CP8848 Series

impact wrench

1. Technical Data

Model

Drive Torque Free speed Weight Blows per minute Dimension

LxWxH Battery Voltage Sound pressure

LpA

Sound power

LwA

Vibrations

ahd K

1 2 3 4 5 6 7 8 9 10

[inch] [ft.lbs]

[Nm] min-1 [lb]

[kg] min-1 [mm]

[inch] [volt] [dB(A)] [dB(A)] [m/s²] [m/s²]

ah :Vibration level,kUncertainty; LpA Sound pressure dB(A), KpA = KWA = 3 dB Uncertainty

Declaration of noise and vibration statement (EN60745)

All values are current as of the date of this publication.

These declared values were obtained by laboratory type testing in accordance with the stated standards and are suitable for comparison with the declared values of other

tools tested in accordance with the same standards. These declared values are not adequate for use in risk assessments and values measured in individual work places

may be higher. The actual exposure values and risk of harm experienced by an individual user are unique and depend upon the way the user works, the workpiece and the

workstation design, as well upon the exposure time and the physical condition of the user. We, CHICAGO PNEUMATIC TOOLS , cannot be held liable for the consequences

of using the declared values, instead of values reflecting the actual exposure, in an individual risk assessment in a work place situation over which we have no control. This

tool may cause hand-arm vibration syndrome if its use is not adequately managed.

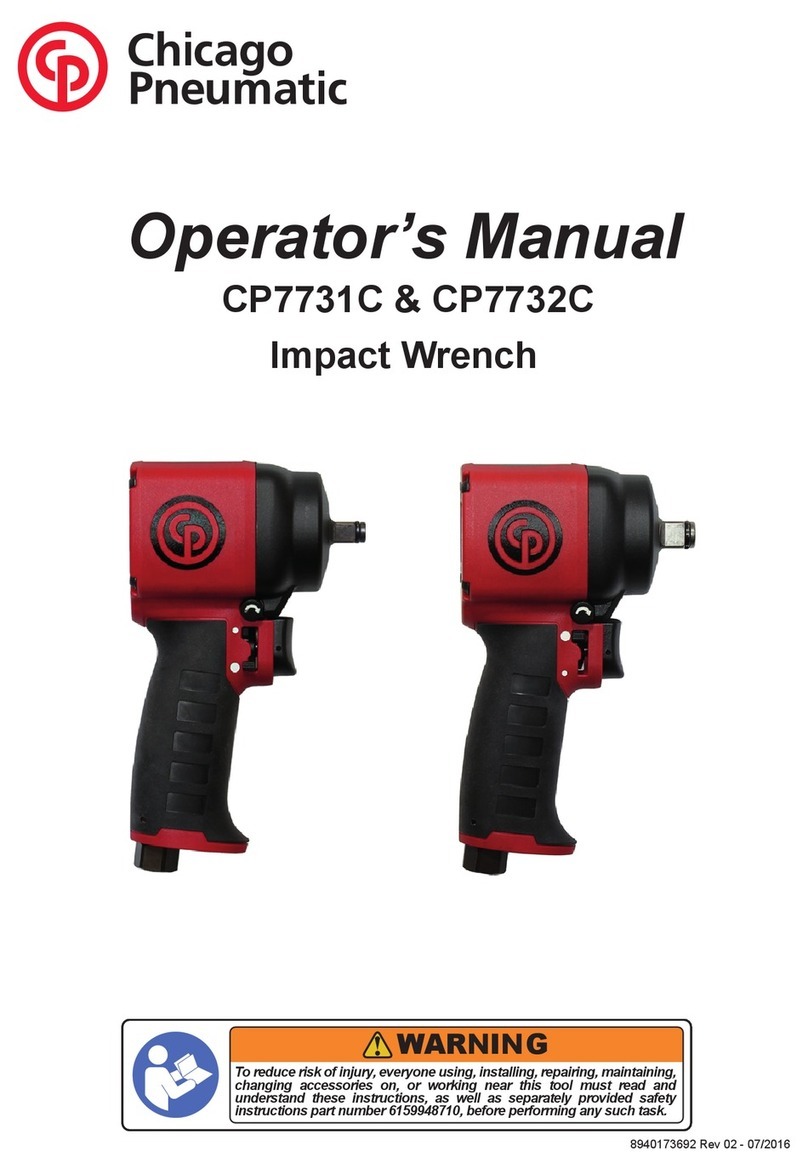

2.Machine type(s)

• This product is designed for installing and removing threaded fasteners in wood, metal and plastic. No other use permitted. For professional use only.

• Please read the instructions carefully before starting the machine.

3. Mounting instruction

• See figures.

4. Battery

• New battery packs reach full loading capacity after 4 - 5 charging and discharging. Battery packs which have not been used for some time should be rechar-

ged before use.

• Temperatures in excess of 50°C (122°F) reduce the performance of the battery pack. Avoid extended exposure to heat or sunshine (risk of overheating).

• The contacts of chargers and battery packs must be kept clean.

• For an optimum life-time, the battery packs have to be fully charged, after use.

5. Maintenance instruction

• Follow local country environmental regulations for safe handling and disposal of all components.

• Maintenance and repair work must be carried out by qualified personnel using only original spare parts. Contact the manufacturer or your nearest authorised

dealer for advice on technical service or if you require spare parts.

• Disassemble and inspect the tool every three 3 months if the tool is used every day. Replace damaged or worn parts.

• Always ensure that the machine is disconnected from energy source to avoid accidental operation.

• High wear parts are underlined in the parts list.

• To keep downtime to a minimum, the following service kits are recommended :

Tune-up kit: see part list

6. Disposal

• The disposal of this equipment must follow the legislation of the respective country.

• All damaged, badly worn or improperly functioning devices MUST BE TAKEN OUT OF OPERATION.

• Repair only by technical maintenance staff.

7. SYMBOL

Please read the instructions

carefully before starting the

machine.

Do not dispose of electric tools together with household waste

material! In observance of European Directive on waste electrical

and electronic equipment and its implementation in accordance

with national law, electric tools that have reached the end of their

life must be collected separately and returned to an environmentally

compatible recycling facility.

European

Conformity

Mark

Remove the battery pack

before starting any work on the

machine. Korean Conformity Mark

EurAsian

Conformity

Mark.

8. EC Declaration of conformity

We : : CHICAGO PNEUMATIC Tool Co. LLC 1800 Overview Drive Rock Hill, SC 29730 - USA

Machine type(s) : impact wrench

Declare that the product(s) : CP8848 Serial Number: From 00001 to 99999

Origin of the product : Hungary

is in conformity with the requirements of the council Directives on the approximation of the laws of the Member States relating : to “Machinery“ : (2006/42/EC), RoHs

(2011/65/EU), EMC (2014/30/EU), applicable harmonised standard(s) :

EN 60745-1:2009 + A11:2010 EN 60745-2-1:2010 EN 60745-2-2:2010

EN 55014-1:2006 + A1:2009 + A2:2011 EN 55014-2:1997 + A1:2001 + A2:2008

Name and position of issuer: Pascal Roussy (R&D Manager)

Learn more about impact wrenches we have.