THE LEADER IN OIL MIST TECHNOLOGY

77740201 REV 4 January 17, 2019

Controlling the Oil Mist

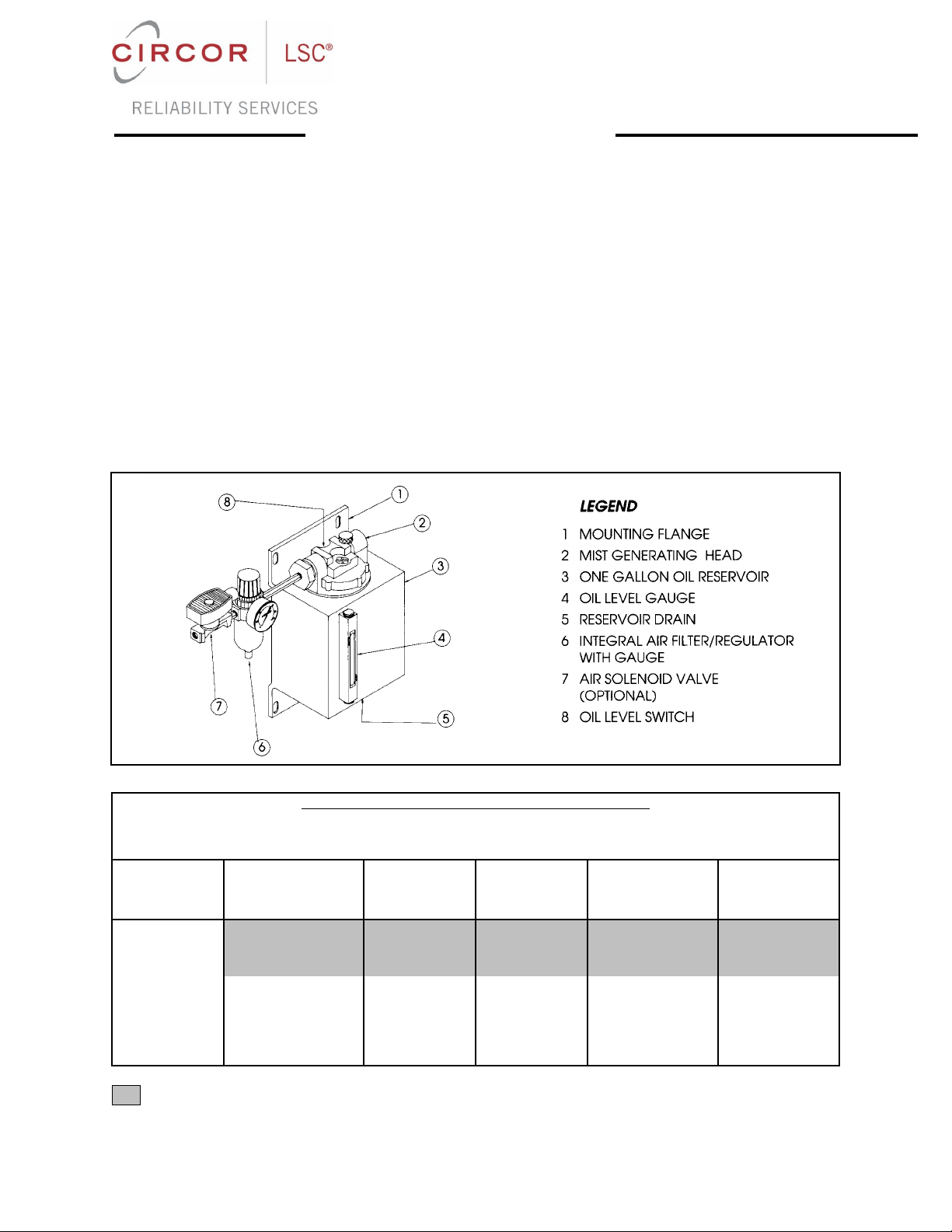

LubriMist®Vortex oil mist generation technology allows for maximum control and adjustment of oil mist properties. There are three basic

controls, refer to Fig. No's. 3 and 6.

1. The Integral Air Filter/ Regulator is used to adjust the volume of air flow to the Vortexchamber which in turn controls oil mist volume,

refer to Item 7, Fig. No. 3. The volume of oil mist is proportioned to each bearing or application point by the reclassifier. With the air

by-pass valve (described below) closed, the air pressure regulator setting must be high enoughfor oilmistproduction (Min.10 PSIG).

Regulated air pressure should be adjusted to maintain proper mist pressure. Since changes in regulated air pressure affect the

volume of oil mist produced, it also affects oil consumption.

2. The OIL FLOW VALVE controls oil mist density (oil/air ratio). Its normal position is fullyclosed. By turning it counter clockwisetoward

"Less" (opening the by pass) the mist densitycan be reduced when leaner density oil mist is desired. It should not be opened more

than three turns. Adjustments to the oil flow valve do not affect oil mist pressure in the distribution lines or in the generator; see Fig. 6

for location.

Note: The oil/air ratio or mist density is also dependent on the characteristics of the oil, oil temperature, and supplyair temperature.

Density decreases with lower temperatures and higher oil viscosity.

3. The AIR BY-PASS VALVE controls mist pressure without increasing oil output, its normal position is fully closed, but by turning it

counter clockwise toward "Open" more air will be added to the oil mist leaving the generatorthus increasingmist pressure. Velocityof

mist through the distribution lines and reclassifiers will also increase when this valve is opened, see Fig. 6 for location.

Note: The oil/air ratio or mist density is reduced by opening the air by-pass valve. However, oil output is not affected.

Operation

The daily operation of the oil mist system has been reduced to checks of the generator and lubricatedequipment.Exceptforemergencies,

routine adjustment of the generator is not required. Each oil mist system, once installed and balanced, supplies a constant amount of oil

mist to a number of lubrication points. Any change in the oil mist pressure or in the regulated air pressure (load pressure) from the initial

set points is an indication that some component has failed. Minor adjustments that might offset the failure symptoms may lead to more

serious problems before detection and corrections can be made.

Daily Checks

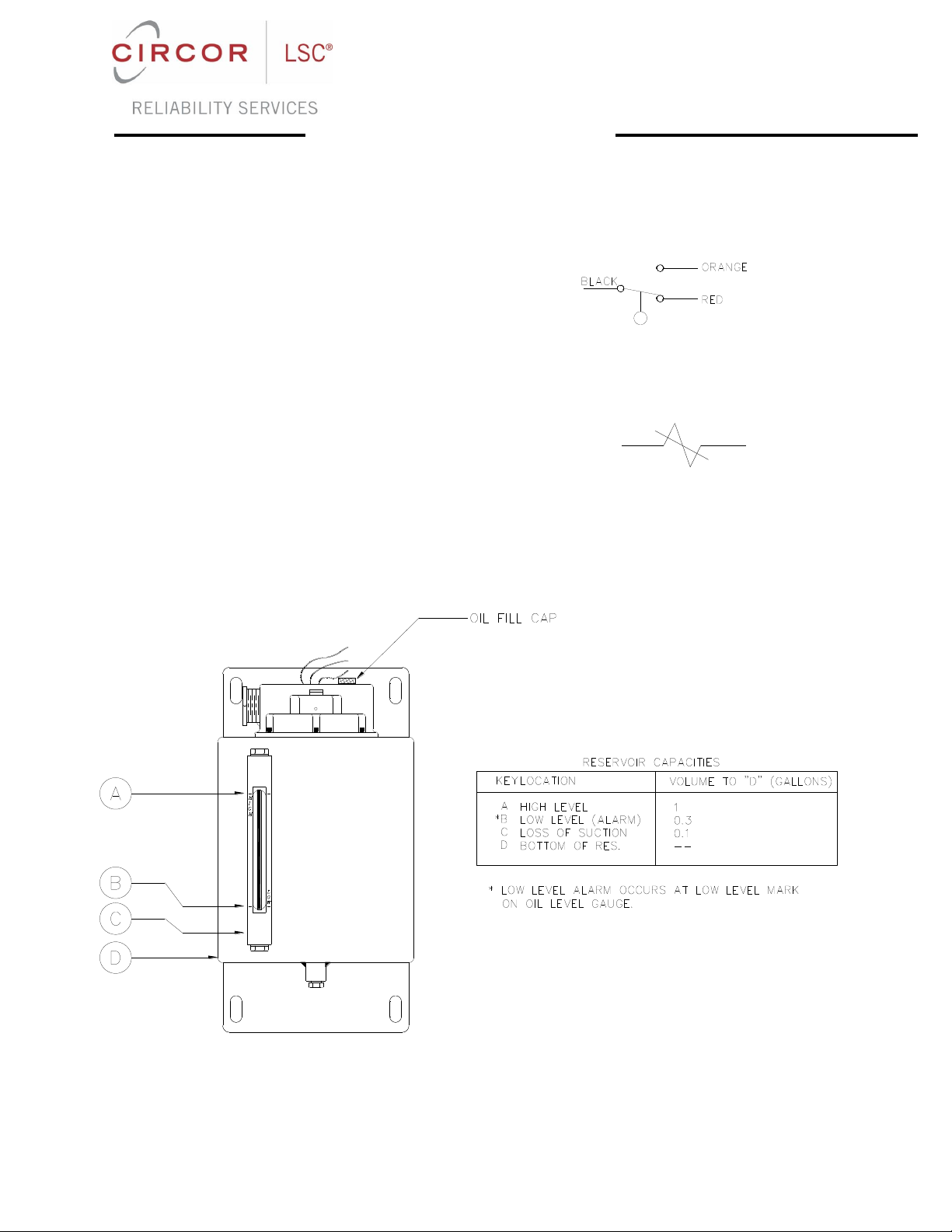

1. Check reservoir oil level and fill as required.

THE UNIT MUST BE SHUT DOWN TO FILL THROUGH THE OIL FILL CAP.

4. Check the regulated air pressure and mist header pressure gauges (if installed). Changes or fluctuations in mistpressure readings

indicate broken or plugged lines and fittings in the distribution system - correct as required.

Maintenance

The following maintenance procedures are recommended to help insure proper system operation.

1. Replace air filter element semi-annually.

2. Inspect and clean interior of reservoir semi-annually.

3. Inspect and clean oil suction tube screen semi-annually.

NOTE: When draining the reservoir the fill port must be open to atmosphere.

IMPORTANT: DO NOT DISASSEMBLE THE VORTEX MIST HEAD.