Ciscomotors C-Max User manual

Ciscomotors

CiscomotorsCiscomotors

Ciscomotors

C

CC

C-

--

-Max

MaxMax

Max

SIMPLIFIED MAINTENANCE MANUAL

All information in this publication is based on latest specification’s product available at the time

of approval for printing.

CISCOMOTORS reserves the right to make changes at any time without notice and without

incurring any obligation.

No part of this publication may be reproduced without written permission.

CISCOMOTORS 2008 .

INDEX Page 2

. OPERATING INSTRUCTIONS Page 3

• . Basic operation Page 3

• .2 Start engine Page 4

• .3 Running in procedure Page 6

2. SPECIFICATIONS Page 7

• 2. Engine installation on chassis Page 7

• 2.2 Technical characteristics Page 8

3. MAINTENANCE Page 9

• 3. General service information Page 9

• 3.2 Routine cleaning Page 9

• 3.3 Maintenance schedule Page 0

4. STORAGE Page

5.

6. ASSEMBLY/DISASSEMBLY STARTER Page 2

7. REGULATION BELT TRANSMISSION Page 3

8. REGULATION CARBURATION Page 4

9. ELECTRICAL SCHEDULE C-MAX ELECTRIC Page 5

0. TROUBLESHOOTING Page 6

• 0. The engine don’t start Page 6

• 0.2 Engine laks power Page 6

• 0.3 Exessive vibrations of the engine Page 7

. TORQUE VALUES ENGINE Page 8

Page 3

1. OPERATING INSTRUCTIONS

1.1 BASIC OPERATION

FUEL

• C

CC

C-

--

-Max

MaxMax

Max has a two-stroke engine that

requires a gasoline-oil mixture.

• Use gasoline with a pump octane

number of 92 or higher .If “knocking” or

“pinging” occurs, try a different brand of

gasoline or a higher octane grade.

• To mix gasoline and oil in a ratio of

33: . Prepare the fuel mixture in a clean

container fig. , and shake until

thoroughly mixed before filling the fuel

tank.

• USE A GOOD QUALITY OF

SYNTHETIC 2-STROKE OIL

CAUTION:

To mu h oil will ause ex essive smoking and

spark plug fouling. Too little oil will ause

engine damage or premature wear. Mix fuel

in a ratio of 40 parts gasoline to 1 part oil

(33:1)

• Vegetable oils separate from gasoline

more easily than mineral oils, especially

in cold weather. It is advisable to use

synthetic oil.

CAUTION:

• Do not mix vegetable and mineral based

oils.

WARNING

• Gasoline is extremely flammable and is

explosive under ertain onditions.

Perform this operation in a well-

ventilated area with the engine

stopped. Do not smoke or allow flames

or sparks in the area where gasoline is

drained or stores and where the fuel

tank is refuelled.

FUEL 92/98 o tane

Syntheti oil

litres

l

2

3

4

5

0

0,3

0,6

0.9

2

5

30

Figure

Page 4

1.2 START ENGINE

WARNING

• Never run the engine in an losed area. The exhaust ontains poisonous arbon

monoxide gas that an ause loss of ons iousness and may lead to death.

• Attention to start the engine without the redu er provokes the outbreak of the lut h

and an ause injury or damages.

• Never run the engine without propeller.

• The starter attempt an arry to the spin of the propeller and therefore to possible

lesions.

• The motor running emits disturbs ele tromagneti

Version manual starter with lut h:

. Starter engine to warm:

Figure

. To carry in a pressure (by manual

pump) circuit of the gasoline, if

necessary help by press the diagram.

Fig. 2

Figure 2

2. Don’t engulf the engine but make sure

the gasoline goes in intake pipe.

3. Insert the Block Clutch System (Fig. )

4. Grasp the start and pull gently just after

point more hard (try repeatedly to be

sure)

5. Pull whit energy the handgrip without

speed for 3 o 4 and without groped to

start.

6. Pull with energy the handgrip and

speed slightly after first turn of engine.

7. In case of start failed to repeat again

the operation.

8. After starter engine heat it 2/3 minutes

speeding from 3000 to 4000 turns max.

Starter the engine to warm:

Insert the Block Clutch System (Fig. )

2 Pull with energy the handgrip and

speeding slightly.

Stopping The Engine

• Press the stop button of the engine until

the engine stop completely.

.

Page 5

Version manual starter without lut h:

. To carry in a pressure the circuit of the

gasoline, to help itself pressing the

diagramm (Fig.2)

2. Don’t engulf the engine but make sure

the gasoline goes in intake pipe.

3. To pull the starter and delicately pull just

after the hard point (try repeatedly for be

sure).

4. Pull with energy the handgrip and speed

slightly.

5. In case of start failed to repeat again the

operation .

6. After starter engine heat it 2/3 minutes

speeding from 3000 to 4000 turns max.

Start the engine to warm:

. Pull the handgrip with energy without

speed.

Stop the engine

• To press the stop button of engine until

the engine stop completely .

Version ele tri starter:

. To carry in pressure the circuit of the

gasoline, to help itself pressing the push-

button (Fig.2)

2. Don’t engulf the engine but make sure

the gasoline goes in intake pipe.

3. Act on the start button without speed for

5 or 6 turns engine.

4. In case of start failed to repeat again the

operation.

Start the engine to warm :

. Pull the handgrip with energy without

speed.

Stop the engine

• To press the stop button of engine until

the engine stop completely .

Page 6

1.3 RUNNING-IN PROCEDURE

Following proper break-in procedure helps censure that some of the most important and

expensive components on your new C-Max will provide maximum performance and service

life. (Also follow proper run-in procedure for a newly rebuilt engine)

. Do not hold the throttle in one position for more than a few seconds. It’s better

to roll the throttle on and off, without getting too high altitudes and forcing the

engine.

2. Use the motor for features of 0 minutes at a time and to leave to cool it.

3. After 5 hours of use or approximately 20 litres of gasoline the motor should be

broken in.

4. This same procedure should be followed each time

• Piston is replaced

• Cylinder is replaced

• Crankshaft or crank bearings are replaced

Page 7

2. SPECIFICATIONS

2.1 ENGINE INSTALLATION ON CHASSIS

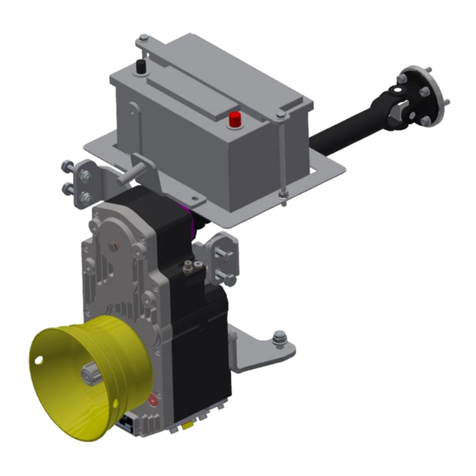

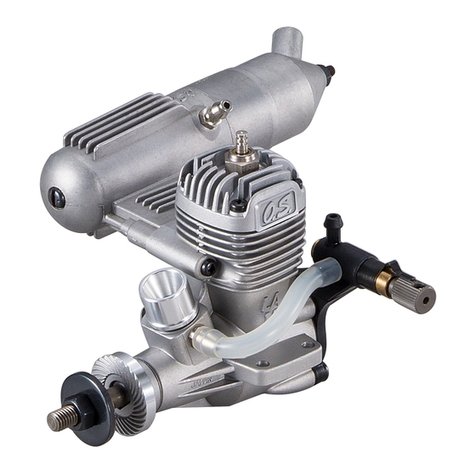

Picture 3

. Support engine 2. Manual starter 3. Electric starter

Page 8

2.2 TECNICALS CHARACTERISTICS

Motor C-MAX

Type 2 strokes cooled to air

Disposition cylinder Mono cylinder

Bore max 65mm

Stroke max 53mm

Displacement 75cc

Compression ratio :

Maxim Power 20 kw (27cv) 7800 turns

Max Torque 25 Nm 7400 turns

Max turn of engine 8 00 turns

Ele tri al system

Ignition Inductive coil

Rotor Neodynium Magnet

Spark plug standard Ngk B8BS

Spark plug summer +30° c Ngk B9BS

Starter Manual / Electric

Carburettor

Type Walbro

Transmission

Clutch Type Centrifugal 3 shoe

Reduction Pulley/Pinion

Reduction ratio /2,6 – /2,8 – /3

Exhaust

Type Expansion chamber

Silencer Glass wool

Support engine

Type N.4 Silent-block

The standard carburation

Temperature 0°c

P 024 Mb

UR 50%

Altitude (S.L.M.) 50 m

\

Page 9

3. MAINTENANCE

3.1 GENERAL SERVICE INFORMATION:

• Wear gloves and glances when you make the maintenance;

• Do not perform maintenance while engine is running. Injury to your fingers, hands or head

may result ;

• Perform maintenance on firm, level ground, using hard work plain , and not directly on

chassis;

• Always install new gaskets, o-rings, piston pin clips, rings etc .when reassemble some

parts.

• When tightening bolts, nuts or screw, start with the larger diameter or inner fasteners, and

tighten them to the specified torque using a criss-cross pattern;

• Use genuine Ciscomotors parts when maintenance your C

CC

C-

--

-Max

MaxMax

Max

• Clean parts in not-flammable cleaning solvent when disassembling. Lubricate any sliding

surface, o-rings and seals before reassembling.

W

WA

AR

RN

NI

IN

NG

G

Gasoline or low flash point solvents are highly flammable or explosive and must never be

used for leaning parts . Fire or explosion ould result.

• After reassembling, check all parts for proper installation and operation

NOTE:

• Specification are listed chapter 2.

3.2 ROUTINE CLEANING

• If the C

CC

C-

--

-Max

MaxMax

Max is only little dirty to clean up it with clean dusts cloth without solvents

• If the C

CC

C-

--

-Max

MaxMax

Max is much dirty to clean up it with biodegradable detergents and not with

solvents, lubricate where is necessary.

Engine Number

Figure B

Page 0

3.3 MAINTENANCE SCHEDULE

FREQUENCY

INSPECT

REPLACE

Before and after each use

Every 50 hours

All screw nuts, bolts correctly

tighten, silent-block in, and

check carburation.

Belt transmission

Clean air filter

Transmission belt

Every 00 hours

Cylinder head decarbonizing

Diameter of clutch and clutch

bell

Bearing crankshaft

Glass wool

Silencer

Spark plug

Every 200 hours Oil seal crankshaft

Piston complete

Cooling belt

Every 500 hours Thermical group .

Connecting rod

Crankshaft bearing

Each year All rubber and plastic

components.

Fuel diaphragm carburettor ,

spark plug.

Page

4. STORAGE

Extended storage such as for winter, requires that you take certain steps to reduce the effects of

deterioration from not use of your C

CC

C-

--

-Max

MaxMax

Max. In addition necessary repairs should be made before

storing your C-Max: otherwise these repairs and clean may be forgotten by the time your C

CC

C-

--

-Max

MaxMax

Max is

removed from storage.

Page 2

6. ASSEMBLY/DISASSEMBLY STARTER

Figure 8

. Remove 4 screws (Fig. 8)

2. Remove the screw (Fig.20) for to arrive

to the pulley

3. Remove the pulley (Fig.2 )

4. Control the screws (Fig. 9) are in a good

conditions and locked.

. Install the pulley and tighten the screw

(pict. 20) to the specified torque

TORQUE : 15Nm( 1,5 kgf/m)

2. Insert the starter in 4 screws (Fig. 9)

3. Tighten the screws (Fig. 8) to the

specific torque using light locking agent

TORQUE: 2Nm (1.2 kgf/m)

Figure 9

Figure 20

Figure 2

Page 3

7. REGULATION BELT TRANSMISSION

The tension of belt must be done very carefully

. Slightly little the 4 fix screws of

bracelet (Fig.32)

2. Insert an Allen key 8 m / m in the seat

(Fig32- point 2) and rotate counter-

clockwise torque of 400 Nm (40kgf / m)

3. Tighten the 4 Allen using the cross

method the specified torque

• TORQUE: 12Nm (1,2 kgf/m)

Figure 32-

CAUTION:

Control the tension as Fig.32-2

. Tension too taut it’s cause of early usury

of bearing

2. Tension too loose it’s cause of exessive

consumpion of belt.

Figure.32

Figure.32-2

Page 4

8. CARBURATION REGULATION

Figure 35

. Regulation min.throttle engine

2. Regulation gasoline/air min. (L)

3. Regulation gasoline/air max (/H)

Standard regulation

In case problems of wrong carburation , replace the originals levels.

Screw regulation of min. turn from all closing. . (Fig.35 point 2)

Attention: regulation of arburation must be made at warm motor.

. Start the engine.

2. To warm the motor for 4 or 5 minute to the regimen of spin of 3500/4000rpm;

3. Regulate the screw of max jet H, ((Fig.35 point 3) from turn to - /4 from all closing.

4. Regulate the screw of the minimal jet L, (Fig. 35 point 2)from 3/4 to turn, to put the

motor to 5000 rpm, to screw or to unscrew the screw until when the motor turns cleaned up

and does not mutter;

5. To leave the motor for some second ones at minimum, to accelerating normally , now the

motor must quickly accelerate without mumbling or to come less.

6. To regulate the lessened motor spin of the 2000/2200 rpm. (Fig. 35 point ) C-Max clutch

7. To regulate the lessened motor spin of the 2500/2600 rpm. (Fig. 35 point ) C-Max electric

or manual starter.

Page 5

8. ELECTRICAL SCHEDULE

Ele tri starter with re harge battery

Page 6

10. TROUBLESHOOTING

10.1 THE ENGINE DON’T START

CHECK

POSSIBLE CAUSES

SOLUTION

No fuel in tank

Fill tank for fueling

Clogged fuel line or fuel filter

Replace and clean

Check if fuel is jetting to the

carburettor

Diaphragm fuel pump broken

Replace the diaphragm

(Fig. 5)

The engine stop switch is to ON

Move it on OFF

Faulty spark plug

Replace

Check electric

Broken or shorted ignition coil

Replace

10.2 ENGINE LAKS POWER

CHECK

POSSIBLE CAUSES

SOLUTION

Fuel air mixture to lean

Unscrew the min screw

(Fig. 35- 2)

Fuel air mixture to reach

To screw the max screw

(Fig. 35- 2)

Clogged fuel line or fuel filter

Replace or clean

Check the carburation

Diaphragm fuel pump broken

Replace the diaphragm

(Fig. 27)

Page 7

10.3 EXESSIVE VIBRATIONS OF THE ENGINE

CHECK

POSSIBLE CAUSES

SOLUTION

Excessive wear, holder rubber

Replace (Max 70 Sh)

Silent-block engine

Prop out of balance

Balance or replace

Page 8

11. TORQUE VALUES ENGINE

ITEM

Thread diam. x

pitch

Torque

Kgf-m

Cap screw propeller hub M6 M 6 x ,0 .2

Cap screw propeller hub M8 M 8 x ,25 .5

Spark plug M 4 x ,25 ,8

Cap screw cooling air duct M 5 x 0.8 0,6

Cap screw crankcase starter M 6 x .2

Bolt cylinder head M 8 x ,25 ,5

Screw transmission eccentric M 6 x ,0 ,2

Bolt silent-block exhaust M 8 x ,25 .5

*Bolt clutch M 8 x .25 4.0

All bolts M 6 x

*Bolts starter M 0 x ,25 3,0

Bolts pinion transmission M 2 x .25 4,0

* Apply locking agent

Table of contents

Other Ciscomotors Engine manuals

Popular Engine manuals by other brands

ABB

ABB A175-M62 Operation manual

STEYR MOTORS

STEYR MOTORS Marine Engine 2012 Series Service manual

Nicotra

Nicotra RLO Mounting instructions

Emerson

Emerson TITAN II Installation, operation and maintenance manual

GEIGER

GEIGER SOLIDline GJ56 Series Original installation and operating instructions

Flux

Flux F 416 EX Original attachment