Cimon CM3-SP32PWM User manual

Total Solution for Industrial Automation

Before You Start

This manual contains important information on the use and operation of this device.

Please read all the information carefully for optimal performance and to prevent any

damage or misuse of the device.

Safety symbols are classified into two categories, “WARNING” and “CAUTION”.

Warning This symbol describes situations that could cause major or fatal injury to

the user.

Caution This symbol describes situations that may cause minor injury or damage

to the device.

SAFETY SYMBOLS USED IN THIS PRODUCT MEANS:

This symbol warns the user of potential hazards.

This symbol warns the user of uninsulated voltage within the unit that can cause

dangerous electric shock.

Keep this manual nearby the user operating devices so it can be easily checked.

A-class equipment (Broadcasting communication

equipment for business)

This product has passed the testing for electromagnetic waves for business use, and

has not been designed or manufactured to be used as a household item; users are

advised as such.

Total Solution for Industrial Automation

Design Precautions ( Warning)

Please install a safety circuit to protect entire control system in case of an

unexpected power shut-down and PLC module malfunction. Such anomalies may

severely compromise the integrity of the overall system.

External to the PLC, please install circuits and switches to safeguard the system from

mechanical damages (ex. Emergency stop, upper/lower limit switches,

forward/reverse direction interlocking circuits, etc)

When the PLC detects either of the following failure conditions, it may stop

operation and turn off all outputs.

-The overcurrent protection or overvoltage protection of the power supply

module is activated.

-The PLC CPU detected a failure, such as the watchdog timer error or module

installation failure, with its self-diagnostic function.

In addition, all outputs may be turned on when there is a failure that the PLC CPU

cannot detect, such as in the relay or TR terminal. Build an extra monitoring circuit

that will monitor any output signal that could cause serious accidents.

A greater than normal current passed through the PLC for an extended period of

time, or a short-circuited load flows in the output module may cause a fire.

Build a circuit that turns on the external power supply after the PLC power supply is

turned on. If the external power supply is turned on first, it could result in output

failure or malfunction.

In order to ensure that the system operates safely, please configure an interlock

circuit in the scan program for the following situations.

-When exchanging data with computer or other devices.

-When operated by a computer or other devices.

Not doing so could result in output failure or malfunction.

Precautions for design ( Caution)

Do not bundle the input/output signal or communications cables with the main

circuit and power cables. They should be installed at least more than 100 mm

(3.94inches) apart. Not doing so could result in output failure or malfunction.

Total Solution for Industrial Automation

Precautions for mounting ( Caution)

Use the PLC in the environment that meets the general specifications given in this

manual. Using this PLC in any environment outside the range of the general

specifications could result in electric shock, fire, malfunction, or damage to or

deterioration of the product.

Please ensure that each module is installed correctly in its place. Loosely or

incorrectly installed pieces may result in malfunction, failure, or free-fall.

Power supply in PLC should be turned off before mounting the module. Not doing

so could cause an electric shock or damage to the device.

Install I/O devices or extension connectors correctly. If they are installed incorrectly, it

may result in an input or output failure.

Do not convey direct vibration into PLC. Not doing so could cause electric shock, fire

or malfunctions.

After wiring work, please make sure to close the terminal cover before turning on

the power for the PLC system.

Precautions for wiring ( Warning)

Make sure to check the device’s rated voltage and circuit arrangement before wiring.

Failure to do so may cause electric shock or damage on the device.

Make sure to close the terminal cover before turning on the power of PLC system

after wiring work. Failure to do so may cause electric shock.

Precautions for wiring ( Caution)

Make sure to check device’s regular voltage and sequence of terminals. Failure to do

so may cause fire, electric shock and malfunctions.

Make sure to tighten the screw with standard torque. Loose connections may cause

short, fire or malfunctions.

In grounding the FG ground terminals, be sure to conduct the product at least D

type (Class 3) grounding. Not doing so could result in electric shock or malfunctions.

When wiring, make sure that wiring debris do not enter the module. Failure to do so

may cause fire, equipment damage or malfunctions.

Total Solution for Industrial Automation

Precautions for test run and repair ( Warning)

Please do not touch the terminals when the power is ON. Doing so could cause an

electric shock or malfunctions.

When cleaning or tightening the screw, turn off the power of PLC and all other

systems. Failure to do so could cause an electric shock or malfunctions.

Do not charge, disassemble, heat up, short, or solder the battery. Doing so could

cause the battery to heat up, rupture or ignite thereby harming the user.

Precautions for test run and repair ( Caution)

Do not dissociate the PCB from the module’s casing or make any modifications to

the device. Doing so may cause fire, electric shock or malfunction.

When mounting or separating the module, make sure to turn off power to PLC and

all other devices. Failure to do so could cause an electric shock or malfunctions.

Use radio, walkie-talkie or cellphone devices at least 30cm away from the PLC. Not

doing so could result in malfunction.

Total Solution for Industrial Automation

1

PWM Output Module User’s manual

CONTENTS

1Introduction .................................................................................................. 2

1.1 Features ............................................................................................................................ 4

1.2 Design and Dimensions ..................................................................................................... 5

1.3 Configuring terminal blocks and names............................................................................. 6

2Specification ................................................................................................. 7

2.1 General specification ......................................................................................................... 7

2.2 I/O Specification ................................................................................................................ 8

3Data Memory ................................................................................................ 9

3.1 I/O Memory....................................................................................................................... 9

3.1.1 Output area................................................................................................................... 9

3.2 Buffer Memory................................................................................................................ 11

4Functions .................................................................................................... 13

4.1 Enable of PWM output (Buffer Memory Offset 0)............................................................ 14

4.2 Controlling frequency (Buffer Memory Offset 1 ~ 3)........................................................ 15

4.3 Controlling duty cycle (PWM) (Buffer Memory Offset 10 ~ 21) ........................................ 16

4.4 Ramp control .................................................................................................................. 16

4.4.1 Frequency ramp control (Buffer memory Offset 5 ~ 7) ................................................. 17

4.4.2 Duty cycle ramp control (Buffer memory Offset 30 ~ 41) ............................................. 18

5Operating the PWM Output Module............................................................. 19

5.1 Example for basic operation ............................................................................................ 19

5.2 Practical Examples ........................................................................................................... 21

6Maintenance work and repair....................................................................... 26

6.1 Maintenance work .......................................................................................................... 26

6.2 Repair ............................................................................................................................. 27

6.3 Trouble shooting ............................................................................................................. 28

Appendix 1 Using FROM∙FROMP/TO∙TOP Instructions.......................................... 29

Appendix 2 Method of Address Allocation .......................................................... 35

INDEX............................................................................................................... 43

Total Solution for Industrial Automation

2

CH 1. Introduction

1Introduction

This manual will guide the reader through installation, functions, safety use and

operation of the PWM output module (CM3-SP32PWM) of the PLC-S. This manual

will need to be read and understood before attempting to install or use the device.

Store this manual in a noticeable place so that you can take it out and read it

whenever necessary. Contents of this manual is as below:

Chapter 1 discusses the overview of the manual and introduces important

features of the product.

Chapter 2 explains the general and performance specifications of the product.

Chapter 3 explains the types and features of the data memory stored in the

product.

Chapter 4 goes over the capacities of the product, and how to control the

system.

Chapter 5 guides the user through programming examples of the product.

Chapter 6 explains repair and maintenance methods, and how to operate the

device safely.

In order to run the device properly, the following specifications are required.

Product

Version

Software(CICON)

V6.20 or above is recommended

PLC-S CPU

V6.13 or above is recommended

Below is an instruction on how to check the latest version of the software and CPU.

Run the CICON and click the [Help] –[About CICON information] located in the

upper right side of a menu bar. You can check the version of software in the dialog

box.

[Figure 1] Route to check software version

Total Solution for Industrial Automation

3

PWM Output Module User’s manual

Run the CICON and make a connection with PLC. Click the [Online] –[About PLC

information] or the icon below. You can check the version of CPU firmware in the

dialog box.

[Figure 2] Route to check CPU firmware

Total Solution for Industrial Automation

4

CH 1. Introduction

1.1 Features

PWM (Pulse-Width Modulation) is a digital output that can be used as an analog

output by controlling the duty cycle that contains a certain frequency.

CIMON PWM Output Module has a pulse output function added onto the general

digital output, so it has the same specifications as a CM3-SP32EOC when used as a

general digital output. The module:

Provides general digital outputs up to 32 points.

Supports for PWM pulse outputs up to 12 channels.

The PWM Output Module supports configurable functions such as controlling

frequencies and duty cycles. You can control 4 channels as a group with one

frequency, for a total of 3 groups.

Programming of the PWM pulse frequency can be done up to 4000pps, and the

duty cycle of the output pulse range can be adjusted from 0.0% to 100.0%, in

1/1000 resolution.

Moreover, duty cycle can be controlled individually by each channel, for up to and

total of 12 duty cycles are able to be controlled individually. In addition, the product

supports the ramp control on the frequency and duty cycle.

<Summary>

Programmable duty cycle of output pulse range is from 0.0% to 100.0%, in

1/1000 resolution.

The maximum programmable PWM pulse frequency is 4000pps.

Frequencies can be controlled in group with 4 channels as a unit, for a total of

3 groups.

A total of 12 duty cycles are able to be controlled individually.

The PWM device supports ramp control on frequency and duty cycle.

Total Solution for Industrial Automation

5

PWM Output Module User’s manual

1.2 Design and Dimensions

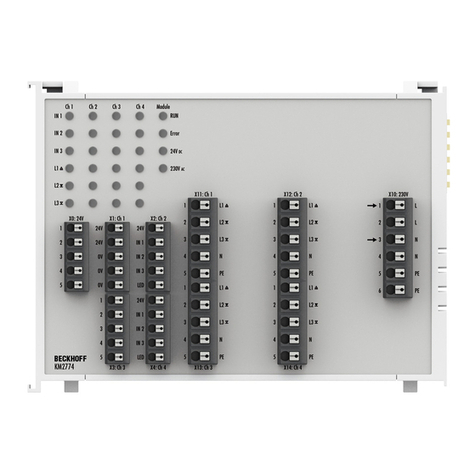

[Figure 3] PWM module appearance

Total Solution for Industrial Automation

6

CH 1. Introduction

1.3 Configuring terminal blocks and names

[Figure 4] Arrangement of terminals and its notations

For long cables, there is a

potential for unintended

distortion of the PWM pulse.

Therefore, 1.0M cable is

strongly recommended.

Each DC12/24V and DC

GND are connected to the

corresponding terminal

internally.

Total Solution for Industrial Automation

7

PWM Output Module User’s manual

2Specification

2.1 General specification

[Table 1] General specification of PWM module

Items

Specification

Standards

Operating

Temperature

-10 ~ 55 ℃(14 ~ 131℉)

Preserving

Temperature

-25 ~ 80 ℃ (-13 ~ 176℉)

Operating

Humidity

Relative Humidity 5 ~ 95%, Avoid condensation

Preserving

Humidity

Relative Humidity 5 ~ 95%, Avoid condensation

Inner Vibration

Frequency (Hz)

Continual Vibration

Intermittent Vibration

Number

IEC61131-2

Acceleration

(㎨)

Amplitude

(mm)

Acceleration

(㎨)

Amplitude

(mm)

10 ≤ f < 57

57 ≤ f ≤150Hz

4.9 {0.5G}

0.035

9.8 {1G}

0.075

10 times

for each

direction

X, Y, Z

Inner Impact

Maximum impact acceleration : 147 ㎨(15G)

Impression time : 11ms

Pulse wave : a sine half-wave pulse (3 times for each direction ±X, ±Y, ±Z, total on 3

times)

IEC61131-2

Inner Noise

Square wave impulse

noise

±2kV(10 minutes)

CIMON Internal

Test Standard

Electromagnetism

discharge

Voltage : 4kV(Contact Discharge)

IEC61131-2

IEC61000-4-2

Radiation EMF Noise

27 ~ 500 MHz 10V/m

IEC61131-2

IEC61000-4-3

FAST transient burst

Noise

Power supply Module

2kV

IEC61131-2

IEC61000-4-4

Digital input output (≥24V)

1kV

Digital input output (<24V)

0.25kV

Analog input output

Communication interface

Ambient

Conditions

Avoid Corrosive gas and dusts

Operating

Altitude

≤2000m

IEC61131-2

Pollution level

≤2

IEC61131-2

Colling System

Air natural cooled

Total Solution for Industrial Automation

8

CH 2. Specification

2.2 I/O Specification

Types

Specifications of item

Rated input/output voltage

DC 12V ~ 24V

Response time

≤1ms

Operating indicator

LED lighting when the power ON

Insulation for anticorrosion

Photocoupler

Input method

-

Output method

Source

External connection circuit

Internal circuit

[Table 2] I/O Specification of PWM module

Total Solution for Industrial Automation

9

PWM Output Module User’s manual

3Data Memory

Data memory is largely classified into two categories: I/O memory and buffer

memory. I/O memory exchanges I/O data with the CPU through the X and Y area.

Buffer memory exchanges user data with data areas in CPU module using FROM∙

FROMP/TO∙TOP instruction.

[Figure 5] Data exchange between PWM module and CPU

3.1 I/O Memory

I/O memory is an input/output memory area which is provided by the module. This

area can be operated in the scan program. The addresses of the X and Y are

determined by the location where the module is mounted. Please refer to Appendix

2 for details. PWM output module can offer 32-pin output through the I/O memory

area. Please refer to the table in 3.1.1 to check for more details of each point.

3.1.1 Output area

An output area of digital output module outputs the value of data received from the

CPU.

•External indicator: LED (a LED per channel)

•32 Y points (Yn0 ~ Y(n+1)F) (‘n’ states a number that can be decided by

mounted in slots.

Total Solution for Industrial Automation

10

CH 3. Data Memory

Signal Direction : CPU →PWM Output Module

Input

Signal Name

Output

Signal Name

Y20

General output

Y30

General output

Y21

General output

Y31

General output

Y22

Frequency A, CH1, PWM output

(or a general output)

Y32

Frequency C, CH9, PWM output

(or a general output)

Y23

Frequency A, CH2, PWM output

(or a general output)

Y33

Frequency C, CH10, PWM output

(or a general output)

Y24

General output

Y34

Frequency C, CH11, PWM output

(or a general output)

Y25

General output

Y35

Frequency C, CH12, PWM output

(or a general output)

Y26

Frequency A, CH3, PWM output

(or a general output)

Y36

General output

Y27

Frequency A, CH4, PWM output

(or a general output)

Y37

General output

Y28

General output

Y38

General output

Y29

General output

Y39

General output

Y2A

Frequency B, CH5, PWM output

(or a general output)

Y3A

General output

Y2B

Frequency B, CH6, PWM output

(or a general output)

Y3B

General output

Y2C

Frequency B, CH7, PWM output

(or a general output)

Y3C

General output

Y2D

Frequency B, CH8, PWM output

(or a general output)

Y3D

General output

Y2E

General output

Y3E

General output

Y2F

General output

Y3F

General output

[Table 3] Usage of each point of PWM module

※Stated points will follow the table above it the device is mounted in the first

slot.

※All points can be used to emit as general output. The PWM output could only

be operated as the points where it says ‘PWM output’.

Total Solution for Industrial Automation

11

PWM Output Module User’s manual

3.2 Buffer Memory

The PWM output module is equipped with shared memories inside to exchange the

data with CPU. One of these is called buffer memory, which is a collection of word

(16Bit)-unit data. This buffer memory is readable and configurable on scan program,

using FROM∙FROMP/TO∙TOP instructions. Please refer to the Appendix 1 to get

information about FROM∙FROMP/TO∙TOP instructions.

The PWM output module offers 64words of buffer memory in total. Following table

shows the meaning and usage of each data.

OFFSET

Item

Set-up value

parameter

Initial

value

Access

0

PWM output Enable

BIT #0~#11

(Total 12

channels)

0

R/W

1

CH1,2,3,4 Frequency

0~4000(pps)

0

R/W

2

CH5,6,7,8 Frequency

0~4000

0

R/W

3

CH9,10,11,12 Frequency

0~4000

0

R/W

4

Available Later

5

CH1,2,3,4 Frequency ramp control time(x10ms)

Ex) When Frequency ramp control time is set to 100,

100 x 10ms = 1,000ms (1sec)

0~65535

(x 10ms)

0

R/W

6

CH5,6,7,8 Frequency ramp control time(x10ms)

0~65535

0

R/W

7

CH9,10,11,12 Frequency ramp control time(x10ms)

0~65535

0

R/W

8

Available Later

9

Available Later

10

CH1 duty cycle ratio

Ex) When duty cycle ratio is set to 100, 100 x 0.1%

= 10.0%

0~1000

(x 0.1%)

0

R/W

11

CH2 duty cycle ratio

0~1000

0

R/W

12

CH3 duty cycle ratio

0~1000

0

R/W

13

CH4 duty cycle ratio

0~1000

0

R/W

14

CH5 duty cycle ratio

0~1000

0

R/W

15

CH6 duty cycle ratio

0~1000

0

R/W

16

CH7 duty cycle ratio

0~1000

0

R/W

17

CH8 duty cycle ratio

0~1000

0

R/W

18

CH9 duty cycle ratio

0~1000

0

R/W

19

CH10 duty cycle ratio

0~1000

0

R/W

Total Solution for Industrial Automation

12

CH 3. Data Memory

OFFSET

Item

Set-up value

parameter

Initial

value

Access

20

CH11 duty cycle ratio

Ex) When duty cycle ratio is set to 100, 100 x 0.1%

= 10.0%

0~1000

(x 0.1%)

0

R/W

21

CH12 duty cycle ratio

0~1000

0

R/W

22

Available Later

30

CH1 duty cycle ramp time(x10ms)

Ex) When Frequency ramp control time is set to 100,

100 x 10ms = 1,000ms (1sec)

0~65535

(x 10ms)

0

R/W

31

CH2 duty cycle ramp time(x10ms)

0~65535

0

R/W

32

CH3 duty cycle ramp time(x10ms)

0~65535

0

R/W

33

CH4 duty cycle ramp time(x10ms)

0~65535

0

R/W

34

CH5 duty cycle ramp time(x10ms)

0~65535

0

R/W

35

CH6 duty cycle ramp time(x10ms)

0~65535

0

R/W

36

CH7 duty cycle ramp time(x10ms)

0~65535

0

R/W

37

CH8 duty cycle ramp time(x10ms)

0~65535

0

R/W

38

CH9 duty cycle ramp time(x10ms)

0~65535

0

R/W

39

CH10 duty cycle ramp time(x10ms)

0~65535

0

R/W

40

CH11 duty cycle ramp time(x10ms)

0~65535

0

R/W

41

CH12 duty cycle ramp time(x10ms)

0~65535

0

R/W

…

Available Later

63

OS Version

0

R

…

Available Later

[Table 4] Usage and meaning of each buffer memory (PWM module)

※R/W represents for the module’s Read/Write accesses from the CPU. (R: Read W:

Write)

※All values in buffer memory will be erased and set to 0 when the power to the

CPU is turned off or stopped.

Total Solution for Industrial Automation

13

PWM Output Module User’s manual

4Functions

PWM (Pulse-Width Modulation) is a digital output that can be used as an analog

output by controlling the duty cycle that contains a certain frequency. Duty cycle is a

ratio of the ON to OFF status in 1 cycle (pulse).

[Figure 6] Definition of PWM output and duty cycle

As illustrated above, the PWM controls the output from minimum to maximum

values by changing the duty cycle of the pulse.

CIMON PWM output module can be either general digital output or PWM output.

The general digital output can be used up to 32-pin points. From these 32-pin

points, a total of 12-pin points support PWM output. Also, you can prevent drastic

change of the frequency and duty cycle by using the ramp control.

Total Solution for Industrial Automation

14

CH 4. Functions

4.1 Enable of PWM output (Buffer Memory Offset 0)

When PWM-capable points’ BIT value is set to 0, it will be possible to use them as

general output points. Similarly, if it is set to 1, it will be operated as PWM output.

The PWM output function can be enabled by using TO instruction in the buffer

memory Offset 0. Please refer to the 3.2 for information about the buffer memory.

[Table 5] Enabled points of PWM output

Example to enable PWM output of CH1, 3, 9 and output the frequency of CH1 to

1000pps and duty cycle to 50.0%.

BIT

15

BIT

14

BIT

13

BIT

12

BIT

11

BIT

10

BIT

9

BIT

8

BIT

7

BIT

6

BIT

5

BIT

4

BIT

3

BIT

2

BIT

1

BIT

0

Buffer

Memory

Offset 0

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

1

Binary

(H0105)

Disable

CH

12

CH

11

CH

10

CH

9

CH

8

CH

7

CH

6

CH

5

CH

4

CH

3

CH

2

CH

1

Channel

No.

Operates as below when M00 is ON:

a) Enable the PWM output in CH1, CH3, CH9.

b) Set the frequency of CH1 as 1000pps.

c) Set the duty cycle of CH1 as 50.0%.

In case of power reset or CPU stop, enable the PWM output again by using TO

instruction as all value of the buffer memory will be initialized to 0.

BIT

15

BIT

14

BIT

13

BIT

12

BIT

11

BIT

10

BIT

9

BIT

8

BIT

7

BIT

6

BIT

5

BIT

4

BIT

3

BIT

2

BIT

1

BIT

0

Buffer

Memory

Offset 0

Disable

CH

12

CH

11

CH

10

CH

9

CH

8

CH

7

CH

6

CH

5

CH

4

CH

3

CH

2

CH

1

Channel

No.

Example 1: Enable PWM Output

Table of contents

Other Cimon Control Unit manuals

Popular Control Unit manuals by other brands

Flow-Tek

Flow-Tek M1 Series Installation, operation and maintenance manual

Silicon Laboratories

Silicon Laboratories EMBER EM358 series Reference manual

RAKwireless

RAKwireless RAK4200 quick start guide

Digi

Digi ConnectCore 8X Hardware reference manual

Trenz Electronic

Trenz Electronic TE0720 Schematics

Exhausto

Exhausto EBC 10-P Installation & operating manual