CONTENTS

.

.

See

ti0

1

.

2

.

3

.

4

.

5

.

6

.

7

.

8

.

9

.

10

.

11

.

12

.

n

Ti

rle

Page

SPECIFICATIONS

.............................................

1

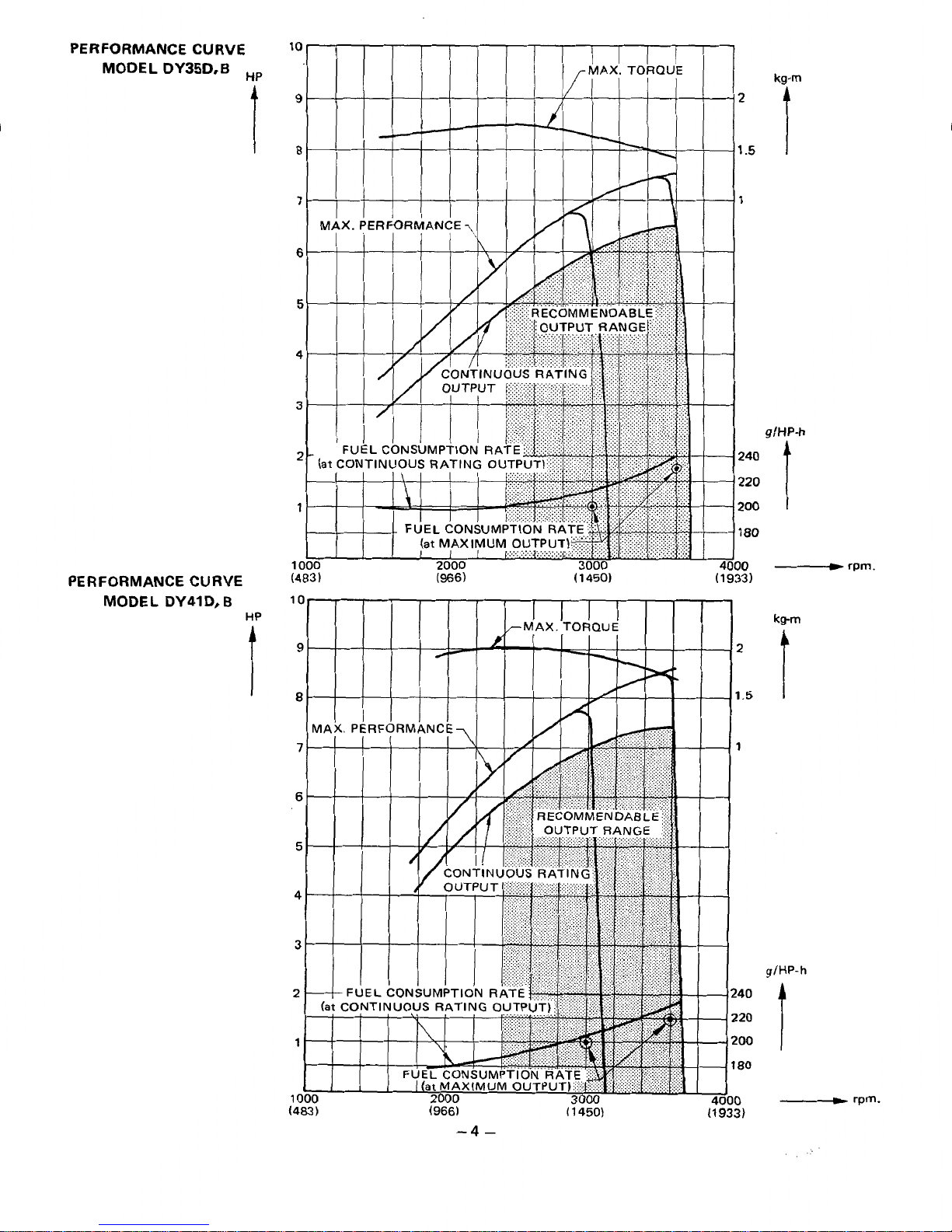

PERFORMANCE

..............................................

3

2-1 MaximumOutput

.........................................

3

2-2 Continuous RatedOutput

...................................

3

2-3 MaximumTorque and Fuel Consumption Ratio

at

MaximumOutput

.......

3

FEATURES

.................................................

5

GENERALDESCRIPTION

of

ENGINECONSTRUCTION

..................

5

4-

1

Crankcase

.............................................. 5

4-2 Crankshaft

.............................................

6

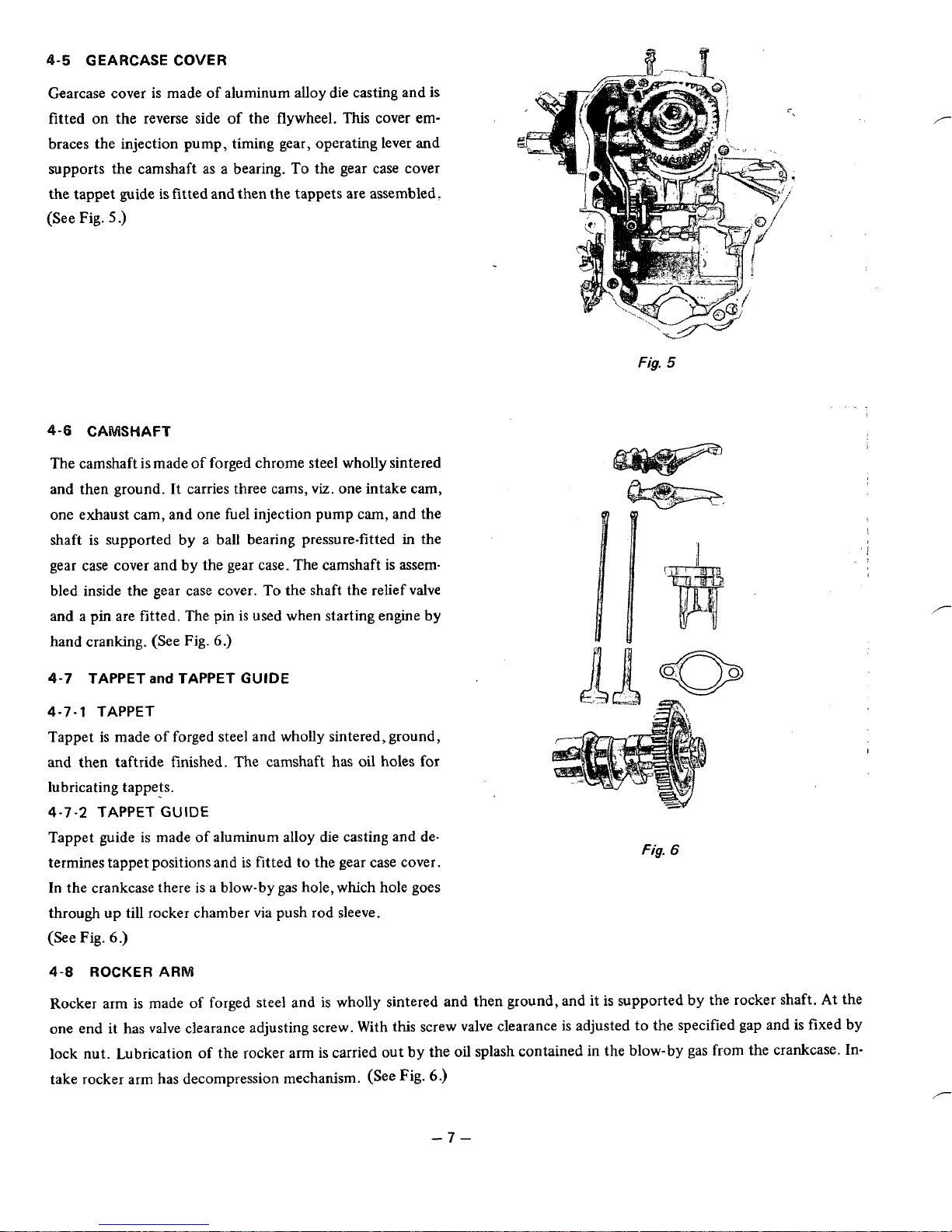

4-4 Cylinder andCylinderHead

..................................

6

4-5 GearCaseCover

..........................................

7

4-6 Camshaft

..............................................

7

4-8 Rocker Arm

............................................

7

4-9 Rocker Cover

............................................

8

4-10 GovernorSystem

.........................................

8

4-1

1

Lubrication System

........................................

8

4-13 Injection Pump

..........................................

9

4-14 Nozzle

................................................

9

4-

15 CombustionSystem

.......................................

10

4-16Sectional View of Engine

....................................

11

DISASSEMBLY

and

REASSEMBLY

.................

!

...............

13

5-2 Special

Tools

............................................

13

5-3 DisassemblySequence

......................................

14

5-4 How to Reassemble

........................................

20

FUEL

......................................................

28

6-1

Qualityof Fuel

..........................................

28

GENERALDESCRIPTION

of

AUXILIARYGADGETS

and

PARTS

...........

29

7

.

1 Fuel Injection

Pump

Mechanism

...............................

29

7-2

Fuel Injection Nozzle Holder

.................................

33

7-3 GovernorMechanismand Operation

.............................

36

7-4 Lubrication Systemand

Oil

Pump

..............................

38

7-5 OilFilter

...............................................

38

7-6 Electric Apparatus

........................................

39

INSTALLATION

..............................................

40

8-1 Installing

...............................................

40

8-2

Ventilation

.............................................

40

8-3 ExhaustGasDischarge

......................................

40

8-4

FuelSystem

............................................

40

8-5

PowerTransmission to DrivenMachines

..........................

40

CHECKS

and

CORRECTIONS

.....................................

41

TABLE

of

CORRECTIONSTANDARDS

..............................

42

MAINTENANCE

and

STORING

....................................

45

11

-1

Daily Checks andMaintenance

.................................

45

11

-2

Every

25

Hours Checksand Maintenance

.........................

45

11

-3

Every

50

Hours

(10

days)Checksand Maintenance

...................

45

11-4 Every

100

-

200 Hours (Monthly)Checksand Maintenance

.............

45

11

-5

Every

500

-

600 Hours(Semiannual) Checks

and

Maintenance

...........

46

11

-6

Every

1000

Hours (Yearly)Checksand Maintenance

..................

46

11

-7 Every

1500

Hours(Overhauls)

................................

46

11

-8 Preparationfor LongAbeyance

................................

46

REDUCTIONS

for

BTYPEENGINES

................................

47

12-1 Configuration

of

1/2 Reducer

................................

:

48

12-2 Structure

of

1/2 Reducer

....................................

49

12-3 DisassemblyandReassembly

of

1/2 Reducer

.......................

51

4-3 Connecting Rod andPiston

..................................

6

4-7 TappetandTappetGuide

....................................

7

4-12 CoolingSystem

..........................................

9

5-

1

PreparationsandSuggestions

.................................

13