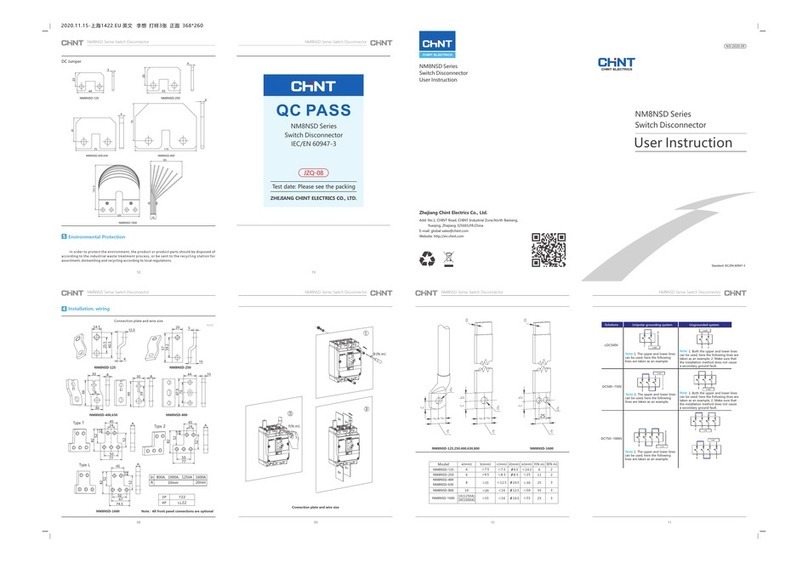

CHINT NXZM User manual

NO:2021.04

Standard: IEC/EN 60947-6-1

User Instructions

NXZM、NXZ(H)M

Automatic Transfer Switch

Safety Warning

1

2

3

4

Only professional technicians are allowed for installation and maintenance.

Installation in any damp, condensed-phase environment with inflammable

and explosive gas is forbidden.

You are prohibited from touching the conductive part when the product is

operating.

Do not install the product at places where gas medium can cause metal

corrosion and insulatin damage.

After installing the product, finishing the inspection of load side line and

splitting the fire-resistance circuit, the controller must be set to “Manual”

position and the product must be set to split position. Switch the controller

to “Auto” position after line fault is eliminated.

To avoid dangerous accidents, the products should be installed and

secured according to the instructions.

This product is applicable to environment A. The product will generate

harmful electromagnetic interference if used in environment B, in which

case, user should take proper protective measures.

5

6

7

1

2

Applicatin Information

a) The normal application temperature of the product is -5℃~+40℃;

Note: If you need to use the product under -25℃~+70℃, please consult the manufacturer.

b) If you need to use the product above 2000m altitude, please consult the manufacturer;

c) Pollution class: class 3;

d) Installation category of main circuit: Ⅲ

e) Enclosure protection class: IP20.

;

Inspection and Test

01

NXZM、NXZ(H)M Automatic Transfer Switch

Inspection

Tools required

Phillips screwdriver

Word screwdriver

Allen wrench

Hex wrench

Fig 1 Inspection

Product

model

Total

(Pcs)

Wiring screw

Flash barrier

M6 X 12 M8 X 16 M8 X 16 M10 X 30 M12 X 35 3P

4P

3P

4P

2X6

2X8

2X4

2X6

NXZM-63、125

HNXZ M-63、125

NXZM-160

HNXZ M-160

NXZM-250

HNXZ M-250

NXZM-400、630

HNXZ M-400、630

NXZM-800

HNXZ M-800

wiring

terminal

of

external

signal

(controller)

Type A

Type AT

Type B

Type BT

split wire 2m (optional)

5

6

7

1

Tabla 1 Standard accessories

1.Determine

product

technical

parameters.

2.Type AT and

BT controllers

have the

function of

communication.

NXZM、NXZ(H)M Automatic Transfer Switch

02

Manual test

Power-on test

Turn the toggle switch to

the Manual position

Off position Normal On position

Alternative

On position

Off position

Reset the handle

Turn the toggle switch to

the Automatic position

Automatic mode Manual mode Setting mode

Failure alarm

(absent for PC class)

Automatic transfer

Operating transfer

delay time

Automatic transfer

Return transfer

delay time

Generator activationStop mode

Fig 2 Manual test

Fig 3 Power-on test

03

NXZM、NXZ(H)M Automatic Transfer Switch

3

Outline and Installation Dimensions

Outline & installation dimensions

Unit: mm

Product model

NXZM-63、125

NXZHM-63、125

NXZM-160

NXZHM-160

NXZM-250

NXZHM-250

NXZM-400、630

NXZHM-400、630

NXZM-800

NXZHM-800

A B B1 B2 C D G L SHSHSHM N

H H1 H2

300

340

390

535

660

240

250

250

334

344

230

245

367

464

477

223

240

240

342

344

267

307

357

475

600

220

230

230

304

314

25

30

35

44

58

178

194

225

304

385

178

167

181

161

180

190

151

152

155

190

195

216

9

9

9

1166

1168

17

17

17

26

26

5647

50

5049

198

203

234

238

Fig 4 Outline and Installation Dimensions

Tabla 2 Outline and Installation Dimensions

A

C

LG

D

B

B1

B2

M

N

Hmax

H1

H2

NXZM、NXZ(H)M Automatic Transfer Switch

04

Dimensions of split module of controller and cabinet door

105

64 4.5

17

101

60

60≤a≤62

101≤b≤103

Thickness≤2.5

Unit: mm

4

Installation and wiring

Wire connection dimension

Unit: mm

Product model

NXZM/NXZHM-63

NXZM/NXZHM-125

NXZM/NXZHM-160

NXZM/NXZHM-250

NXZM/NXZHM-400

NXZM/NXZHM-630

NXZM/NXZHM-800

a b c Torque

8.0

7.5

10

10.5

15

17.5

16

23.5

30.5

43

6.5

8.5

8.5

11.5

14

4 N·m

10 N·m

12 N·m

30 N·m

40 N·m

Fig 5 Dimensions of split module of controller and cabinet door

Fig 6 Wire connection dimension

Tabla 3 Wire connection dimension

NXZM、NXZ(H)M Automatic Transfer Switch

05

Unit: mm

Rated current

Cross-sectional

area of copper

wire or copper bar

10 16 25 32 40 50 63 80 100 125 160 180

The number of copper

wire or copper bar

Cross-sectional

area of copper

wire or copper bar

The number of copper

wire or copper bar

Rated current 200 225 250 315 350 400 500 630 700 800

1.5 2.5 4.0 6.0 10 10 16 25 35 50 70 95

95 95 120 185 185 240 150 185 240 240

1

1 2

Product wiring diagram

4P Product wiring diagram

Normal power bus-bar Alternative power bus-bar

Load bus-bar

Normal power Alternative power

4P

3P Product wiring diagram

3P

Normal power

bus-bar

Alternative power

bus-bar

Wiring terminal of

neutral line

Load bus-bar

Normal

power

Alternative

power

Tabla 4 Sectional area, width and number of copper wire

Fig 7 Product wiring diagram

Voltage signal

sampling line

Main power

supply

1. Main power

supply and

voltage signal

sampling line

phase

sequence must

be consistent.

2. During

wiring, the

voltage signal

sampling line in

order as shown.

Wrong wiring

may lead to

burn down of

the controller.

NXZM、NXZ(H)M Automatic Transfer Switch

06

Normal

neutral line

Alternative

neutrul line

Connect to the external

terminal of controller

directly.

Any forms of electrical

connection of these terminals is

strictly forbidden.

Signal and control terminal wiring diagram

Note: Please tear off the sticker before use

and keep it for future use.

It is used under the

Grid-power generator

mode and may be omitted,

but the delay of generator

start-up default to 0s.

Note:

Active output

AC230V/0.5A

Do not connect

201 and 202.

Used for Grid-Power generator

mode only and connected to the

generator as needed, In the case

of the normal power supply fails,

terminal 601 land 603 are

connected.

To the remote power

of generator

Terminals 501 and 502 can

onlybe connected to passive

signal, optionally via a relay

contactor.

Terminals 503 and 504 are

connected after the off of fire

control. After the fire control

signal bering removed, for the

ATSE switch to“Manual”and

then press Confirm/Return in

automatic mode, or press

Comfirm/Return directly in

manual mode.

Note:

1: Dotted line is the internal structure of the controller.

2: Type A controller doesn’t have functions of generator control

(601 602 603) and feedback output of fire protection control (503, 504).

3: Type AT and BT controllers have the function of communication.

Commom

CommonCommon

Fig 8 Signal and control terminal wiring diagram

201 202

1. Any type of

electrical

connection

between

terminal 201

and teminal

202 is

prohibited,

otherwise the

controller will

be burnt!

2. Terminal 501

and 502 of

controller can

only be

connectd with

passive closing

signal to

achieve fire

cintrol linkage.

If they are

directly

connected to

any active

signal, the

controller will

be burnt.

3. Strip at least

8mm of the

insulation of

the wire before

inserting it into

the terminal.

07

NXZM、NXZ(H)M Automatic Transfer Switch

Installation of the display module (on cabinet door)

Installation of flash barrier

5

Controller setup

Indication of automatic working mode;

Indication of manual working mode;

Failure indication

When the breaker is tripped due to failure or short-

circuit of the switch, this lamp will be on; (absent for

class PC)

Display area of normal power voltage parameters

It displays normal power voltage parameters and

transfer delay time under the working condition, and

displaying symbols under the setting condition;

Indication of the on or off of breaker on the normal

power side, the light will flash if a failure of the

normal power occurs;

Indication of setting condition;

Indication of on or off of breaker on the alternative

power side, the light will flash if a failure of the

alternative power occurs;

Instructions of controller operation interface

2221

20

2

11

2

3

4

5

6

7

4

9

10

11

12

13

23

19

18

17

16

15

14

8

7

6

3

5

Fig 9 Installation of the display module

Fig 10 Installation of flash barrier

Fig 11 Controller setup

If a megameter with capacity over 500V

is used to measure the insulation

resistance of the circuit breaker, please

disconnect the secondary circuit of the

controller.

NXZM、NXZ(H)M Automatic Transfer Switch

08

Indication of the start of stop function;

Unit of voltage time and frequency of the normal power;

Phase of A, B, C;

Unit of voltage, time and frequency of the alternative power;

Display area of alternative power voltage parameters

It displays alternative power voltage parameters and transfer delay time under the working

condition, and displaying symbols under setting condition;

Indication of the start signal of generator;

Confirm/return button

Press this button to save changes and exit in setting mode;

And restore normal operation status in fire protection linkage mode;

Button for compulsorily switch to the normal power

Under manual control mode, If the normal power supply is normal,press this button, it can

compulsorily switch to normal power;

If it is setting condition, this button is the “scroll up” button of setting programs;

Button for compulsorily switch to the alternative power

Under manual control mode, if the alternative power supply is normal press this button, it can

compulsorily switch to alternative power;

If it is setting condition, this button is the “scroll down” button of setting programs;

Off button

Under manual control mode, if either line of both power lines is normal and press this button, it will

switch to the off position;

If under the setting mode, this button is the minus button for setting parameters;

Failure inquiry button

When the switch fails and malfunction lamp on the failure screen is on, press this button, the detail

malfunction code can be displayed in the screen;

Setting button

Press this button to enter into the parameter setting menu of the controller;

Indication of automatic charge and automatic recovery mode;

Indication of automatic charge and without automatic recovery mode;

Indication of generator (automatic charge and automatic recovery) mode;

Indication of communication status.

,

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

For setting of the switching value of normal

power supply undervoltage,press to increase

and to decrease

For setting of the switching value of normal

power supply overvoltage,press to increase

and to decrease

For setting of the switching delay time,press

to increase and to decrease

For setting of the switching valueaof alternative

power supply undervoltage,press to increase

and to decrease

For setting of the switching valueaof alternative

power supply over voltage,pr ess to increase

and to decrease

For setting of the return delay time,press

to increase and to decrease

For setting of the delay time of generator

start-up,press to increase and to decrease

For setting of the delay time of generator

stop,press to increase and to decrease

For setting of switching modes,press and

to change mode.(If the digital is 000,it refers to

grid-grid autormatic charge and automatic return;

if the digetal is 001,it refers to grid-grid automatic

chargr and without automatic return;if the figital

is 002,it refers to grid-power generator mode)

For setting of modbus communication address

in the range of 1-247,press to increase and

to decrease

For setting of modbus communication baud rate.

0:9.6kbps; 1:19.2kbps.

Remote locking:(on/off)default off.

09

NXZM、NXZ(H)M Automatic Transfer Switch

Parameter setting for controller

Note: The parameter settings for display

module and communication

default as follows:function

1 Setting of undervoltage switching

value: Default to 187V, user-settable

160V~200V.

2 Setting of overvoltage switching value:

Default to 263V, user-settable

240V~290V.

3 Setting of switching delay: Default to

5s, user-settable 0s~180s.

4 Setting of return delay: Default to 5s,

user-settable 0s~180s.

5 Setting of generator start-up delay:

Default to 5s, user-settable 0s~180s.

6 Setting of generator shutdown delay:

Default to 5s, user-settable 0s~180s.

Button instruction:

When the controller is in

operation, press the set button

to set the interface of parameter

setting menu, and press“ ”

and “ ”in the setting menu

to page up / down the setting

items. Press the comfirm/return

button to exit the setting menu;

press“ ”and“ ” to

modify parameters.

Fig 12 Parameter setting for controller

NXZM、NXZ(H)M Automatic Transfer Switch

10

Normal operation of

normal power supply

Failure of normal

power supply T1

Disconnection of

normal power supply

Disconnection of

normal power supply

Disconnection of

normal power supply

Power up of alternative

power supply

Connection of alternative

power supply

Connection of alternative

power supply

Connection of alternative

power supply

Recovery of normal

power supply T2

Normal operation of

normal power supply

Normal operation of

normal power supply

Start-up of generator

Generator output reaches

set value T1

Failure of alternative

power supply T2

Power supply of

alternative power source

Recovery of normal

power supply T2

Disconnection of

alternative power supply

Disconnection of

alternative power supply

Disconnection of

alternative power supply

Power up of normal

power supply

Power up of normal

power supply

Power up of normal

power supply

Power up of normal

power supply T4

Connection of normal

power supply

Connection of normal

power supply

Connection of normal

power supply

Generator shutdown

Flow Chart of Automatic Charge and Automatic

Recovery (Grid - Grid) of Controller

Flow Chart of Automatic Charge and No Automatic

Recovery (Grid - Grid) of Controller

Flow Chart of Automatic Charge and Automatic Recovery

(Grid - Power Generation) of Controller

Failure of normal

power supply T1

Failure of normal

power supply T3

Power up of alternative

power supply

Power up of alternative

power supply

Recovery of normal

power supply

Controller operation process

I: Normal power supply

II: Alternative power supply

T1: Switching delay time

Failure of normal power supply, time before

disconnection of I

T2: Return delay time

Recovery of normal power supply, time

before disconnection of II

T3: Generator start-up delay time: 0s~180s

adjustable

T4: Generator shutdown delay time: 0s~180s

adjustable

Fig 13 Controller operation process

NXZM、NXZ(H)M Automatic Transfer Switch

6

Product troubleshooting

11

Table 5 Non-common fault and solution

Description Causes and solutions

Controller display failure

Press Inquiry button. An indication of E-1 corresponds to

circuit breaker trip on the normal power supply side, and

that of E-2 corresponds to circuit breaker trip on the

alternative power supply side. the code (E-1/E-2) appears.

check if the main power supply has a short-circuit or a

overload failure,After elimination of the failure, switch

the product to the manual mode. Then press stop button

or rotate the handle to stop position then closing. And an

indication of E-3 corresponds to motor failure or motor

line disconnection. The code (E-3) appears, switch the

product to manual mode and press Normal or Alternative

button to confirm whether the product can be converted.

If not, repair or replace the product.

Table 6 Common failure and solution

Description

The display interface of controller is

not on after powering up

Cause Solution

Poor contact at incoming line terminal.

Controller fuse is blown.

Make sure the incoming line terminal is

firmly connected and in good contact.

Replace the fuse.

The product still shows fire control linkage after the fire

control linkage signals are removed from 501 and 502

terminals of the controller.

After the signals are removed, switch the product to

manual mode and press Confirm/Return button. It is only

after this sequence that the controller will retreat from fire

protection linkage mode to normal operation.

When a fault occurs to the normal or alternative power

supply, the product fails to switch to the faulty power

supply automatically or manually.

After the controller detects a failure of the normal or

alternative power supply, it will not switch on the faulty

power supply in manual or automatic mode, unless a

closing is forced with the handle.

The product fails to automatically transfer in automatic

mode when the main power supply has recovered from a

fault to the under (over)-voltage transfer setting value.

There is a +10V return value between undervoltage

transfer value and recovery value, and a -10V return

difference between overvoltage transfer value and

recovery value. The recovery value for power supply must

be bigger than the total of transfer value and return value.

The product is not connected to neutral

phase, especially for a 3P product.

Make sure the incoming line terminal is

firmly connected and in good contact.

Phase loss or failure. Check if the main circuit voltage is

normal.

The displayed voltage of phase A, B

and C is above 300V

One circuit of power supply of the

product is not connected to neutral

pole of the product is connected to

the live wire by mistake.

Conduct wiring correctly according to

the Instructions (main circuit). Wrong

connection will burn down the

controller.

NXZM、NXZ(H)M Automatic Transfer Switch

12

7

Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to

the industrial waste treatment process, or be sent to the recycling station for assortment, dismantling and

recycling according to local regulations.

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO., LTD.

NXZM、NXZ(H)M

Automatic Transfer Switch

IEC/EN 60947-6-1

PD1 Check 15

13

NXZM、NXZ(H)M Automatic Transfer Switch

NXZM、NXZ(H)M

Automatic Transfer Switch

User Instruction

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

This manual suits for next models

1

Table of contents

Other CHINT Switch manuals