chromasens allPIXA SWIR CD40199 User manual

allPIXA SWIR GigE Camera | Manual

CD40199

R01 / 2022-06-02

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 2

Table of Contents

allPIXA SWIR GigE Camera | Manual 1

1General information 4

1.1 About Chromasens 4

1.1.1 Contact information 4

1.1.2 Support 4

1.2 Firmware version and references 5

1.3 Definitions and abbreviations 5

1.4 Scope of supply of the allPIXA SWIR camera 7

1.5 Design of a line scan camera system 8

2Specifications and definitions 9

2.1 Camera highlights 9

2.2 Available camera models 9

2.3 Import and export regulations 10

2.4 Technical specification 10

2.5 Features Reference and SDK 11

2.6 Sensor orientation 12

2.7 Factory settings 13

3Safety 13

3.1 Depiction of safety instructions 13

3.2 Basic safety regulations 14

3.3 Safety instructions on the allPIXA SWIR camera 14

3.4 Purpose / applications 14

3.5 Staff requirements 15

3.6 Organizational measurements 15

3.7 Safety instructions for maintenance / cleaning 15

3.8 Maintenance and cleaning of the allPIXA SWIR camera 16

3.8.1 Cleaning intervals 16

3.8.2 Cleaning process 16

3.9 Disposal 16

4allPIXA SWIR –basic functionality 17

4.1 Basic design of the allPIXA SWIR camera 17

4.2 Line Scan Sensors of the allPIXA SWIR camera 18

4.2.1 Design 18

4.2.2 Spectral sensitivity 18

5Installing the allPIXA SWIR camera 19

5.1 Connectors and LEDs of the camera with GigE Vision interface 19

5.1.1 Power supply 19

5.1.2 RJ45 connector 20

5.1.3 Digital I/O connector 20

5.2 Connectors and LEDs of the camera with Camera Link interface 23

5.3 Using an encoder or external triggers 23

5.3.1 Using an encoder as line trigger source 24

5.3.2 Using an external line trigger signal 26

5.3.3 Using a light barrier to trigger frame start 27

5.4Mechanical installation 28

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 3

5.5 Thermal links / cooling 28

5.6 Electrical installation 29

5.6.1 Power supply 30

5.6.2 Connecting external I/O devices to the allPIXA SWIR GigE camera 30

5.6.3 Connecting the camera to the computer 31

6Working with GCT 32

6.1 Discovering and connecting the camera in GCT 32

6.2 Updating the firmware 32

7Camera system set-up 33

7.1 Installing the camera 33

7.2 Starting up the system 34

7.3 Adjusting camera and illumination 35

7.4 Creating flat field correction tables 37

8Troubleshooting and support 40

8.1 Returning material (obtain an RMA number) 40

8.2 Temperature warnings and errors 40

8.3 Before contacting Chromasens technical support 41

9Appendix 42

9.1 Support request form 42

9.2 Mechanical specification 43

9.2.1 Mechanical dimensions of the allPIXA SWIR GigE camera 43

9.3 Adapters and accessories 44

9.3.1 Power supply connector and cables 44

9.3.2 C-Mount adapter 44

9.3.3 F-Mount adapter 45

9.3.4 I/O Cables 45

9.4 EU declaration of conformity for allPIXA SIWR GigE cameras 47

9.5 EU declaration of conformity for allPIXA SIWR CameraLink cameras 48

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 4

1 General information

1.1 About Chromasens

The name of our company, Chromasens, is a combination of 'Chroma' which means color, and

'Sens' which stands for sensor technology.

Chromasens designs, develops, and produces high-quality and user-friendly products:

◼Line scan cameras

◼Camera systems

◼Camera illumination systems

◼Image acquisition systems

◼Image processing solutions

Today, Chromasens GmbH is experiencing steady growth and is continually penetrating new

sales markets around the globe. The company's technologies are used, for example, in products

and for applications such as book and document scanners, sorting systems and inspection

systems for quality assurance monitoring.

Customers from all over the world of a wide range of industrial sectors have placed their trust in

the experience of Chromasens in the field of industrial image processing.

1.1.1 Contact information

Chromasens GmbH

Max-Stromeyer-Str. 116

78467 Konstanz

Germany

Phone: +49 (0) 7531 / 876-500

Fax: +49 (0) 7531 / 876-303

Email: support@chromasens.de

HP: https://www.chromasens.de/

1.1.2 Support

Should you ever have problems with the allPIXA SWIR camera that you cannot solve by

yourself, look into this manual for additional information, check the troubleshooting chapter 10,

contact your local distributor, or send us an e-mail.

Chromasens GmbH

Max-Stromeyer-Str. 116

78467 Konstanz

Germany

Phone: +49 (0) 7531 / 876-500

Fax: +49 (0) 7531 / 876-303

Email: support@chromasens.de

HP: https://chromasens.de/support

Visit our website at https://www.chromasens.de which features detailed information on our

company and products.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 5

1.2 Firmware version and references

This document refers to the following firmware and document versions:

◼allPIXA SWIR GigE Camera Firmware Package Version 1.3.0

◼Features Reference for allPIXA SWIR Camera XML Version 4.5.3

◼GenICam Standard Features Naming Convention (SFNC) Version 2.7

Newer firmware versions may contain additional features and bugfixes. Check

https://chromasens.de/allpixa-swir-downloads or contact the Chromasens support for updates.

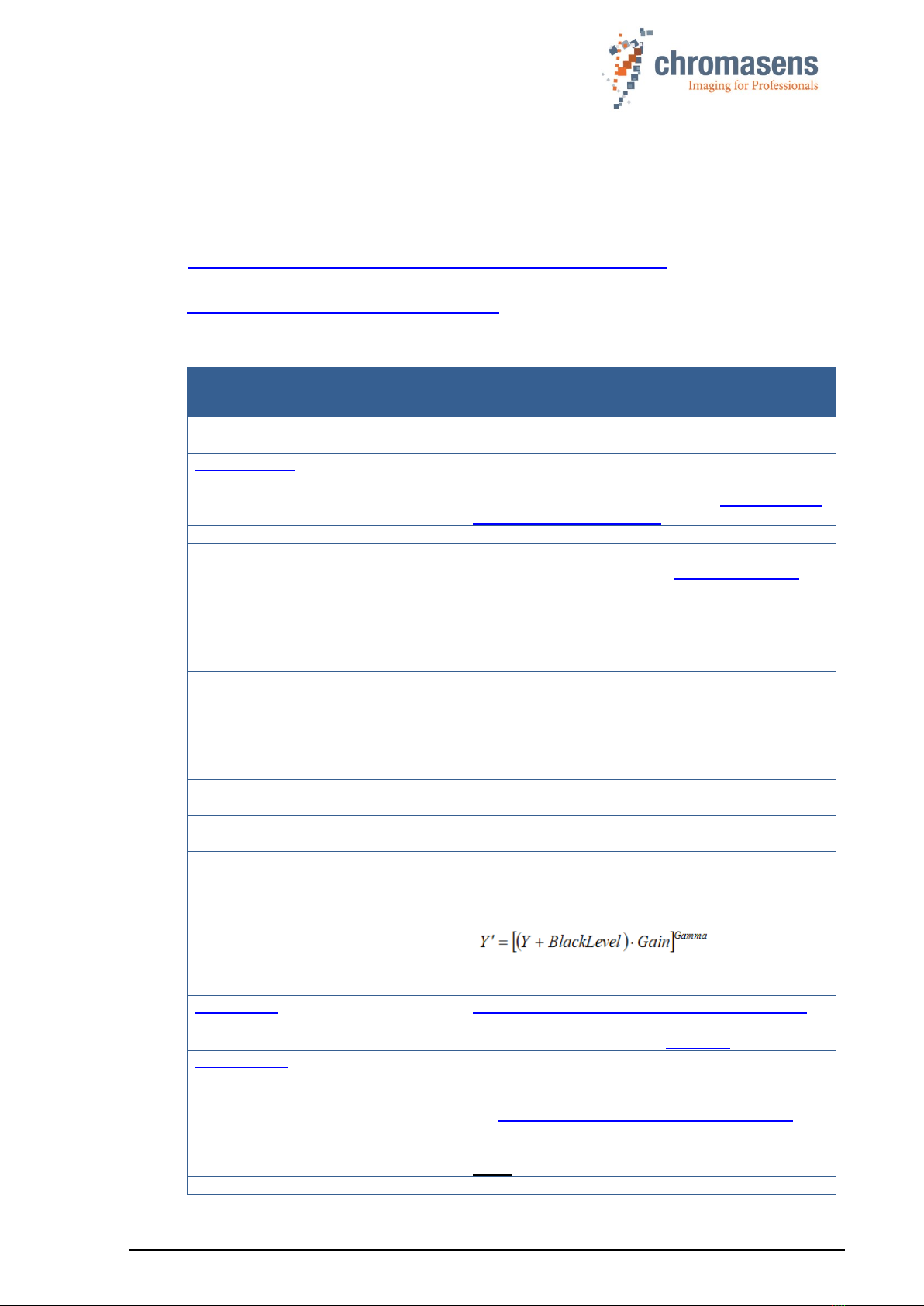

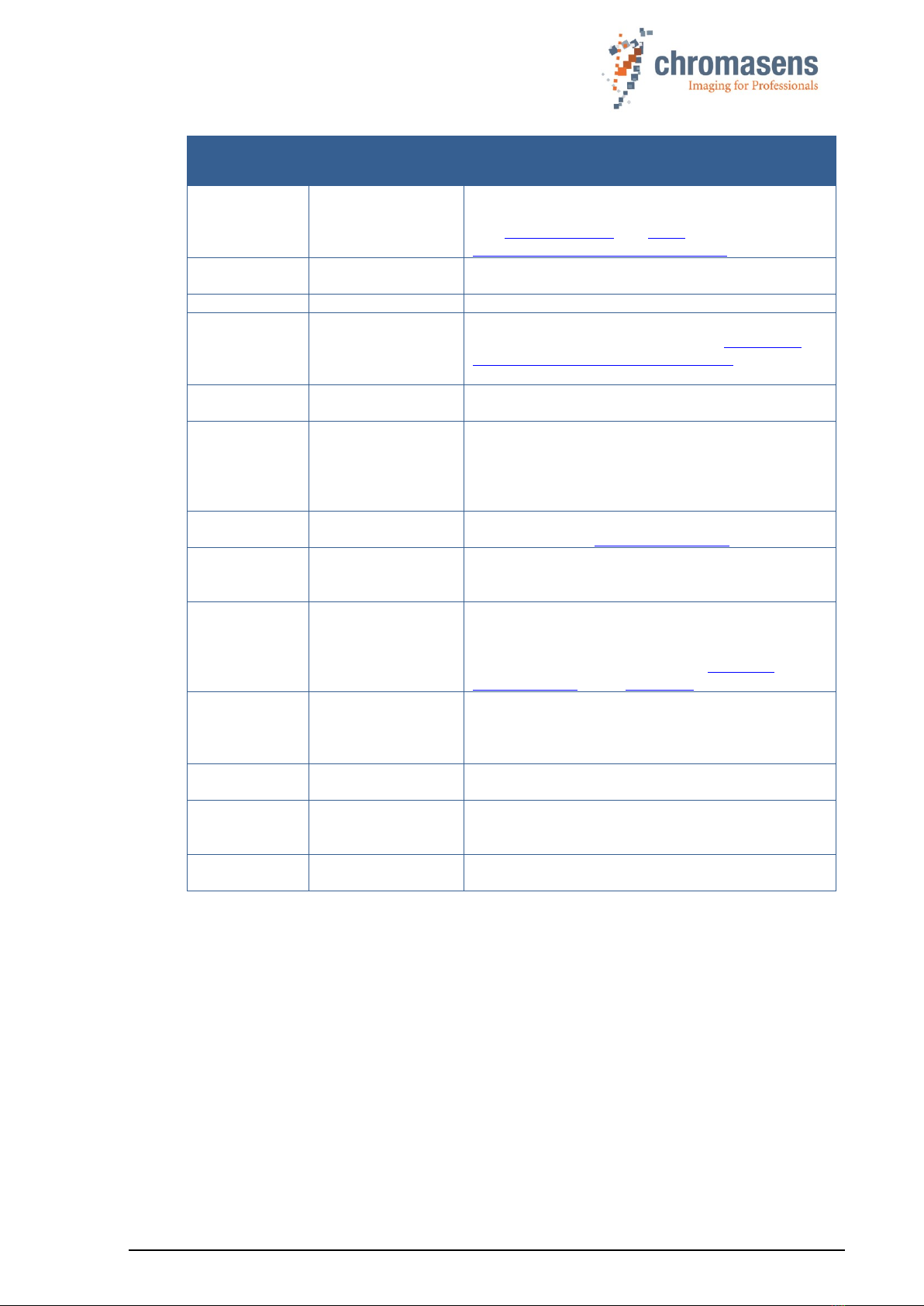

1.3 Definitions and abbreviations

Term /

Abbreviation

Synonym /

Meaning

Expanation

Black level

Offset

Used for additive (“brightness”) corrections, see

also gamma

Camera Link®

Communication

protocol standard

for camera interface

applications

The Camera Link standard is maintained and

administered by the Automated Imaging

Association (AIA), , now part of the Association for

Advancing Automation (A3)

Corona II

LED illumination

Chromasens product

DHCP

Dynamic Host

Configuration

Protocol

A network management protocol for automatically

assigning IP addresses. See DHCP (Wikipedia)

DSNU

Dark signal non-

uniformity

Irregularity in the dark image (offset of the

individual pixels), additive part of the fixed-pattern

noise (FPN)

DVAL

Data valid

Pixel-by-pixel enabled for Camera Link

FFC

Flat-field correction

Can be used to correct the fixed-pattern noise of

the image sensor, the vignetting of the lens, and

the non-uniformity of the illumination. FFC is

performed in the camera by means of dark signal

non-uniformity (DSNU) and photo response non-

uniformity (PRNU) correction tables

FPN

Fixed-pattern noise

Temporally constant lateral non-uniformity of the

imaging system

FVAL

Frame valid

Frame signal for an image on the Camera Link

(corresponds to VSync)

Gain

Used for multiplicative (“contrast”) corrections

Gamma

Gain, BlackLevel and Gamma features will

transform the original pixel value Y to a new value

Y' according to the following formula:

GCT

GenICam Control

Tool

Chromasens camera control and configuration tool

for GenICam cameras

GenICam™

Generic Interface

for Cameras

Generic camera programming interface standard

published and maintained by the European

Machine Vision Association emva.org

GigE Vision®

Ethernet-based

Camera interface

standard

Camera interface standard using the Gigabit

Ethernet communication protocol initiated by the

Automated Imaging Association (AIA), now part of

the Association for Advancing Automation (A3)

GPIO

General-purpose

input/output

Versatile, configurable digital signal pin, e.g. at the

digital I/O connector of the camera (see section

5.1.3)

LED

Light emitting diode

-

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 6

Term /

Abbreviation

Synonym /

Meaning

Expanation

LLA

Link-local address

Local IP address, typically automatically assigned

when no DHCP server is available.

See LLA (Wikipedia) and Zero-

configuration_networking (Wikipedia)

LUT

Lookup table

Array with precalculated values, to store e.g.,

gamma correction or tone response curves (TRCs)

LVAL

Line valid

Frame signal for a line on the Camera Link

LVTTL

Low-voltage TTL

Transistor-Transistor-Logic with reduced supply

voltage (3.3 instead of 5V). See e.g. Transistor–

transistor_logic Sub-types (Wikipedia)

PRNU

Photo response

non-uniformity

Difference in sensitivity of the individual pixels,

multiplicative part of the fixed-pattern noise (FPN)

ROI

Region of interest

A rectangular section of the captured frame or a

contiguous subsection of the image sensor. Can

already be defined in the camera, e.g., to reduce

the amount of data to be transferred or to increase

the achievable frame rate.

RS422

RS-422,

TIA/EIA-422

Technical standard for Differential Interface

Circuits. See e.g. RS-422 (Wikipedia)

SDK

Software

Development Kit

A set of tools, headers, libraries, sample code, and

documentation to facilitate software developers

creating custom applications.

SFNC

GenICam Standard

Features Naming

Convention

Provides a standard features naming convention

and a standard behavioral model for the devices

based on the GenICam standard. Can be

downloaded free of charge on the GenICam

download page of the emva.org web site.

TRC

Tone reproduction

curve (or tone

response curve)

Can be used to encode more complex response

curves (like the L* or sRGB response curve) as

LUTs which can otherwise only be approximated by

a gamma value.

VSync

Vertical

synchronization

Frame signal for an image (corresponds to FVAL)

White

reference

The white reference is a physical patch in the field

of view of the camera that can be used for gain

adjustment

XLC4

Light controller

Controller that permits to control up to four

channels of Corona II illuminations.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 7

1.4 Scope of supply of the allPIXA SWIR camera

Check your device upon delivery to ensure that it is undamaged and complete.

The following components are supplied with the allPIXA SWIR camera:

◼allPIXA SWIR camera packaging

Check the packaging for damage, which may have occurred during transport.

◼allPIXA SWIR camera with C-mount adapter

Check the camera for damage, which may have occurred during transport.

The rating plate is located on the rear of the allPIXA SWIR camera. It shows the camera

resolution and the serial number.

◼Additionally ordered and supplied accessories

Cables, extension rings, lenses and other accessories are not included in the standard scope

of delivery. These items must be ordered separately as accessories.

Check additionally ordered accessories for completeness and for damage, which may have

occurred during transport.

Read this manual carefully before using the camera, contacting your local partners or the

Chromasens support.

Should there be any questions left, do not hesitate to contact your local partner or us.

We would be pleased to be of assistance to you.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 8

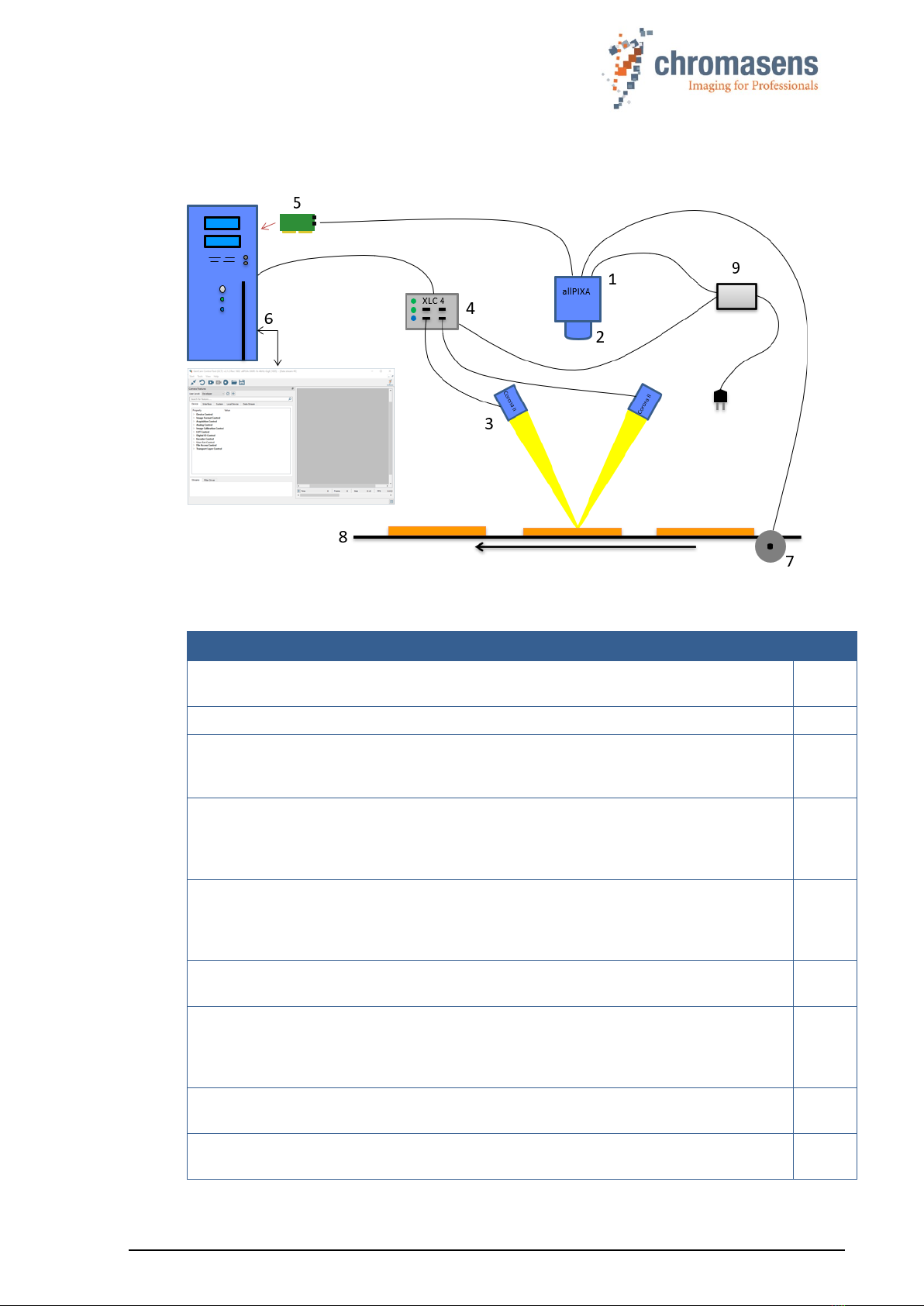

1.5 Design of a line scan camera system

The following figure demonstrates the basic setup of a typical line scan camera system:

Figure 1: Design of a line scan camera application

The following components are present in typical line scan camera applications:

Component

No.

Line scan camera: An allPIXA SWIR camera, which scans the image line by line and

communicates with the PC (5).

1

The optical system: Optical lenses with tubes and mounts with an adjusted focusing

2

Illumination: The illumination system lights up the information carrier / scan area on

the passing object. The Chromasens Corona II SWIR illumination system is an ideal

supplementary option for the allPIXA SWIR camera.

3

Illumination controller: Controls and monitors the illumination unit. The Chromasens

Corona II illumination (3) has integrated temperature sensors which can be read out

with the XLC4 controller. By use of the XLC4 controller, the illumination unit can be

monitored and kept stable.

4

Network cable and suitable network adapter: The image data are sent to a PC

using a standard 1000BASE-T network connection. Use a Cat-5e, Cat-6, or better

S/STP Gigabit Ethernet cable and a suitable Gigabit Ethernet network adapter in the

PC.

5

PC: The PC system performs subsequent processing of the image data and can

optionally control the illumination system (3 + 4).

6

Speed control: The line rate of the camera can be controlled and synchronized with

the transport speed of the object or conveyor belt by means of an optional rotary

encoder or external line trigger signal. Synchronization of the camera with strobed

illumination is also possible this way.

7

Conveyor unit: The conveyor unit moves the scanned object past the allPIXA SWIR

camera.

8

Power supply: Both, the allPIXA SWIR camera and the illumination system, require a

suitable power supply.

9

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 9

2 Specifications and definitions

The allPIXA SWIR GigE camera is compliant with the GigE Vision 2.0 specification which

defines the communication interface protocol for any GigE Vision device. The device description

of the camera is contained in an XML file. For more information about GigE Vision see:

https://www.automate.org/a3-content/vision-standards-gige-vision.

Flat-field correction (FFC), which consists of an offset and a shading correction, compensates

for differences in pixel sensitivities, lens vignetting, and lighting unevenness.

FFC is performed in the camera by means of dark signal non-uniformity (DSNU) and photo

response non-uniformity (PRNU) correction tables.

DSNU and PRNU correction tables can be created with the in-camera wizard, saved to the PC,

and later restored to the camera.

By default, the camera is delivered with a C-Mount adapter. An F-Mount is available as

accessory. Other lens adapters are available on request.

2.1 Camera highlights

The allPIXA SWIR camera is especially suitable for inspection systems requiring a very high

speed and a consistently high image quality.

◼Short-wave infrared line scan camera

◼High-speed InGaAs line scan sensor with 512 or 1024 pixels and up 40 kHz line frequency

◼8, 10 or 12-bit mono output

◼Digital I/O port on GigE camera models for direct input and output of external trigger signals,

e.g. from/to incremental encoders, photoelectric sensors or lighting controllers

◼Built-in floating point encoder frequency converter to simplify synchronization between camera

and transport speed

◼Flatfield correction: Factory calibration and internal wizard for calculating custom shading

(PRNU) and offset (DSNU) corrections

◼Robust metal housing

◼Lens adapter: C-Mount lens adapter included, F-Mount adapter available as accessory

◼Internal test image generator

2.2 Available camera models

The allPIXA SWIR camera is available in the following configurations:

GigE version

CP000700-IR-01K-GE

CP000700-IR-512-GE

Camera Link version

CP000700-IR-01K-CL

CP000700-IR-512-CL

Number of pixels

1024

512

pixels

Pixel size

12.5 x 12.5

25 x 25

µm

Image size

12.8 x 0.0125

12.8 x 0.025

mm

Spectral response range

950 … 1700

nm

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 10

2.3 Import and export regulations

IMPORTANT

NOTE:

We would like to point out that the cameras described in this manual are

covered by Annex I to EC Regulation No. 2021/821 under ECCN 6A003,

also known as "dual-use” items. Prior the import, export, transit or

transfer, the exporter shall diligently check on its own responsibility for

any applicable reporting or license requirements, restrictions, and

prohibitions. The import, export, transit, or transfer may be subject to

licensing requirements, or prohibited in accordance with the

aforementioned regulation. We also point out that similar licensing

obligations as well as restrictions or prohibitions may apply outside the

European Union according to the respective export control law and

regulations of the country from where the products shall be exported to or

shall be imported into.

2.4 Technical specification

Sensor

InGaAs short-wave infrared line sensor

Spectral sensitivity

950 nm to 1700 nm

Resolution

1024 px or 512 px

Pixel size

12,5 µm or 25 µm (square)

Pixel bit depth

8 / 10 / 12 bit

Line scan operating mode

Free-running / software trigger /

external trigger

Maximum line frequency

40 kHz

Minimum integration time

21 µs

Interface

GigE Vision (1000BASE-T, RJ-45)

Other interfaces

Power supply (6-pin Hirose, male)

External I/O (12-pin Hirose, male)

Digital input

3x RS422 or LVTTL

Digital output

2x RS422

Lens mount

C-Mount (F-Mount on request)

Protection class

IP40

Conformity

CE, RoHS

Power supply

12 to 24 VDC +/- 10 %; 6 W

Housing dimensions

L = 62 mm, H = 62 mm, D = 52 mm

Weight

170g

Storage temperature

-20 °C to +70 °C; -4 °F to +158 °F

Operating temperature (housing)

-10 °C to +50 °C; +14 °F to +122 °F

Maximum operating temperature mainboard

+100 °C; +212 °C

Maximum operating temperature sensor

+60 °C; +140 °F

Air humidity during operation

10% - 90% relative air humidity,

non-condensing

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 11

General ambient conditions

Operation

IEC 721-3-3:IE33

Transport

IEC 721-3-2:IE21

Storage

IEC 721-3-1:IE11

NOTE:

You should use thermal conductive mounting (for example direct attachment

on metal frame) to decrease temperature, improve camera performance and

avoid damages to the camera. See also section 5.5.

2.5 Features Reference and SDK

For detailed information on camera controls and features, please refer to the allPIXA SWIR

Features Reference, which is available on the allPIXA SWIR download page

https://chromasens.de/allpixa-swir-downloads and to the GenICam Standard Features Naming

Convention (SFNC) which is available free of charge on the GenICam download page of the

EMVA web site https://www.emva.org/.

The allPIXA SWIR Features Reference describes all standard and camera specific GenICam

features. Make sure that you always refer to the features reference that matches the XML

version used in your firmware.

Further documentation and downloads for software developers can be found in the Chromasens

Download Center https://chromasens.de/downloads. The Windows SDK is optional component

of the GCT installer, the Linux SDK is available on request.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 12

2.6 Sensor orientation

The sensor lines of different camera models vary in length, depending on maximum resolution

and pixel size.

Figure 2: Camera sensor line location

NOTE

The logo Chromasens on the side of the camera indicates the orientation of the

pixel line and the position of the first pixel.

Pixel 1

Sensor line

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 13

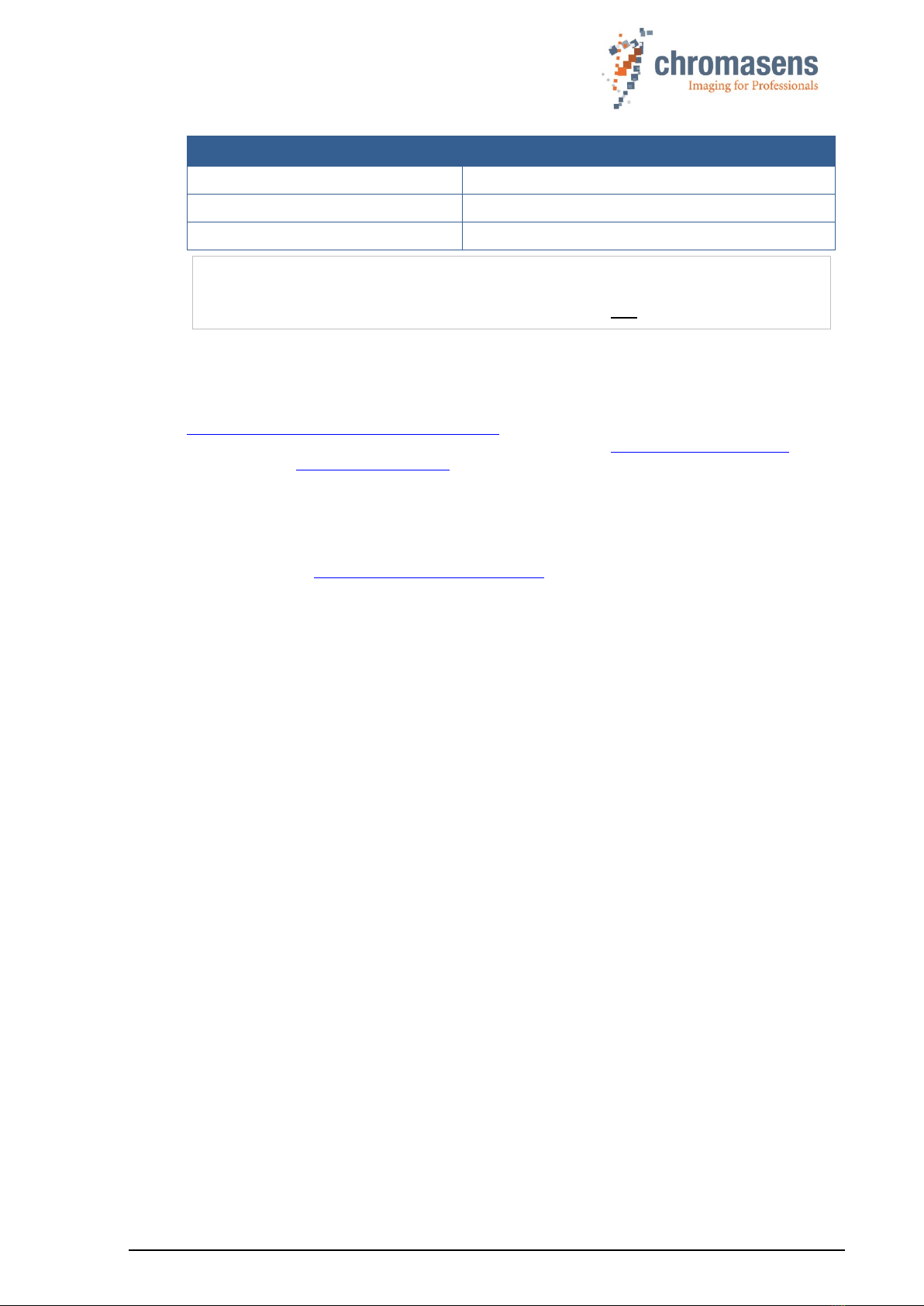

2.7 Factory settings

SWIR cameras are delivered with the following factory settings, which can be changed in the

Gev Interface Selector 0 of the GigE Vision subcategory in the Transport Layer Control

feature group:

Gev Feature

Value

Persistent IP Address

192.168.100.10

Persistent Default Gateway

0.0.0.0

Persistent Subnet Mask

255.255.255.0

Current IP Configuration LLA

On

Current IP Configuration DHCP

On

Current IP Configuration Persistent IP

Off

To use DHCP or LLA autoconfiguration, you have to disable Persistent IP as this has the

highest priority.

3 Safety

3.1 Depiction of safety instructions

Safety-relevant information is indicated in this manual as follows:

WARNING

Indicates a potentially hazardous situation or task, which, if not avoided,

could result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation or task, which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation or task, which, if not avoided, could

result in damage to the product or the surrounding environment.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 14

3.2 Basic safety regulations

Always observe the following:

◼Do not attempt to install the device or start operation before you have read all supplied

documentation carefully and have understood its contents.

◼Safe and correct operation of the device requires correct and appropriate transport, storage,

mounting and installation as well as careful operation and maintenance.

◼Operation of the allPIXA SWIR camera device is only permitted if it is in a faultless and safe

condition. If a fault or defect occurs, the allPIXA SWIR camera, the machine, or the system in

which the allPIXA SWIR camera is installed, must be stopped immediately, and the responsible

person must be informed.

◼Modifications and extensions to the allPIXA SWIR camera are only permitted if the prior written

consent of Chromasens GmbH is obtained. This applies in particular to modifications and

extensions which can negatively affect the safety of the allPIXA SWIR camera.

◼Compliance with the ambient conditions described in this manual is essential.

3.3 Safety instructions on the allPIXA SWIR camera

Risks from hot surfaces

The body of the allPIXA SWIR camera heats up during operation.

Do not touch hot surfaces without suitable protective gloves. Always allow hot

surfaces to cool down before carrying out any work on the unit.

Electric voltage hazard

The allPIXA SWIR camera runs with electric power. Before any work is carried

out on the allPIXA SWIR camera, be aware to disconnect the mains cables.

Make sure that the device is safely isolated from the power supply!

Risk of electrostatic discharge

The allPIXA SWIR camera contains components and units which are sensitive

to electrostatic charge.

Observe all precautionary measures for handling electrostatically sensitive

equipment.

Make sure that the allPIXA SWIR camera, its corresponding tools, its equipment,

and the person who is handling it have the same electrical potential.

3.4 Purpose / applications

◼The allPIXA SWIR camera is designed for machines and systems which are used for

commercial and industrial applications.

◼The owner of the machine or system in which the allPIXA SWIR camera has been installed is

responsible for compliance with relevant safety regulations, standards, and directives.

Commissioning of the allPIXA SWIR camera is only permitted if the machine or system, in which

the allPIXA SWIR camera is installed, complies with the safety regulations and standards of the

country in which the allPIXA SWIR camera runs.

◼The owner of the machine or system with the installed allPIXA SWIR camera must verify the

suitability of allPIXA SWIR camera for its intended use.

◼Safety regulations of the country in which the device is used must be complied with it.

◼The allPIXA SWIR camera may only be connected or used as described in this manual.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 15

◼The allPIXA SWIR camera must be set up and installed in compliance with the instructions

contained in this manual.

3.5 Staff requirements

◼The system owner must ensure that all persons working on the system are trained for the

required work and have read and understood this manual. This applies particularly to the

employees who only work occasionally with the allPIXA SWIR camera, for example, during

commissioning and maintenance work.

◼Work on the electrical installation of the system may only be carried out by a qualified electrician

or persons who have undergone the necessary electrotechnical training under the supervision

of a qualified electrician, in compliance with applicable electrotechnical regulations.

◼Be aware that only suitably trained and qualified persons are permitted to work with the allPIXA

SWIR camera. Such persons are qualified to work with the allPIXA SWIR camera device if they

are familiar with its assembly, installation, care, and all necessary precautionary measures.

◼Assignments and responsibilities of the staff charged with operation, commissioning,

maintenance, and repair must be clearly defined and specified by the owner of the device in

which the allPIXA SWIR camera is installed.

3.6 Organizational measurements

◼The instruction manual must be stored safely in the vicinity of the camera in operation.

◼Information contained in this manual must be integrated into the documentation of the device in

which the allPIXA SWIR camera is installed.

◼The allPIXA SWIR camera and all connected peripheries must be checked regularly for visible

external damages.

3.7 Safety instructions for maintenance / cleaning

◼Before any service or maintenance work is carried out, the responsible staff must be informed.

◼Deadlines and intervals for regular inspections must be complied with.

◼Before maintenance is started, the allPIXA SWIR camera must be isolated from the power

supply.

◼Due to the risk of fire, devices such as radiators, heaters, or lighting equipment must be allowed

first to cool down.

◼Only technicians of the Chromasens GmbH are permitted to open or slacken screws or housing

sections of the allPIXA SWIR camera.

◼Necessary repairs may only be carried out by Chromasens GmbH.

◼Cleaning of the device is only allowed with a soft, lint-free cloth and Isopropanol (optional).

◼To avoid damages, the camera should only be transported in its original packaging.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 16

3.8 Maintenance and cleaning of the allPIXA SWIR camera

During operation of the device, particles such as dust etc. may be settled on the optical

components (lens) of the camera. These deposits affect the optical image and the function of

the camera negatively.

Chromasens recommends regular inspection and cleaning. The cleaning

intervals depend on the actual operating and ambient conditions (for example

dust-laden atmosphere).

3.8.1 Cleaning intervals

Cleaning intervals depend on the environment. Regular inspection and cleaning intervals must

be specified depending on the degree of soiling.

3.8.2 Cleaning process

Body of the allPIXA SWIR camera heats up during operation.

Before cleaning, you must switch off the device. Always allow hot surfaces

to cool down before cleaning the device.

The device works with electric power. Before cleaning the device, make

sure that the device is disconnected from the power supply.

All surfaces requiring cleaning can be wiped with a soft, lint-free cloth which can be moistened

with Isopropanol.

Never use any other liquid or cleaning agent than those stated in this manual.

Never use hard or sharp tools for cleaning the device.

Inspect the device to ensure that cleaning was effective and repeat, if necessary.

If it is not possible to clean a component due to irremovable contamination, it must be replaced.

3.9 Disposal

This symbol indicates that electrical and electronic equipment should not be

disposed with normal garbage at the end of its working life. To prevent

possible harm to the environment or human health from uncontrolled waste

disposal, please separate this from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources.

Please dispose this product in accordance with your local regulations and contact your local

government office, for details of where and how they can take this item for environmentally safe

recycling.

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 17

4 allPIXA SWIR – basic functionality

4.1 Basic design of the allPIXA SWIR camera

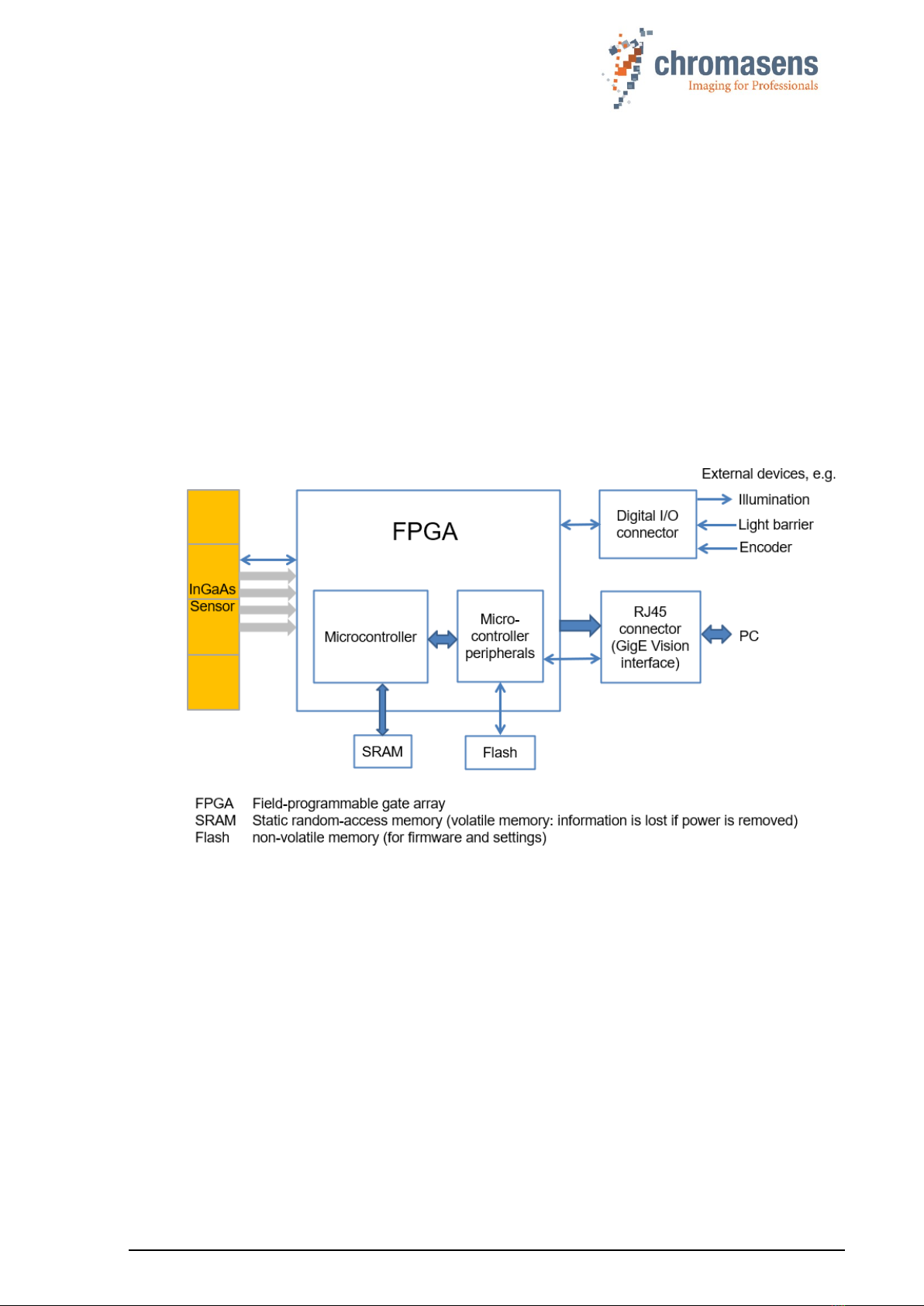

During operation, an object is scanned line by line by the InGaAs sensor.

The FPGA also includes a softcore microcontroller (or microprocessor) with its peripherals like

RAM and flash memory. The software running in the microcontroller configures and supports

the FPGA logic to process and transfer image data and to communicate with the host

application.

The allPIXA SWIR camera can be used and configured with any GigE Vision 2.0 compliant

Software or SDK. We recommend using the Chromasens GenICam Control Tool (GCT) and the

Chromasens SDK which is available for Linux and Windows. The Windows SDK is an optional

component of the GCT installer, the Linux SDK is available on request.

External trigger signals from sources like incremental encoders, light barriers, or light and trigger

controllers can be input by the GPIOs (general purpose inputs/outputs) of the Digital I/O

connector of the GigE models or by the CC of the camera.

Figure 3: Basic design of the allPIXA SWIR camera (block diagram)

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 18

4.2 Line Scan Sensors of the allPIXA SWIR camera

4.2.1 Design

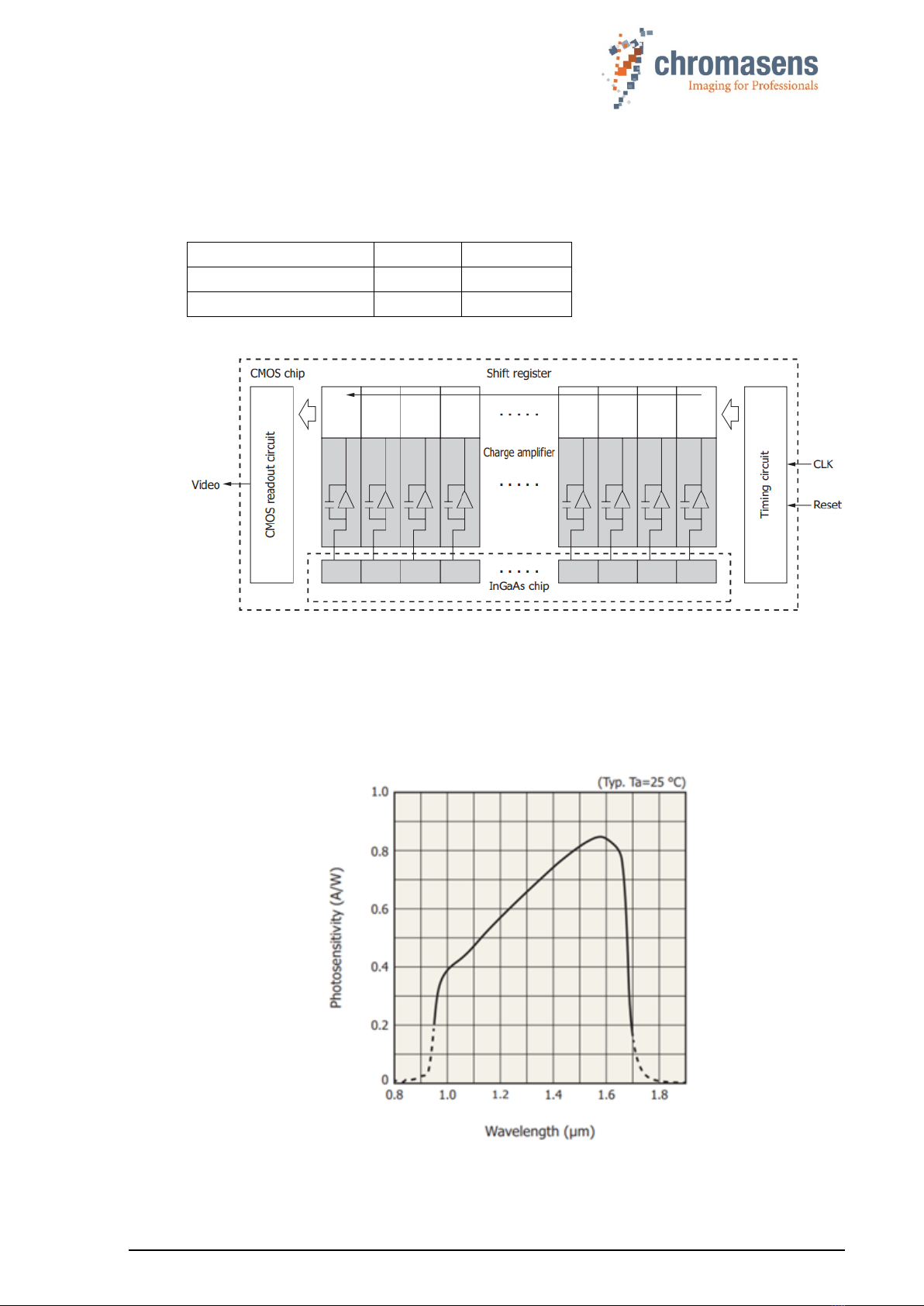

The allPIXA SWIR camera is available with two sensor variants:

Total number of pixels

512

1024

Pixel size (µm)

25 x 25

12.5 x 12.5

Pixel pitch (µm)

25

12.5

Figure 4: Camera sensor (block diagram)

4.2.2 Spectral sensitivity

The figure below represents the spectral response of the camera sensor (spectral responsivity

in A/W). The representation is based on sensor vendor information.

Normalized spectral sensitivity of the color camera (range 950nm –1700nm):

Figure 5: Spectral sensitivity of the line scan sensor

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 19

5 Installing the allPIXA SWIR camera

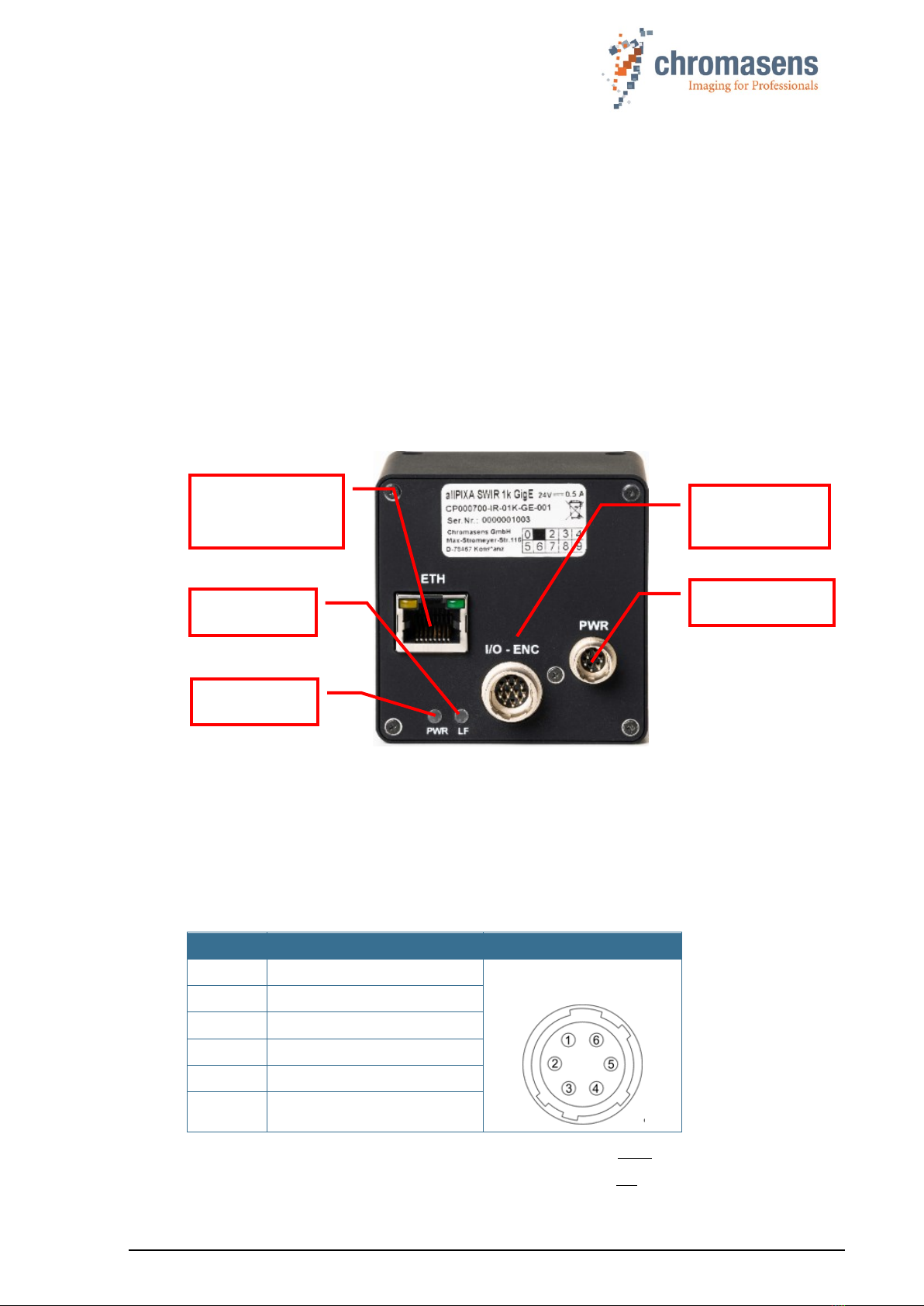

5.1 Connectors and LEDs of the camera with GigE Vision interface

On the backside of the camera, you find the following interfaces:

◼An RJ-45 Gigabit Ethernet connector for image signaling and for communication between the

allPIXA SWIR camera and the image processing computer.

◼A general-purpose digital input/output (GPIO) connector (Hirose 12 pin HD10A-10P-12S(73)

male) to connect external trigger sources like incremental encoders, light barriers or other

external devices.

◼A power connection (Hirose HR10A-7P-6S(73) male) for power supply

◼A red power LED, which indicates whether the allPIXA SWIR camera is connected to the

power supply.

◼An orange status LED, which blinks as soon as the camera firmware has booted successfully.

Figure 6: Connections and LEDs of the allPIXA SWIR GigE camera

5.1.1Power supply

Following connector is required for the power supply cable:

Manufacturer: Hirose

Manufacturer Part no.: HR10A-7P-6S “female”

(male counterpart is located on the camera)

Pin no.

Description

1

Power +24 V

Connector on camera

(male, front view):

2

Power +24 V

3

Not connected

4

Ground

5

Ground

6

Not connected

For available power supply cables and connectors see section 9.3.1.

For more details about input voltage and currents, see section 2.4.

RJ-45 Gigabit

Ethernet jack

(GigE Vision)

Power LED

Status LED

Digital I/O

connector

Power connector

PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx 20

5.1.2 RJ45 connector

The GigE RJ-45 jack connector permits to use a Cat-5e, Cat-6 or better S/STP Gigabit Ethernet

cable with lengths of up to 100 m.

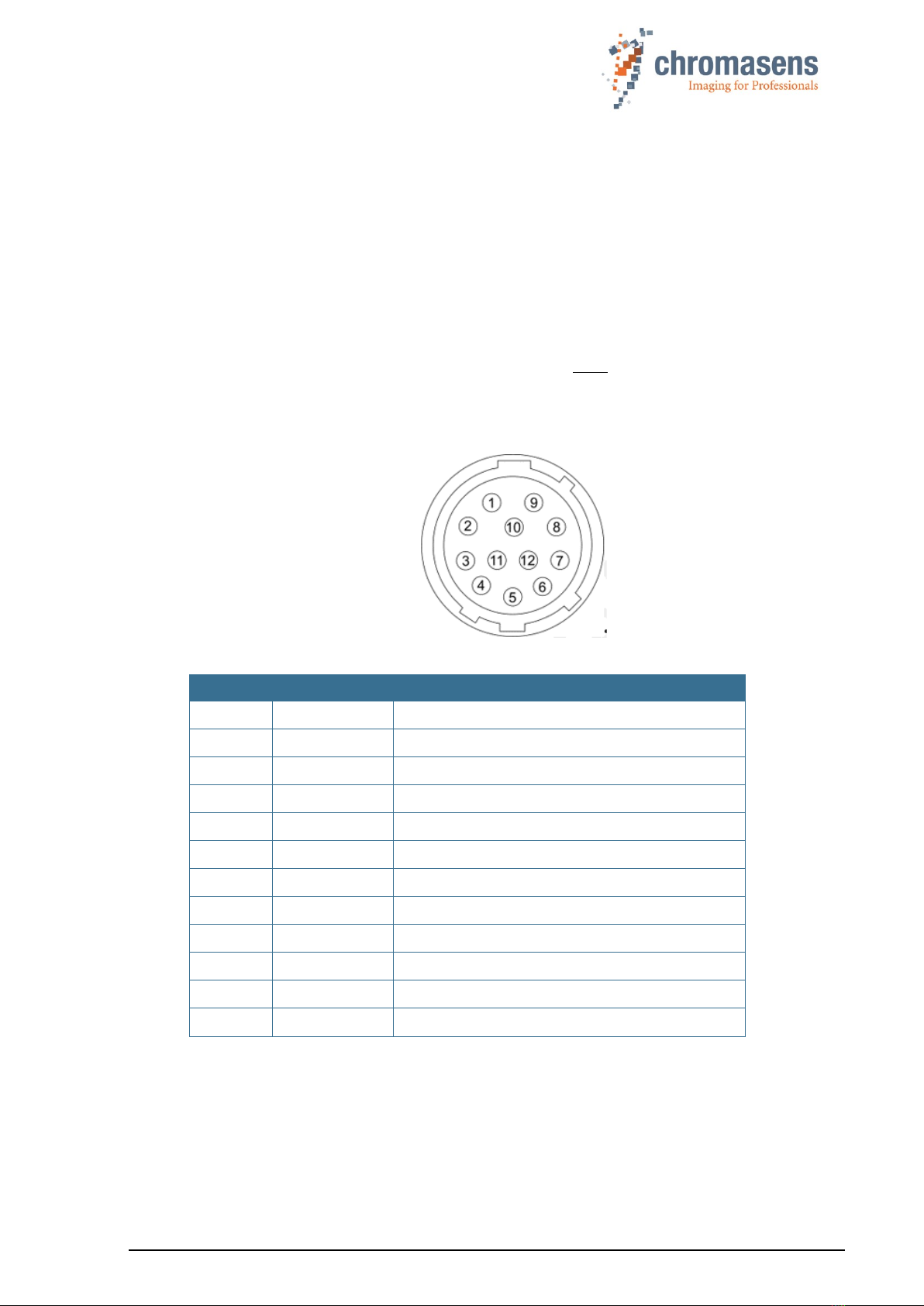

5.1.3 Digital I/O connector

Manufacturer and Type: Hirose 12 pin (male part on camera side)

Standard mating part: HR10A-10P-12S(73) (female on cable).

Mating cables: T18445 (5m, straight, open leads),

T18446 (5m right angle, open leads).

For more details about available I/O cables, see section 9.3.4.

You can connect up to three digital input signals and two digital output signals to the digital I/O

connector of the camera.

Figure 7: I/O connector on camera (male, front view)

Pin

Signal

Description

1

IN1 -

RS422 Digital Input Line 1 -

2

IN1 +

RS422 or LVTTL Digital Input Line 1 +

3

IN3 -

RS422 Digital Input Line 3 -

4

IN3 +

RS422 or LVTTL Digital Input Line 3 +

5

GND I/O

I/O Ground reference

6

OUT1 -

RS422 Digital Output Line A -

7

OUT1 +

RS422 Digital Output Line A +

8

IN2 -

RS422 Digital Input Line 2 -

9

IN2 +

RS422 or LVTTL Digital Input Line 2 +

10

N.C.

Not Connected

11

OUT2 -

RS422 Digital Output Line B -

12

OUT2 +

RS422 Digital Output Line B +

Table of contents

Other chromasens Digital Camera manuals