CHINT BZMJ Series Installation instructions

BZMJ Series

Self-healing Low Voltage

Shunt Capacitors

Standard:IEC 60931-1-2014

IEC 60831-2-2014

NO:2021.01

Safety Warning

1 Only professional technicians are allowed for installation and maintenance.

2 Installation in any damp, condensed-phase environment with inflammable and explosive gas is

forbidden.

3 When the product is being installed or maintained, the power must be switched off.

4 You are prohibited from touching the conductive part when the product is operating.

Use Purpose and Range of Applications

Type Key and Definitions

Conditions for Normal Use, Installation and

Transportation, and Storage

Key Technical Parameters and Performance

Installation, Commissioning and Operation

Main Features, Outline and Installation Dimensions

Analysis and Troubleshooting of Faults

Maintenance and Storage

Product Selection and Ordering Information

Environmental Protection and Warranty Period

11 Environmental Protection

01

01

01

02

04

04

06

06

07

08

08

01

Conditions for Normal Use, Installation and Transportation, and Storage

YN: refers to split-phase compensation, star connection

Phase number: 3-three phase, 1-single phase

Rated capacity (kvar)

Rated voltage (kV)

2 refers to built-in current limiting reactor

Medium code (Metalized polypropylene film)

Impregnant code (Z for rapeseed oil)

Series code (B for shunt capacitor)

B □ MJ □ □ □ □ YN

Model

Harmonic source power

/transformer capacity

Harmonic source power

/transformer capacity

Harmonic source power

/transformer capacity

NLL≤10%NLL≤20%20%≤NLL≤40%

Voltage total

harmonic distortion THDu≤3%3%<THDu≤5%THDu>5%

Rated voltage

of capacitor 0.4kV, 0.45kV 0.45kV, 0.48kV 0.48kV, 0.525 kV

Harmonic

suppression measures

Not needed Recommend to use

series reactor 7%

Series reactor 7%

or 14%

3.3.3. If detuning low voltage series reactor is installed at the front end of the capacitor, the rated voltage of

the capacitor should be selected as below: If the reactance rate of the reactor is 6% or 7%, the rated voltage

of the capacitor should be 0.45kV or 0.48kV, if the reactance rate of the reactor is 12% or 14%, the rated

voltage of the capacitor should be 0.525kV.

Table 1 Capacitor selection and harmonic suppression measures under harmonic environment

Note: If harmonic power ratio NLL>40%, user must install CKSG series reactor or take harmonic suppression measures.

3.1 Environmental conditions: See Table 2 for ambient air temperature, relative temperature and altitude.

3.2 Installation conditions: On condition that the safety precautions are met, the installation site should be

free from hazardous gases and vapors, conductive or explosive dusts, and strong mechanical vibration.

3.3 Application conditions

3.3.1 The rated voltage of the capacitor must be higher than the voltage of user’s grid. When the

environmental conditions exceed the limits in 3.1, user must derate the capacitor by raising its rated voltage,

otherwise the service life of the capacitor can be significantly shortened after long-term overvoltage or

overtemperature operation.

3.3.2 Harmonic current amplification is the primary cause for capacitor damage. Common harmonic sources

include: power electronic equipment, frequency converter (energy saving transformation, such as motor

speed regulation, variable frequency air conditioner, etc.), DC rectifier, inverter, electrolytic plating

equipment, electric arc furnace and intermediate frequency furnace, etc. See the table below for capacitor

selection and harmonic suppression measures under harmonic environment:

BZMJ series self-healing low voltage shunt capacitors (hereinafter referred to as capacitors) are

applicable to power frequency AC power systems with rated voltage up to 1,000V for power factor increase,

reactive power loss reduction and voltage quality improvement.

Use Purpose and Range of Applications

Type Key and Definitions

BZMJ Series Self-healing Low Voltage Shunt Capacitors

02

Rate voltage (kV)0.23~1.2 See Table 3

Rate capacity (kvar)1~60 See Table 3

Rate frequency (Hz)50 or 60 Default 50

Capacitance deviation (%) -5~+8 Short circuit

discharge before test

Dissipation factor ≤ 30kvar product: tanδ≤0.0012

>30kvar product: tanδ≤0.0015

Withstand voltage (kV)Inter-pole: power frequency 2.15UN, 2s

Pole-to-case: 2.0 UN+2 kV or 3 kV (take higher), 5s

Maximum allowable

overvoltage

1.1UN, no more than 8h of continuous operation

within 24h

Maximum allowable

overcurrent

1.3IN, no more than 2h of continuous operation

within 24h Short time≤2.0IN

Self-discharge

characteristics

Residual voltage drops from √2UN to 75V(DC)

or below within 3min after power off.

Ambient temperature (℃) -25~+50 (-25/C)

Customizable -40~+50

Relative temperature ≤50% at 40℃, ≤90% at 20℃

Altitude (m)≤2000

Tightening torque (N·m)M6 screw ≤7, M8 screw ≤10

Safety protection Self-healing + overpressure protection+

discharge device

Short circuit

discharge before test

Installation method Vertical

Rated voltage

UN(kV)

Optimal capacity

Qc(kvar)

Rated current IN(A)Outline and installation dimensions

3-three

phase

1-single

phase

Capacity

range Height HFigure

number

0.23, 0.25 3, 5, 6, 7.5, 10, 12,

15, 20, 25, 30

1~4120 Figure 1

5140 Figure 1

6~8190 Figure 1

10 195 Figure 2

12 220 Figure 2

14~16 250 Figure 2

18~20 295 Figure 2

25 250 Figure 3

30 315 Figure 3

Qc

√3UN

Qc

UN

3.3.4 See 6.2 for product installation spacing. We suggest double the installation spacing if the product is

installed above an altitude of 2000 meters. User should take effective measures to ensure good ventilation

and heat dissipation of the capacitors under high temperature environment and keep the capacitors away

from heat source.

3.4 Transportation conditions: The capacitors should be transported within original package (packed in foam

box). The product should be handled carefully during transportation, to prevent the capacitor body from

deformation due to collision. The product should be placed on upper level when loaded onto the truck. The

capacitor assembly must be placed vertically during transportation, with an inclination less than 30 degrees.

Key Technical Parameters and Performance

4.1 See Table 2 for key technical parameters

Table 2 Key technical parameters

Note: The rated voltage (1.0~1.2)kV of the capacitor is special specification, the maximum customizable capacity

is 40kvar.

4.2 See Table 3 for specifications and outline dimensions of main models

Table 3 Specifications and outline dimensions of main models

BZMJ Series Self-healing Low Voltage Shunt Capacitors

BZMJ Series Self-healing Low Voltage Shunt Capacitors

03

Table 3 (continue)

4.3 The capacitors are placed in the capacitor compensation cabinet which should provide the following

protection measures. See Table 4 for details.

Table 4 Capacitor protection measures in cabinet

Protective

characteristics Name and function of support devices Typical models

Transient

overvoltage

protection

Zinc-oxide surge arrestor or surge protector FYS-0.28 or NU6-2

Transient

overcurrent

protection

Capacitor dedicated contactor, current limiting reactor,

or smart compound switch with zero-cross detection. CJ19, XD1 or ZCK

Steady stage

overvoltage

protection

Generally, compensation controller can provide

overvoltage protection.NWK1-G, NWKL1

Steady stage

overcurrent

protection

Thermal relay or capacitor switch with overcurrent

protection function.JR36 or ZCK

Short circuit

protection

Choose fast acting fuse for short circuit protection. For

capacitors with capacity<30kvar, user can use miniature

circuit breaker for short circuit protection. For capacitors

with capacity ≥30kvar, miniature circuit breaker is not

recommended.

RT36 or NT00

Rated voltage

UN(kV)

Rated voltage

UN(kV)

Optimal capacity

Qc(kvar)

Optimal capacity

Qc(kvar)

Rated current IN(A)

Rated current IN(A)

Outline and installation dimensions

Outline and installation dimensions

3-three

phase

1-single

phase

Capacity

range

Capacity

range

Height H

Height H

Figure

number

Figure

number

0.4, 0.45, 0.48

1, 3, 4, 5, 6, 7.5, 8,

10, 12, 14, 15, 16,

18, 20, 24, 25, 30,

35, 40, 45, 50, 60

1~595 Figure 1

6~8120 Figure 1

10 140 Figure 1

12~16 190 Figure 1

18~20 220 Figure 1

22~25 220 Figure 2

28~32 250 Figure 2

35~40 250 Figure 3

45~60 315 Figure 3

3YN split-phase

compensation capacitor

0.45, 7.5, 10,

15, 20, 25, 30

Y refers to star

connection,N refers

to null line lead out.

5~7.5140 Figure 2

10 195 Figure 2

14~16 250 Figure 2

20 295 Figure 2

25~30 315 Figure 3

0.45, 0.48, 0.525 5, 7.5, 10,

15, 20, 25, 30

5~7.5140 Figure 2

10 195 Figure 2

14~16 220 Figure 2

20 250 Figure 2

315

Figure 3

Note: The dimensions of 0.525 kV, 0.69kV, 0.75 kV, 0.86 kV, 1.2 kV single phase products may be different from those in the table, please refer to

the real products. See the outline and installation dimensions in this manual for the figure number of outline and installation dimension drawings.

Qc

√3UN

Qc

UN

Qc

√3UN

25

30 Figure 3

250

04

The capacitors are made from metalized polypropylene film with excellent self-healing properties.

They are compact, light-weighted and easy to install. The capacitor case is made from tinned steel sheet

with sprayed surface.

Note: Refer to Table 3 based on capacitor model, then look for the outline and installation dimensions in Figure 1,

Figure 2 and Figure 3.

Example: For model BZMJ0.45-20-3, user can refer to Table 3 and find that H=220mm, then check Table 1 for

outline and installation dimensions and find that the outline dimension is 198mm×64mm×250mm and the installation

dimension is 180mm×37mm.

Figure 1 Outline and installation

dimensions of waist-shaped products

Figure 2 Outline and installation

dimensions of small square products

Figure 3 Outline and installation

dimensions of large square products

Main Features, Outline and Installation Dimensions

Installation, Commissioning and Operation

6.1 Assembly and fixing of mounting feet

Figure 4 Installation drawings of mounting feet

Insert the plastic mounting feet from the bottom of the case and fixed it onto the mounting plate. If

the locking bar at the bottom of the mounting feet is not flat (as shown in Figure 4), the capacitor is not

properly installed. In this case, the capacitor body can easily fall out if there is any strong vibration during

transportation.

6.2 See Figure 5 and Table 5 for installation spacing

25

28

30

37

H

37

56

64

50

70

78

70

93

110

160

180

198

178

206

224

210

260

274

7x1 0

25

H

H

28

25

25

Not properly installed properly installe

BZMJ Series Self-healing Low Voltage Shunt Capacitors

05

6.3 Wiring requirements

The capacitors should be connected by stranded soft conductors, with pressed dedicate copper

connecting lug. See Table 6 for the selection of conductor sectional area.

Capacity (kvar)Minimum installation

spacing S1(mm)

Safety distance at the top

of capacitors S2(mm)

1~20 30 ≥50

22~32 50 ≥50

35~60 80 ≥50

Rated voltage (kV)Rated capacity (kvar)2

Conductor sectional area (mm )

0.4, 0.45, 0.525 ≤10 4.0

0.4, 0.45, 0.525 12~20 6.0

0.4, 0.45, 0.525 24~32 10.0

0.4, 0.45, 0.525 35~60 16.0 or 25.0

Figure 5 Capacitor installation drawing

Table 5 Safety distance

6.4 Preparation and inspection before use

6.4.1 Before using the capacitor, user should check if the model on the nameplate is consistent with that of

the product. User should also check if the included accessories are complete.

6.4.2 Capacitor testing: Use digital capacitance meter to test the capacitance value between any of the two

phases of the 3-phase capacitor, the result should not be smaller than half of the rated value.

6.4.2 Before using the capacitor, user should check if all the connections are secure and if the dust guard is

installed, make sure the capacitor is reliably grounded.

6.5 Monitoring and recording during operation

6.5.1 User should check the operating status of the capacitors on a regular basis, check if the 3-phase

current is balanced by using the amperemeter in the cabinet.

6.5.2 If the 3-phase current is not balanced, use clamp on amperemeter to test the current and voltage of

phase A, phase B and phase C of each group of capacitors.

6.5.3 If there is voltage but no current between phases, it means the overpressure protector is disconnected,

user should maintain the product in time or replace it if necessary.

6.5.4 Check the surface temperature of capacitor case during operation, if the temperature of any individual

capacitor case exceeds 65℃, maintain the product or replace it if necessary; if the temperature of all the

capacitor cases is higher than 65℃, take effective ventilation and heat dissipation measures and check if any

harmonic source device (such as frequency converter, rectifier and inverter, and medium and high frequency

heating furnace) is used at user load end.

6.6 Operation procedure, method and precautions for shut down

6.6.1 If any deformation is found on the capacitor case, there is oil leakage or the reactive compensation

Table 6 Selection of conductor sectional area

S2

S1

BZMJ Series Self-healing Low Voltage Shunt Capacitors

BZMJ Series Self-healing Low Voltage Shunt Capacitors

06

1

The measured current of a

newly connected capacitor is

much smaller than the rated

current on its nameplate (same

for multiple capacitors).

If a capacitor with higher rated

voltage is connected to 380V grid,

the actual output current will be

much smaller, which is normal.

There is nothing wrong with the

capacitor, it is just derated.

User should determine the

status of a capacitor based

on its measured capacitance

value (μF). The actual

operating current IC=

Uc/UN ×IN

2

The current of the capacitor is

closed to rated current when

it is first put into operation,

but the current drops after a

period of time.

The current drops as the capacitance

value of the capacitance decreases.

There are several reasons for

capacitance decrease such as

improper use, large harmonic or

quality defect.

Find out the reason and

solve the problem. User

must replace the capacitor

if the capacitance value

drops below 50%.

No.Faults Cause analysis Troubleshooting method

Analysis and Troubleshooting of Faults

Table 7 Analysis and Troubleshooting of Faults

7.1 Daily maintenance and calibration

Check if the operating current of the capacitor is normal by using the amperemeter and compensation

controller in the cabinet. Check if there is any deformation, oil leakage and overheating.

Abnormalities such as overcurrent and overtemperature caused by harmonic will reduce the service life

of the capacitor and can cause damage to other components and conductors in the cabinet due to overload.

7.2 Maintenance during operation

Tighten the terminal screws of the capacitor on a regular basis (once half a year) to prevent poor

contact. Remove dust and greasy dirt.

User should pay close attention to the cabinet and replace any damaged capacitor in time if any under

-compensation of power factor occurs due to significant capacitance drop (50% current decrease), otherwise

it may lead to penalty. If all the capacitors are operating and in good condition but the power factor still

cannot meet requirement, user must add capacity in time to ensure the automatic cycle operation of the

capacitors.

7.3 Service cycle

User should determine the service cycle based on the application conditions, the recommended service

cycle for cabinet is once half a year.

7.4 Maintenance for long-term idle

If the capacitor has been idled for one year or longer, please check if its capacitance value is within the

allowable deviation range (-5%~+8%); conduct pole-to-case voltage withstand test again (apply AC 3kV for

5 seconds); or use megameter to test if the insulation resistance between the three phase terminals and the

case is larger than 100MΩ before using the product.

7.5 Storage conditions, storage period and precautions

The smart capacitor should be stored in a dry and well-ventilated room and protected from rain, moist,

chemicals and dust. The maximum storage period of the product is 36 months. Do not put the smart

capacitor or its package directly on the floor.

controller is not working normally, shut down the equipment for inspection and repair.

6.6.2 If the busbar in the cabinet is of bottom-in and top-out type, user must disconnect the bus before

replacing the capacitors or other electric components. However, user only needs to disconnect the isolation

switch in the cabinet when changing the secondary wiring or testing the capacitors.

6.6.3 Before testing and touching the capacitors, user must conduct short circuit discharge between each

two terminals of the 3-phase capacitor.

Maintenance and Storage

07

9.1 Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to

the industrial waste treatment process, or be sent to the recycling station for assortment, dismantling and

recycling according to local regulations.

9.2 Warranty period

The warranty period of the product is 30 months from production (delivery) date if the product is kept

under normal storage conditions and the package or the product itself is in good condition. If the warranty

period has expired, please inspect the product and make sure it meets all the requirements before installing

and using the product. The following circumstances are not within the scope of warranty (excluding repair

or replacement):

1) Damage due to improper use, storage or maintenance by user

2) Damage due to dismantle or repair by unauthorized agency or personnel or by user itself

3) The warranty period or service life of the product has expired.

4) Damage due to force majeure

5) Other man-made damages

3

The terminal screws of the

capacitor generate heat or

even turn into black during

operation.

The wire nuts are loose or not

tightened properly during installation.

If the nuts are tightened properly, the

reason might be long-term

overcurrent due to harmonic current

amplification in the grid.

Tighten the nuts, replace

nuts, flat gaskets, elastic

washer if necessary.

4

The fuse in branch circuit

blows frequently (or miniature

circuit breaker trips frequently);

the CJ19 contactor fuses; the

current-limiting resistance

burns frequently; the surface

of XD1 current-limiting reactor

case cracks, etc.

These symptoms are typical when

the grid harmonic is too big or

there is intermittent resonance in

the grid.

Conduct grid harmonic test

or check if there are

harmonic sources such as

frequent converter, rectifier,

intermediate frequency

furnace or electric-arc

furnace installed at load

end. See 3.3.2 for harmonic

suppression measures.

5

Sometimes there is buzzing

sound in the cabinet during

operation.

There is harmonic current passing

through the capacitor.

User must take harmonic

suppression measures if

the harmonic current is too

big (same as 4)

6

There is significant current

increase when adding a

capacitor into a group.

Either abnormal power frequency

resonance (underloading), or

harmonic current amplification or

there is resonance.

Same as 4

7

Slight deformation occurs to

the capacitor case after the

capacitor has been used for a

period of time, and no current

can be detected.

Long-term overtemperature or

overcurrent operation of the

capacitor which cause self-healing

breakdown of internal components

that generates gases and increases

internal pressure. When the

overpressure protector breaks, slight

deformation can occur to the

capacitor case.

Use heat dissipation

measures to lower the

ambient operating

temperature of the capacitor.

Select products with higher

rated voltage. Harmonic

suppression measures are

the same as described in 4.

No.Faults Cause analysis Troubleshooting method

Environmental Protection and Warranty Period

BZMJ Series Self-healing Low Voltage Shunt Capacitors

08

10.1 User should provide product parameters such as rated voltage, rated capacitance, number of phases,

etc;

10.2 User should provide as many application conditions as possible, such as altitude, grid harmonic

environment and application industry.

Product Selection and Ordering Information

Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to

the industrial waste treatment process, or be sent to the recycling station for assortment, dismantling and

recycling according to local regulations.

BZMJ Series Self-healing Low Voltage Shunt Capacitors

09

DR/J03

BZMJ Series

Self-healing Low Voltage

Shunt Capacitors

IEC 60831-1-2014

IEC 60831-2-2014

BZMJ Series Self-healing Low Voltage Shunt Capacitors

10

BZMJ Series Self-healing Low Voltage Shunt Capacitors

BZMJ Series

Self-healing Low Voltage

Shunt Capacitors

Table of contents

Other CHINT Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

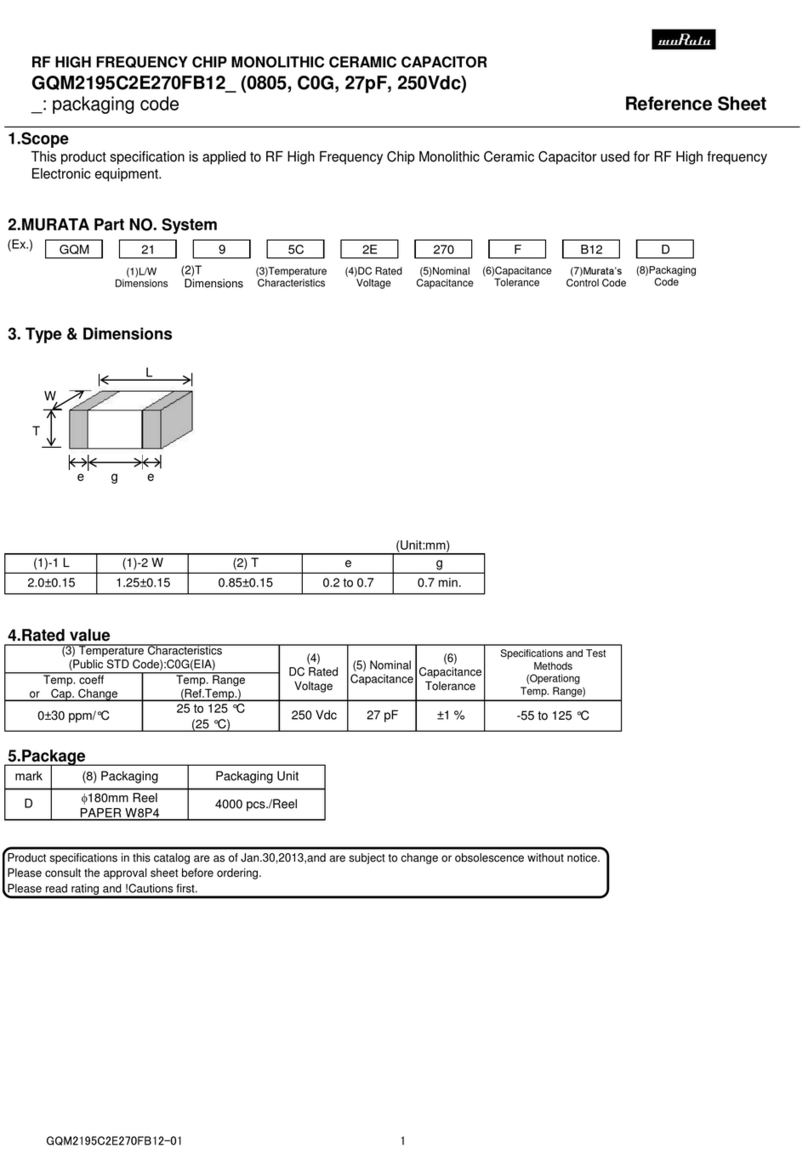

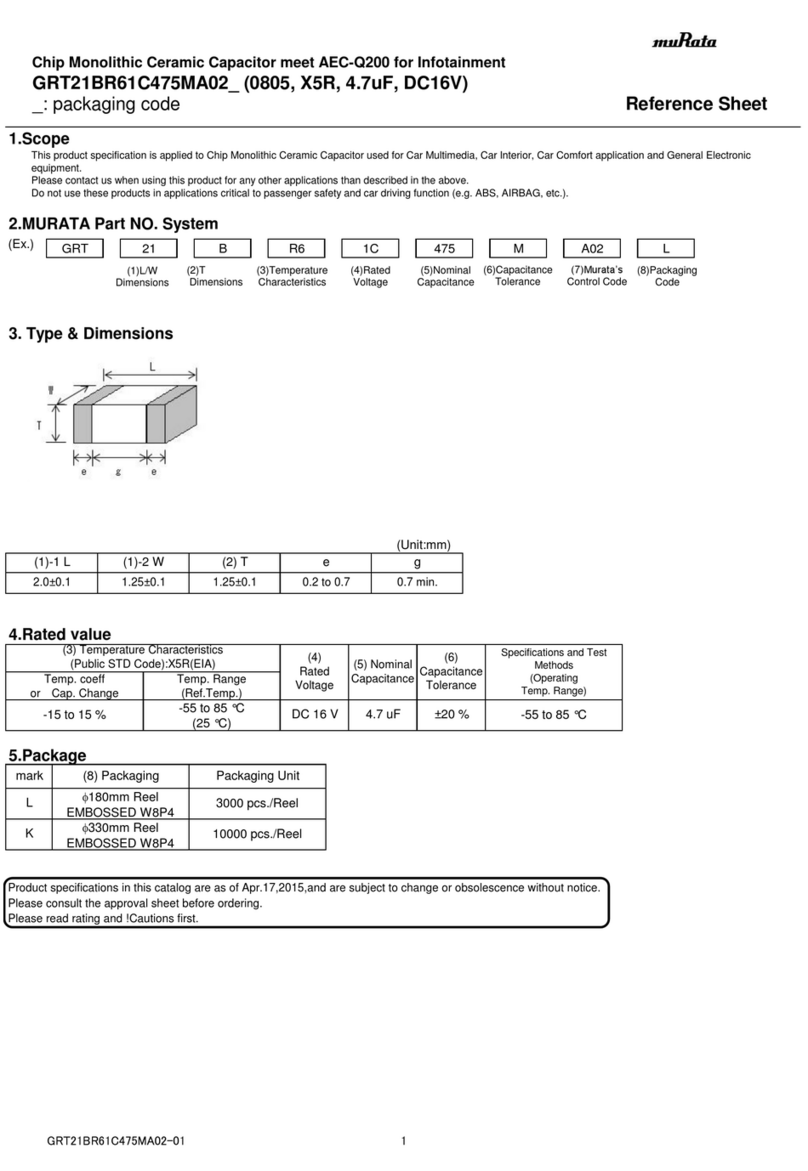

Murata

Murata GRT21BR61C475MA02 Series Reference sheet

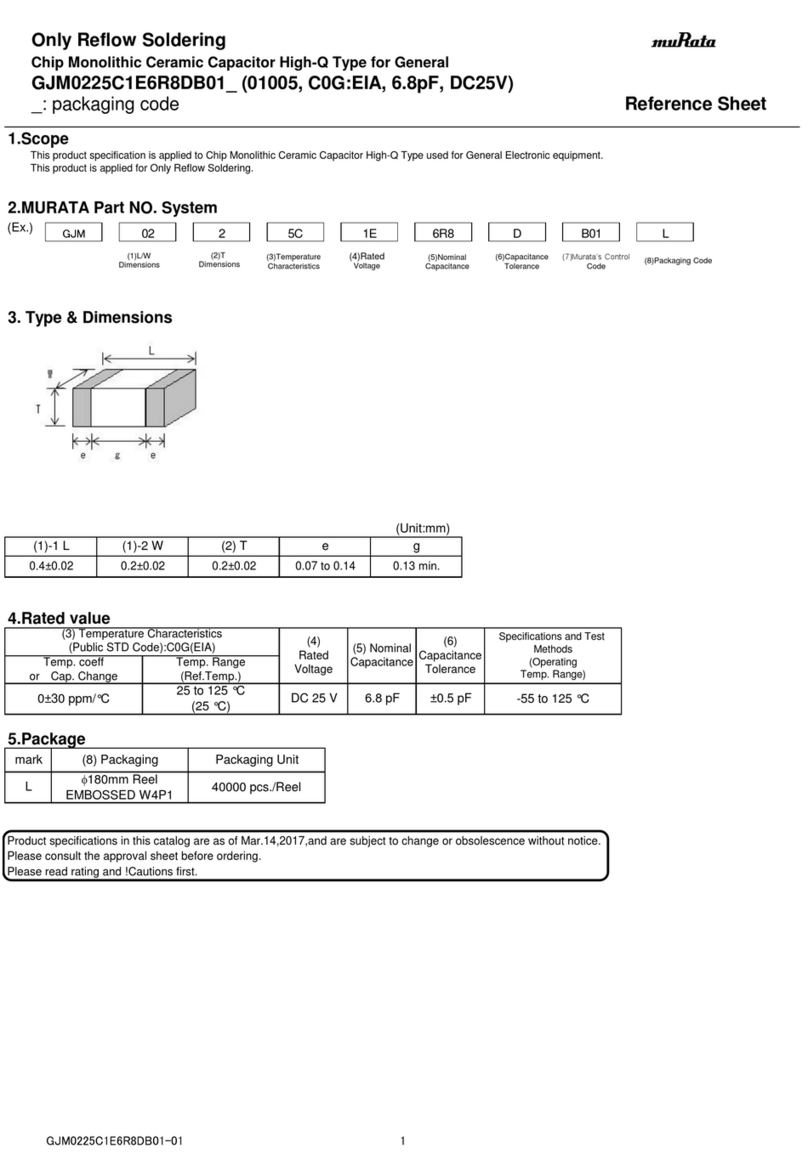

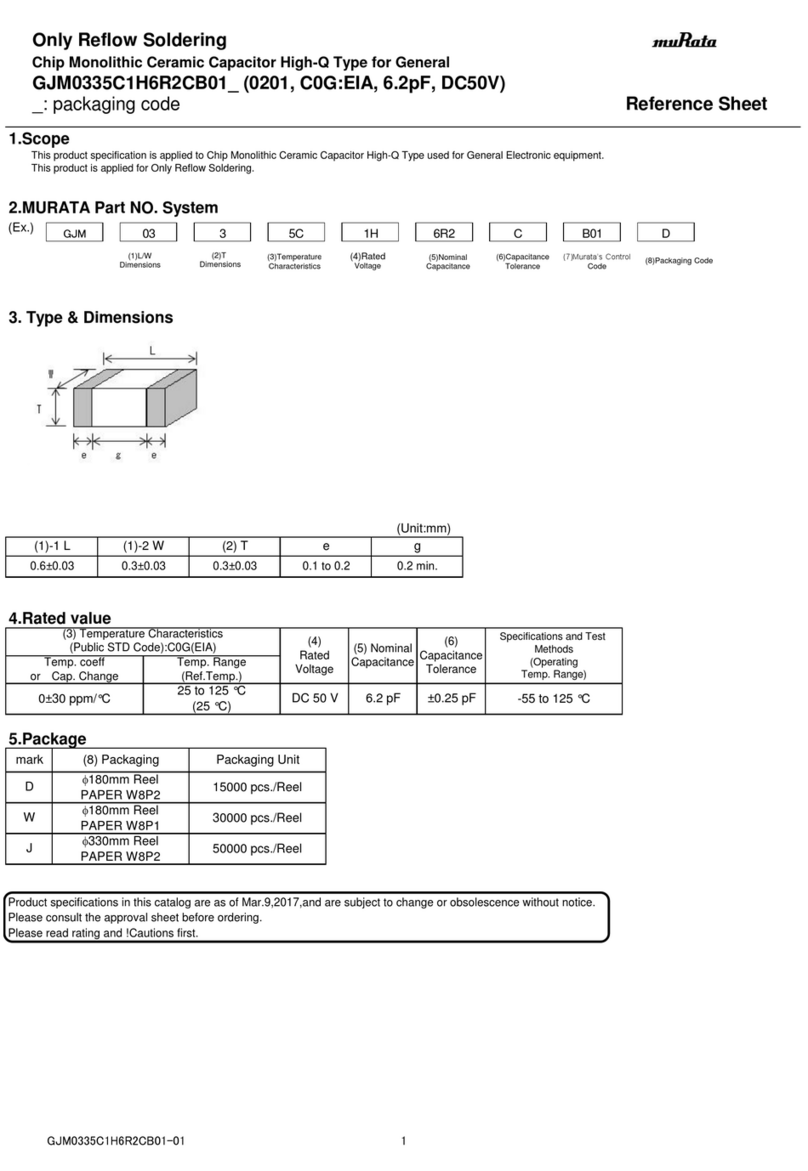

Murata

Murata GJM0335C1H6R2CB01 Series Reference sheet

Synergy

Synergy SwitchPak SPAK 4S/2D installation instructions

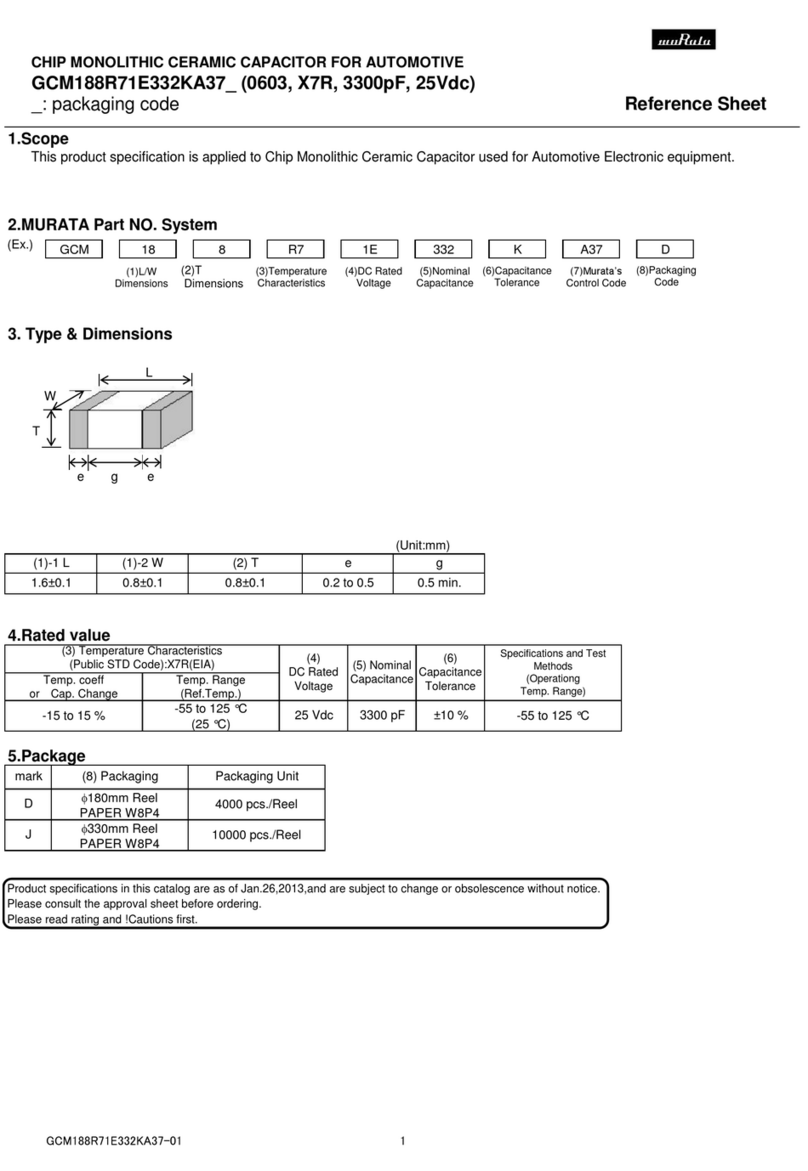

Murata

Murata GCM188R71E332KA37 Series Reference sheet

Altronix

Altronix TROVE T1KE34V installation guide

Lucent Technologies

Lucent Technologies Lineage 2000 J85503C-3 product manual