CISECO Slice of Pi User manual

Deciding what order to fit the parts We suggest you normally start with the smallest height parts first, leaving the larger parts till later on, this usually leaves most room to manouvere the iron. Dry fit the parts What is a really good thing to do on boards where the parts are close to each other is to do a dry fit first. This means pushing parts into place without soldering so you can decide what order is easiest for you. Left handed people almost always decide to do things in a different order to a right handed person for example. The order is ultimately up to you so dont rush in, think about it first. Not confident in soldering? Google soldering guide or soldering how to. Theres many great articles that people have produced. Theres videos on YouTube also. Soldering is simple to learn. Why not ask your local school / college for a little help or what we hope people have near them is a Hackspace or Makerspace (google it) they are brilliant places to join.

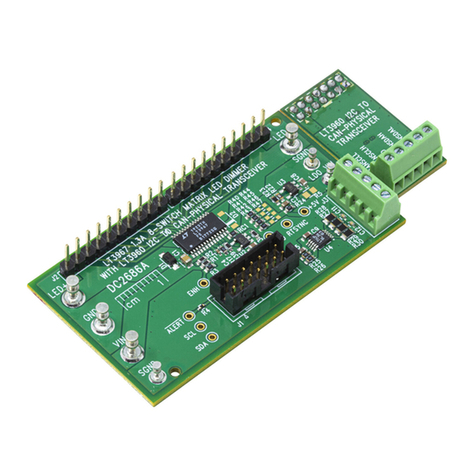

Solder the parts Soldering normal electronic parts (none in this kit) 1. Carefully push the part through the board, hold in place by either Blutack or gently bending the part legs before turning upside down to solder. DO NOT hold with your finger, most parts easily conduct heat, dont burn yourself! Soldering connectors (some are in this kit) 1. Using the Blutack or your fingers, hold the connector in place and solder just a single pin at one end. 2. Check that the connector is aligned in every direction, if not simply reheat for a second or two and gently move. Avoid excessive heat and always be patient, soldering is a skill anyone can do badly, doing it well is about practice and not rushing things. 3. When you are happy, solder the pin at the opposite end of the connector. Check visually very carefully again as the is the last time it will be easy to move position of the part. Complete by soldering the rest of the connector pins. Soldering surface mount parts (none in this kit) 1. Tin (cover in a coat of solder) a single pad first, put the part on top, perfectly aligned with the other pads. Melt the tinned pad so that the first pin is soldered down. Re melt till the part is aligned then solder the rest of the pads. Tweezers are perfect for holding parts, whilst soldering. Handy tips for this kit (Slice of Pi) 1. The 2mm connectors are easiest to install if you have a Radio to plug into the headers to hold them whilst soldering this keeps them perfectly parallel. 2. When soldering the 2mm connectors DO NOT use excessive amounts of solder because the solder can flow into the connector and block it. 3. Only install the connectors you actually need for your project you can always add the ones you didnt use later if needed. Eg if you do not intend to use a radio, leave out the 2mm connectors. You will need these tools 1 x Soldering iron 1 x Length of electronics solder wire (not plumbers solder) 1 x Side cutters Optional but will make the build much easier 1 x Blob of Blutack 1 x Multimeter (preferably with continuity check) Note: The Blutack is very good at holding parts while soldering. Checking the solder joints for good connections will in our experience save you time overall First check the contents for 6 items 1 x Green printed circuit board (PCB) 1 x 2x13 female 2.54mm pitch connector 2 x 1x8 female 2.54mm pitch connector 2 x 1x10 female 2.00mm pitch connector For help please email: [email protected].ukSlice of Pi v1.12CISECO

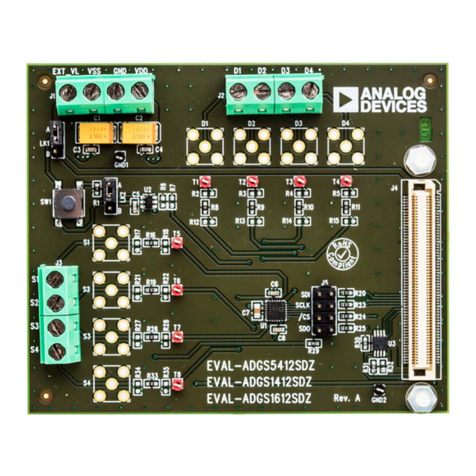

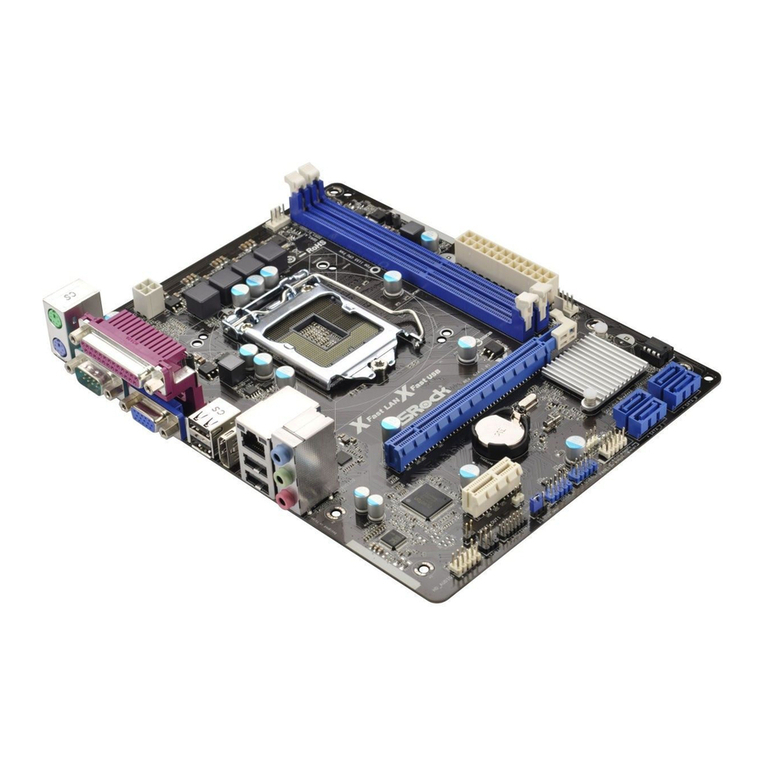

© 2013 - CISECO PLC4 Location of the parts Install the 2 row x 13 way header as shown (facing down) The single row smaller 10 way 2mm sockets face upwards The larger single row 8 way 2.54mm sockets face upwards5613Always read this guide before beginning. This kitrequires basic soldering skills before use.Getting started guideThe Slice of Pi is an add on for the Raspberry Pi miniature computer, it is a 3 in 1 board. The suggested uses are:To connect and power an XRF or Xbee style radio module in to the Raspberry Pi serial port (UART).Convenient breakout of the GPIO pins into an easier layout for strip board or bread boarding projects.Small prototyping area for compact or simple electronic projects. Check everything Even if you are confident in soldering, please still check your work. Almost all the problems we see (where boards do not function correctly) are down to a poor/dry joint somewhere. With a multimeter make sure you have good connections between the various pins. On the back of this page is the schematic layout so you can see what is connected where. Testing & Building your projects Build and test as you go in small stages, take your time and always check twice before soldering, this extra small amount of effort is always worthwhile. Rushing is the best recipe for getting things wrong, backwards or poorly soldered.

© 2013 - CISECO PLC79 Information Last point of manufacture UK Ciseco Plc, Cleantech Centre, St Peters St, Nottingham NG7 3EN Always recycle where possible. Blutack is a registered name of Bostik Limited Raspberry Pi is a registered name of the Raspberry Pi Foundation Xbee is a registered name of DiGi International

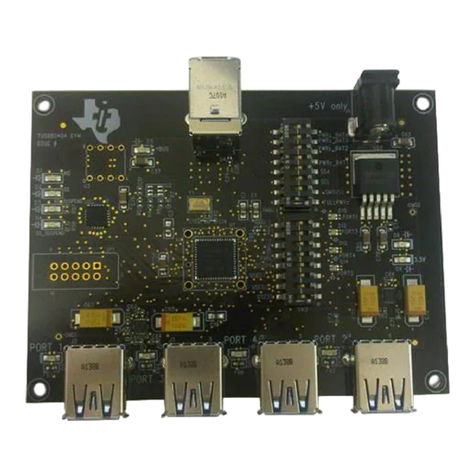

Schematic WARNING: Never exceed the current capability of the Pi input, output and power supply pins. Consult the Pi manual if you are unsure of the limits. The kit does not contain an XRF, Xbee or similar radio within the kit8 The finish is just the start Now your kit is built here comes the interesting part. What are you going to do with it? Our forum is a great place to discuss your ideas with others. We love to hear what people are up to and have built. Feel free to drop in and say hello. Our forum is not just about our products its also intended for any discussion and sharing about the use of computers with microcontrollers, electronics and wireless. www.openmicros.org what your board might look when installed