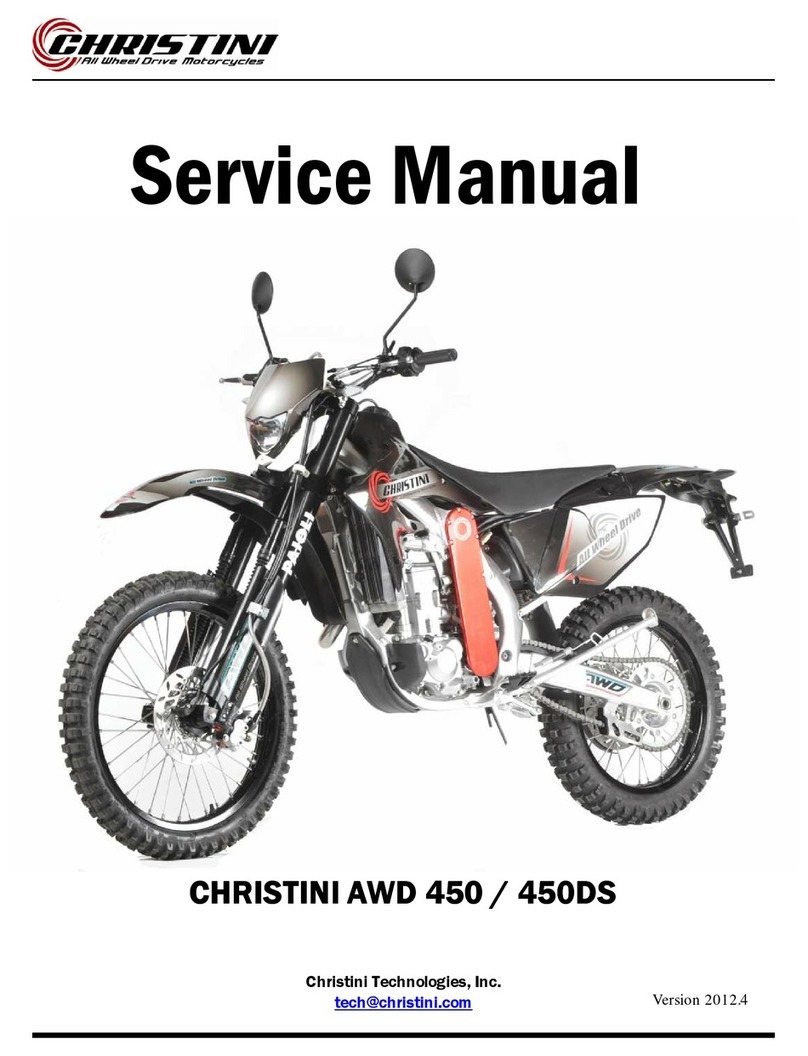

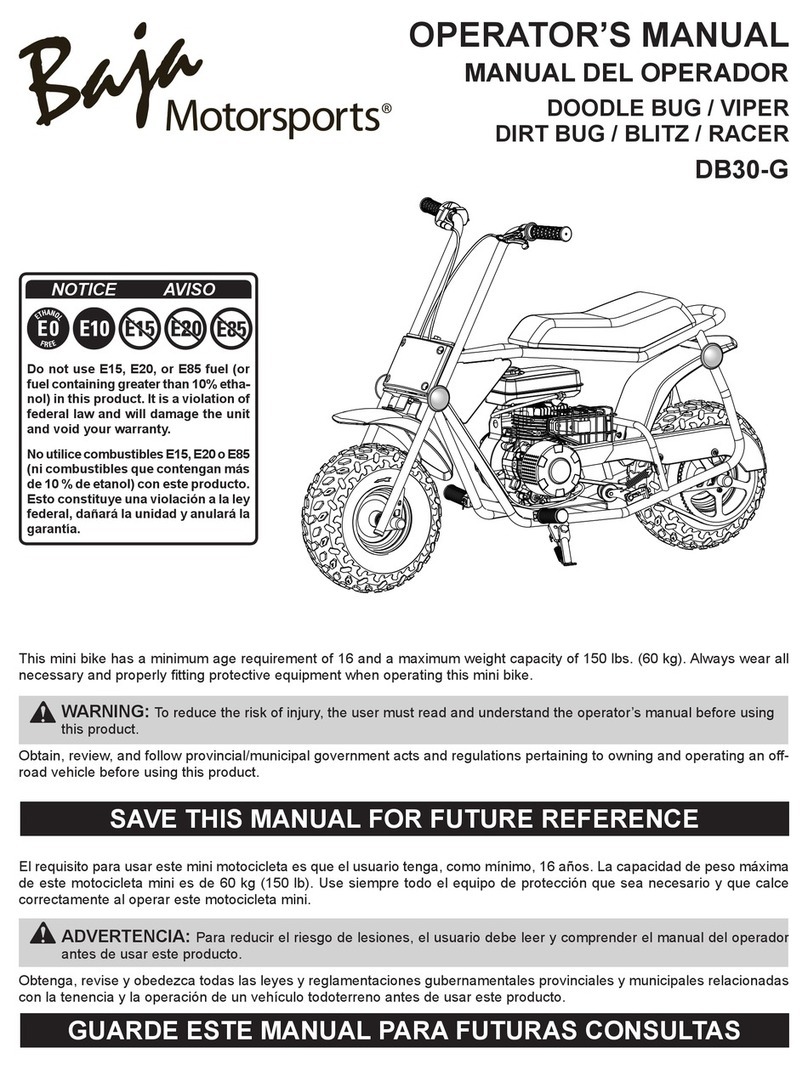

Christini AWD 450DS User manual

Page

Introduction

Congratulations for making the choice to become and AWD rider!

The instructions in this book will provide a simple and understandable guide to your motorcycle’s operation and

maintenance

Whenever you see the symbols shown below, heed their instructions!

Always follow safe operating and maintenance practices

If improperly conducted, the sport has the potential to cause environmental problems as well as conflicts with other

people Responsible use of your motorcycle will ensure that these problems and conflicts do not occur

TO PROTECT THE FUTURE OF YOUR SPORT, MAKE SURE YOU USE YOUR BIKE LEGALLY, SHOW

CONCERN FOR THE ENVIRONMENT, AND RESPECT THE RIGHTS OF OTHER PEOPLE

This manual should be considered a permanent part of the motorcycle and should remain with the motorcycle when

resold or otherwise transferred to a new owner or operator

We reserve the right to amend this motorcycle service manual due to periodic improvements and upgrades

WARNING

This warning symbol identifies special instructions or procedures which, if not correctly followed, could result in personal

injury, or loss of life

CAUTION

This caution symbol identifies special instructions or procedures which, if not strictly observed, could result in

damage to or destruction of equipment

NOTE

This note symbol indicates points of particular interest for more efficient and convenient operation

Page 3

Table of Contents

General Bike Service

General Information 5

Lubricant System Specifications 7

Cooling System Specifications 7

Tire Specifications 8

Battery Specifications 8

Spark Plug Specifications 8

Basic Operating Instructions 9

Precaution 9

Pre-Ride Inspection 10

Starting/Stopping Engine 11

Break-In 12

Maintenance 13

General Service Information 13

Maintenance Schedule 13

Service Information 16

General Specifications 5

Wiring Diagram 33

Page 4

Table of Contents

AWD Service

Required tools 35

AWD detailed illustration 36

Routine maintenance schedule 38

AWD clutch test 39

AWD sprag test 40

AWD chain removal 41

AWD engagement switch 45

Front wheel removal 50

Front wheel service 52

Fork removal and installation 59

Dropout service 61

Fork spline bearing service 70

Boot Replacement 75

Triple clamp removal 77

Triple clamp service 79

Main drive shaft removal 94

Head tube bearing service 95

Triple Clamp Installation 98

Gearbox removal 102

Gearbox service 103

AWD clutch removal 108

AWD clutch Service 109

Troubleshooting 113

Warranty 114

Main drive shaft installation 97

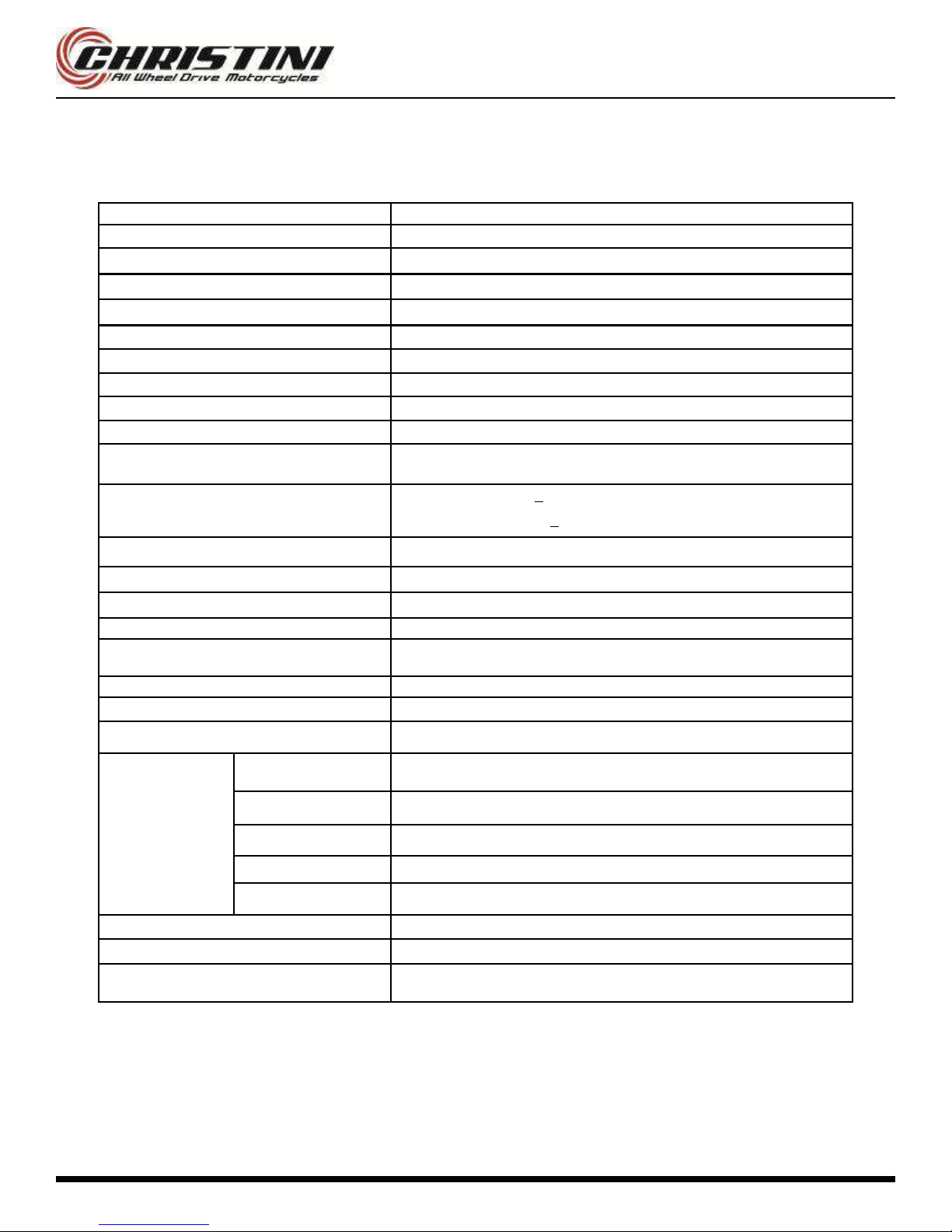

Page 5

I T E M

TECHNI CAL D A T A

O F FR OAD

DUAL SP OR T

M O TA RD

D I MEN S I O N S

OVERALL L E N G T H

2175mm

OVERALL W IDTH

810mm

OVERALL HE I G H T

1240mm

F/R W HELL AXI S DIS-

T A N CE

1505mm

SEAT HEI G H T

60m m

GROUND CLE A R A N CE

320mm

N.W

118kg

130kg

130kg

C HA SSI S

FRAME T YP E

ALU MIN I U M AL L O Y TW IN-SPAR

FRON T TI RE S I Z E

80/100-21

80/100-21

110/70-17

REAR TI R E S I Z E

110/ 0-1 ’ ’

110/100-18

140/70-17

FRON T S US P E N S I ON

INVER TE D C A R T R I DGE FORK W ITH R E-

BOUN D C O M P R E S S I ON-DAMP IN G A D J U S T

REAR S USP E N S I ON

MON OS H O C K W I TH SPRING-PREL OA D , R E -

BOUN D A N D C O M P R E SSION- D A M P I N G A D -

JUS T

FUEL TAN K C A P A C I TY

8.0L W ITH R E SERVE V A L V E

E N G IN E

TYPE

SINGLE CYLINDER, 4-STROKE, LIQUID COOLED

MAX POWER

32KW /7500RPM : 43.5HP/7500R P M

General Specifications

General Information

Page 6

General Information

RATED POWER

3 0 .5KW / 7 0 0 0 RP M

MAX TORQUE

4 2 . 5N M/ 6 5 0 0 R P M

IDLE SPEED

1700±150 RPM

FUEL CONSUMPTION

≤340 g/kW.h

BORE X STROKE

6×62.1 mm

DISPLACEMENT

44 ml

COMPRESSION RATIO

11:1

VALVE TRAIN

CHAIN DRIVE SOHC FOUR VALVE

LUBRICATION TYPE

PRESSURE SPRAY

LUBRICATION OIL TYPE

SAE 10W-40

IGNITION ADVANCE DEGREE

12°BTDC [3000RPM]

VALVE CLEARANCE(COOL)

INTAKE VALVE: 0.16+0.03 mm

EXHAUST VALVE: 0.28+0.03 mm

DECOMPRESS CLEARANCE

EX VALVE CLEARANCE (0.28mm)+0.15mm=0.43mm

SPARK PLUG TYPE

DENSO IK24/IK27

DIMENSION

350mm×2 7mm×423 mm

DRIVE TYPE

CHAIN

DRIVE SPROCKET

13T

CLUTCH TYPE

MANUAL, MULTI-WET

TRANSMISSION TYPE

CONSTANT MESH, 5 SPEED, LEFT FOOT OPERATED

PRIMARY ADJUCTION RATIO

2.73 (63/23)

GEAR RATIO

1ST

2.230(2 /13);

2ND

1.625(26/16)

3RD

1.235(21/17)

4TH

1.000(1 /1 )

5TH

0.826(1 /23)

IGNITION TYPE

DC/AC CDI

STARTER

KICK / ELECTRIC

STARTING CAPACITY

≤15 s

General Specifications — Continued

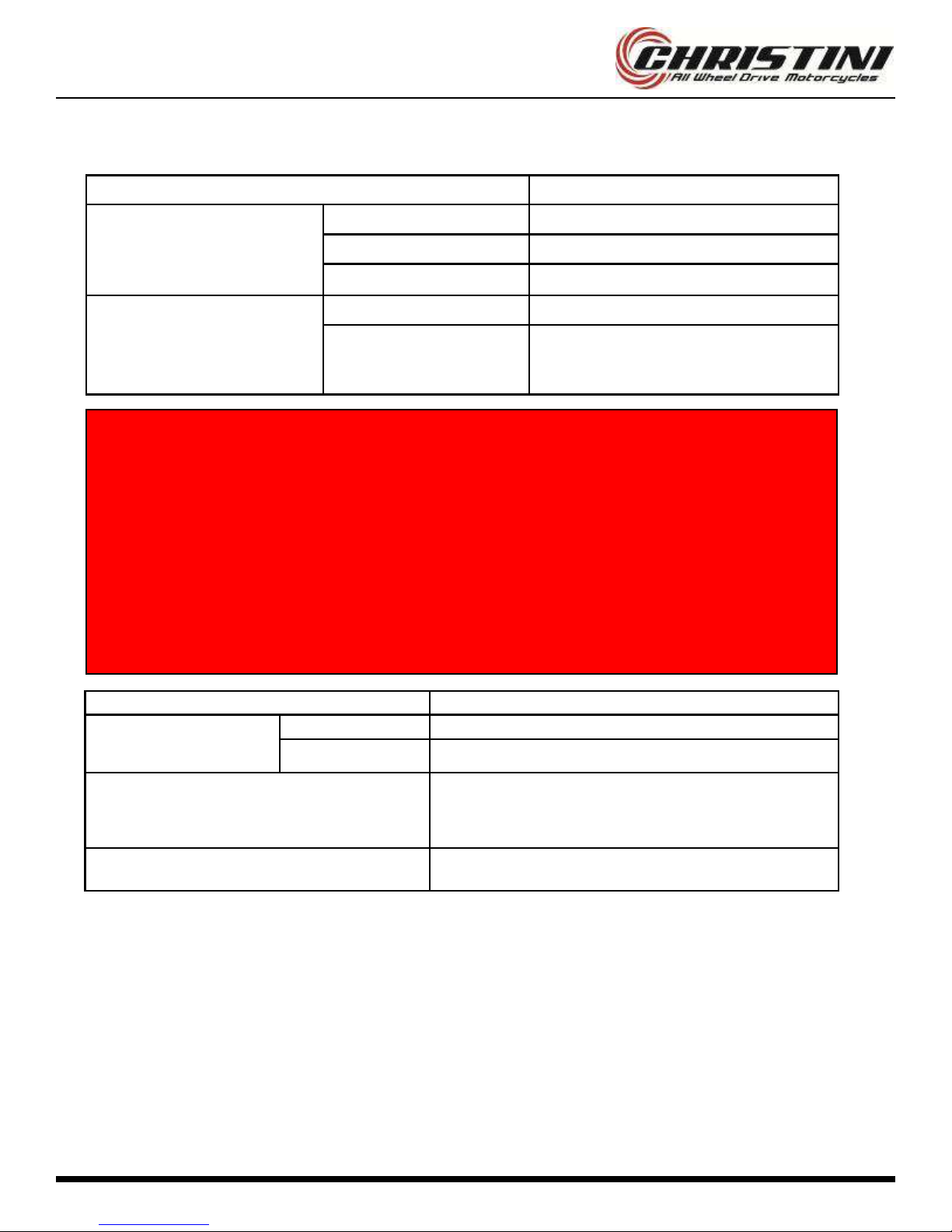

Page 7

General Information

Lubrication System

I T E M

D A TA

ENGIN E O I L 8 7 0 m l

API SG o r h i g h e r

SAE10W-40

A T DRAI N IN G

670 m l

A T FIL T E R C H A N GE

700ml

A T DISAS S E M B L Y

870m l

TRANS MIS S I O N O I L 5 0 m l

API SG or higher

SAE 10W-40

A T DRAI N IN G

850ml

A T DISAS S E M B L Y

00m l (Appro x i m a t e l y On e Quar t )

I T E M

D A TA

COOLA N T C A P A C I T Y

A T CHA N G E

1.11 liter

D I SA S S E M B L Y

1.20 liter

A N TIF RE EZ E

HIGH QU A L I T Y E THYLENE GL Y COL A N T I F R EEZE

CON TAI NI N G S I L I CATE-FREE C O R R O S I ON IN-

H IBI TO RS

S TANDA RD S C O OLANT CONC E N T R A -

T I ON

1:1 MIXTU R E W ITH DISTILL ED W ATER

Coolant System

WARNING:

Low Oil level in Transmission can cause transmission failure.

Warranty Voi if transmission oil is not kept at man atory level.

Failure to change transmission oil an oil filter on sche ule maintenance an

at recommen e level of 950ml can cause the transmission to lock an cause

serious injury or eath.

Page 8

General Information

I T E M

S T AN DA R D S

REPAIR L I M I T

COLD TI R E P R E S S URE

33/2.3 (psi / b a r )

MAX LOAD

F R O N T

430 / 1 5 (lbs/kgs)

R EA R

548 / 265 (lbs / k g s )

Tire Specifications

I T E M

D A TA

B A T TE R Y

C A P AC I T Y

12V-6Ah

CURRE N T C O N S U MPTION

MAX 0.1mA

V OL TAG E ( 20

0

/68

0

F )

FULL

13.0-13.2V

Battery Specifications

I T E M

D A TA

SPARK P L U G

S T AN DA R D S

D E N SO

IK24

O P TI O N A L

NGK

I F R8H -11

Spark Plug Specifications

Page 9

Basic Operating Instructions

PRECAUTION

For your safety, you must obey the following 9 rules while riding the motorcycle:

- Wear your helmet: Safe ride begins with putting on helmet You must wear helmet while riding

- Wear simple and convenient clothes Pay attention to avoid wearing loose clothing Please wear tight and

closed clothes to ensure that your hands and feet move freely

- Check the pre-ride inspection before riding: Always check before starting the engine

- Get familiar with the assembly and performance of this motorcycle

-Your riding skills and knowledge of this motorcycle are the basis of safe riding You should practice riding

in an open area without vehicles to master riding skills

- Get to know the speed limit of safe riding

-The motorcycle’s safe riding speed depends on the ground condition and your riding skills Knowing the

speed limit based on your riding ability can avoid accidents

- Do not ride after drinking or taking medicine

- This bike is designed for adult operators only Be sure you are allowed to ride this kind of motorcycle

based on your local laws

- Pay special attention to riding in rain

-Riding on wet roads is very dangerous Turn during acceleration and a keep safe distance from vehicles in

front of your motorcycle Remember that the braking distance in rain is twice of that in sunny days, and

please pay special attention to traffic signs Once the condition of the road changes, reduce your speed

-Exhaust gas contains harmful substance such as carbon monoxide Only start the engine in well-ventilated

places

Page 10

Basic Operating Instructions

PRE-RIDE INSPECTION

Check the following before each ride.

For Enduro and Super Moto Models version check below for additional requirements

Inspection Item Inspection Objective

Engine oil

Inspect for proper fill level

Transmission oil

Inspect for proper fill level (900ml)

Coolant

Inspect for proper fill level

Fuel

Be sure there is enough fuel to ride planned distance

Cooling system

Inspect for leaks, cracks, and fluid flow

Throttle

Check for free travel of throttle grip and that the throttle grip has a smooth

operation and in both the forward and back to the closed position

Clutch

Adjust the clutch cable to fully disengaged

Steering

Be sure the bars move freely from lock to lock and steering head is tight

Brake

Inspect for free travel of pedal and lever and that there is full braking power

Tire

Check tire pressure and inspect tires for cracks

Spokes

Inspect and tighten loose spokes if necessary

Other Bolts and Parts

Inspect attachment points and other bolts to ensure they are tight

Exhaust muffler

Inspect for loose bolts and the exhaust is secure

WARNING

You should practice driving in a safe and spacious area if you ride this type of motorcycle for the first time

Riding with one hand is extremely dangerous; you should hold the two handle bars tightly with your both hands In no cir-

cumstances can you release the handle bars

Do not accelerate when turning You must reduce the speed to safety range

If the ground is wet or slippery, you must reduce the speed

At the exit of a tunnel or valley or when meeting large vehicles, you must be careful and reduce the speed

Obey the transportation rules and limit your speed

Page 11

Basic Operating Instructions

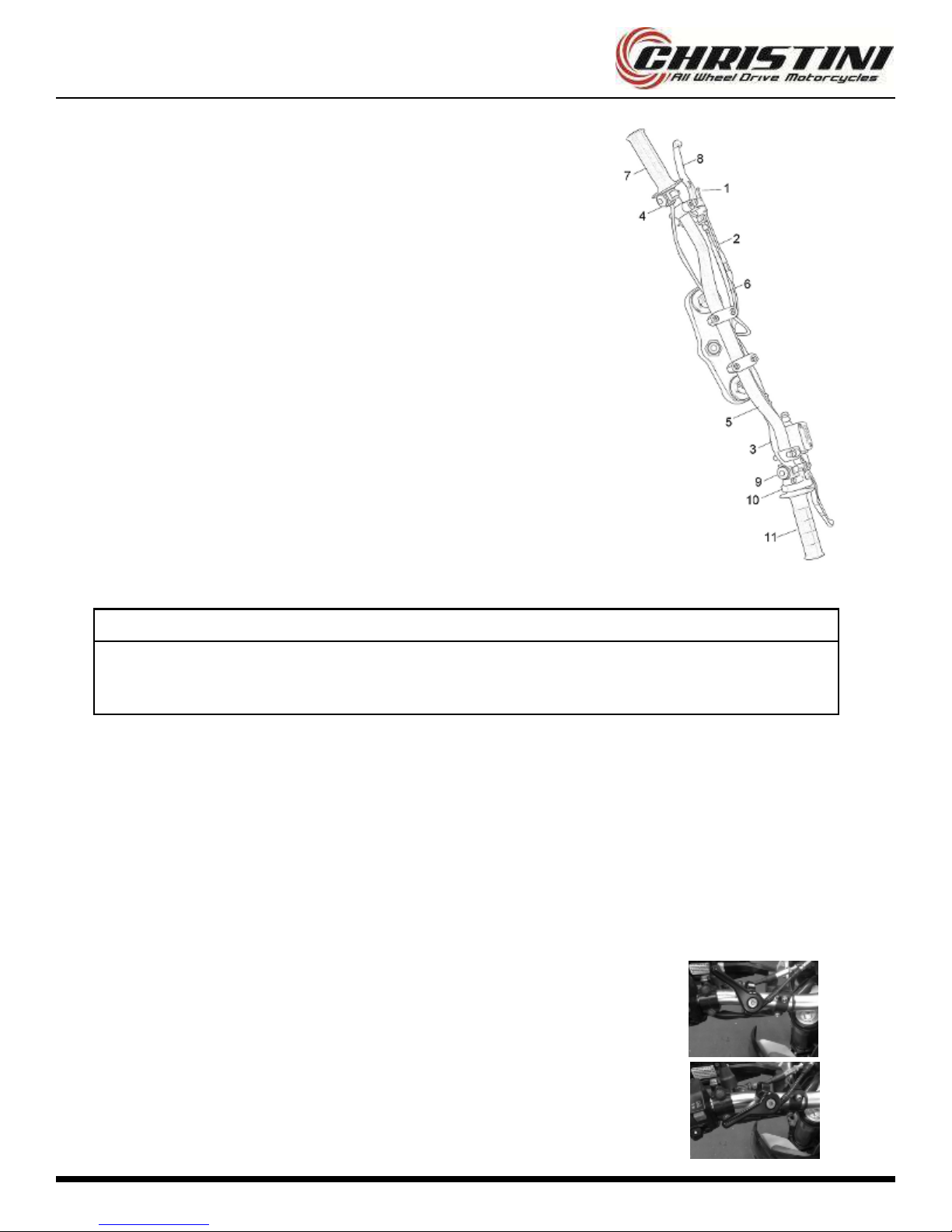

Starting the engine — EFI Models

Shift the transmission into neutral

Pull in the clutch lever when starting the engine For Dual Sport and motard ver-

sion, turn the ignition switch to “ON” and push the engine start/stop switch to

right side

(For Off-road 450E version, the right switch should be turned to the left)

Close the throttle grip(11), operate the kick starter starting from the top of the

kick starter stroke, kick through to the bottom with rapid, continuous motion

COLD START:

For Electric Start, push and hold the button for 2-3 seconds Then release Then

Push and hold button again for 5 seconds If the bike does not start, repeat pro-

cedure

If the engine backfires, it may be flooded If this happens, Cycle the key switch

on/off then back on Then hold the throttle 100% open and crank the engine

with the starter This disables the Fuel Injection and cleans out the cylinder

If you still have starting issues, the battery may be low and try kick starting the

bike

Once engine is started, let the EFI go through the high idle warm up for 10-20

seconds

Stop the engine

Shift the transmission into neutral

Push the stop button(4) (or push the engine start/stop switch to left side for enduro and motard version)

In case emergency engine stop, press the stop button directly (or push the engine start/stop switch to left side for enduro and

motard version)

Turn the ignition switch to “OFF” if available on your bike

AWD Engagement

Switch Forward will switch OFF the AWD system You can do this at any speed

Switch Backward will turn ON the AWD system This should only be done at low speeds (first gear)

CAUTION

Do not keep the starter button pressed for more than 5 seconds at a time Release the starter button for approximately 10 seconds

before pressing it again

If the clutch lever(8) is pulled, the engine could be started in any gear

Page 1

Basic Operating Instructions

BREAK-IN

During initial break-in newly machined surfaces will be in contact with each other and these surfaces will wear in quickly Break-in

maintenance at 150km is designed to compensate for this initial minor wear Timely performance of the break-in maintenance will

ensure optimum service life and performance from the engine

The general rules as follows:

Start the engine and let it run at idle until the engine is thoroughly warmed up

Avoid full-throttle starts and rapid acceleration

Maximum continuous engine speed during the first 150km must not exceed 5,000 rpm (or 10 hours Max)

After 150km ride maintenance the machine per the maintenance schedule

After the break-in procedure has been properly carried out, the motorcycle is ready for regular operation However, since

premature high r/min (rpm) will lead to engine trouble, take care to use the necessary skill and technique in operating the

motorcycle

Never run the engine with full throttle at low speed operation This rule is applicable not only during break-in but at all

times

This procedure should be followed each time:

•

Piston is replaced

•

Piston rings are replaced

•

Cylinder is replaced

•

Crankshaft or crank bearing are replaced

CAUTION

The motorcycle is shipped with break in Oil only! Once the engine is run for an initial 30 minutes, drain and

replace the oil with a Synthetic

API SG or higher

SAE 10W-40

Failure to do so may decrease the engine transmission life or cause premature failure

Page 13

Maintenance

The Maintenance Schedule specifies how often you should have your motorcycle served, and what things need attention It is es-

sential that your motorcycle be served as scheduled to retain its high level of safety, dependability, and emission control perform-

ance Remember, proper maintenance is your responsibility

PRECAUTION

Make sure the engine is off before you begin any maintenance or repairs

Exhaust contains poisonous carbon monoxide Be sure there is adequate ventilation whenever you operate the engine

Let the engine and exhaust system cool before touching

Be careful when working around gasoline Keep cigarettes, spark, and flames away from all fuel related parts

MAINTENANCE RULE

Place the motorcycle on the firm level ground using optional work stand or equivalent support

Use genuine or recommend part and lubricants or other equivalents Parts that do not meet design specifications may cause dam-

age to the motorcycle

Use only metric tools when servicing the motorcycle, metric nuts, bolts, screws are not interchangeable with British fasteners

Always replace with new gaskets, O-rings, cotter pins, piston pin clips, snap rings, etc after disassemble engine

When tightening bolts and nuts, begin with larger diameter or inner bolt first Then tighten to specified torque diagonally in incre-

mental steps unless a particular sequence is specified

Clean parts in cleaning solvent upon disassembly ,lubricate and sliding surface before assembly

Always inspect all parts for proper installation and operation after reassemble

Route all electrical wires, cables and harness routing as designed

MAINTENANCE SCHEDULE

Required maintenance schedule is based upon average riding condition Sustained high speed operation, or operation in unusually

wet or dusty conditions, will require more frequent service than specified in the REQUIRED MAINTENANCE SCHEDULE See SPECIAL

MAINTANCE SCHEDULE for competition maintenance need

Perform the Pre-ride inspection at each scheduled maintenance period

Symbol in maintenance schedule means:

I Inspect and Clean , Adjust , Lubricate or Replace if necessary

C Clean

R Replace

A Adjust

L Lubricate

* Unless the rider is mechanically qualified and has proper tools, see authorized dealer for service

* * Special maintenance strongly recommend to look for authorized dealer service

NOTE1 Clean after every ride for dusty conditions

NOTE2 Replace every 2 years Replacement requires mechanical skill

NOTE3 Replace after the first break-in ride

NOTE4 Inspect after the first break-in ride

NOTE5 Replace the transmission oil once change the clutch plate

Page 14

Maintenance

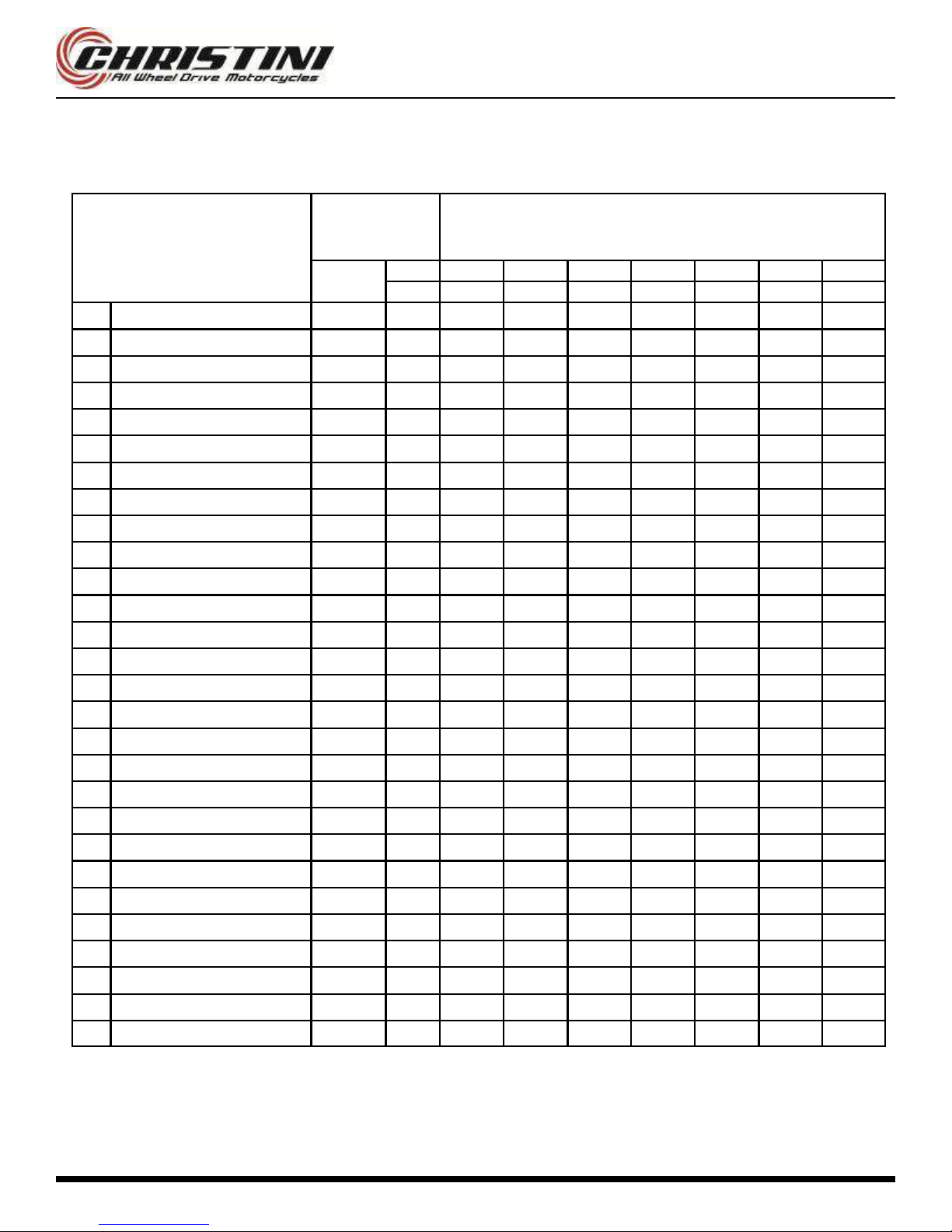

Required Maintenance Schedule

Maintenance Schedule in Kilometers

ITEMS

NOTE

km 150 1500 3500 6000 000 12000 15000

Time 10 Hrs

* ENGINE OIL (NOTE 3) R R R R R R R

* ENGINE OIL FILTER (NOTE 3) R R R

TANSMISSION OIL R R R R R R R

AIR CLEANER (NOTE 1) R R

RADIATOR COOLANT (NOTE 3) R R

* VALVE CLEARANCE (NOTE 4 ) I I

SPARK PLUG R R

* * FUEL FILTER (In Tank)

C C

* THROTTLE CABLE I I I I I I I

* THROTTLE OPERATION I I I I I I I

CRANKCASE BREATHER (NOTE 2) I I I I I I I

COOLING SYSTEM I I I I I I I

SECONDAY AIR SUPPLY (NOTE 2) I I I I I I I

DECOMPRESSOR SYSTEM I I I I I I I

ENGINE IDLE SPEED (NOTE 4) I I I I I I I

DRIVE CHAIN (NOTE1) I, L I, L I, L I, L I, L I, L I, L

DRIVE CHAIN SLIDER (NOTE1) I I

I I I I I

BRAKE FLUID (NOTE3) I I I I I I I

BRAKE PAD WEAR I I I I I I I

BRAKE SYSTEM I I I I I I I

* HEADLIGHT FOCUS I I I I I I I

CLUTCH SYSTEM I I I I I I I

SIDE STAND I I I I I I I

* SUSPENSION I I I I I I I

* MUFFLER I I I I I I I

* NUTS .BOLTS .FASTENERS I I I I I I I

* * WHEEL / TIRES I I I I I I I

* * STEERING HEAD BEARINGS I I I I I I I

Page 15

Maintenance

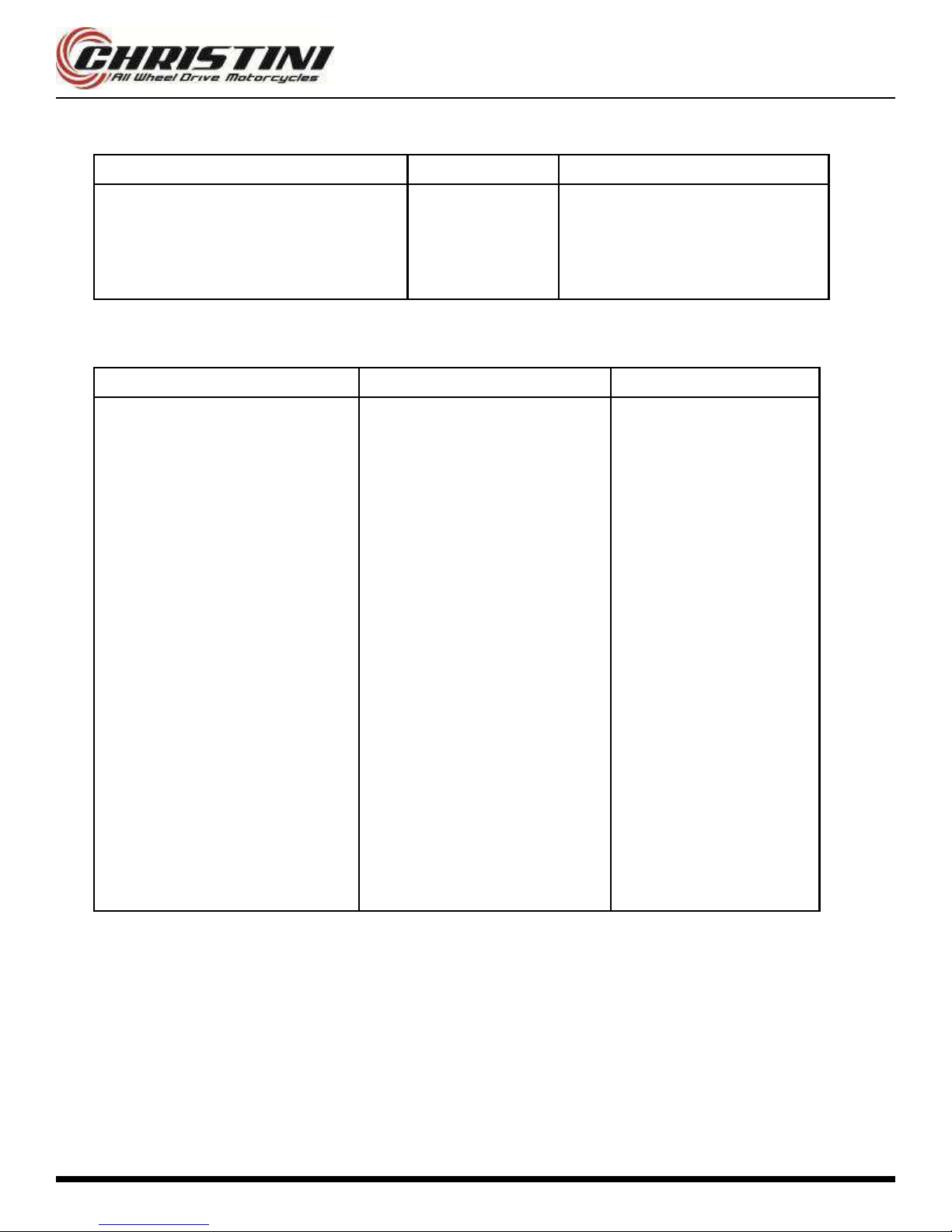

SPECIAL MAINTENANCE SCHEDULE

FREQUENCY

ITEMS

NOTE

About

2.5hs

About

7.5 hs

About

15hs

About

22.5hs

About

30hs

SWING ARM/SHOCK LINKAGE

L

FORK OIL

FORK TUBE/SLIDER

(NOTE3)

R

DAMPER

R

NUTS . BOLTS. FASTENERS

I

WHEELS / TIRES

I

STEERING HEAD BEARINGS

I

Page 16

Maintenance

ENGINE

CHASSIS

NOTE:

These parts and their possible replacement schedule are based upon average riding conditions

Machines subjected to severe use require more frequent servicing

ITEM

CAUSE

REMARK

Cylinder head gasket

Clutch disc

Cylinder gasket

Right crankcase cover gasket

Compression leak

Wear or discoloration

Leakage

Damage

Replace whenever disassembled

Replace whenever disassembled

Replace whenever disassembled

ITEM

CAUSE

REMARKS

Front / rear tire

Front / rear brake pad

Sub-frame mounting bolts

Chain guide plate

Side cover

Front number plate

Front / rear fender

Clutch lever / holder

Brake lever

Air throttle lever

Handlebar

Throttle housing

Grip rubber

Gearshift pedal

Brake pedal

Chain adjuster / bolt

Air cleaner

wear

wear

Fatigue or damage

Wear or damage

Damage

Damage

Damage

Free play or damage

Free play or damage

Free play or damage

Free play or damage

Bends or cracks

Damage

Damage

Damage

Damage

Damage

Minimum knob height:8mm

Minimum thickness:1mm

Page 17

Maintenance

FUEL LINE

•

Inspect the fuel line for damage or leak, if necessary replace fuel line

FUEL FILTER SURFACE

•

Remove the fuel tank Drain the gasoline into a container and remove the fuel line, nuts ,and the clamps

•

Wash the fuel filter and reinstall the O-ring and reinstall components onto the fuel tank

•

Reinstall the fuel tank on the motorcycle Make sure the tank does not leak

THROTTLE OPERATION

•

Check for smooth throttle grip at full opening and automatic full closing in all steering positions

•

Check the throttle cable and replace them if they are deteriorated, kinked or damaged

•

Lubricate the throttle cable if throttle operation is not smooth

•

Measure the free play at the throttle grip flange

FREE PLAY

:

3-5mm(1/8-3/16in)

•

Throttle grip free play can be adjusted at either end of the throttle cable

•

Minor adjustments are made with the upper adjuster Remove the dust cover from the adjuster Adjust the free play by

•

Loosening the lock nut and turning the adjuster

•

Tighten the lock nut after making the adjustment Reinstall the dust cover and recheck the throttle operation

•

Major adjustments are made with the carburetor end of cable

Page 18

Maintenance

AWD Lever

FREE PLAY: 2-3mm(1/8-3/16in)

•

Check for smooth Lever operation and lubricate the cable if required

•

Inspect the cable for cracks which could allow moisture to enter Replace

the cable if necessary

•

Measure the lever free play at the lever end Lever free play can be ad-

justed Adjust the free play by loosening the lock nut and turning the ad-

juster

•

Tighten the lock nut Reinstall the dust cover Recheck the free play at the

lever

AIR FILTER

•

Loosen the air cleaner retaining bolt Remove the air filter

•

Remove the air filter from the holder

•

Thoroughly wash the air filter in clean non-flammable or high flash-point

cleaning solvent Then wash the element again in a solution of hot water

and dishwashing liquid soap Clean the inside of the air cleaner housing

•

After cleaning, be sure there is no dirt or sand trapped between the inner

and outer layer of the cleaner Wash again if necessary

•

Allow the air cleaner to dry thoroughly After drying, soak the air filter in

clean Foam Filter Oil or an equivalent

•

Apply air filter oil to the entire surface of the air filter and rub it with both

hands to saturate the element with oil

•

Gently squeeze out excess oil It is important not to over oil or under oil

the element Apply a thin coat of grease or an equivalent to the sealing

surface

•

Assemble the air filter and the holder Slip the air cleaner retaining bolt

through the assembly Tighten the retaining bolt securely

NOTICE: If the air filter assembly is not installed correctly ,dirt and dust may

enter the engine resulting in wear of the piston ring and cylinder

CRANKCASE BREATHER

•

Remove the breather hose drain plug, then drain any fluids or dirt from

the hose into a proper container Reinstall the drain plug

Page 19

Maintenance

SPARK PLUG

REMOVAL

•

Remove the fuel tank and disconnect the spark plug cap Remove The

spark plug and inspect it for damage

•

Clean around the spark plug base with compressed air before removing

and be sure that no debris is allowed to enter the combustion chamber

INSPECTION

•

Check the following and replace if necessary:

1 ·insulator for damage

2 ·electrodes for wear

3 ·burnt or discoloration

•

If the electrode is contaminated with accumulated debris or dirt replace

the spark plug

(this motorcycle’s spark plug is equipped with an iridium center electrode Re-

place the spark plug if the electrode is contaminated )

•

Replace the plug if the center electrode is rounded as shown in the pic-

ture

(Always use the specified spark plugs on this motorcycle)

RECOMMENDED SPARK PLUG (OR EQUIVALENT)

Standard: DENSO: IK24

Optional : DENSO: IK27

Check the gap between the center and side electrodes with a wire

Type feeler gauge

(To prevent damaging the iridium center electrode, use a wire type

Feeler gauge to check the spark plug gap Do not adjust the spark

Plug gap if the gap is out of specification , replace with a new one )

Spark plug gap: 0 4mm

Make sure that the 1mm diameter plug gauge does not insert between the

gap

If the gauge can be inserted into the gap , replace the plug with a new one

INSTALL

•

Reinstall the spark plug into the cylinder head and hand tighten , then

torque to specification

Torque: 22N m(2 2kgf m,16lbf ft)

Other manuals for AWD 450DS

1

Table of contents

Other Christini Motorcycle manuals