CHINT NXZ Series User manual

NO:2021.04

Standard: IEC/EN 60947-6-1

User Instructions

NXZ Series

Automatic Transfer Switch

Safety Warning

1

2

3

4

Only professional technicians are allowed for installation and maintenance.

Installation in any damp, condensed-phase environment with inflammable

and explosive gas is forbidden.

You are prohibited from touching the conductive part when the product is

operating.

Do not install the product at places where gas medium can cause metal

corrosion and insulatin damage.

After installing the product, finishing the inspection of load side line and

splitting the fire-resistance circuit, the controller must be set to “Manual”

position and the product must be set to split position. Switch the controller

to “Auto” position after line fault is eliminated.

To avoid dangerous accidents, the products should be installed and

secured according to the instructions.

This product is applicable to environment A. The product will generate

harmful electromagnetic interference if used in environment B, in which

case, user should take proper protective measures.

5

6

7

1

2

Applicatin Information

a) The normal operating ambient temperature of the product is - 5 ℃ ~ + 40 ℃;

Note: if it is used within the range of - 35 ℃ ~ + 70 ℃, please consult with the manufacturer.

b) If the altitude exceeds 2,000m, please consult with the manufacturer;

c) Class of pollution: Class 3;

d) Main circuit installation category:Ⅲ

e) Enclosure protection class: IP20.

;

Inspection and Test

01

NXZ Automatic Transfer Switch

Inspection

Determine product technical parameters.

Necessary tools

Cross screwdriver

Straight screwdriver

Outer hexagon

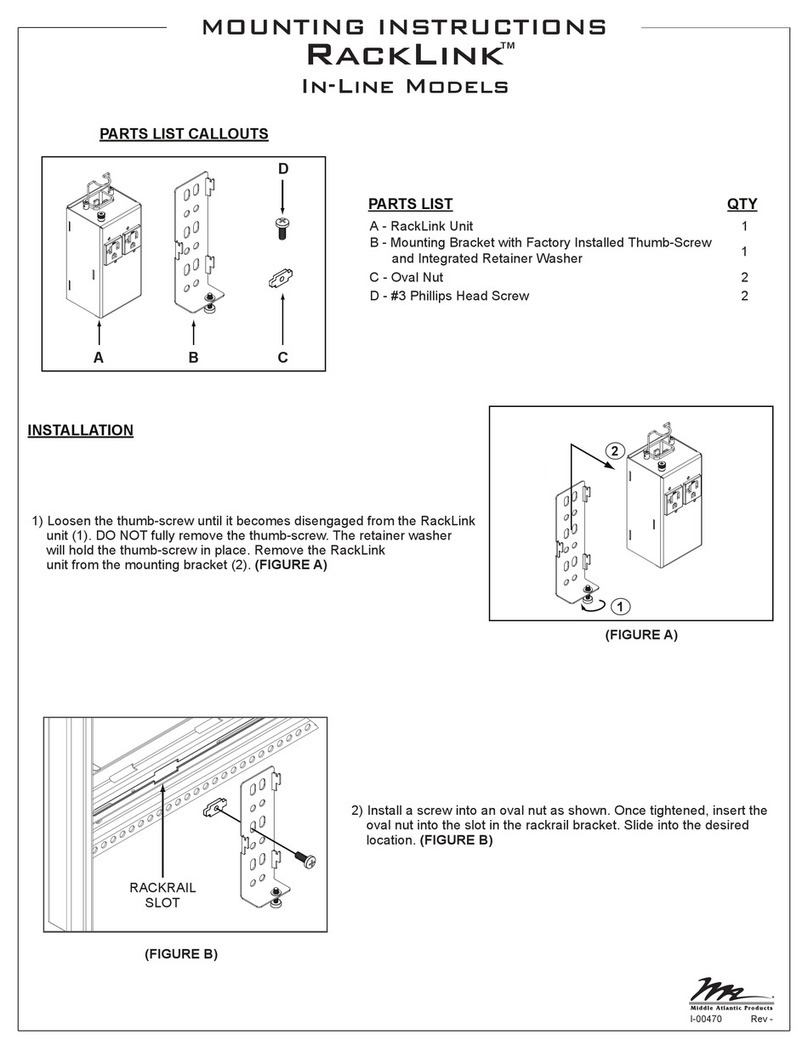

Figure 1 Inspection

2m

M3×12,M3

M4×60,M4 M5×70,M5

×1

×1

×3 ×1

×3 ×1 ×1

M8×100,M8

Product model NXZ-125 NXZ-250 NXZ-630 Note

Specification

of mounting

screw and nut

Standard

Flash

barrier

3P

4P

4

8

9

5

6

1

1

2

2

External

signal

terminal

Type

A

Type

B

Wire

Wire holder

Wire holder

mounting

screw

Mounting

screws and

nuts

Optional, for split

type installation of

display module,

indicated when

ordering.

Tabla 1 Standard accessories

NXZ Automatic Transfer Switch

02

The installation, operation and maintenance of the product are only carried out by

qualified professional.

Double switch off position

① ②

Normal switch on position Standby switch on position

③④

Manual debugging

Power -on test

Setting state mode Start-up mode of generator

Move the orange

button to the

operating

position

Automatic mode

+

-

+

-

SET

+

-

AUTO GENERATCR

AUTO

on on

OFF

SET

ON

OFF

AUTO

MANU

I II

I

II

on on

OFF

SET

ON

OFF

AUTO

MANU

I II

I

II

on on

OFF

SET

AUTO

MANU

I II

Figure 2 Manual debugging

Figure 3-1 Power -on test

03

NXZ Automatic Transfer Switch

A B B1 E F GL H H1 H 2 H 3 H4 A1 Dd

Start-up mode of fire control

Manual mode

+

-

+

-

STOP

B(max)

B1

D

A(max)

A1

E

F

L

G

H4

H(max)

H1

H2

H3

+

-

Normal Standby

Duplexing

Setting

Automatic

Manual

2XØd

3

Outline and Installation Size

Outline and Installation Size of NXZ-125 630~

Unit: mm

Product

model

Outline size Installation size

NXZ-125

NXZ-250

NXZ-630

245

295

436

130

175

272

220

304

461

30

35

58

4.5

6

9

5.5

8

13

126

175

230

21

29

41

71

99

131

107.5

146

192

21

29

41

229.5

275

400

113

152

240

4.5

6

9

21.5

27.5

43

MANU

on on

OFF

SET

ON

OFF

AUTO

MANU

I II

I

II

AUTO

on on

OFF

SET

OFF

AUTO

MANU

I II

I

II

OFF

Figure 3-2 Power -on test

Figure 4 Outline and Installation Size of NXZ-125~630

Tabla 1 Manual debugging

NXZ Automatic Transfer Switch

04

1 The phase sequence of normal and standby power supply must be

consistent. Phase N wiring cannot be wrongly connected. Normal

power supply has priority over standby power supply in terms of wiring

of power line end.

The front end of the normal and standby main circuit of the product

shall be equipped with SCPD (fuse) produced by the company

consistent with the identification on the product nameplate or SCPD

(fuse) with the same breaking capacity.

2 For the wiring of the load end of 3P product, the N pole is not

connected, and the wiring of its power line end is same as 4P product.

During wiring, incorrect N-pole wiring may result in the

burn-out of the controller!

Main circuit conductor

Normal power bus Alternative power bus.

Load bus

4P product wiring diagram

Main

circuit

Normal power supply I Normal power supply Ialternative power supply II alternative power supply II

1 3 5 N1 3 5 N1 3 5 N1 3 5 N

3Pole 4Pole

4

Installation and Wiring

Installation method

Figure 5 Installation method

NXZ Automatic Transfer Switch

≤a

≤b

≥φc≤a

≤b

≥φc

abc

NXZ-125

NXZ-250

NXZ-630

8

10

15

21.5

27.5

43

6

8

12

2

25~50mm

70~120mm2

185mm (≤320A)

2

240mm (400A)

2

150mm (500A)

2

185mm (630A)

2

6N·m

12N·m

5610

30N m·

M6×16

M8×20

M12×35

NXZ-125 NXZ-250 NXZ-630

1

1

1

1

2

2

Wire connection

Unit: mm

Product model Cable specifications Number of conductors allowed

to be clamped into the terminal

Product model

Specification of binding screw

Torque

Wrench

05

Figure 6 Wire connection

Tabla 3 Sectional area, width and number of copper wire

NXZ Automatic Transfer Switch

06

Note: Only communication terminal wiring is added to type B controller

on the basis of the signal and control terminal wiring of type A controller.

RS485

Active AC230V/0.5A

Indication of normal state Indication of alternative state

Normal neutral

Power signal

Power signal

Alternative neutral

Closing signal

Closing signal

The user should connect corresponding terminal as needed

Passive input

Passive output

Passive contact

Note: The dash line refers to the internal circuit of controller

Auxiliary power

supply

Fire control

signal

Control of power

generation start-up

Auxiliary power

Passive Input Passive Output

Fire Linkage Control

Split interface

Generator control

II Power indicator

Passive outputAC230V Output

I Power indicator

Signal and control terminal wiring

Figure 7 Type A controller

AC230V Output

07

NXZ Automatic Transfer Switch

Used in grid - power generation mode only

and connected to the generator as needed,

or omitted. In case the normal power supply

fails,terminals 502 and 503 are connected.

1.Used in grid - power generation mode and may be omitted, but the

delay of generator start-up defaults to 0s.

2.Communication terminal wiring must be connected.

Normal neutral

Normal power supply

Normal closing

Alternative neutral

Alternative power supply

Alternative closing

To fire control room

State of internal contact

of the normal controller

of normal power supply

To the remote power

of generator

Connected to upper computer (RS485)

Terminals 401 and 402 can only be connected to passive signal.

If the fire control signal is active signal, the normally open contact of

relay must be connected to the controller after switching through the

relay. Terminals 403 and 404 are connected after the duplexing of fire

control. After the fire control signal being removed, the normal

operating state can be restored by pressing any key on the controller.

+ -

RS485

+ -

Figure 8 Type B controller

Typical application

Auxiliary power

Passive Input Passive Output

Fire Linkage Control

Split interface

Generator control

II Power indicator

Passive output

AC230V Output

I Power indicator

AC230V Output

Figure 9 Typical application

NXZ Automatic Transfer Switch

08

1. Any form of electrical connection is prohibited between the two groups of terminals; otherwise it may result in the burn-out of controller!

Indication of normal state Indication of alternative state

2. Terminals 401 and 402 of type A and type B controllers can be connected with passive closing signal only to achieve fire control

linkage. If they are directly connected to any active signal, the controller will be burnt out.

① The product is in the state. Move the orange button

the manual position.

to

② Pull out the limiting piece and lock it.

5

Installation of Isolation Padlock

Figure 10 Installation of isolation padlock

09

NXZ Automatic Transfer Switch

54

109

127

829

6

Split-type Display Module

Outline size

127

111~112

55~56

2Xφ3.5

Installation cabinet opening size (mm)

Figure 11 Split-type display module

Figure 12 Installation cabinet opening size

NXZ Automatic Transfer Switch

10

3

2

0.8N·m

ST2.9

4

2 nuts

2 screws

Note: The nuts are installed by fastening screws on the back.

0.9N m·

M3

5 6

7

12

2

Split (cabinet surface) installation of display module

Figure 13 Split installation of display module

NXZ Automatic Transfer Switch

AUTO MANU

ON

OFF

Over

Under

Over

Under

ON

OFF

SET GENERATOR STOP +

-

Ⅰ on

OFF

on Ⅱ

SET

AUTO

MANU

7

Display and Operation Interface

Description of the operation interface of controller display module

① Indication of automatic and manual operating modes;

② Indication of state setting;

③ Indication of generator start-up signal;

④ Indication of fire control linkage function start-up;

⑤ The display area of normal power state parameters shows normal supply voltage parameters with

switching delay time in the state and of operation , and shows setting items parameters in the setting

state;

⑥ The display area of alternative power state parameters shows standby alternative voltage parameters

and return delay time in the operating state and setting parameters in the setting state;

11

⑦ Setting button (press this button to enter the parameter setting menu of controller);

⑧ Select button of automatic / manual switching mode

It is used to select the automatic / manual switching mode in normal use and to save and exit in the

setting state;

⑨ Off button

In the manual control mode, if any of the two circuits of power supply is normal, press this button to

switch to the off position, while in the setting state, this button is used to set parameter decrease;

⑩ Switching button of normal power supply

In the manual control mode, if the switch is in the alternative position, press this button to switch to

the normal power supply, while in the setting state, this button is used as the page-up button of

setting items;

Switching button of alternative power supply

In the manual control mode, if the switch is in the normal position, press this button to switch to the

alternative power supply, while in the setting state, this button is used as the page-down button of

setting items;

+button

This button is used to set parameter increase in the setting state.

Ⅰ

Ⅱ

Figure 14 Display and operation interface

NXZ Automatic Transfer Switch

12

Parameter setting of controller display module

AUTO

MANU

For setting of the switching value of normal power supply

undervoltage, press to increase and to decrease.

+

For setting of the switching value of normal power supply

overvoltage, press to increase and to decrease.

+

For setting of switching delay, press to increase and

to decrease.

For setting of the switching value of alternative power supply

undervoltage, press to increase and to decrease.

+

+

SET

AUTO

ON

OFF

For setting of the switching value of alternative power supply

overvoltage, press to increase and to decrease.

+

For setting of return delay, press to increase and

to decrease.

+

For setting of the delay of generator stop, press to

increase and to decrease.

+

For setting of the delay of generator start-up, press

to increase and to decrease.

+

For setting of switching mode, press and keys to change the

switching mode (if the last digital is 0, it refers to grid - grid automatic

charge and automatic recovery; if the last digital is 1, it refers to automatic

charge and no automatic recovery; if the last digital is 2, it is grid - power

generation mode).

+

I

II

SET

AUTO

MANU

AUTO

MANU

AUTO

MANU

AUTO

MANU

AUTO

MANU

AUTO

MANU

AUTO

MANU

AUTO

MANU

SET

SET

SET

SET

SET

SET

SET

SET

Figure 15 Parameter setting of controller display module

For setting of communication address, press to increase and

to decrease.

For setting of parity check, 0 refers to no check, 1 refers to odd

parity, and 2 refers to even parity.

Setting of baud rate: 1:2400 2:4800 3:9600 4:19200

5:38400

+

NXZ Automatic Transfer Switch

13

AUTO

ON

OFF

I

II

AUTO

MANU

SET

AUTO

MANU

AUTO

MANU

AUTO

MANU

SET

SET

SET

SET

(Note: Please ask our after-sales service staff for communication protocol.)

■ Button instruction:

When the controller is in operation, press th e s ett ing bu tto n t o s et the interface of

parameter setting menu, and press “ ” and “ ” in the setting menu to page up / down

the setting items. Press the automatic / manual button to exit the setting menu; press “ ”

and “ ” to modify parameters.

+

Note: The parameter settings for display module and communication function default as follows:

Setting of undervoltage switching value: Default to 187V, user-settable 160V~200V;

Setting of overvoltage switching value: Default to 263V, user-settable 240V~290V;

Setting of switching delay: Default to 5s, user-settable 0s~300s;

Setting of return delay: Default to 5s, user-settable 0s~300s;

Setting of generator start-up delay: Default to 5s, user-settable 0s~300s;

Setting of generator shutdown delay: Default to 5s, user-settable 0s~300s;

Switching and power mode: Default setting: automatic charge and automatic recovery (grid - grid), and user

can set automatic charge and no automatic recovery (grid - grid), automatic charge and automatic recovery

(grid - power generation);

Default parameter setting for communication function: address: 1; baud rate: 9600bps; parity check bit: odd

parity; data bits: 8; stop bit: 1.

Figure 16 Parameter setting for communication function

NXZ Automatic Transfer Switch

Normal operation of

normal power supply

Failure of normal

power supply T1

Disconnection of

normal power supply

Disconnection of

normal power supply

Disconnection of

normal power supply

Power up of alternative

power supply

Connection of alternative

power supply

Connection of alternative

power supply

Connection of alternative

power supply

Recovery of normal

power supply T2

Normal operation of

normal power supply

Normal operation of

normal power supply

Start-up of generator

Generator output reaches

set value T1

Failure of alternative

power supply T2

Power supply of

alternative power source

Recovery of normal

power supply T2

Disconnection of

alternative power supply

Disconnection of

alternative power supply

Disconnection of

alternative power supply

Power up of normal

power supply

Power up of normal

power supply

Power up of normal

power supply

Power up of normal

power supply T4

Connection of normal

power supply

Connection of normal

power supply

Connection of normal

power supply

Generator shutdown

Flow Chart of Automatic Charge and Automatic

Recovery (Grid - Grid) of Controller

Flow Chart of Automatic Charge and No Automatic

Recovery (Grid - Grid) of Controller

Flow Chart of Automatic Charge and Automatic Recovery

(Grid - Power Generation) of Controller

Failure of normal

power supply T1

Failure of normal

power supply T3

Power up of alternative

power supply

Power up of alternative

power supply

Recovery of normal

power supply

Motion flow of controller

14

I: Normal power supply

II: Alternative power supply

T1: Switching delay time

Failure of normal power supply, time before

disconnection of I

T2: Return delay time

Recovery of normal power supply, time before

disconnection of II

T3: Generator start-up delay time: 0s~300s

adjustable

T4: Generator shutdown delay time: 0s~300s

adjustable

Figure 17 Motion flow of controller

NXZ Automatic Transfer Switch

8

Installation of Flash Barrier

15

Inter-phase flash barrier

①Be sure to install flash

barriers before product

operation.

Do not operate the

product with wet

hands.

Check if the wiring is

correct.

After installation, the

insulation resistance to

the ground shall not be

less than 10mΩ.

Before insulation test,

please pull out the

product controller first.

②

③

④

9

Common Faults and Solutions

Table 4 Non-common Faults and Solutions

Description Causes and solutions

The state of fire control linkage remains after the fire

control linkage signal of terminals 401 and 402 of the

controller is removed.

When the normal power supply or alternative power

supply fails, the product cannot be manually or

automatically switched to the failed circuit of power supply.

In automatic state, when the normal power supply recovers

from the fault to the set undervoltage switching value, the

product does not switch automatically.

After the signal is removed, the user needs to press any

key to exit the fire control linkage state and resume the

normal state of operation.

The controller will not switch on and connect to the failed

power supply either manually or automatically when it

identifies the failure of normal power supply or alternative

power supply, unless it is switched on with the handle.

The undervoltage switching value and recovery value of

the controller have +10V return difference, and the

overvoltage switching value and recovery value have -10V

return difference, so the power supply recovery value must

exceed the switching value plus the return difference.

Figure 18 Inter-phase flash barrier

NXZ Automatic Transfer Switch

16

Table 5 Common Faults and Solutions

Description

The indicator lamp of controller is not

on after powering up.

Causes Solutions

Poor contact at incoming line terminal.

Failure of the fuse on the controller.

Make sure the incoming line terminal is

firmly connected and in good contact.

Install a new fuse.

Phase loss of controller. Corresponding phase voltage is lower

than the set undervoltage.

Eliminate the wiring failure.

Poor contract of corresponding phase

wiring.

Power failure, switch to the normal

power supply.

The controller displays the failure of

normal switch in switching. The controller is in manual state. Move the orange button to the electric

position.

The controller displays the voltage of

phases A, B and C above 300V.

One circuit of power supply of the

product is not connected to the zero

line or the N pole of the product is

connected to the live wire by mistake.

Conduct wiring correctly as per the

instructions (main circuit). Incorrect

connection to the live wire may burn

out the controller.

10

Warranty

Under the normal storage and transportation conditions and on the premise that the product

packaging or product itself is in good condition, the warranty period of the product is 36 months from the

date of production, and the following situations are not covered by the warranty:

1)Damage caused by user’s improper use, storage and maintenance.

2)Damage caused by the organization or personnel not designated by the company or by the user's

own dismounting and repair.

3)The product exceeds the warranty period.

4)Damage caused by force majeure.

11

Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to

the industrial waste treatment process, or be sent to the recycling station for assortment, dismantling and

recycling.

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO., LTD.

NXZ

Automatic Transfer Switch

IEC/EN 60947-6-1

PD1 Check 15

17

NXZ Automatic Transfer Switch

NXZ Series

Automatic Transfer Switch

User Instructions

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

This manual suits for next models

3

Table of contents

Other CHINT Switch manuals