Christini AWD KTM User manual

Service Manual

Christini Technologies, Inc.

tech@christini.com

Version 2011-1.0

CHRISTINI AWD KTM

CHRISTINI AWD KTMCHRISTINI AWD KTM

CHRISTINI AWD KTM

Page 2

Warnings:

•

Do not adjust the choke while the bike is moving!

Page

Page 4

Table of Contents

Introduction; required tools

5

AWD detailed illustration 6

Routine maintenance schedule 7

AWD clutch test 8

AWD chain removal 9

AWD engagement adjustment 11

ront wheel removal 12

ront wheel service 14

ork removal and installation 21

Dropout service 23

ork spline bearing service 32

Triple clamp removal 39

Bottom triple clamp disassembly 41

Bottom taper bearing removal 48

Bottom triple clamp assembly 49

Top triple clamp disassembly 53

Top taper bearing removal 54

Top triple clamp assembly 55

Main drive shaft service 56

Headset bearing service 57

Gearbox removal 64

Gearbox/Transfer Case Service 67

AWD clutch Service 81

Troubleshooting 85

Warranty 86

AWD cable removal 65

Boot Replacement 37

Table of Contents

Page 5

•

Socket set, metric

•

Pliers set

•

all peen/ dead blow hammers

•

Soft tip metal punch (brass/aluminum)

•

Screw driver set

•

AWD clutch wrench (optional)

•

Open ended wrenches, metric

•

Allen key set, metric

•

Snap ring pliers, 45 or 90 degree

•

earing punch set

•

lind side bearing removal kit (Motion Pro 08-0292)

•

2 large adjustable wrenches

•

Torque wrench 0-75 ft-lbs

•

Split bearing puller

•

Small pick or awe

•

Safety wire pliers

•

Safety wire .032”

•

Grease gun (included with frame kit. Fill with Shell grease)

•

Shell Albida EP1 Lithium grease (do not substitute)

•

Spectro SPL grease of equivalent

•

lue Loctite #242

•

Red Loctite #262

•

Green Loctite #609

The Tools You Will Need for Maintenance

Required Tools

Page 6

AWD Detail Illustration

Page 7

Pre-ride check list:

•

Check secondary AWD chain tension.

•

Lube secondary AWD chain.

•

Check clutch setting with front wheel torque test (see next page).

•

Check front wheel rim lock nut torque.

As Needed

•

Replace bearings if excessive noise or friction develops.

•

Lubricate spline shafts through grease port with supplied grease

gun and Shell grease.

•

Replace worn or damaged seals and boots.

Routine Maintenance

AVOID:

AVOID:AVOID:

AVOID:

•

Pressure washing the dropouts, head tube area, side bar

and main gearbox.

Page 8

•

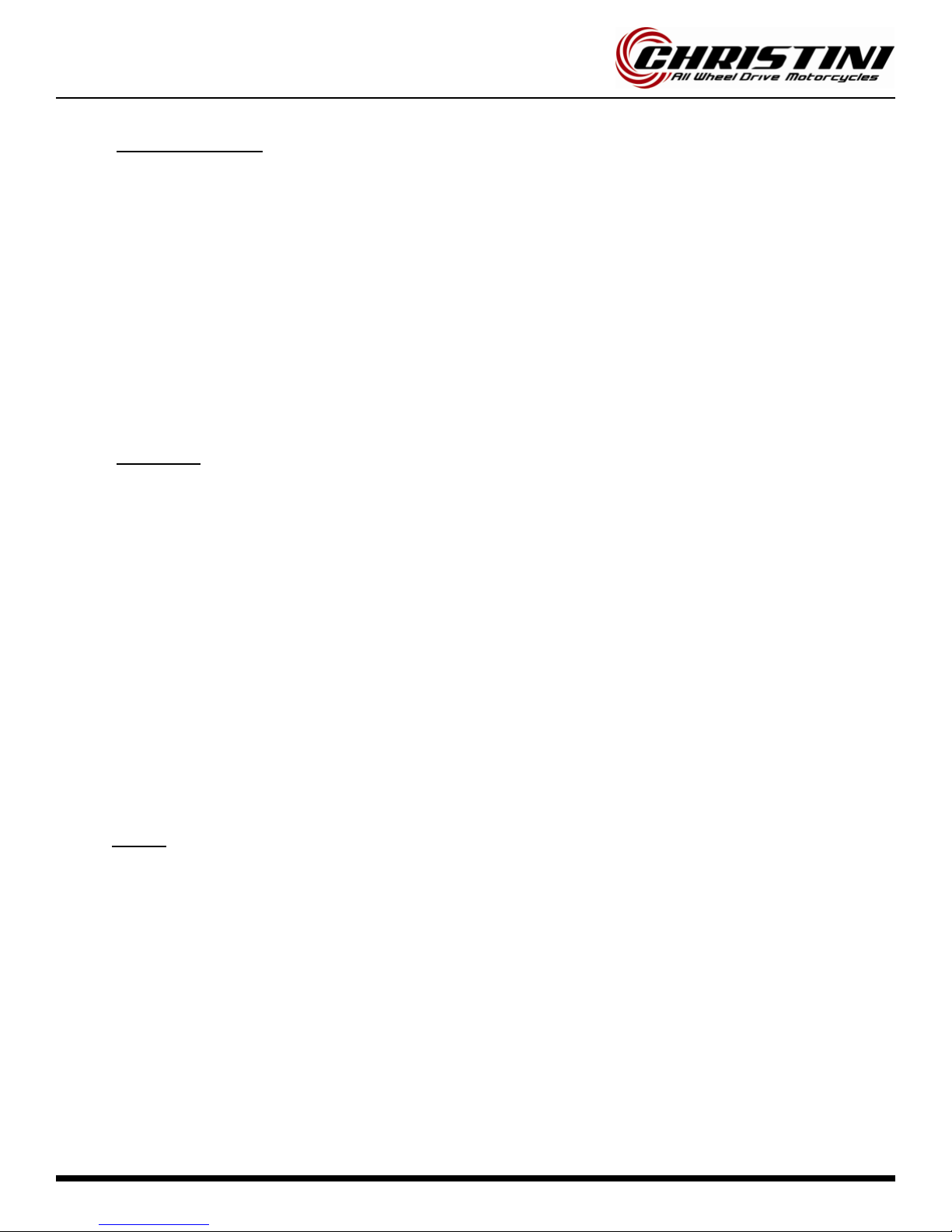

Place the bike on a stand and make sure that the front wheel is

not touching the ground.

•

Shift the bike into gear.

•

Turn the AWD switch to the on position and check to make sure

the AWD is engaged.

•

Grab the front wheel with two hands and try to spin it backwards.

The front wheel should spin backwards but require a large amount

of effort to do so. If the wheel will not break free, the clutch is set

too high. If the wheel turns backwards very easily, the clutch is set

too low.

•

If the clutch needs to be adjusted, pull the gas tank off the bike.

Loosen the set screw on the clutch locknut and turn the locknut in

or out a 1/2 turn at a time until the front wheel moves backward

with the correct amount of force. Make sure the set screw is posi-

tioned over a flat in the clutch hub and tighten the set screw down

and reinstall the tank. (note: picture shows clutch off the bike for

clarity).

AWD Clutch Test

There are two ways to check that the clutch is set to the right torque. The first method is to take the clutch off the

bike and use the Christini AWD clutch tools and a torque wrench (see page 74). This is only recommended when the

clutch assembly is being rebuilt with new pads. The following test should be sufficient under most circumstances:

Page 9

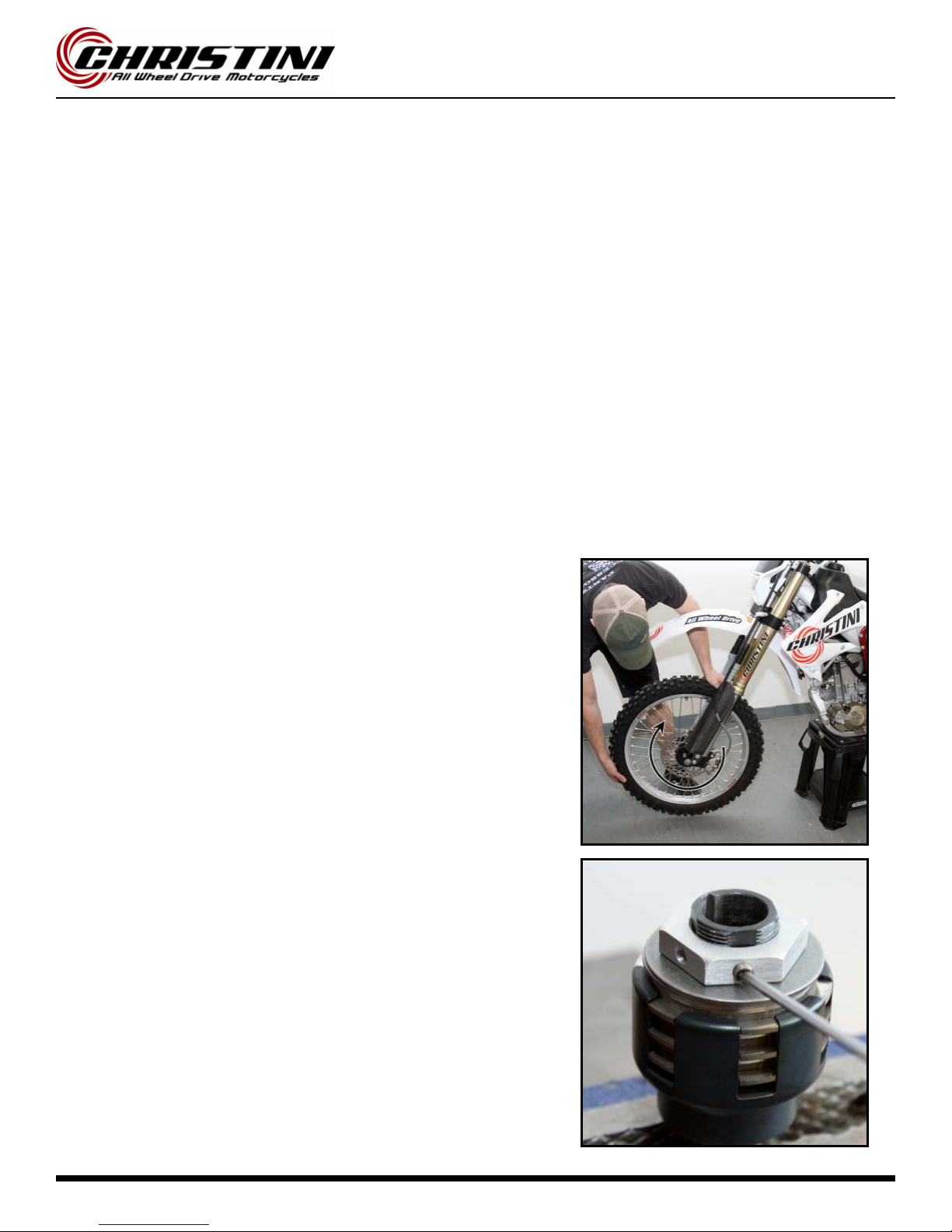

• Remove the 4 cover bolts with an 8mm socket or t-handle and pull

cover off of the frame.

• To remove the chain, pull the sprocket out with fingers or non-

marring pliers. Remove the chain from countershaft sprocket.

• Check the following:

1. Sidebar bearing and cover bearing should be smooth turn

ing.

2. Check engagement spline action by engaging and disen-

gaging switch on handle bars.

3. Sidebar seal and cover seal for wear.

4. Excessive wear on chain tension block.

Warning:

Warning:Warning:

Warning: Do not use an O-ring chain as there is not enough

clearance for one and it would rub the frame.

Cover and Chain Removal

Page 10

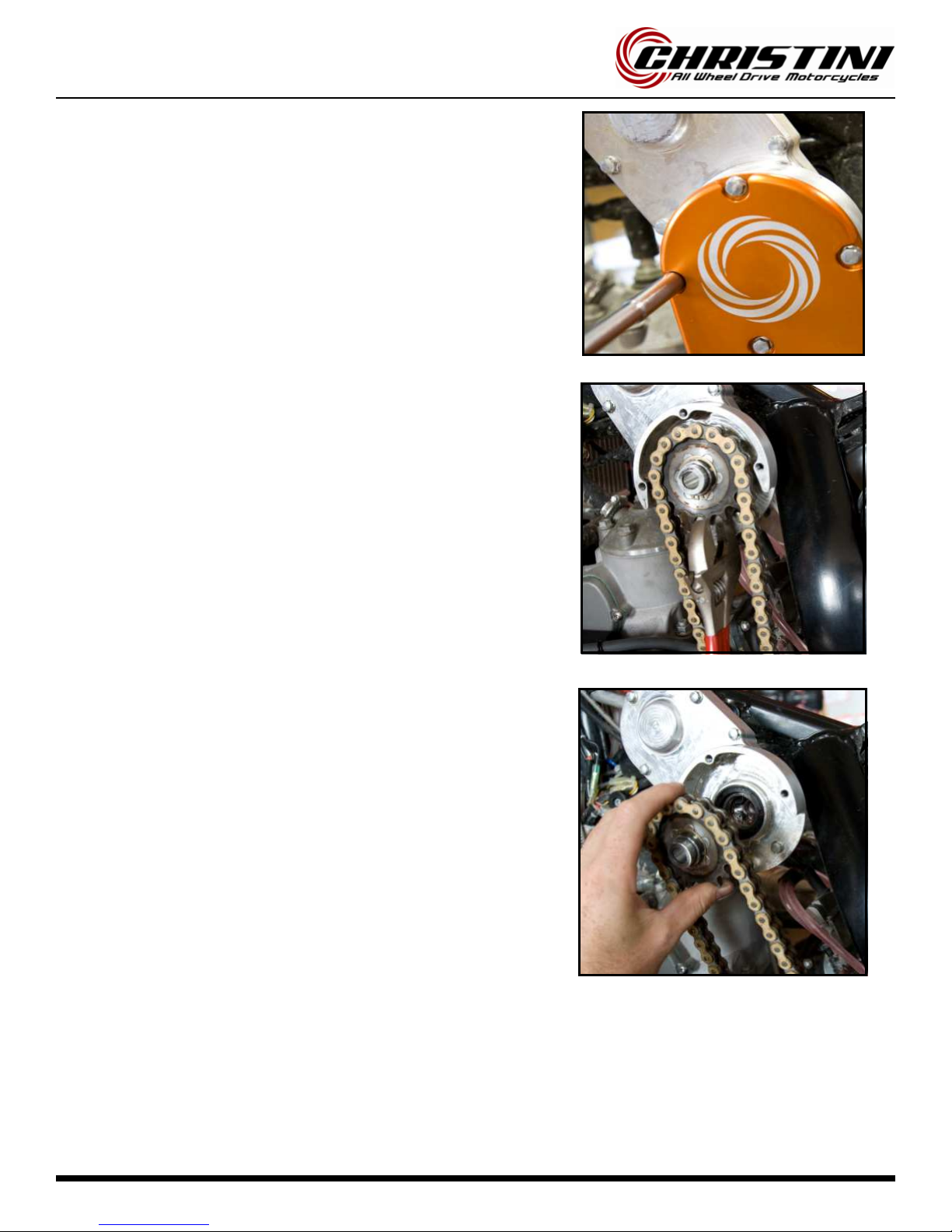

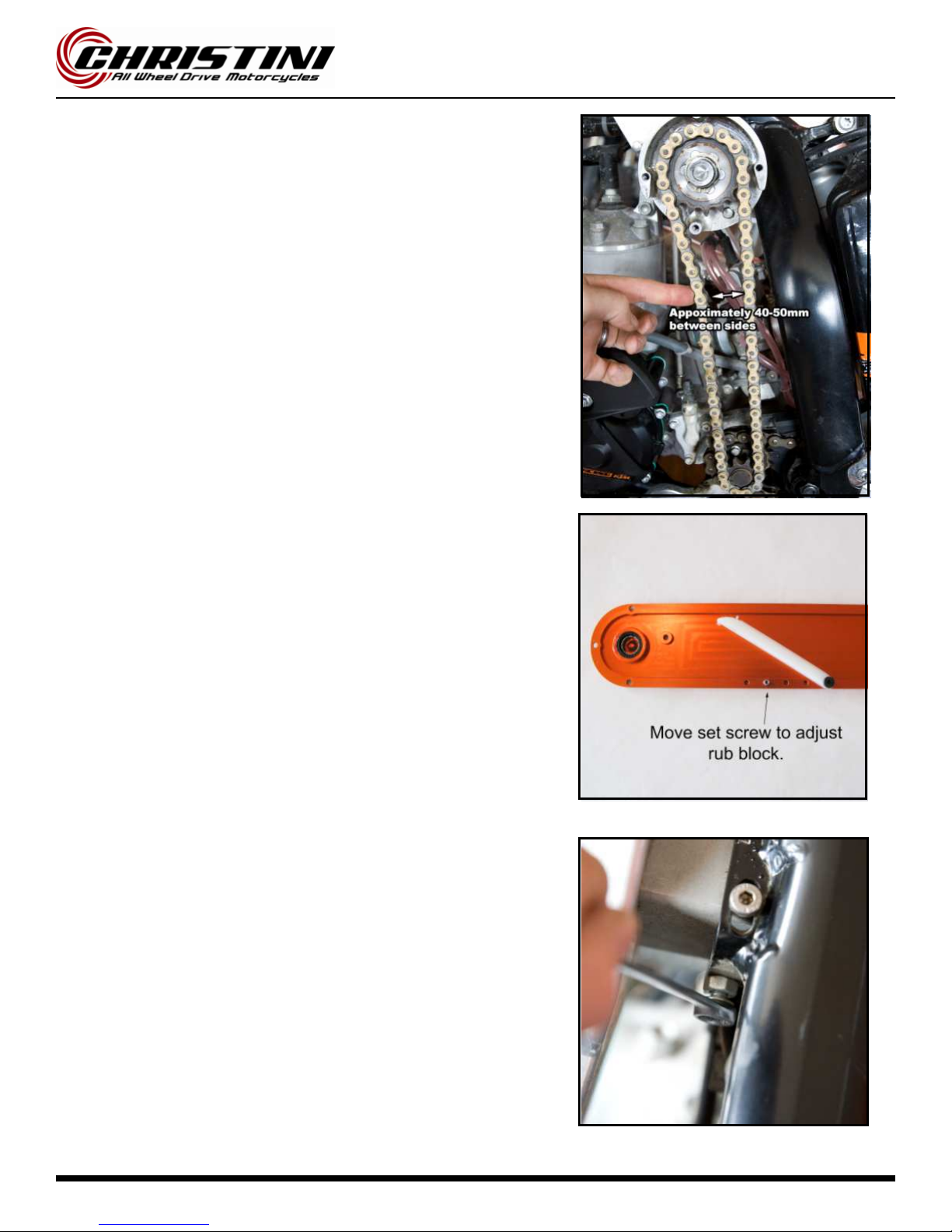

• Reinstall chain and top sprocket.

• Loosen gearbox with 4mm Allen wrench and slide it forward or

back until the chain has roug hly 40mm (1.5in) of space between

sides when pressure is applied.

• If the gearbox is all the way forward and the chain is still too slack,

keep moving the set screw on the chain cover closer to the rub

block until a good chain tension is created.

• Replace chain cover. Torque cover bolts to 8 ft-lb.

• Move jack bolt in until it touc hes the gearbox and tighten the lock-

nut.

Cover and Chain Removal

Page 11

AWD Engagement Adjustment

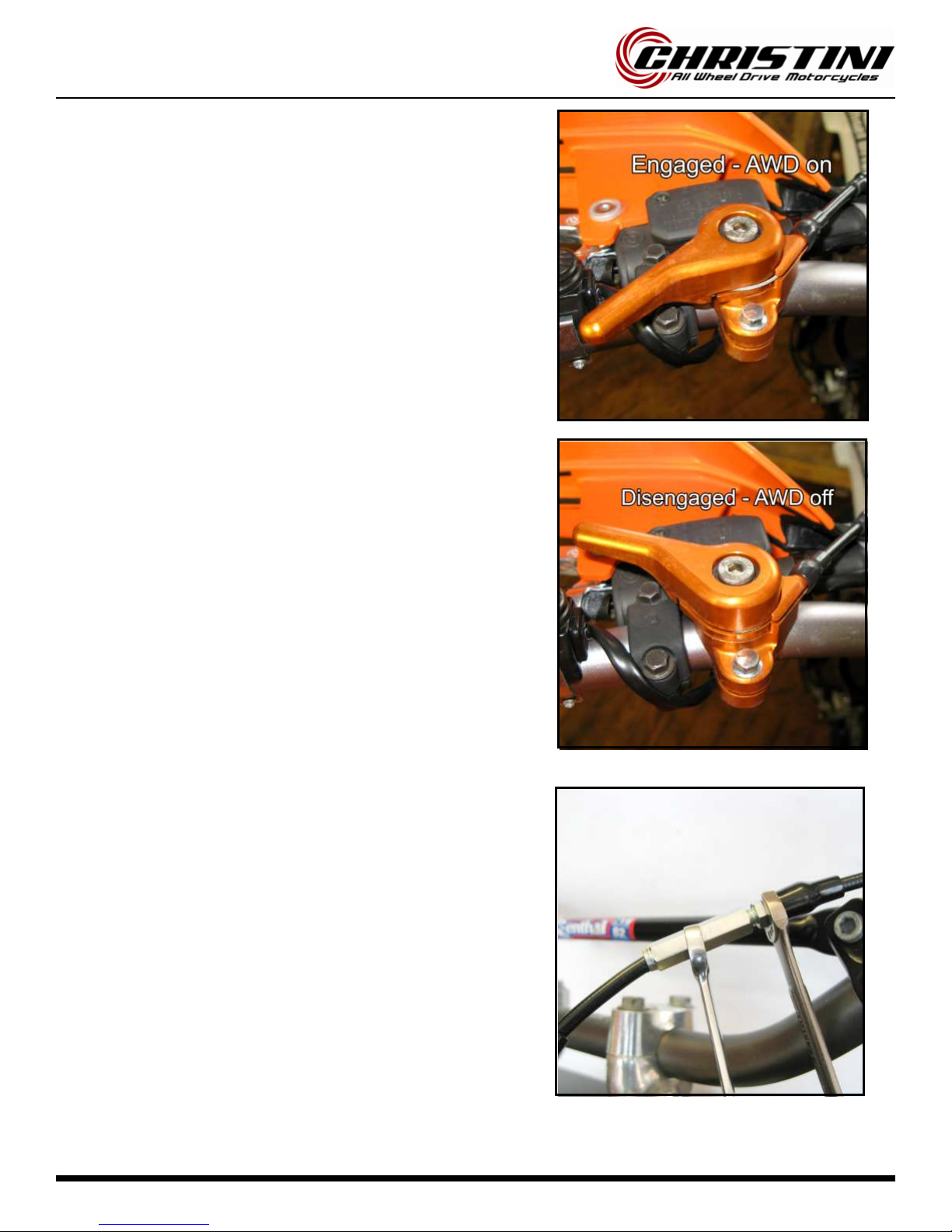

•

Put motorcycle on a stand so both wheels are off the ground and

make sure the bike is in neutral.

•

Turn engagement switch back towards rider to the on position.

•

Spin rear wheel of motorcycle and make sure that the front wheel

is spinning as well (it may take a few turns before AWD clicks in).

•

Push engagement switch forward to the off position.

•

Spin rear wheel and make sure front wheel is no longer moving.

•

If the front wheel is still moving. Turn barrel adjuster on cable out

until the AWD system disengages and front wheel is no longer

moving.

Page 12

Note:

Note: Note:

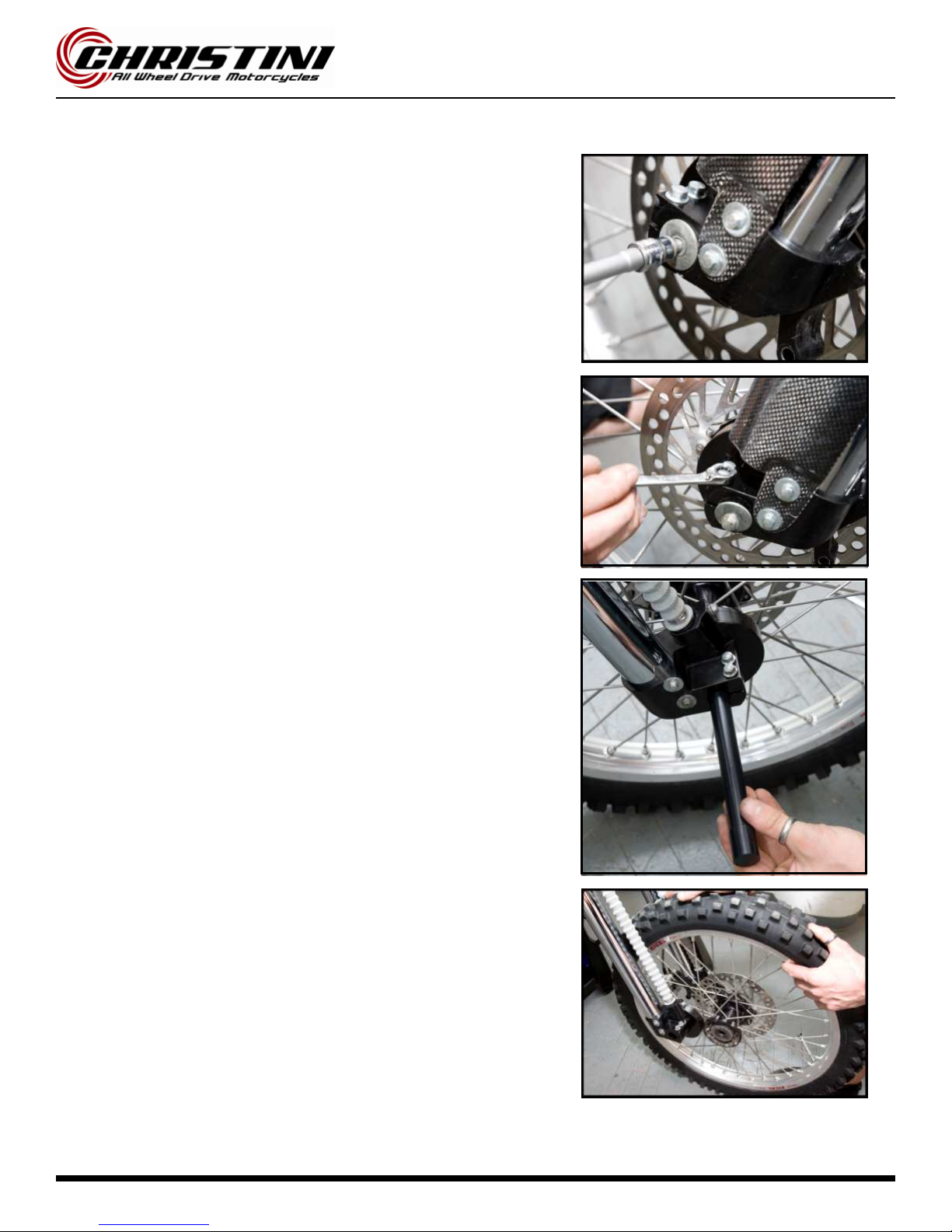

Note: Due to AWD hub design, front wheel removal and installation is

aided by removing front caliper first.

• Remove front brake caliper (note: do not squeeze front brake

lever while caliper is off.

• Remove axle bolt from axle.

• Loosen axle pinch bolts on both sides of dropout.

• Slide axle through wheel and remove.

• Remove front wheel from dropouts.

Note:

Note: Note:

Note: The hub inserts will not fall out like the spacers on a normal hub.

They will also rotate independent of each other; this is ok.

Front Wheel Removal

Page 1

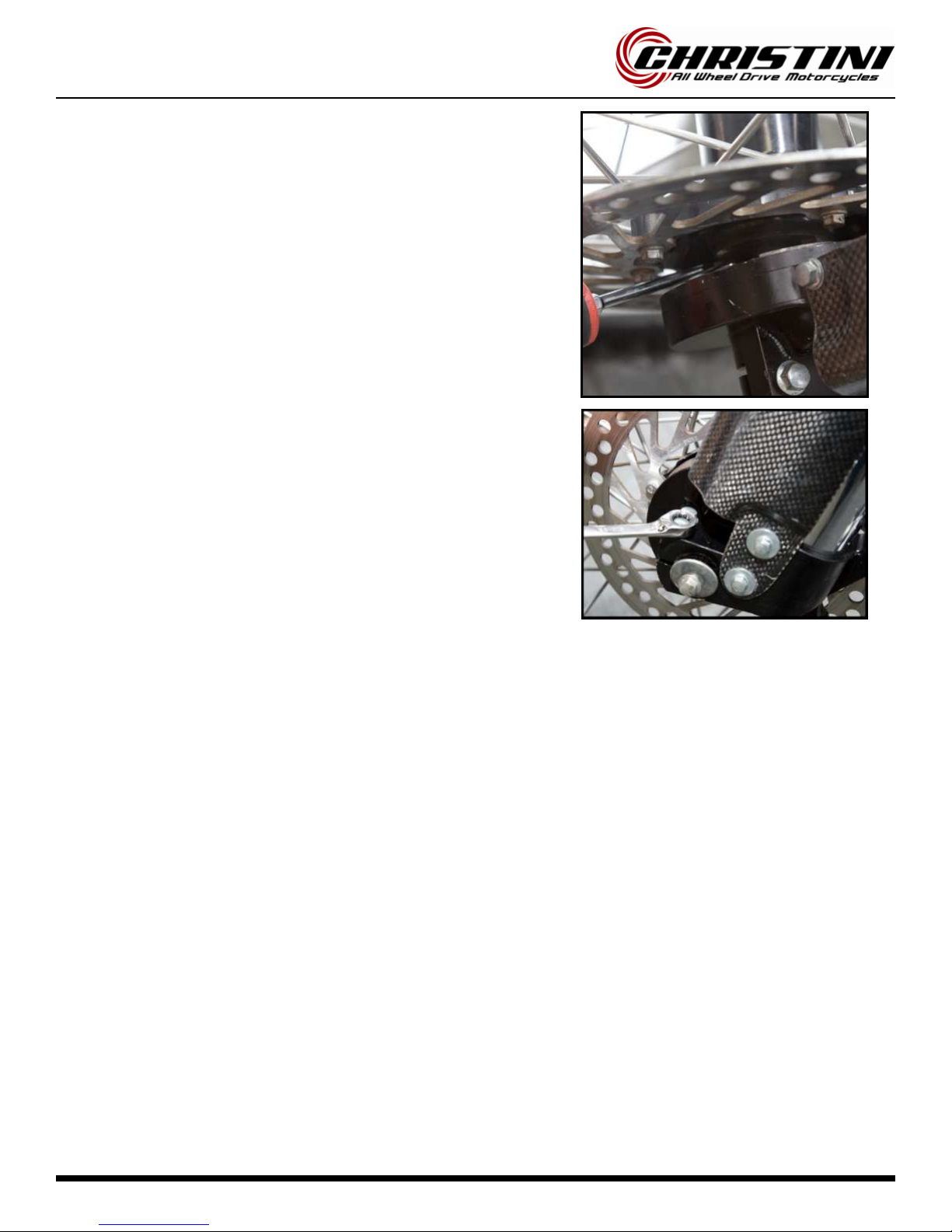

• Lightly grease dropout o-rings and hub seals before installing the

front wheel.

• With brake caliper removed, install front wheel into forks by care-

fully aligning right drive carrier on dropouts with hub inserts. Once

the right carriers are seated, slide axle throug h to other end of

hub.

• Carefully align left carriers and slide axle completely throug h to the

other side. Note, a flat blade screw may be needed to align hub

insert with drive carrier. Note that the hub inserts will only rotate

in one direction in the hub.

• Thread axle bolt back into the end of axle and tighten to 12ft-lb.

Tighten axle pinch bolts to 12 ft-lb. Note:

Note: Note:

Note: If wheel does not spin

freely, axle bolt is too tight!

• Reinstall front brake caliper.

Front Wheel Installation

Page 14

Front Wheel Service

Page 15

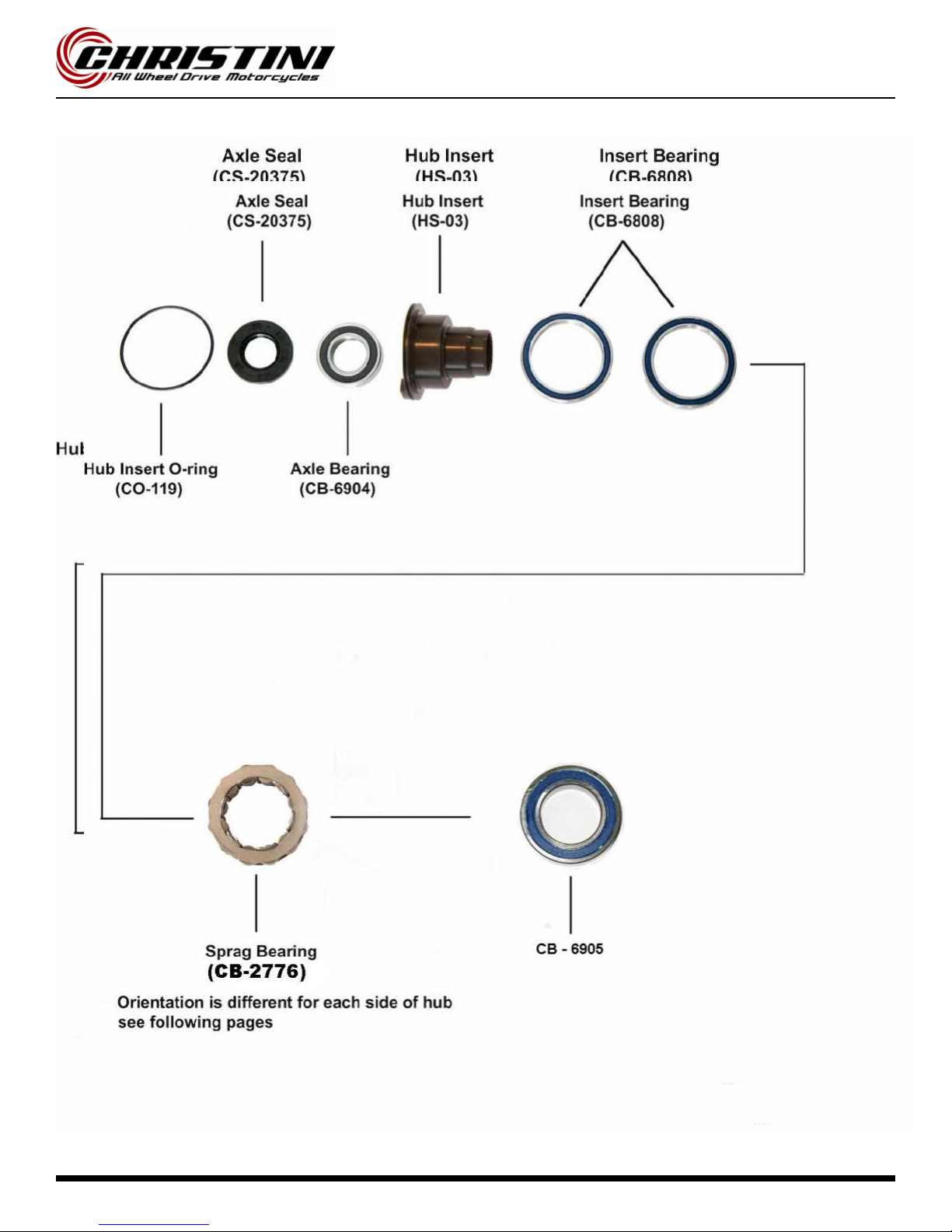

Warning:

Warning: Warning:

Warning: efore taking hub apart, make sure that you have a full set

of spare sprag bearings. Sprag bearings are likely to be damaged dur-

ing the disassembly process and new onesmay be required.

•

Using a soft punch, remove the hub inserts from either side of the

hub.

•

Carefully remove all bearings, sprags and spacers from hub with a

punch and hammer. e careful not to tap bearings out crooked as

it may damage hub shell.

Front Wheel Service

Page 16

•

Pry the insert seals out of the inserts using a flat bladed screw-

driver.

•

Remove the hub insert o-rings with a pick.

•

Punch the axle bearings out of the inserts using the access holes

in the back of the inserts.

Front Wheel Service

Page 17

Front Wheel Service

•

Using a bearing punch, install new axle bearings into the hub in-

serts.

•

Press the axle seals into the hub inserts.

•

Install the hub insert o-rings.

Page 18

•

Press C -6905 bearing into the Hub Inner Race

•

e sure that the bearing is seated completely

•

Insert sprag bearing into hub shell. (correct direction will be deter-

mined in next steps.). Lightly grease inside of sprag bearing with

Shell grease.

Front Wheel Service

Warning:

Warning: Warning:

Warning: Sprag bearings must be installed in the correct orientation in the hub for the AWD system to work properly.

If the sprag bearings are not installed correctly, the AWD system can be damaged.

Page 19

•

Test fit hub insert into hub, twisting as it is inserted.

•

Spin the hub insert and check to make sure it is freewheeling in

Spin the hub insert and check to make sure it is freewheeling in Spin the hub insert and check to make sure it is freewheeling in

Spin the hub insert and check to make sure it is freewheeling in

the correct direction.

the correct direction. the correct direction.

the correct direction. If it is not, remove the hub insert and flip the

sprag bearing around. Recheck to verify that hub insert free-

wheels in the correct direction before moving on to next step.

Front Wheel Service

Table of contents

Other Christini Motorcycle manuals