0

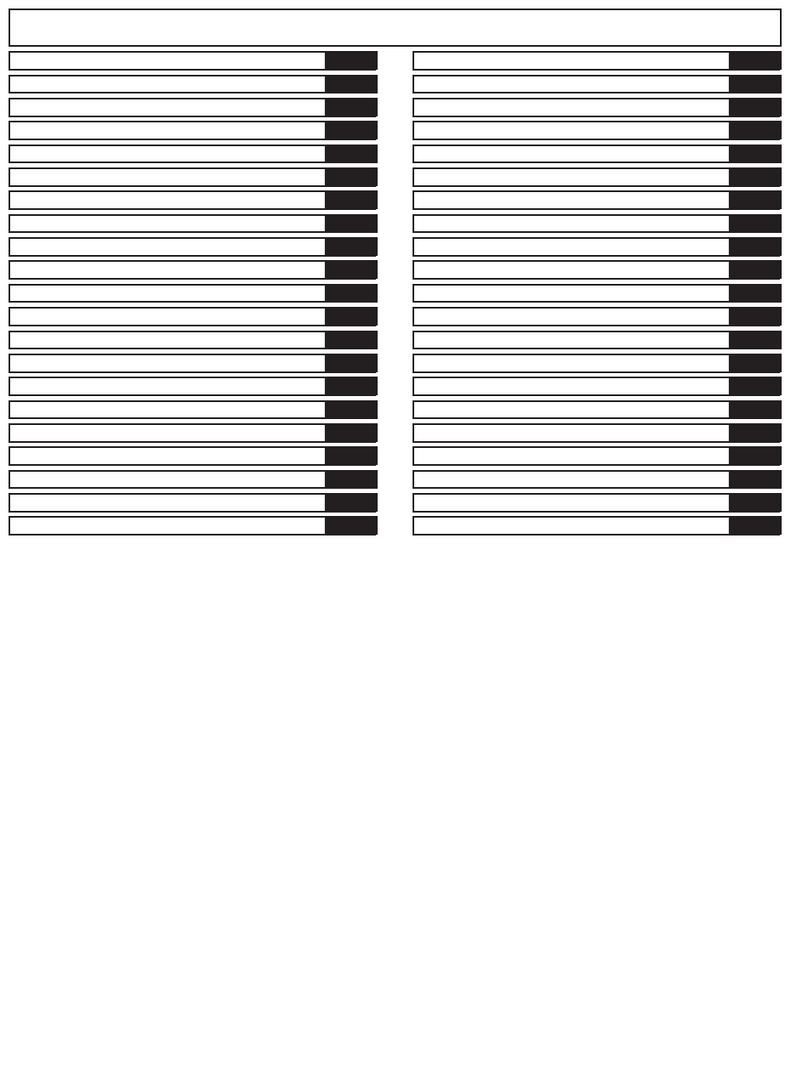

GROUP

0

LUBRICATION AND MAINTENANCE

CONTENTS

Page

ALTERNATOR

.........................

11

BATTERY

.............................

11

BODY MAINTENANCE

..................

25

BRAKES

..............................

9

CAPACITIES

..........................

5

CARBURETOR AIR CLEANERS

..........

17

CARBURETOR CHOKE SHAFT

..........

19

CERTIFIED

CAR CARE

.................

1

CHASSIS LUBRICATION

...............

6

CLASSIFICATION

OF

LUBRICANTS

......

1

CLUTCH LINKAGE

.....................

10

COOLING SYSTEM

.....................

11

CRANKCASE VENTILATION SYSTEM

....

14

DISTRIBUTORS

.......................

11

ENGINE OIL FILTERS

..................

14

ENGINE OIL-SELECTION OF

..........

12

ENGINE PERFORMANCE EVALUATION

.

.

17

FREQUENCY OF OIL CHANGES

.........

13

FRONT WHEEL BEARINGS

.............

23

FUEL FILTERS

........................

19

HEADLIGHTS

.........................

12

HOlSTlN

G

............................

6

HOOD LOCK, RELEASE MECHANISM

AND SAFETY CATCH

................

25

CERTIFIED CAR CARE

Certified Car Care

is

a thorough servicing program

that helps make sure the cars you sell receive the

regular attention you know they need.

Certified Car Care helps build business for you in

the best way known-through customer satisfaction.

Inform your customers that the best approach to

trouble-free driving

is

Certified Car Care.

This

is

a practical plan to help you build up sales

and service volume, by providing regular service cus-

tomer

visits.

SUMMARY OF LUBRICATION AND

MA1NTENANCE SERVICES

Maintenance and lubrication service recommenda-

tions for Chrysler Corporation-built Dodge cars have

been compiledto provide maximum protection for the

car owner’s investment against all reasonable types

of driving conditions.

Since these conditions vary with the individual car

owner’s driving habits, the area

in

which the car

is

operated and the type

of

service to which the car

is

subjected,

it

is

necessary to prescribe lubrication and

Page

HYDRAULIC BRAKE SYSTEM

..........

9

LUBRICATION AND MAINTENANCE

SCHEDULE

.........................

4

Normal Service

......................

4

Trailer Towing and Severe Service

......

5

LUBRICATIONAND MAINTENANCECHART

Dart

and Coronet

6

Cylinder Models

Dart, Coronet and Charger

.............

2

8

Cylinder Models

....................

3

MANIFOLD HEAT CONTROL VALVES

....

17

MATERIALS ADDED

TO

ENGINE OILS..

..

13

PARKING BRAKE MECHANISM

.........

10

PARTS REQUIRING NO LUBRICATION

..

29

PROPELLER SHAFT AND UNIVERSAL

JOINTS 20

REAR

AXLE

...........................

8

SPE

ED0

METER CABLE

................

24

STEERING GEAR

......................

20

SUMMARY OF LUBRICATION AND

MA1NTEN

A

N

C

E

SERVICES

...........

1

THROTTLE LINKAGES

.................

28

TIRES 24

TRANSM

I

SS

IO

N

(Auto

matic)

............

22

TRANSMISSION (Manual)

..............

21

WINDSHIELD WIPER BLADES

..........

12

2m

....

.............................

................................

maintanance service on a time frequency as well as

mileageintervalbasis.

Information pertaining to Lubrication and Main-

tenance requirements is shown on charts (Figs.

1

and

2)

and on the Schedule.

Vehicles operated under conditions not classified as

normal service for passenger cars, such as in trailer

towing service, operation at higher than normal load-

ing,

or

police

or

taxicab operation, require servicing

at more frequent intervals.

This

information

is

in-

cluded in each group under the heading “Trailer

Towing,Package and Severe Service”.

CLASS1FlCAT10N OF LUBRICANTS

Oils, lubricants and greases are classified and

graded according to standards recommended by the

Societyof Automotive Engineers

(SAE),

the American

Petroleum Institute (API) and the National Lubricat-

ing Grease Institute (NLGI).

Engine

Oil

The SAE grade number indicates the Viscosity

of

engine oils, for example, SAE

30,

which

is

a single

grade oil, Engine

oils

are also identified by

a

dual

MyMopar.com