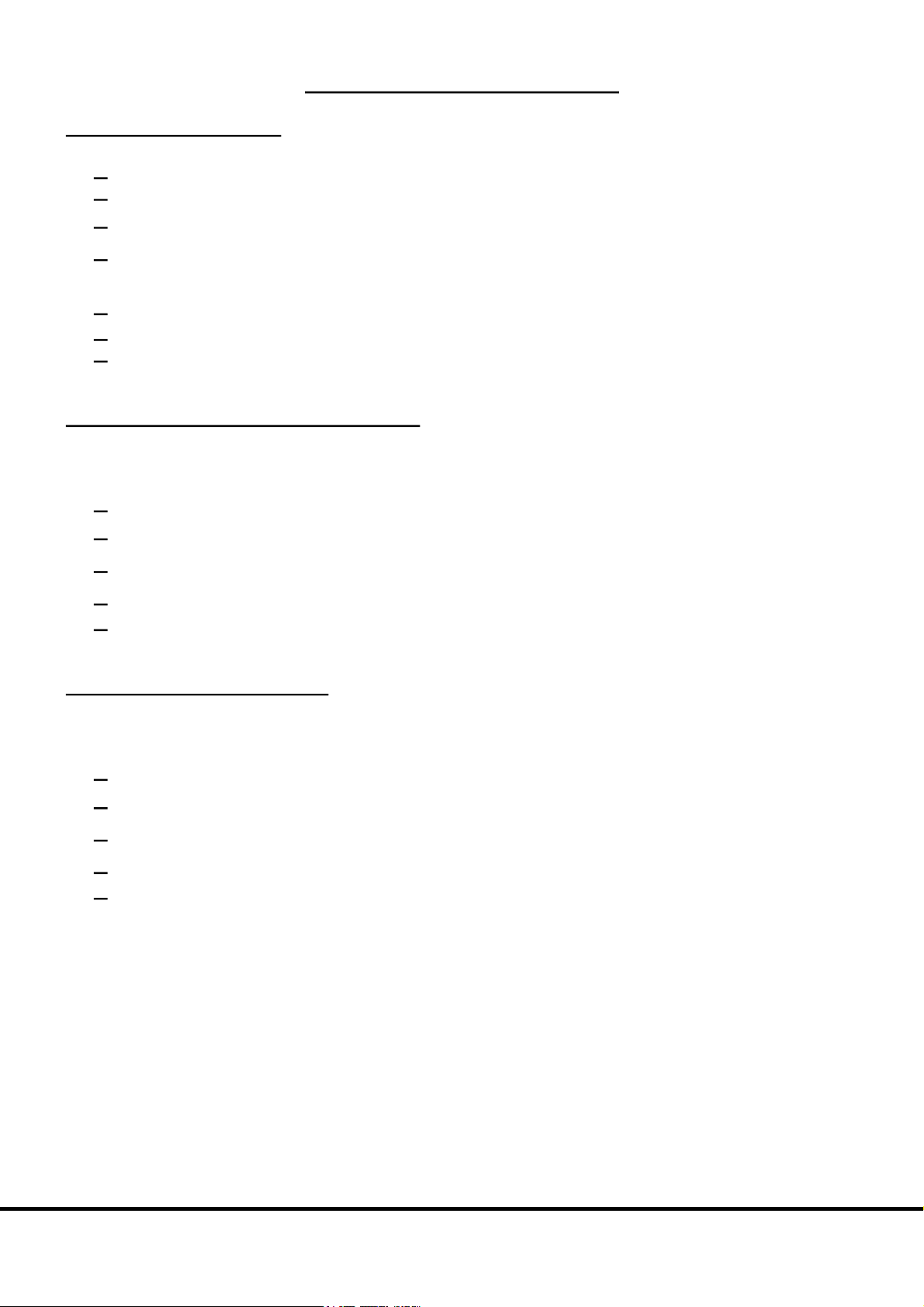

TRACKINGTHEBLADE

1. Firstdisconnectthemachinefromthepowersupply

2. Openthebladeguard.

3. Loosenthetensionontheblade,byturningbladetensionknob Ⓑ(seeFig.2).

4. Loosen grub screw Ⓘ (see Fig. 3). This will enable the motor pulleyⒿ (see Fig. 3) to be

adjustedwhilstontheshaft.

5. WhenthepulleywheelisadjustedretightengrubscrewⒾ.

6. Replacetensiononthebladeusingthebladetensionknob,andclosethebladeguard.

7. Reconnectthepowersupply.

BLADEGUIDEBEARINGADJUSTMENT

Itisimpossibletogetsatisfactoryworkfromthesawifthebladeguidesarenotproperlyadjusted.

1. Disconnectthemachinefromthepowersupply.

2. LoosentheHex.nutⓀ(seeFig.4).

3. AdjustbearingsⓁ(seeFig.4).

4. RetightenHex.nutⓀ.

5. Reconnectpowersupply.

BLADEGUIDEADJUSTMENT

Therearetwobladeguides,oneeachsideoftheworkpiece.

1. Disconnectmachinefrompowersupply.

2. FirstloosenHex.boltⓂ(seeFig.5).

3. PivotbladeadjustmentbracketⓃuntilthebladeissquarewiththemachinebed.

4. RetightenHex.boltⓂ.

5. Reconnectpowersupply.

Note:Bladeguideassemblycanbeadjustedbyunclampingknob Ⓖ(seeFig.2).

ChesterUKH80Bandsaw

5

MACHINEADJUSTMENTDIAGRAMS

ChesterUKH80Bandsaw

6

MAINTENANCE

1. Cleanthebandsawaftereachoperation.

2. Coatthemachinewithrustproofoil.

3. Use a standard grade oil to lubricate the bandsaw’s components. SAE30 oil is

recommendedforthispurpose.

TROUBLESHOOTING

Symptom PossibleCauses CorrectiveAction

ExcessiveBladeDamage 1.Materialislooseinthevice. 1.Clampworksecurely.

2.Incorrectspeedorfeed. 2.Adjustthespeedorfeed.

3.Bladeteethspacingistoolarge. 3.ReplacewithasmallerTPIblade.

4.Materialistoocourse. 4.Usebladeatslowerspeed&TPI.

5.Incorrectbladetension. 5.Adjusttensionsobladedoesnot

sliponthewheel.

6.Bladeisincontactwithmaterial 6.Placebladeincontactwithwork

beforethesawisstarted. onlyafterthemotorhasstarted.

7.Bladerubsonthewheelflange. 7.Adjustthewheelalignment.

8.Misalignedguidepivots. 8.Adjustguidepivots.

9.Bladeistoothick. 9.Useathinnerblade.

PrematureBlade Dulling 1.Bladeteetharetoocourse. 1.UseasmallerTPIblade.

2.Toomuchspeed. 2.Reducethespeed.

3.Inadequatebladetension. 3.Adjustthespring

4.Hardspotsorscaleonmaterial. 4.Reducespeed,increasefeedpressure.

5.Bladeistwisting. 5.Replaceblade,adjustbladetension.

6.Insufficientbladetension. 6.Tightenbladetension.

7.Bladeissliding. 7.Tightenbladetension,reducespeed.

UnusualWearonSideor 1.Bladeguidesareworn. 1.Replacebladeguides.

BackofBlade 2.Bladeguidepivotsaremisaligned. 2.Adjustguidepivots.

3.Bladeguidebracketsareloose. 3.Tightenbladeguidebrackets.

TeethRippingfromBlade 1.Bladeistoocourseforthework. 1.UseafineTPIblade.

2.Toomuchpressure,speedistooslow. 2.Decreasepressureandincreasespeed.

3.Workpieceisvibrating. 3.Clampworkmoresecurely.

4.Bladeistoofineforthework. 4.UseacourseTPIblade.

MotorOverheating 1.Bladetensionistoohigh. 1.Reducethebladetension.

2.Drivebelttensionistoohigh. 2.Reducethedrivebelttension.

3.Bladeistoocourse. 3.UseasmallerTPIblade.

4.Bladeistoofine. 4.UseacourserTPIblade.

5.Gearsneedlubrication. 5.Lubricategears.

6.Cutisbindingblade. 6.Decreasethefeedandspeed.

Bad,CrookedorRoughCuts 1.Feedpressureistoogreat. 1.Adjustspringtoreducepressure.

2.Guidepivotsaremisaligned. 2.Adjustguidepivots.

3.Inadequatebladetension. 3.Increasebladetension.

4.Bladeisdull. 4.Replaceblade.

5.Incorrectspeed. 5.Adjustspeed.

6.Bladeguidesarespacedouttoomuch. 6.Adjustguidespacing.

7.Bladeguideassemblyisloose. 7.Tightenguideassembly.

8.Bladeistoocourse. 8.UseafinerTPIblade.

BladeisTwisting 1.Cutisbindingblade. 1.Decreasefeedpressure.

2.Bladetensionistoohigh. 2.Decreasethebladetension.

ChesterUKH80Bandsaw

7

ELECTRICALCONNECTION&OPERATION

ELECTRICALCONNECTION

1. Themetalcuttingbandsawisequippedwithastandardplugtoconnecttopowersourcewith

singlephase,50Hz,and220Vor240V.

2. Fortheprotectionofthecontroldevice,werecommendtheoperatortosupplyafusewith6A

currentoffuse.

3. Thetotal length between supply fuse and plug/ socket connectionshall not be greater than

1.5m.

ELECTRICALDISCONNECTION

1. Removing the plug from the socket carries out the disconnection of the metal cutting band

saw.

2. Besuretodisconnectthemachinefromthepowersource,whenyouwanttostopthejoband

maintainorinspect.

GROUNDING

1. Thegroundingsystemofthismachineisprovidedinthewayofastandardplug,whichisin

compliancewiththelocalstandard.

2. WARNING!“Donotchangetheplugintoanyothertypethanisprovided.”

OPERATION

1. START: Pressthebuttonmarked“I”.

2. STOP: Pressthebuttonmarked“0”.

3. STOPATTHEENDOFCUTTING: This machine will stop automatically at the end of

cutting.

INTERLOCK&ADJUSTMENTS

INSTALLATION:

1. Beforeinstallation,sufficientspacewithatleast2.5m*2.5mbyafreespaceofatleast0.8min

alldirectionsshallbeprovidedforthemachine.

2. Theplaceprovidedforthemachineshouldbecleanandflat.

3. Sufficientlightingshouldbeprovidedaccordingtothelocalregulationformetalworking,orat

least300Luxambientlightingintensity,ifnoregulationsexists.

ADJUSTMENTS:

Adjustmentsofsawblade

1. Thebladetensionknobwiththeindicatorcarriesouttheadjustmentofthesawblade.

2. Suitable blade tension is adjusted by hand without the help of a tool. For a suitable blade

tension, you should not be able to move with the pressure of your finger, with appropriate

forceatthesawblade.

Adjustmentsofbladecover(Left&Right)

Theleftandrightadjustablebladecover isdesignedtopreventaccesstothemovingsaw blade

duringcutting.Theymustbeadjustedasnearaspossibletotheworkpiece.

ChesterUKH80Bandsaw

8

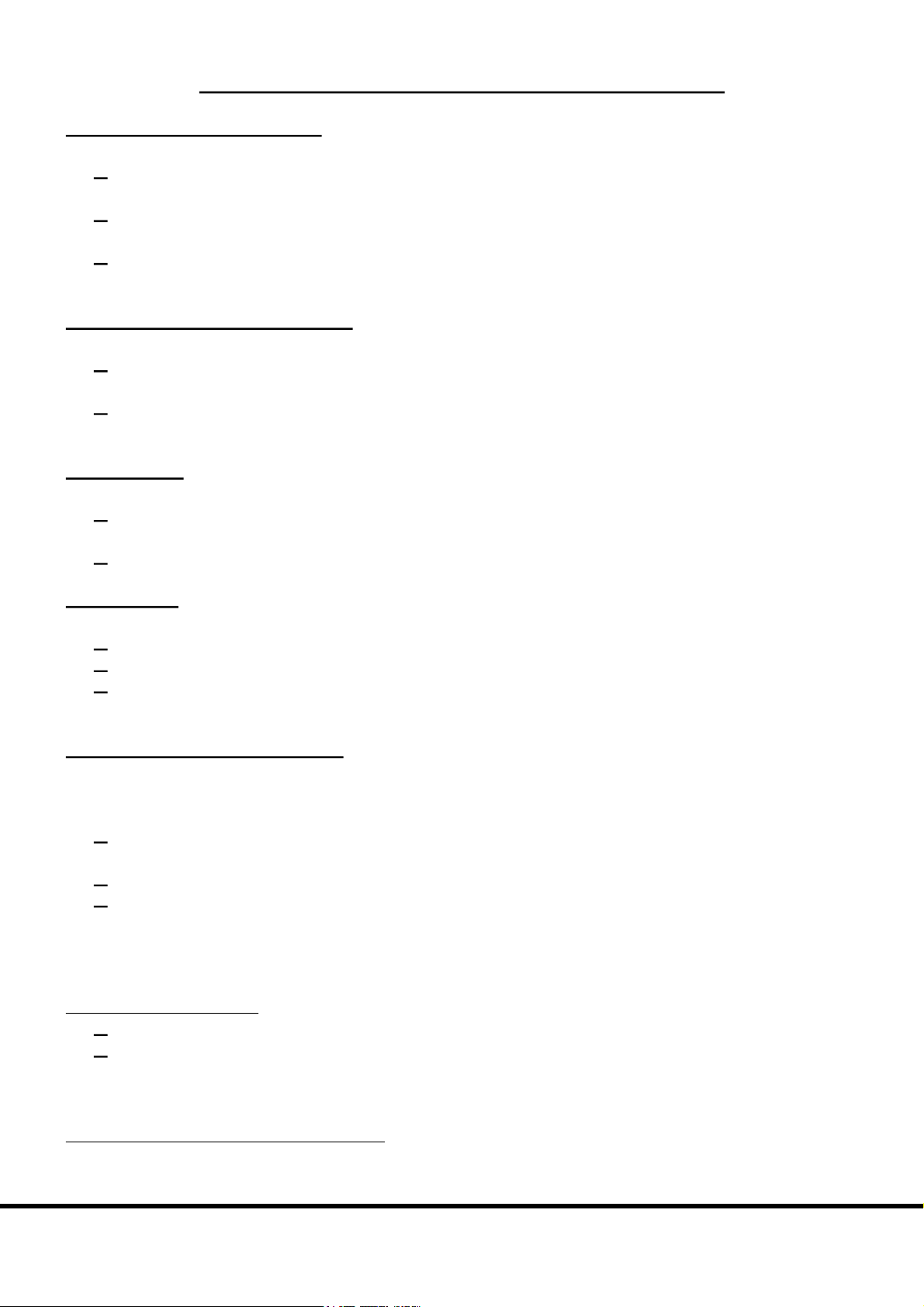

PARTLIST

ItemNo. ItemDescription ItemNo. ItemDescription ItemNo. ItemDescription

1 Base 40 Bracket 79 Pulley

2 Bolt 41 Plate 80 Bearing

3 Chain 42 Bracket 81 Shaft

4 Pad 43 Bracket 82 SealingPlate

5 Washer 44 LockingHandle 83 Pulley

6 Bolt 45 Knob 84 Oilseal12.32.7

7 Nut 46 Bolt 85 Sleeve

8 Bolt 47 Washer 86 VBelt

9 Bolt 48 Washer 87 Pulley

10 Bolt 49 Bracket 88 Washer

11 Washer 50 Plate 89 Screw

12 Bolt 51 SealingWasher 90 PulleyCover

13 TurnionBracket 52 Gear 91 Key

14 Nut 53 Bolt 92 Motor

15 Handle 54 Bolt 93 AdjustingKnob

16 Spring 55 Bracket 94 Base

17 Nut 56 Bracket 95 Bolt

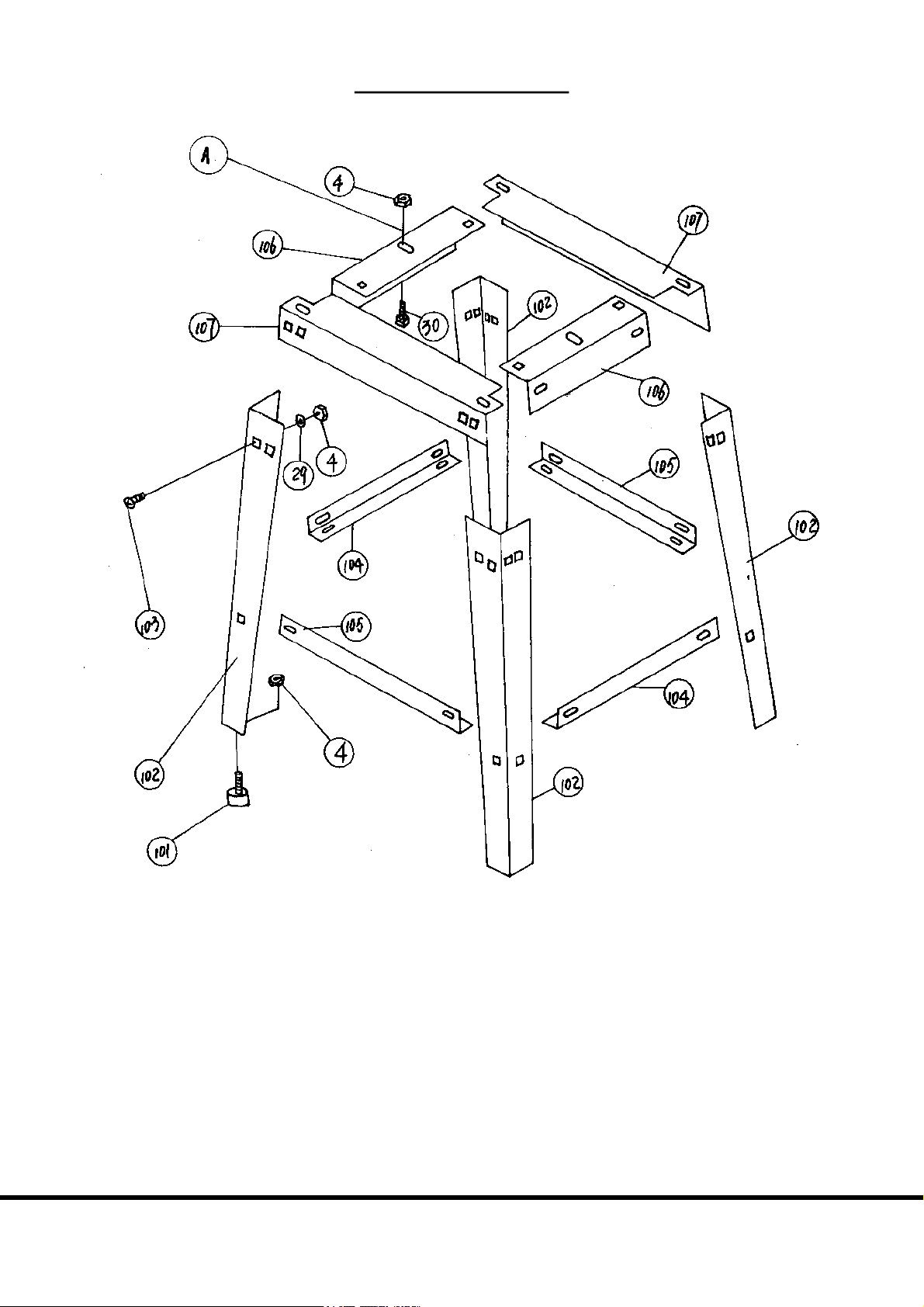

18 Plate 57 Bearing 101107 STAND

19 Bolt 58 Sleeve

20 Axle 59 Washer

21 Shaft 60 Knob

22 ScaleLabel 61 Bolt

23 Bolt 62 Axle

24 Washer 63 Wheel

25 Pointer 64 RetainingRing

26 Washer 65 Bolt

27 Hex.Bolt 66 Bracket

28 WheelHandle 67 Plate

29 Washer 68 Pin

30 Bolt 69 Blade

31 ClampJaw 70 Knob

32 Bolt 71 Cover

33 Plate 72 Screw

34 Washer 73 Wheel

35 SpringWasher 74 Shaft

36 Vice 75 Washer

37 ThreadedShaft 76 Key

38 Knob 77 MainBody

39 Bolt 78 GearBox

ChesterUKH80Bandsaw

9

PARTDIAGRAM

ChesterUKH80Bandsaw

10

STANDDIAGRAM

ChesterUKH80Bandsaw

11

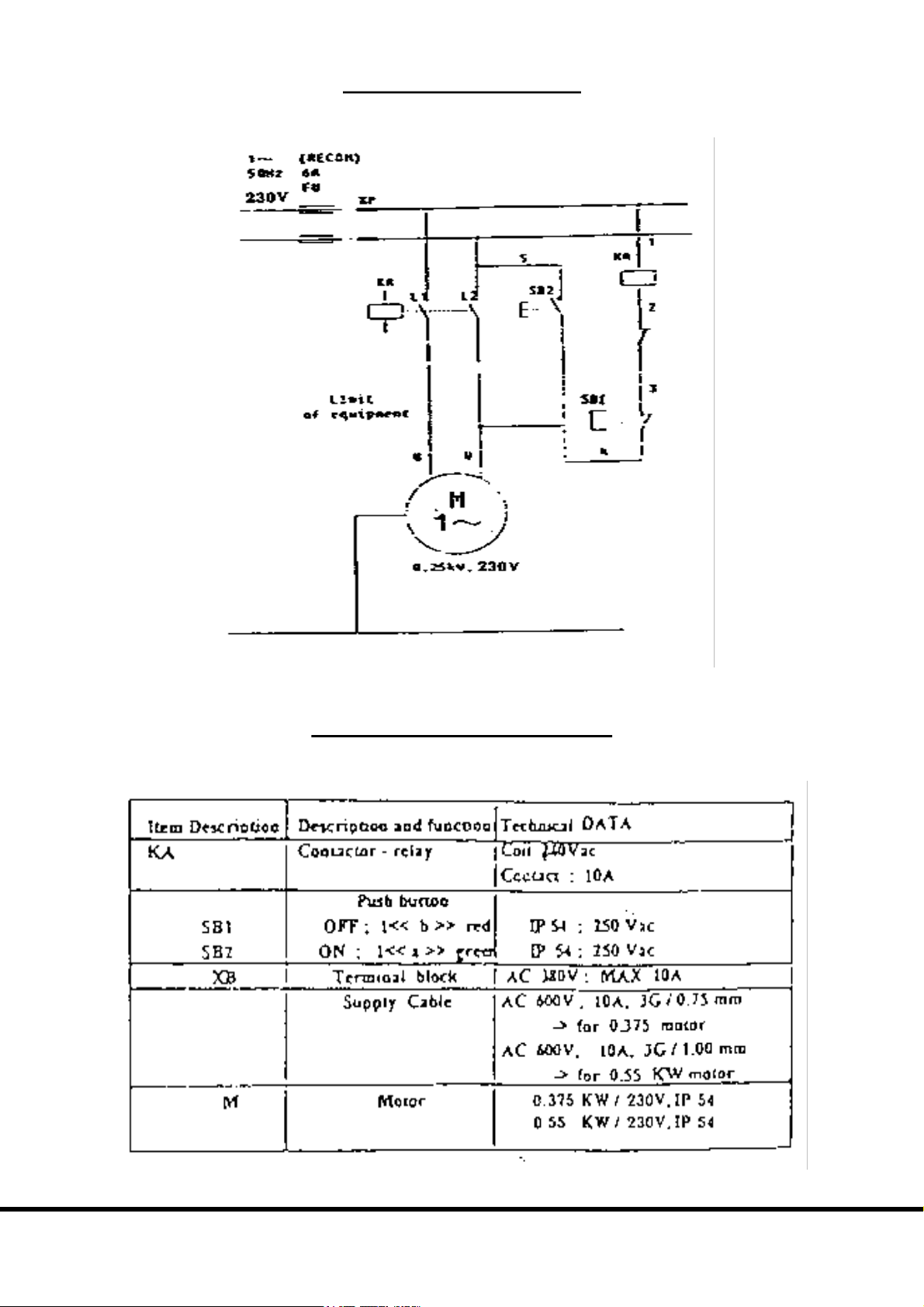

CIRCUITDIAGRAM

ELECTRICALPARTLIST

ChesterUKH80Bandsaw

12

Table of contents

Other CHESTER U.K. Saw manuals

Popular Saw manuals by other brands

Gude

Gude GWS 400 ECO Translation of original operating instructions

Fieldmann

Fieldmann FDK 2001-E instruction manual

Promaker

Promaker PRO-TZ2400 user manual

Gude

Gude PRS 700 Translation of original operating instructions

Makita

Makita 5704R instruction manual

Stanley

Stanley FATMAX SFMCS305 Original instructions