CHRYSLERSERVICEMANUALSTEERING—395

tighteningofthescrewsshouldcausetheend

playtojustdisappear withthetorquerequired

torotatethewheelfrom% to% ofa pound,

whenmeasuredwiththepullappliedatrimof

wheel.Ifa bindintherotationofthetubeoccurs

whenthecoverscrewsarefullytightened,it

willbenecessarytoaddshimthicknessuntil

bindjustdisappears.Ifendplayispresentafter

final tightening,lessshimthicknessisrequired.

Shimsareavailablein.003,.006,.011and.025

inch.Byusing a micrometertomeasureshims,#

thepropercombinationcanbechosen.

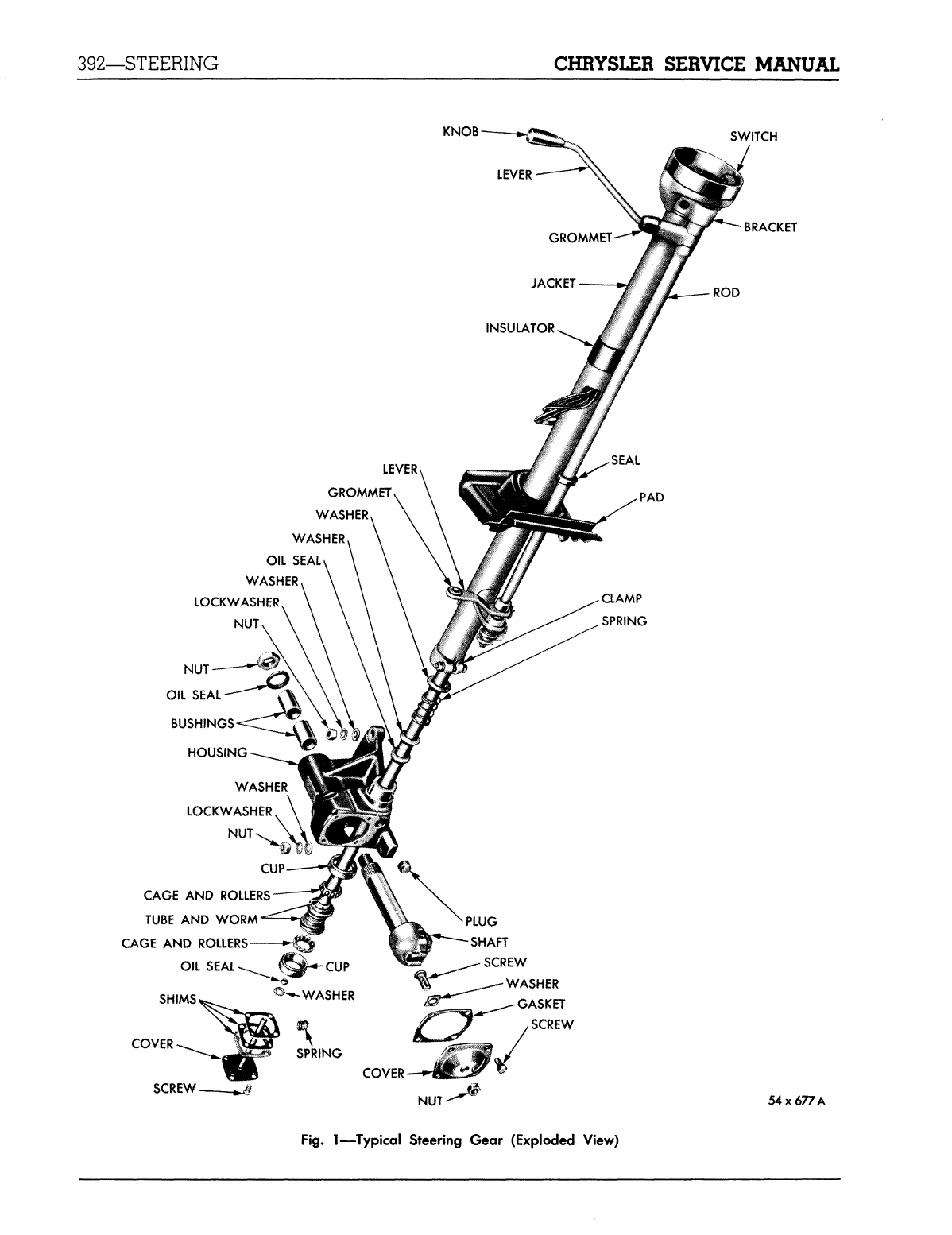

RefertoFigure2 and3.Installtheroller

shaftbearinginthehousing.Beforeinstalling

thecover,turn.theadjustingscrewalltheway

out(counter-clockwise).Whentherollershaft

assemblyiscompletelyinstalled,withtheex-

ceptionofthePitmanarm,adjustasfollows:

Placethesteeringwheelonthetubeandro-

tatethewheelineitherdirectiontotheendof

itstravel.Then,rotateintheoppositedirection

totheendoftravelwhilecountingtheturns.

Rotatethewheelback1/2thefullnumberof

turns.

Thisisthecenteroftravel(mid-travelor

highpoint).Turntheadjustingscrewin(clock-

wise)untilallendplayintherollershaftdis-

appears.Rollthewheelbackandforthseveral

times.

Thereshouldbenobind.Rotatethewheel

tooneoftheendsoftravelandapplya spring

scaleortorquewrench.Withthepullapplied

attherimofthewheel,thetensionshouldmea-

surefrom1 to2 pounds.Rotatethewheelback

tothecenterandonpastthecenterposition.

Thegreatesttensionshouldbefeltasthewheel

isrotatedthroughthecenterposition.Adjust

thebearingloadbyturningadjustingscrewin

oroutofthecover,asrequired.Installlock

plate,nut,andPitmanarm.Fillthegearhous-

ingwithSAE90FluidGearLubricant.Rotate

thewheelbackandforththroughitsfulltravel

severaltimestobesureallpartsarefullylu-

bricatedandcheckforleaks.

7.

ADJUSTINGWORMBEARINGS(InCar)

Rotatesteeringwheeltoextremerightorleft

andturnback% turn.Pressa finger atjoint

betweenbottomofsteeringwheelhubandshell.

Haveanothermechanicshakethefrontwheels

hardsideways,butnotenoughtoturnsteering

wheel.Anyendplayinwormbearingscanbe

feltatsteeringwheelhub.Thereshouldbeno

endplayatthe

hub.

Endplayshouldnotbecon-

fusedwithclearancebetweentherollerand

worm.Ifanyexcessiveendplayexists,remove

thesteeringgeararm,drainthehousing,and

disconnectthehornwireatconnectorbetween

steeringgearandhorn.

Removecap

screwswhichholdgreaseretainer

coveratbottomofsteeringgearhousing.Re-

moveshimsofsufficientthicknessbetweenthis

coverandhousingtoeliminatetheendplayin

worm,butnotenoughtocausebindingwhen

coverisboltedtightlyinplace.Turnsteering

wheelfromextremerighttoleft.Ifany

stiff-

nessexists,toomanyshimshavebeenremoved,

orthesteeringgearassemblyismisalignedon

car.

8.INSTALLATIONANDALIGNMENTOF

STEERINGGEARASSEMBLY

a.Installation

Wheregearchuckandwormshaftassemblyhas

beenremovedforservice,installasfollows.

Raisefrontofcar,insertwormshaftintojacket

andmovegearchuckassemblyupintoposition.

Itmaybenecessaryforanassistanttoguide

thetopofthewormshaftthroughtheupper

jacketalignmentbearing.Installgearchuckto

bracketattachingboltsandtightenforward

bolttoa snugfit. Lowercartofloor. Centerthe

jacketintheinstrumentpanelandtighten

bracketbolts.Installandtightendustpadre-

tainingscrews.Installsteeringwheelhornring

andornament.Raisefrontofcar.Tightenat-

tachingbolts.Installsteering(Pitman)arm

andtightennut.

b.

Alignment(AllModels)

Aslightbindofthesteeringgearissometimes

causedbyshiftingofbodyduetoloosenedbolts.

Ifthisconditionoccurs,bodyboltsshouldfirst

betightened.Then,thesteeringgearshouldbe

loosenedatframe,framebracketanddash

bracket,andallowedtoseekitsnaturalposition.

Positionthecenterofsteeringcolumnincen-

terofinstrumentcluster.Ifthiscannotbeac-

complishedbytheshiftingoftheframebracket,

asprovidedforbytheoversizeandelongated

mountingscrewholes,itwillbenecessaryto

addmetalwashershimsbetweentheframeand

framebracket.Tightendashbracketandtight-

ensteeringgeartoframe.