. PRESTART CHECKLIST

Lubricating Oil: Check crankcase oil level on dipstick- fill as needed to bring level up to Full mark.

Refer to Page 2. 1 for oil specifications.

Cooling System: On closed type cooling systems, remove radiator cap or cap on water cooled exhaust

manifold, then add clean fresh water until level is just below overflow tube. 7 to 7-l/2 quarts are

required for initial fill on radiator models, 5 to 57 f/2 quarts for heat exchanger models. If freezing

temperatures are anticipated, add antifreeze to radiator cooled and heat exchanger models. On direct

water cooled models, make sure cooling system is properly installed to insure sufficient coolant.

Direct systems are of the open type and cannot therefore be protected with antifreeze.

Air Cleaner: If oil bath type used,

bowl. Use same weight and grade

no prestart service except to make

unfas

of oil

sure

CARBURETOR ..-.w..v..ww

ten bowl retaining clamp and add oil to level marking (bead) in

as used in engine. Dry type and flame arrestor units require

elements are in place so that unfiltered air cannot enter engine.

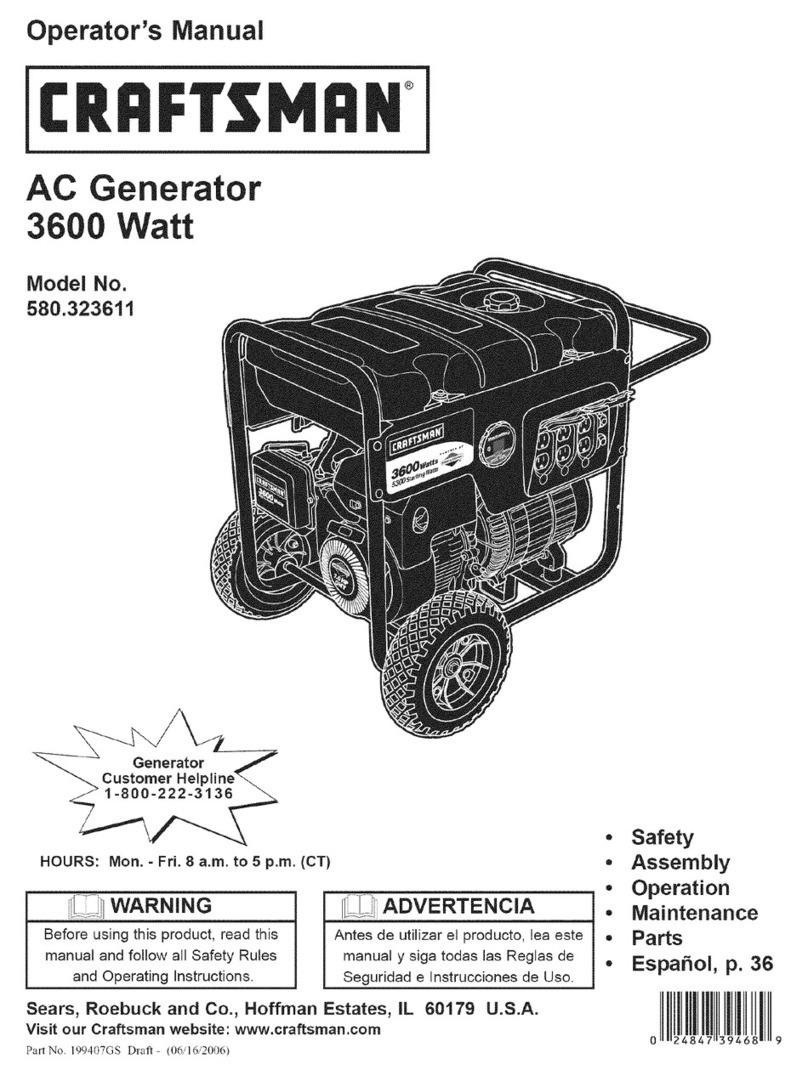

FIGURE1-3-- CARBURETORSIDEVIEW- TYPICALRADIATORCOOLEDPLANTWITHL654ENGINE

connect lines

g-Z g$iF@%&%ZE~Z~ gasoline. from storage tank to the fuel pump. Fill tank

Use priming lever on fuel pump to prime system

before initial start up. On gas fueled plants, make sure system is properly hooked up before starting.

Refer to Fuel Section for typical arrangement and preliminary adjustments.

Battery: These elect&c plants feature exciter cranking which offers higher cranking speeds for

more positive starting. When battery current is applied to the generator, it functions as a motor and

cranks the engine during starting then is autotitically switched back to its generating function after the

e’ngine starts.

A 24 volt battery is required for DC generator models and a 12 volt battery for AC generator

models. 32 volt cranking is available for marine models. Connect the positive (t) terminal of the bat-

tery to the P terminal of controller and the negative (-) battery terminal to the N terminal on controller.

(Stamped on base of controller near starting solenoid or C coil. )

‘ITo start three-wire automatic start plants, it will be necessary to center tap the 120volt battery

or use two 67volt batteries to create a difference in voltage between leads Ll and L2. Without this,

both leads have to be connected to the battery positive (t) terminal, and cranking relays in L2 will not

operate when the voltage is the same. With the center tap, lead Ll is connected to battery + terminal,

L3 to the center tap and L2 to ground which is battery negative (0).

13

l