Cincinnati KS-70 User manual

KS-70 RACK WASHER

Version 1.04

October, 2014

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

This ALVEY WASHING EQUIPMENT machine was installed by

(lead installer)

on the day of

(month / day / year).

Serial #:

Customer PO #:

Manufacturer SO #:

For parts and services, call

ARMOR AFTERMARKET

at

1-800-725-9957

or email partsandservice@armoraftermarket.com

KS-70 RACK WASHER

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Dear Valued Customer,

Thank you for your trust in, and relationship with CINCINNATI INDUSTRIAL MACHINERY. We hope you have many

years of uninterrupted service from our Alvey Brand product.

If you need parts, service, or support, contact ARMOR AFTERMARKET at 1-800-725-9957, or email

partsandservice@armoraftermarket.com. Some advantages of requesting ARMOR AFTERMARKET to fill your

replacement parts orders are:

1. Being the original manufacturer of this equipment offers simplicity in order replacement.

2. We are entitled to original equipment manufacturer discounts, which are passed on to our customers.

3. It is our primary responsibility to serve you in a timely and professional manner.

A suggested spare parts list for your machine is included in the CD we are providing your company. This CD

has been created to assist you in learning about and using your new machine. The program will help you quickly

find documentation and instructions regarding common usage and parts. Adobe Acrobat Reader will be

required to view the manual; a download is available from the CD.

If the CD does not start automatically, run “CD_Start.exe” on your CD drive. Should you have problems reading

any files, please contact us.

Sincerely,

Cincinnati Industrial Machinery

Documentation and Manual Team and The Parts and Service Department

KS-70 RACK WASHER

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Section Title Page

I. Warranty and Notice 1

II. General Description 3

III. Assembly of Washer and Auxiliary Equipment 6

IV. Service Connections 8

V. Start-Up 9

VI. Sequence of Operations 10

VII. Shut Down 11

VIII. Service and Maintenance 12

IX. Trouble-Shooting Guide 13

X. Recommended Spare Parts 16

XI. Illustrations (See Attached)

KS-70 RACK WASHER

TABLE OF CONTENTS

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

All licenses and permits, including without limitation,

any building or erection licenses and permits, if

necessary, shall likewise be paid by Purchaser; and

should Manufacturer be required to furnish any Bond or

Bonds on the within contract, the cost thereof shall also

be added to the quoted price.

ADDITIONAL MATERIAL AND LABOR - Any material

added to, or labor performed on or in connection with

the Equipment or installation thereof, shall be at

Purchaser's own expense, unless otherwise agreed to

in writing by Manufacturer.

SAFETY DEVICES - Manufacturer will supply such

safety devices or fire protection equipment as is

specified in writing in its proposals. If Purchaser

desires or requests through local, State or Insurance

Underwriter's Specifications or regulations, other

additional safety devices or equipment, Manufacturer

will undertake, without being obligated therefore, to

furnish same at Purchaser's cost. Manufacturer

assumes no liability for loss or damage to persons or

property occasioned by any accident or casualty

resulting from the use of fuel gas, fuel oil, oven or

immersion tube atmosphere gas in connection with the

Equipment.

USE OF SPECIFICATIONS AND DRAWINGS - The

drawings, designs, specifications and data

accompanying any proposal are Manufacturer's

property and are subject to recall by Manufacturer at

any time. Such drawings, designs, specifications and

data, or any part of them, shall not be used by

Purchaser for competitive bidding or similar purposes

without Manufacturer's prior written approval.

TITLE AND OWNERSHIP - It is the intention that the

Equipment be sold to Purchaser and that title to the

same shall be acquired by Purchaser upon shipment

from Manufacturer’s premises. Manufacturer shall

retain a purchase money security interest lien on each

piece of Equipment, including without limitation, any

accessories to such Equipment, proceeds from the

sale thereof and any insurance proceeds related to

such Equipment, until final payment thereof is made as

per the agreed terms. If Manufacturer gives Purchaser

possession before final payment is made, it is hereby

mutually agreed that:

a) The title and the right of possession of the

Equipment shall transfer to the Purchaser upon

shipment; provided however, Manufacturer shall retain

a purchase money security interest lien on each piece

of Equipment, including without limitation, any

accessories to such Equipment, proceeds from the

sale thereof and any insurance proceeds related to

such Equipment until full and final payment therefore

(including payment of any promissory notes and/or

other security taken in lieu of or in accordance with the

terms hereof) shall have been made. Purchaser also

authorizes Manufacturer to act as its agent and

attorney-in-fact (where permitted by law) for the limited

purpose of preparing, executing in Purchaser’s name,

and filing on its behalf, a financing statement (for

example, a UCC-1) to perfect Manufacturer’s purchase

money security interest in each piece of Equipment.

Until title or license has passed to Purchaser and full

and final payment has been received by Manufacturer,

Purchaser shall not cause nor permit any piece of the

Equipment to be sold, leased, or subject to a lien or

other encumbrance other than Manufacturer’s security

interest;

b) In the event of default or breach of any of the Terms

and Conditions of the contract, Manufacturer may, at

its option, repossess the Equipment and all additions

thereto, wherever found, free from all claims

whatsoever;

c) Any risk of loss during shipment shall be borne by

Purchaser and any loss or damage to the Equipment

during shipment shall not relieve Purchaser of its

obligations hereunder, including but not limited to

making full and final payment to Manufacturer.

The Equipment, or any part thereof, shall not be

considered a fixture or be incorporated into realty by

reason of its attachment thereto, and may be

separated from realty, as well as personality, for the

purpose of repossession. Manufacturer shall not be

liable to Purchaser, nor shall Manufacturer be subject

to any legal proceedings, criminal or civil, for

Manufacturer's acts in such repossession, nor for the

repayment of any money paid before such

repossession as part payment for the Equipment,

which shall be retained by Manufacturer as or on

account of liquidating damages.

Page 01

KS-70 RACK WASHER

WARRANTY AND NOTICE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

In addition to the purchase money security interest lien

described above, Manufacturer shall have the right to

elect or assert Manufacturer's claim of a mechanics

lien against the property upon which the Equipment

may erected and to waive Manufacturer's right to

repossess under section (b) above at any time before

the expiration of the time fixed by law for filing such

lien.

CLAIMS/LIABILITY -

a) Manufacturer shall not be liable for loss, damage,

detention, or delay resulting from causes beyond its

control or by acts of God, including floods, and acts of

foreign nations, or caused by fire, strike, civil or military

authority insurrection or riot, embargoes, car shortages,

wrecks or delay in transportation.

b) Manufacturer shall have no responsibility for loss or

damage to the Equipment after delivery to the carrier.

c) Manufacturer's liability arising out of the supplying of

the Equipment or its use shall not under any

circumstances exceed a credit of the purchase price,

F.O.B. Manufacturer's factory, of the Equipment.

d) IN NO EVENT SHALL MANUFACTURER BE

LIABLE FOR LIQUIDATED DAMAGES, OR

INDIRECT, OR CONSEQUENTIAL DAMAGE OF ANY

NATURE.

WARRANTIES -

a) Manufacturer warrants to Purchaser that the material

and workmanship of the Equipment is of good quality

and free of defects and the Equipment of its own

manufacture and design delivered hereunder shall be

of the kind and quality described in the specifications,

and that it shall be suitable for performing the work

therein described; provided, however, that the work for

which it is intended shall have been fully and

adequately presented, shown and described to

Manufacturer. The warranty period will start upon

shipment from a facility of Manufacturer and conclude

based upon a separate prearranged warranty period

agreed to in writing by Manufacturer.

b) EXCEPT AS SPECIFICALLY PROVIDED IN (a)

ABOVE, MANUFACTURER MAKES NO WARRANTY,

EXPRESS OR IMPLIED, RELATING TO THE

EQUIPMENT, ITS MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE.

c) Manufacture does not provide a separate warranty

for parts or components not manufactured by

Manufacturer. Equipment, parts and accessories made

by other manufacturers are warranted only to the

extent of the original manufacturer's warranty to

Manufacturer, which if extendable, Manufacturer will

extend to Purchaser.

d) In the event of Manufacturer's breach of its warranty

as provided in (a) above, Manufacturer’s total liability

shall be to repair or replace the Equipment and in no

event shall Manufacturer have any liability for any

consequential, incidental or other special damages,

including but not limited to damages or loss of profits

resulting from failure of the Equipment or delay caused

by its repair.

e) All transportation costs of returning defective goods

shall be borne by Purchaser. All transportation costs of

returning repaired or replaced products to Purchaser

shall be borne by Purchaser.

f) This warranty shall not be in force and effect unless:

Purchaser is current with all payments due to

Manufacturer; Purchaser gives Manufacturer

immediate notice of defective part or parts; Purchaser

affords the Manufacturer the opportunity to inspect

defective part or parts; material is still property of the

original owner; material is still part of the original

installation operating under normal usage (eight hours

per day and five days per week constitutes normal

usage); and material is properly maintained and

lubricated per factory instructions.

g) THE ABOVE WARRANTY DOES NOT COVER

PARTS WHICH UPON INSPECTION ARE

DETERMINED BY MANUFACTURER TO HAVE BEEN

SUBJECTED TO MISUSE, NEGLECT,

ALTERATIONS, ACCIDENT, ABUSE, DAMAGE BY

FIRE, FLOOD OR OTHER SIMILAR CASUALTY.

PATENTS - Manufacturer shall hold Purchaser

harmless from any and all costs and damages which

shall be recovered against Purchaser in any suit at law

or in equity for any infringement of any Letters Patent

by reason of the use by Purchaser of the Equipment.

Page 02

KS-70 RACK WASHER

WARRANTY AND NOTICE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

In addition to the purchase money security interest lien

described above, Manufacturer shall have the right to

elect or assert Manufacturer's claim of a mechanics

lien against the property upon which the Equipment

may erected and to waive Manufacturer's right to

repossess under section (b) above at any time before

the expiration of the time fixed by law for filing such

lien.

CLAIMS/LIABILITY -

a) Manufacturer shall not be liable for loss, damage,

detention, or delay resulting from causes beyond its

control or by acts of God, including floods, and acts of

foreign nations, or caused by fire, strike, civil or military

authority insurrection or riot, embargoes, car

shortages, wrecks or delay in transportation.

b) Manufacturer shall have no responsibility for loss or

damage to the Equipment after delivery to the carrier.

c) Manufacturer's liability arising out of the supplying of

the Equipment or its use shall not under any

circumstances exceed a credit of the purchase price,

F.O.B. Manufacturer's factory, of the Equipment.

d) IN NO EVENT SHALL MANUFACTURER BE

LIABLE FOR LIQUIDATED DAMAGES, OR

INDIRECT, OR CONSEQUENTIAL DAMAGE OF ANY

NATURE.

WARRANTIES -

a) Manufacturer warrants to Purchaser that the

material and workmanship of the Equipment is of good

quality and free of defects and the Equipment of its

own manufacture and design delivered hereunder shall

be of the kind and quality described in the

specifications, and that it shall be suitable for

performing the work therein described; provided,

however, that the work for which it is intended shall

have been fully and adequately presented, shown and

described to Manufacturer. The warranty period will

start upon shipment from a facility of Manufacturer and

conclude based upon a separate prearranged warranty

period agreed to in writing by Manufacturer.

b) EXCEPT AS SPECIFICALLY PROVIDED IN (a)

ABOVE, MANUFACTURER MAKES NO WARRANTY,

EXPRESS OR IMPLIED, RELATING TO THE

EQUIPMENT, ITS MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE.

c) Manufacture does not provide a separate warranty

for parts or components not manufactured by

Manufacturer. Equipment, parts and accessories

made by other manufacturers are warranted only to the

extent of the original manufacturer's warranty to

Manufacturer, which if extendable, Manufacturer will

extend to Purchaser.

d) In the event of Manufacturer's breach of its warranty

as provided in (a) above, Manufacturer’s total liability

shall be to repair or replace the Equipment and in no

event shall Manufacturer have any liability for any

consequential, incidental or other special damages,

including but not limited to damages or loss of profits

resulting from failure of the Equipment or delay caused

by its repair.

e) All transportation costs of returning defective goods

shall be borne by Purchaser. All transportation costs of

returning repaired or replaced products to Purchaser

shall be borne by Purchaser.

f) This warranty shall not be in force and effect unless:

Purchaser is current with all payments due to

Manufacturer; Purchaser gives Manufacturer

immediate notice of defective part or parts; Purchaser

affords the Manufacturer the opportunity to inspect

defective part or parts; material is still property of the

original owner; material is still part of the original

installation operating under normal usage (eight hours

per day and five days per week constitutes normal

usage); and material is properly maintained and

lubricated per factory instructions.

g) THE ABOVE WARRANTY DOES NOT COVER

PARTS WHICH UPON INSPECTION ARE

DETERMINED BY MANUFACTURER TO HAVE

BEEN SUBJECTED TO MISUSE, NEGLECT,

ALTERATIONS, ACCIDENT, ABUSE, DAMAGE BY

FIRE, FLOOD OR OTHER SIMILAR CASUALTY.

PATENTS - Manufacturer shall hold Purchaser

harmless from any and all costs and damages which

shall be recovered against Purchaser in any suit at law

or in equity for any infringement of any Letters Patent

by reason of the use by Purchaser of the Equipment.

Page 03

KS-70 RACK WASHER

WARRANTY AND NOTICE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

herein specified; provided and upon the express

condition that the Equipment is used in the manner

directed and exclusively for the purpose for which it is

sold without any changes and installed or used in

compliance with Manufacturer's plans and instructions,

and upon further express condition that Purchaser shall

immediately after service of the writ in any such suit at

law or in equity notify Manufacturer in writing of the

commencement of such suit, giving the names of the

parties and the title of the court, and shall permit

Manufacturer to defend same by its own counsel and at

its own expense and to have exclusive control and

management of the defense, and that Purchaser shall

give Manufacturer all needed information, assistance

and authority to enable Manufacturer to defend such

suit.

INDEMNIFICATION - Purchaser agrees to indemnify

Manufacturer, and hold Manufacturer harmless from,

all costs and expenses incurred by Manufacturer,

including, without limitation, costs of investigation,

attorneys' fees, and amounts paid in settlement or

satisfaction of claims, proceedings, or judgments, in

connection with all claims and proceedings against

Manufacturer based upon claimed defects in design in

any item or items manufactured for Purchaser by

Manufacturer to Purchaser's design and/or

specifications.

CANCELLATIONS - In the event Purchaser should

request cancellation of this contract, or part of it,

Purchaser agrees to pay Manufacturer the contract

price on any articles which are delivered and ready for

delivery on the date when such cancellation becomes

effective. As to all such articles not so delivered,

Purchaser shall have the option:

1) To require completion and to pay the contract

price thereof; or

2) To reimburse Manufacturer for actual

expenditures made with respect to the articles which

are uncompleted; to reimburse Manufacturer for

commitments incurred with respect to the uncompleted

articles of the contract; and to pay Manufacturer for the

anticipated profit of the entire contract.

Manufacturer may, by written notice to Purchaser and

without any liability, cancel Purchaser’s contract if

Purchaser (i) fails to perform any of the terms and

conditions hereof and does not cure such failure within

a period of 10 days after receipt of written notice from

Manufacturer specifying such failure: (ii) in

Manufacturer’s opinion has not established or

maintained credit to meet promptly the payment terms

imposed by Manufacturer: (iii) becomes insolvent,

makes an assignment in favor of creditors, or becomes

subject to any bankruptcy, dissolution, or similar

proceedings; or (iv) is merged into, or all or a

substantial part of its assets are sold to, another

company.

FORCE MAJEURE - Delays by Manufacturer or by

Purchaser in the performance of this contract shall be

excused whenever Manufacturer or the supplying

manufacturer is prevented from producing of delivering,

or Purchaser from receiving or using the above

material, by strikes, differences with workmen, fires,

accidents, delays or difficulties in transportation acts of

God or the public enemy, or other causes beyond the

reasonable control of Purchaser or of Manufacturer or

of the supplying manufacturer, as well as acts or

demands of the government in times of war or national

emergency. Any such delayed performance, however,

shall not in any way invalidate this contract or any part

thereof.

JURISDICTION - Purchaser irrevocably consents and

voluntarily submits to personal jurisdiction of the courts

located in Warren County and the United States District

Court for the Southern District of Ohio, Western

Division in any proceeding arising out of or relating to

the contract and agrees that all claims raised in such

proceeding may be heard and determined in such

court.

GOVERNING LAW – The contract shall be governed

by and construed in accordance with the internal laws

of the State of Ohio, United States of America, without

regard for its choice and or conflict of laws provisions

and without regard to the United Nations Convention

on Contracts for the International Sale of Goods.

Purchase Orders and/or contracts may only be

accepted in writing by an authorized representative of

Manufacturer from the Mason Office of Armor Metal

Group.

Page 04

KS-70 RACK WASHER

WARRANTY AND NOTICE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

OVERVIEW

The model KS-70 is a walk-in type compact stainless

steel cabinet washer designed to clean racks, carts,

and delivery cabinets. The washer is fully assembled

and tested at the factory, then knocked down and

crated for shipment and re-assembly at the job site.

The machine is designed for installation in a shallow

pit. When constructing a pit is not desired, a floor-

mounted option with load ramp or a side-mounted tank

can be ordered.

The machine subjects work to a recirculating high-

pressure spray wash through two rotating spray arms

followed by a fresh water rinse. The wash tank is

manually filled with cold or hot water which is heated

by one of the optional systems: a steam injector,

steam heated coils, electric immersion heaters, or a

natural gas or propane burner. The wash water

temperature is thermostatically controlled.

AVAILABLE OPTIONS

Rinse water booster heater - electric, gas or steam

Exhaust fan with controls - factory wired

Draft inducer for gas burner exhaust - factory wired

Higher capacity pump

Second door for pass through operation

Double capacity with two additional wash arms

Insulated housing

Automatic water fill

Carts, racks, and baskets

Floor-mounted tank and load ramp

Side-mounted tank

Page 05

Pit-Mounted Option Shown

KS-70 RACK WASHER

GENERAL OVERVIEW

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Selecting a Location

When selecting the location to install your Alvey KS-

70 Rack washer, review the dimension sheets and

consider access to the utility requirements.

Determine the minimum distance from outside wall or

roof to optimize ventilation. Ensure there is ample

floor space for maintenance and for storage of

cleaned and soiled work. Finally, confirm whether

the machine is pit or floor mounted. If pit mounted,

ensure that the pit for the tank has been constructed.

If floor mounted, confirm that there is sufficient space

for the machine loading ramp.

Receiving the Machine

The machine will be received disassembled. The

wash chamber and attached equipment have been

removed from the tank in preparation for shipment.

Panel flanges and tank is match marked before

disassembly of wash chamber. Wiring is

disconnected at junction boxes with leads marked;

piping is disconnected at unions. Solenoid coils are

slipped off valves and remain attached to conduit

assemblies. Mounting hardware is left attached to

studs on cabinet panels. An assembly kit contains an

adequate length of sealing strip, tubes of silicone

caulk, and sufficient hardware to secure chamber

panels.

Examine equipment for agreement with packing slip

and dimension sheet. Notify factory immediately

concerning any shortages or shipping damage.

Page 06

KS-70 RACK WASHER

SETUP

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Preparation for Assembly

Inspect pit to assure agreement with drawing and

dimension print. Examine panels; determine

assembled location of each panel by noting match

marks and equipment mounting stud locations. Note

that flange shape determines order of assembly of

panels. Clean flange faces of tank and chamber

panels after removing protective paper.

Tank Assembly

Locate tank assembly in desired positions and levels.

If unit is suspended on edge of pit by a boundary

angle, leveling is not required.

Sealing Strip

Place sealing strip on tank and chamber panel

flanges. One strip is required per joint. Avoid door

area. Strip is tacky and will remain in place. Applying

a liquid soap solution to exposed surface of strip will

allow panels to be more easily shifted during bolting.

Use silicon caulk at corners where sealing strips join

and other areas where leaks might occur.

Chamber Panels

Install chamber panels.

1. After removing door, locate front panel assembly

in position on tank.

2. Locate right and left rear corner panels in position

on tank. (If washer has pass through option,

repeat steps 1 for second door.)

3. Temporarily position rinse manifolds in chamber,

before continuing, as they will not easily fit

through door.

4. Continue setting the remaining vertical panels in

position and loosely bolt.

5. Now place front and rear top panels in position

before installing center top panel. Be certain to

apply caulk at corners as before. Loosely bolt.

6. Reinstall door into front panel assembly. Align

assembly so that door will latch and seal

properly; tighten only those bolts holding front

assembly to the tank.

7. Align next adjacent panels and tighten bolts

attaching them to the front panel assembly. Start

at the bottom. Repeat for each successive

Interior Piping

1. Attach interior rinse piping to rinse manifolds at

unions and extend threaded nipple through

chamber wall. Secure with pipe nuts and rubber

and metal washers. Bolt rinse manifold brackets

to chamber panel flanges.

2. Screw vertical wash pipes tightly into wash

manifold and then bolt spray elbows to wash

pipes and chamber flanges.

3. Install wash arms assemblies and align with

chamber wall to avoid interference with rinse

manifolds and guard rails. Be sure all pipe joints

are tight.

4. Install guard rails and verify that they do not

interfere with wash arms.

Control Panel

Install control panel and conduit assemblies and

attach related wiring.

1. Attach control panel and conduit assemblies to

housing with studs and nuts provided. Connect

wires at appropriate locations on terminal strip.

See wiring diagram.

2. Attach proximity switch 1PROX to bracket by

door and associated magnet and bracket to studs

provided on door. With pass through option,

repeat with second door.

3. Connect flexible conduit to motor (leads IT1, IT2,

IT3) and to gas burner (leads 14, 16, 17, 2) (Gas

heated tank only.)

4. Attach flexible conduit from float switches to

fittings on conduit assembly; connect tagged

wires (3, 12). Only washers with electric and gas

tank heat have a low-level float. Only washers

with automatic water fill have a high level float.

5. Assemble STEAM HEAT solenoid coil (2, 15)

onto steam solenoid valve. (Steam heated tank

only.)

Page 07

vertical panel until all are secure. If washer has

second door, repeat step 6 for rear panel

assembly.

8. Now tighten the remaining bolts holding the

vertical panels to tank and to top.

9. Tighten bolts securing top panels to each other.

KS-70 RACK WASHER

ASSEMBLY OF WASHER AND AUXILIARY EQUIPMENT

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Gauge Panels

Install gauge panel and related temperature and

pressure probes.

1. Attach panel to chamber on studs provided.

2. Install probe from wash temperature gauge into

bracket provided in tank.

3. Install probe from rinse temperature gauge into

fitting on external rinse manifold.

4. Install fitting on wash pressure gauge tubing into

tapped hole on wash pump.

5. Install capillary tube from temperature control into

bracket next to wash temperature probe.

Exterior Piping

Install exterior rinse piping assembly (and booster

heater when provided).

1. Place booster heater, when provided, in required

position.

2. Attach external rinse piping assembly to nipple

extending through chamber wall. Attach rinse

solenoid coil to valve on piping assembly with

clips provided.

3. Steam booster heater option - Attach water inlet,

steam inlet and condensate piping assemblies to

booster heater. Attach rinse booster solenoid coil

to steam valve. Attach piping assembly between

booster and external rinse manifold.

4. Electric and gas booster heater option - Attach

piping assembly between booster and external

rinse manifold.

5. Verify that all rinse water and steam connections

are tight.

Exhaust Fan

Install exhaust fan and draft inducer. Position fan

assembly and attach with gasket and hardware

provided. Draft inducer must be installed in exhaust

stack above draft hood by customer. Connect the

flexible conduit provided to each motor and attach

leads.

Caulk

Caulk cabinet and trim sealing strip. Caulk around

base of machine between tank and floor and between

tank and cabinet. After initial start up, caulk as

required, to eliminate leaks. The sealing strip used at

housing seams will tend to extrude out during the first

few weeks of service. This can be trimmed back with

a utility knife.

Page 08

KS-70 RACK WASHER

ASSEMBLY OF WASHER AND AUXILIARY EQUIPMENT

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Service Connections

TANK WATER FILL

Connect cold water line to 1" ball valve on side of

washer.

FRESH WATER RINSE

Connect 3/4" hot water line to strainer on rinse water

manifold. The rinse flow rate is controlled by the

quantity and size of rinse nozzles. See dimension

sheet for rated flow. Recommended rinse

temperature: 180 – 195° F.

When optional booster heater is provided, connect hot

water line directly to booster. Consult dimension prints

for size and location of connection. Both the electric

and gas boosters come complete with pressure

regulators.

DRAIN

Provide pit with a 2" minimum drain located to allow

access when washer is in position. Tank drain and

overflow empty into pit.

With floor mounted machine, a common 2" outlet for

tank and overflow is provided for direct connection to

customers drain line. Use union or flanged connection

to allow washer to be easily disconnected.

STEAM SERVICE—STEAM HEATED TANK

Connect service to steam inlet valve. Minimum

operating pressure is 10 PSI. When steam plate coil

heat is supplied, a 3/4" condensate return line is

required.

STEAM SERVICE—BOOSTER HEATER

Connect 1 1/2" line with 10-15 PSI pressure to the

valve on booster inlet. A 3/4" condensate return line is

required; see Sec. V D note.

GAS SERVICE

Connect 3/4" gas line with manual shut off valve and

drip leg to burner inlet of gas heated washers. Make a

similar connection to gas booster heater when

provided. Consult dimension prints for line size.

FIRE TUBE EXHAUST—GAS HEATED TANK

Connect 8" dia. stack and draft hood to 6 5/8" outside

diameter burner exhaust tube. The stack should have

no horizontal run; stack sections should be lapped in

the direction of flow. It may be advisable to install

damper in exhaust stack to control draft. See sketch.

When optional draft inducer is furnished, enough

flexible conduit is included to allow inducer

to be mounted in stack within 3' from top of

washer.

VENTILATION

Use 7 9/16” inside diameter watertight duct with inside

lapping of joints in direction of flow. Use gasket

between fan and washer housing to prevent

condensate from seeping. See sketch.

ELECTRICAL—WASHER

Connect outside power line to L-1, L-2 and L-3 on the

terminal block in the control panel. A fused disconnect

shall be provided within sight of the washer to prevent

danger of shock. See dimension sheet for power

requirements.

ELECTRICAL—GAS AND ELECTRICAL BOOSTER

HEATERS

A separate power line with a fused safety switch must

be provided for gas and electric booster heaters. See

dimension sheet for power requirements. See booster

heater installation and operating manual enclosed.

Page 09

KS-70 RACK WASHER

SERVICE CONNECTIONS

Note: To maintain a consistent rise flow rate,

install pressure regulator and adjust for 20 PSI.

Note: If there is backpressure in the condensate return

line, install a check valve after steam trap for

satisfactory performance of the steam coil.

Note: High booster steam pressure will cause an

excessive amount of rinse water to flash into steam.

Install a steam pressure regulator to control the rinse

temperature.

Note: A draft inducer will be required under any of the

following conditions:

Building is under negative pressure

Outside air currents produce down drafts

Exhaust stack design causes excessive restriction

Required by local codes

Note: Stack temperature can exceed 600° F.

Selection of proper material is the customer’s

responsibility.

Note: Do not obstruct loading area with service

connections.

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Note: During first week of operation, closely inspect

spray nozzles and hub assemblies for debris which

may have collected. Clean as per IX.B.

Caution: Shut off power at the disconnect

before opening the control panel.

Note: Gas burner delay timer (1TR) in control panel

prevents buildup of fumes in burner prior to ignition.

Timer is preset at five seconds.

Note: We recommend adjustments to the burner be

made by your local gas company or a reputable

service company.

Important: For satisfactory cleaning the proper

detergent must be used.

Local sales or factory representative will assist in

initial start up unless otherwise stated in order.

1. Remove grip strut walkway from inside of

machine. Open drain valve. Remove filter and

pump protection screens.

2. Flush out tank and inside walls, preferably with

high-pressure hose, to remove contaminants,

which may remain from fabrication, shipment, or

installation. With subsequent cleaning, after

washer operation, care must be taken to clean

float switches, heating elements, tank corners, and

pump compartment.

3. When cleaning is completed, close drain and

replace screens and walkway.

4. To fill tank open manual valve and allow water to

rise to the overflow level. If option included on

washer, press AUTOMATIC WATER FILL button on

the control panel.

1. Verify that tank is filled. Low level cutoff float,

provided with gas and electric heat, will prevent

tank heat from being activated when water is low.

2. Set desired wash temperature (140°-160° F).

3. Turn on power to washer at disconnect switch.

4. Steam Heat - Open manual steam valve; turn

control panel heat switch to ON.

5. Electric Heat-Turn control panel HEAT switch to

on.

Tank Preparation

On initial start-up, check rotation of all motors.

Rotation of Motors

Activating Tank Heat Assembly

When hot water is supplied directly to the washer

rinse manifold, customer's heater must be adjusted to

provide the desired temperature on the rinse

temperature gauge in the control panel.

The electric and gas booster heaters are

thermostatically controlled and preset at time of

manufacture to provide a (180-195 deg. F) rinse.

Consult the respective operating manual enclosed.

The steam booster heater is sized to provide a (180-

195 deg. F) rinse at rated flow and pressure when

supplied with 10-15 PSI. of steam. See dimension

print. Further temperature adjustment can be made

by use of a steam pressure regulator.

Rinse Water Temperature Control

6. Gas Heat

a. Open manual gas valve and turn combination

gas valve to ON.

b. Turn control panel heat switch to ON.

c. Burner is automatically lit. The draft inducer,

when furnished, will be energized.

d. A damper in exhaust stack should be used to

control the amount of draft.

When the wash water reaches operating

temperature, add desired amount of cleaning

compound. Consult chemical supplier for

recommendations.

(Cont.)

Detergent

Page 10

KS-70 RACK WASHER

STARTUP

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Important: Cleaning compound should be the non-

foaming type, and not contain substances that will

react with copper or aluminum.

Use of an automatic detergent dispenser is

recommended. To insure economical use of the

compounds, sensing probes must be kept clean of

any foreign matter. If in powder form, pour detergent

into wash tank, close door, and run wash cycle until

compound has been dissolved. Avoid rinse cycle to

prevent unnecessary dilution. Consult chemical

supplier for equipment recommendations.

Detergent (Cont.)

Note: See note on electrical diagram for soap

dispenser hookup

Page 11

KS-70 RACK WASHER

STARTUP

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014 Page 12

Daily Start-Up

1. Turn on power at customer-provided Disconnect Switch. Electric or gas

booster will be connected to a disconnect separate from washer

2. Turn on washer’s Main Power Switch. The white “Power On” indicator will

light.

3. Ensure that the drain valve is in the closed position.

4. Close door to begin automatically filling the tank. The unit will stop filling

the tank when the proper level is reached.

5. Turn on the Wash Heat Switch to activate the steam heat coil in the wash

tank.

Note: When washer is connected to central exhaust

system, means must be provided to prevent the

exhaust of moist air during the operation of the washer.

Sequence of Operation

1. Set the wash temperature controller, located on the front of the main control

panel, to 160°F / 71.1°C (See temperature controller manual for setting

instructions).

2. When the temperature for the wash tank reaches the 160°F/71.1°C set

point, the washer door can be opened and the racks can be loaded.

3. Adjust the Cycle Time Switch to the light, medium or heavy soil position

depending soil conditions.

4. Push the green Cycle Start Button to begin wash cycle. The red In Cycle

Indicator will light, and stay lit until the cycle is complete.

5. Unload washer after In Cycle indicator goes off and wash cycle ends.

Detergent

When the solution reaches operating temperature, add the proper amount of

cleaning compound at the rate recommended by your chemical supplier. If the

detergent is in a powder form, pour the powder in the filter baskets, then close

the door and run the pump until all compounds have been dissolved. If the

compound has been broken up or partially dissolved, this operation will go

faster.

Notes: Use of an automatic detergent dispenser is

recommended. To insure economical use of the

compounds, be sure that the sensing probes are kept

clean of any foreign matter. Consult your cleaning

compound supplier for recommendations. To obtain

satisfactory cleaning, we cannot stress enough the

importance of the proper detergent. The temperature

controller is located in the control panel.

Caution: The cleaning compound should be the non-

foaming type and should not contain a chemical

substance that will damage copper or aluminum.

WASH TEMPERATURE

RINSE LINE TEMPERATURE

160°

POWER

OFF ON

CYCLE

STOP

CYCLE

START

IN

CYCLE

CYCLE TIME

LT MED HVY

WASH HEAT

OFF ON

160°

POWER

ON

KS-70 RACK WASHER

SEQUENCE OF OPERATIONS

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Shut-Down

1. Turn heat switch to off.

2. Drain machine completely.

3. Remove the filter and pump protection screens; flush tank and inside walls with water. Clean sludge and

scale from the heating system and float switches.

4. Prepare for next start up. Fill wash tank and add detergent. Run wash pump through 2-minute cycle to flush

out piping and moving parts. The door should be left partially open to help eliminate odors.

5. Turn off power at disconnect switch.

Page 13

KS-70 RACK WASHER

SHUTDOWN

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

Service & Maintenance

PUMP

Your Alvey Pan Washer is equipped with a vertical

immersion pump without seals. Pump discharge

pressure is 35 to 45 PSI. To help prevent pump

damage periodically check pump casing for any

foreign matter. Grease pump motor every six months.

Check direction of rotation after electrical

maintenance.

NOZZLE CLEANING AND ADJUSTMENT

1. Poke debris clogging the nozzles back into the

spray arm.

2. Remove nozzle at end of spray arm.

3. Close door and run pump for 5 seconds. Debris

will be flushed out.

4. Replace nozzle.

CLEANING OF HUB ASSEMBLIES

Remove spray arm assembly and flush out bearing

with clean water. Rotate by hand until hub moves

freely.

OPTIONAL EXHAUST FAN

The exhaust fan removes steam vapors from cabinet

when door is open. Two types of fans can be

furnished, a squirrel cage and a tube axial type. The

squirrel cage fan is equipped with sealed bearings,

which will not need grease. The tube axial fan

bearings should be greased at regular intervals. See

fan operating and maintenance instructions included

with this manual.

OPTIONAL RINSE WATER BOOSTER HEATERS

The booster heater raises the water temperature to

meet sanitation requirements for rinsing (180° - 195°

F). See Sec. V for required services. Each booster

has been designed and selected to operate on

specific pressures, temperatures and volumes.

Operating conditions must be known at time of order

to assure a booster is selected that will give

satisfactory performance.

PERIODIC SERVICE AND MAINTENANCE

1. Check filter screens twice daily. More frequently

with heavy cleaning load.

2. Check wash nozzles for clogging twice daily.

This can done at noon break and after shut down.

3. Check twice daily to see that spray hubs turn

freely.

4. Drain solution from the tank and flush at least

once daily. (See Sec. IV A).

5. Keep washer exterior free from an accumulation

of items, which may block air circulation to pump.

The exterior appearance may be maintained by

wiping with a damp cloth. Stainless steel wax or

polish may be applied if desired.

Note: When nozzles are removed, care must be taken

to adjust them to their original position when replacing.

See Figure 1.

Figure 1: Positioning of Nozzles on Spray Arm

Page 14

KS-70 RACK WASHER

SERVICE AND MAINTENANCE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

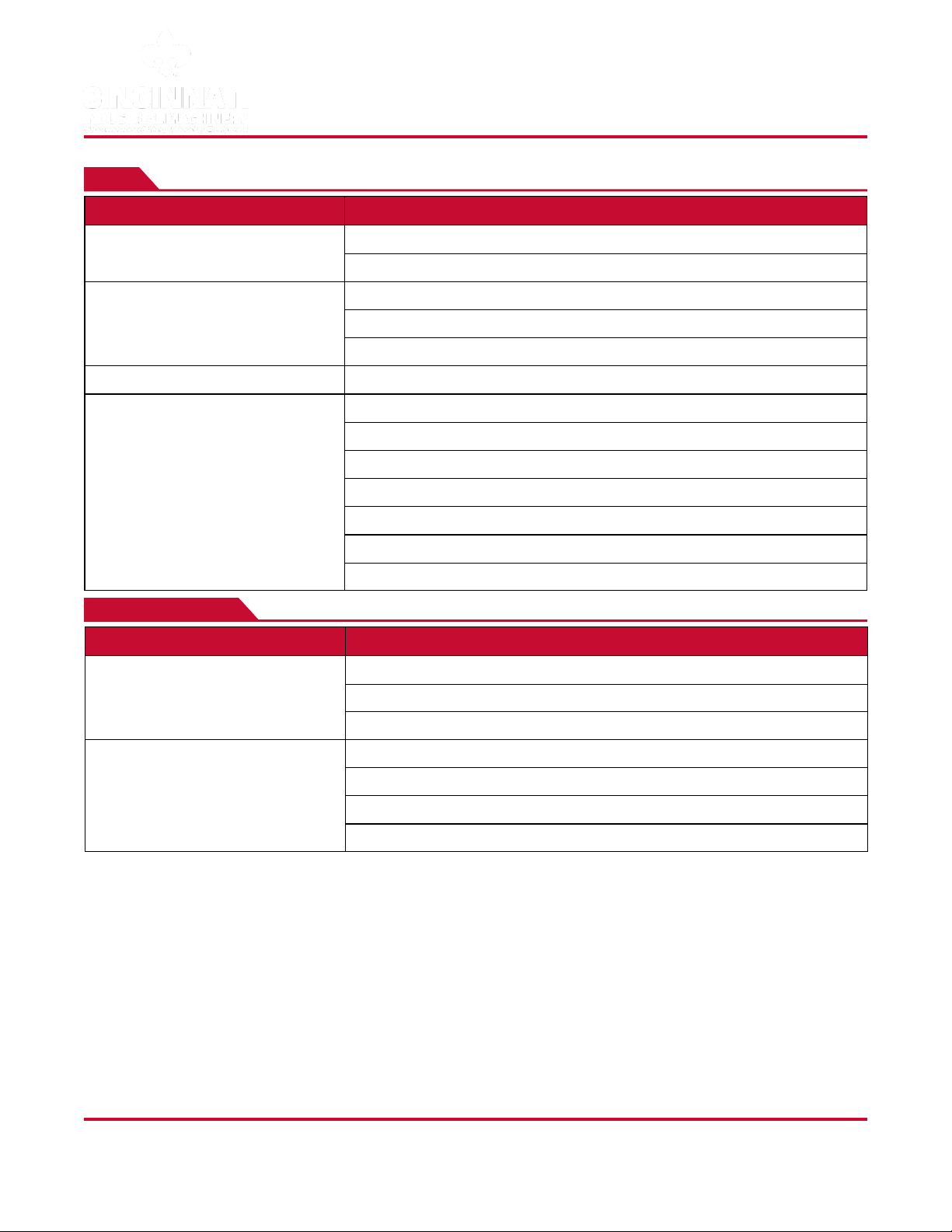

Wash Pump

PROBLEM DIAGNOSIS

Pump is running backwards.Low Pressure

Nozzles missing.

Leak in discharge piping.

Faulty pressure gauge.

Excessive soap suds.

Pump suction clogged.

High Pressure Clogged nozzles or discharge piping.

Faulty pressure gauge.

Pump Vibration Worn impeller.

Worn wear ring.

Bent shaft.

Clogged impeller.

PROBLEM DIAGNOSIS

Motor overheating. Low voltage.

High current draw - missing spray nozzles.

Faulty motor or motor cooling fan.

Motor running backwards.

Motor vibration. Bent shaft.

Worn bearings.

Blown fuse on transformer secondary.Motor will not start.

Overload has dropped out.

Faulty door switch—door not fully closed.

Faulty programmable relay.

Wash Pump

Page 15

Spinning Arm Assembly

PROBLEM DIAGNOSIS

Foreign materials in hub assembly.Arms will not turn.

Interference with guard rails.

Excessive play in arm. Worn bushing in hub assembly.

KS-70 RACK WASHER

TROUBLESHOOTING GUIDE

4600 N. Mason Montgomery Road · Mason, OH 45040

800-677-0076 · Fax: 513-923-5694

A Subsidiary of The Armor Group, Inc.

Version 1.04

October 2014

PROBLEM DIAGNOSIS

Will not shut off. Faulty programmable relay.

Dirty rinse valve (piston sticking open).

Will not turn on. Faulty programmable relay.

Dirty rinse valve (piston sticking closed).

Faulty valve coil.

Excessive water vapor. Water temperature too high.

Water pressure/flow too high.Rinse temperature too low.

Inlet water temperature too low—does not match design conditions.

Gas/Electric booster—temperature controller improperly adjusted.

Steam Booster—low steam pressure.

Steam Booster—clogged strainer.

Steam Booster—back pressure in condensate line.

Steam Booster—faulty steam trap.

Rinse

Exhaust Fan / Motor

PROBLEM DIAGNOSIS

Fan/motor vibration. Worn bearings.

Wheel out of balance.

Bent shaft.

Low voltage.Motor overheating.

Bent shaft.

Worn bearing.

Running backwards.

Page 16

KS-70 RACK WASHER

TROUBLESHOOTING GUIDE

Table of contents