Cito System PC/104 User manual

MillenniumSeries

PC/104MotionControllers

User’sManual

C to Systems

NOTICE

This document contains proprietary and confidential information of Cito Systems, and is

protected by federal copyright law. The contents of this document may not be disclosed to

third parties, translated, copied, or duplicated in any form, in whole or in part, without the

express written permission of Cito Systems.

The information contained in this document is subject to change without notice. No part of

this document may be reproduced or transmitted in any form, by any means, electronic or

mechanical, for any purpose, without the express written permission of Cito Systems.

Copyright 2004 by Cito Systems

Navigator™ and C-Motion™are trademarks of Performance Motion Devices

ii

Warranty

Cito Systems warrants performance of its products to the specifications applicable at the

time of sale in accordance with Cito Systems' standard warranty. Testing and other quality

control techniques are utilized to the extent Cito Systems deems necessary to support this

warranty. Specific testing of all parameters of each device is not necessarily performed,

except those mandated by government requirements.

Cito Systems reserves the right to make changes to its products or to discontinue any

product or service without notice, and advises customers to obtain the latest version of

relevant information to verify, before placing orders, that information being relied on is

current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgement, including those pertaining to warranty,

patent infringement, and limitation of liability.

SafetyNotice

Certain applications using semiconductor products may involve potential risks of death,

personal injury, or severe property or environmental damage. Products are not designed,

authorized, or warranted to be suitable for use in life support devices or systems or other

critical applications. Inclusion of Cito Systems products in such applications is understood

to be fully at the customer's risk.

In order to minimize risks associated with the customer's applications, adequate design and

operating safeguards must be provided by the customer to minimize inherent procedural

hazards.

Disclaimer

Cito Systems assumes no liability for applications assistance or customer product design.

Cito Systems does not warrant or represent that any license, either express or implied, is

granted under any patent right, copyright, mask work right, or other intellectual property

right of Cito Systems covering or relating to any combination, machine, or process in which

such products or services might be or are used. Cito Systems' publication of information

regarding any third party's products or services does not constitute Cito Systems' approval,

warranty or endorsement thereof.

iii

Millennium Series PC/104 Motion Controller Manual

iv

RelatedDocuments

Navigator Motion Processor User’s Guide (MC2000UG)

How to set up and use all members of the Navigator Motion Processor family.

Navigator Motion Processor Programmer’s Reference (MC2000PR)

Descriptions of all Navigator Motion Processor commands, with coding syntax and

examples, listed alphabetically for quick reference.

Content

Warranty....................................……….........................………...............................…….iii

Safety Notice ...........................................................................………...................…….. iii

Disclaimer......................................…….........................................….……............…….. iii

Related Documents.............................................................................………................... iv

Table of Contents..............................................................................................………….. v

1. PC/104 Board Installation………………………………………...……7

1.1. Installation Sequence........................................................................................7

1.2. Components List...............................................................................................7

1.3. Required Hardware...........................................................................................7

1.4. Preparing the Board for Installation ….............................................................8

1.4.1. Setting the Host I/O Mode...............................................................9

1.4.2. Setting the Bus I/O Address...........................................................10

1.4.3. Setting the IRQ Level……............................................................11

1.5. 3mc-0x-Bx Connections Summary.................................................................12

1.6. 3mc-0x-BLx Connections Summary…..........................................................12

1.7. 3mc-0x-B/BLx Connections Summary….......................................................13

1.8. 3mc-0x-MSx Connections Summary..............................…............................14

1.9. 3mc-0x-S Connections Summary...................................................................15

1.10. Applying Power.....................................................................................…15

2. Software Installation…………………………………………………..16

2.1. Using EasyMotion Console............................................................................16

2.2. First Time System Verification.......………....................................................17

2.2.1. Step #1 Set the Motor Amplifier Type....................................…..18

2.2.2. Step #2 Initialize Commutation................................………….....18

2.2.3. Step #3 Check Commutation.................................……….…….. 19

2.2.4. Step #4 Set Filter Parameters....................................……….........20

2.2.5. Step #5 Make a Trajectory Move...........................…………....…20

3. Operation……………………………...……………………………….21

3.1. Card Overview.............................………………………………………...…21

3.2. Dual-Port RAM...............................…………………………………………22

3.3. Safety Features.............................………………………………………...…22

3.3.1. Hard Reset....................…………………………………..........…23

3.3.2. Soft Reset....................…………………………………...........…23

3.3.3. External Reset.............................……………………………...…23

3.3.4. Under Voltage Monitor.....................…………………….........…23

3.3.5. Watchdog timer..........................……………………………....…23

3.3.6. Reset Status Monitor..................………………………............…24

3.4. Card ID Number............................……………………………………….…24

4. Connecting Hardware………………………………………………....24

4.1. Motors Output Command Signals..........................……………………....…24

5

4.1.1. Analog Output Motor Command.............................…………..…24

4.1.2. PWM Output Motor Command............................…………….…25

4.1.3. Pulse and Direction Output Motor Command……………..…….25

4.2. Incremental Encoder.............................…………………………………..…25

4.3. Parallel Feedback Devices.....................…………………………….........…25

4.4. Home and Limit Switches......................…………………………….........…25

4.5. Amplifier Enable Outputs...........................……………………………....…26

4.6. Amplifier Fault Inputs.............................……………………………………26

4.7. Axis Out Signal.............................………………………………………..…27

4.8. General Purpose Digital I/Os.......................………………………….......…27

4.8.1. High power digital I/Os.................……………………............…27

4.9. Analog Inputs.............................………………………………………….…27

4.10. The Synch Signal Connector for Multiple Chip Synchronization……….28

4.11. Serial Transceiver...............................…………………………………...28

5. Appendices……………………………………………………………..30

5.1. Appendix A. PC/104 Motion Controller Electrical Reference.......................30

5.1.1. PC/104 Motion Card Layout................... .............………………30

5.1.2. PC/104 Motion Card Connectors...........................………….......31

5.1.2.1. Motion Processor Synchronization Signal

Connector (J1)…..……………………...………………..31

5.1.2.2. Serial Communication Channel Connector (J2) ..............31

5.1.2.3. Host Interrupt Signal Connector (J3) ...............................32

5.1.2.4. Motion Peripherals Connector (J7) .....................…….....32

5.1.2.5. External Power Supply Connector (J9) ............................33

5.1.2.6. Miscellaneous I/O Signals Connector (J12)………...…..33

5.1.3. PC/104 Motion Controller Jumpers & Switch Block Settings.….34

5.1.3.1. Setting the Host I/O Mode – JP7.............................…….34

5.1.3.2. Setting the Incremental Encoders Input

Signal – JP8 - JP11………………………………….…..35

5.1.3.3. Setting the Committed I/O Signal Voltage Supply

Source – JP12 & JP13………………………..……….…35

5.1.3.4. Setting the High Power Digital Output – JP14 & JP15....36

5.1.3.5. Setting the Analog Input Voltage Reference

Source – JP1 – JP4…...…….….………………………...36

5.1.3.6. Setting the Base Address and the IRQ Level – S1………36

5.2. Appendix B. Outputs to Motor Amplifiers................ ……....................……37

5.2.1. Brushed Servo Motors (MC2100 series)...............................…....37

5.2.2. Brushless Servo Motors (MC2300 series)................................….38

5.2.3. Brush & Brushless Servo Motors (MC2800 series).................….38

5.2.4. Microstepping Motors (MC2400 series).................................…...38

5.2.5. Stepper Motors (MC2500 series)………….............................…..39

5.3. Appendix C. Encoder Inputs.......................................................……………39

5.4. Appendix D. Opto-isolated Committed Inputs...........................................…39

5.5. Appendix F. PC/104 Motion Controller Signal Connections………..…..… 40

5.6. Appendix G. PC/104 Motion Controller Hardware Information.......…….... 42

6

1 PC/104 Board Installation

In addition to the PC/104 card, the Millennium motion controller includes storage media

(CD) with the C-MotionPlus software library and device drivers. C-MotionPlus is a full-

featured C/C++ language library, which simplifies the development of motion applications

for the Navigator chipsets.

1.1 Installation Sequence

For a normal installation of the Millennium controller, you will need to configure the 3mc-

0x-xx board for the PC system and motor hardware that you will connect it to.

Configuration of the 3mc-0x-xx board is described in detail in the section below entitled

"Preparing the board for installation"

Next you will need to connect your system's motors, encoders, amplifiers and sensors as

desired to operate your motion hardware. A description of the connections that are made for

the various Navigator chipsets is found in the "3mc-0x-xx Connections Summary" sections

[1.5 – 1.9].

The final step to finish the installation is to perform a functional test of the finished system.

This is described in the section entitled "First time system verification".

Once all of the above has been accomplished installation is complete. You can now exercise

your motion system.

1.2 Components List

The Millennium controller set contains the following components:

1) Millennium Controller PC/104 board

2) Storage media with:

• C-MotionPlus library (static and DLL)

• Device drivers

• Millennium Series PC/104 Motion Controller – User’s Manual

• Navigator Motion Processor User's Guide (pdf format file)

• Navigator Motion Processor Programmers Reference (pdf format file)

3) Documentation:

Millennium Series PC/104 Motion Controller – User’s Manual

If any of these components are missing, please contact Cito Systems directly, or your Cito

Systems representative.

1.3 Required Hardware

To install the Millennium series PC/104 motion board, you will need the following

hardware:

7

1) PC/104 platform: the minimum platform consists of an Intel (or compatible) processor,

80286 or better, 5MB of available disk space, CD-ROM drive. The recommended

platform is an Intel (or compatible) processor, Pentium or better, 5MB of available disk

space, 32MB of available RAM, and CD-ROM drive. The operating system may be

Windows95/98/Me/NT/2000/XP/CE or Linux. An asynchronous serial

communications port is optional for both the minimum and recommended platforms.

2) 1 to 4 pulse and direction, PWM, or analog-input amplifiers. The type of amplifier

depends on the controller’s chipset type.

3) 1 to 4 step motors or servo motors. These motors may or may not provide encoder

position feedback signals depending on the type of chipset being used.

4) Additional connectors, as required to connect the 3mc-0x-xx PC board to the amplifiers

and the servo motors. Dual male 50-pin header-type connectors will be needed to

interface to the 3mc-0x-xx board's signal cable, part number CAB-100_2x50.

1.4 Preparing the Board for Installation

The board provides the following user-settable hardware options:

Option Set using Default

PC/104 bus I/O Address switch bank S1, 1-4 340 (hex)

PC/104 bus IRQ # switch bank S1, 5-8 IRQ disabled

Host interface mode jumper JP7 PC/104 bus

Table 1-1. PC/104 motion controller board default settings.

The host interface mode jumpers will not need to be changed unless it is desired that the

card be operated in serial mode. If operated in serial mode, a special adapter board is

required.

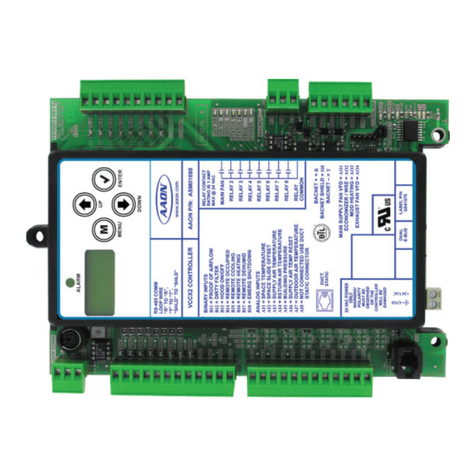

The following diagram shows the location of the jumper JP7:

8

Figure 1-1. Settable jumpers and connectors

If you need to change the default setting values from the Table 1-1, or are not sure if they

need to be changed, the following sections explain more about these settings.

1.4.1. Setting the Host I/O Mode

The PC/104 motion controller supports two different communication modes. This is shown

in the following table:

Mode Description

PC/104

mode The motion processor accepts instructions and data as full 16-bit words, using

the entire 16-bit data path

Serial port The motion processor accepts instructions through an asynchronous serial

port.

The figure below shows how the JP7 jumper should be installed to select the host mode.

PC/104 mode is the default. Shading indicates the location of the jumper.

9

serial port PC/104 parallel

1.4.2. Setting the PC/104 bus I/O address

The PC/104 motion card occupies 16 consecutive I/O addresses on the PC/104 bus,

starting at the "base address", and ending at the base address+F (hex). For example for the

default base address, which is 340 (hex), the total used range of addresses is 340 (hex) – 34F

(hex).

The I/O port base address should be chosen so that it doesn’t conflict with any other

devices using addresses in the range 300h-3FFh. Certain of these addresses are reserved for

specific peripherals, as shown in the following table (not all will be present in a given

system):

Portaddress Device

300-377h available

378-37Fh LPT1

380-3Afh usually available

3B0-3DFh VGA

3E0-3E7h available

3E8-3Efh COM3

3F0-3F7h Hard disk controller

3F8-3FFh COM1

Switch block S1, switches 1 - 4 determine the PC/104 bus base address. In the table below

switches, which should be on are indicated as such. A blank space in the table indicates the

switch should be set off (or left).

Address S1-1 S1-2 S1-3 S1-4

300h on on on on

310h on on on

320h on on on

330h on on

10

340h on on on

350h on on

360h on on

370h on

380h on on on

390h on on

3A0h on on

3B0h on

3C0h on on

3D0h on

3E0h on

3F0h

The default I/O port address is 340 hex (1-4: on, on, off, on)

For more detailed info on the I/O addresses used by the motion controller board, see

Appendix A, "PC/104 Motion Controller Electrical Reference", section 5.1.3.6.

1.4.3. Setting the IRQ level

The PC/104 controller board allows the motion chipset's HostIntrpt signal (used by the

chipset to signal special events) to generate a PC/104 interrupt that can be processed by

interrupt handling routines in the PC/104-based control software. The specific interrupt

(IRQ) that is generated can be programmed on the Millennium board using S1 switches #5-

8. The PC interrupt is generated when the chipset's HostIntrpt signal transitions from high

to low.

The table below shows the IRQs that are selectable and the associated S1 switch settings. If

no IRQ generation is desired than the "IRQ disabled" option should be selected. A blank

space in the table indicates the switch should be off (down).

IRQ# S1-5 S1-6 S1-7 S1-8

3 on on on on

5 on on on

7 on on on

10 on on

11 on on on

IRQ

disabled

The default IRQ setting is "IRQ disabled"

11

1.5 3mc-0x-Bx Connections Summary

The following table summarizes the connections provided and expected by the Millennium

PC/104 board when a MC2140 chipset is installed. Although the MC2140 supports up to

four axes any number of axis between 1 and 4 may be connected.

Chipset: MC2100 series

Maximum # of Axes: 4

Encoder Input Type: Incremental encoder

Encoder Input Signals:

(per axis) A quadrature channel input

B quadrature channel input

Index pulse channel input

# motor output channels:

(per axis) 1

Amplifier Output Signals

(per axis, if PWM sign,

magnitude used)

PWM Direction

PWM magnitude

Amplifier Output Signals

(per axis, if PWM 50/50 used) PWM magnitude

Amplifier Output Signals

(per axis, if analog output used) Differential analog out (DAC output)

Other Control Signals:

(per axis) Home signal channel input

Positive limit switch input

Negative limit switch input

Fault input

AxisOut output

Miscellaneous Signals: GND

+5 V (for encoder power)

For a complete description of the PC/104 card connectors and interfacing

requirements see Appendix A "PC/104 Motion Controller Electrical Reference".

1.6 3mc-0x-BLx Connections Summary

The following table summarizes the connections provided and expected by the Millennium

PC/104 board when a MC2340 chipset is installed. Although the MC2340 supports up to

four axes any number of axis between 1 and 4 may be connected.

Chipset: MC2300 series

Maximum # of Axes: 4

Encoder Input Type: Incremental encoder

Encoder Input Signals:

(per axis) A quadrature channel input

B quadrature channel input

Index pulse channel input

12

# motor output channels:

(per axis) 2 or 3 depending on motor output

selected and # phases

Amplifier Output Signals

(per axis, if PWM 50/50 used) PWM magnitude (phase A)

PWM magnitude (phase B)

PWM magnitude (phase C)

Amplifier Output Signals

(per axis, if analog output used) Analog out (phase A)

Analog out (phase B)

Hall inputs: Hall (phase A)

Hall (phase B)

Hall (phase C)

Other Control Signals:

(per axis) Home signal channel input

Positive limit switch input

Negative limit switch input

Fault input

AxisOut output

Miscellaneous Signals: GND

+5 V (for encoder power)

For a complete description of the PC/104 card connectors and interfacing

requirements see Appendix A "PC/104 Motion Controller Electrical Reference".

1.7 3mc-0x-B/BLx Connections Summary

The following table summarizes the connections provided and expected by the Millennium

PC/104 board when a MC2840 chipset is installed. Although the MC2840 supports up to

four axes any number of axis between 1 and 4 may be connected. Since this chipset allows

controlling a combination of brush and brushless servomotors, two pairs of each motor type

can be used.

Chipset: MC2800 series

Maximum # of Axes: 4

Encoder Input Type: Incremental encoder

Encoder Input Signals:

(per axis) A quadrature channel input

B quadrature channel input

Index pulse channel input

# motor output channels:

(per axis) 1, 2 or 3 depending on motor output

selected and # phases

Amplifier Output Signals

(per axis, if PWM sign,

magnitude used)

PWM Direction

PWM magnitude

Amplifier Output Signals

(per axis, if PWM 50/50 used) PWM magnitude (phase A)

PWM magnitude (phase B)

PWM magnitude (phase C)

13

Amplifier Output Signals for

brush type motors

(per axis, if analog output used)

Differential analog out (DAC output)

Amplifier Output Signals for

brushless type motors

(per axis, if analog output used)

Analog out (phase A)

Analog out (phase B)

Hall inputs: Hall (phase A)

Hall (phase B)

Hall (phase C)

Other Control Signals:

(per axis) Home signal channel input

Positive limit switch input

Negative limit switch input

Fault input

AxisOut output

Miscellaneous Signals: GND

+5 V (for encoder power)

For a complete description of the PC/104 card connectors and interfacing

requirements see Appendix A "PC/104 Motion Controller Electrical Reference".

1.8 3mc-0x-MSx Connections Summary

The following table summarizes the connections provided and expected by the Millennium

PC/104 board when a MC2440 chipset is installed. Although the MC2440 supports up to

four axes any number of axis between 1 and 4 may be connected.

Chipset: MC2400 series

Maximum # of Axes: 4

Encoder Input Type: Incremental encoder

Encoder Input Signals:

(per axis) A quadrature channel input

B quadrature channel input

Index pulse channel input

# motor output channels:

(per axis) 2 or 3 depending on motor output

selected and # phases

Amplifier Output Signals

(per axis, if PWM 50/50 used) PWM magnitude (phase A)

PWM magnitude (phase B)

PWM magnitude (phase C)

Amplifier Output Signals

(per axis, if analog output used) Analog out (phase A)

Analog out (phase B)

14

Other Control Signals:

(per axis) Home signal channel input

Positive limit switch input

Negative limit switch input

Fault input

AxisOut output

Miscellaneous Signals: GND

+5 V (for encoder power)

For a complete description of the PC/104 card connectors and interfacing

requirements see Appendix A "PC/104 Motion Controller Electrical Reference".

1.9 3mc-0x-S Connections Summary

The following table summarizes the connections provided and expected by the Millennium

PC/104 board when a MC2540 chipset is installed. Although the MC2540 supports up to

four axes any number of axis between 1 and 4 may be connected.

Chipset: MC2500 series

Maximum # of Axes: 4

Encoder Input Type: Incremental encoder

Encoder Input Signals:

(per axis) A quadrature channel input

B quadrature channel input

Index pulse channel input

# motor output channels:

(per axis) 1

Amplifier Output Signals:

(per axis) Pulse

Direction

Other Control Signals:

(per axis) Home signal channel input

Positive limit switch input

Negative limit switch input

Fault input

AxisOut output

Miscellaneous Signals: GND

+5 V (for encoder power)

For a complete description of the PC/104 card connectors and interfacing

requirements see Appendix A "PC/104 Motion Controller Electrical Reference".

1.10 Applying Power

Once you have connected the board to the desired number of external amplifiers and motor

encoders, hardware installation is complete and the board is ready for operation.

Upon power up, the motion controller will be in a reset condition. In this condition no

motor output will be applied until the chipset is initialized (see next section on software for

15

details). Therefore, the motors should remain stationary. If the motors do move or jump,

power down the board and check the amplifier and encoder connections. If anomalous

behavior is still observed, call Cito Systems, or your local representative for assistance.

2 Software Installation

On the storage media (CD) provided with the Millennium series PC/104 motion

controller there is a motion functions library called C-MotionPlus. This library contains

functions that are commands for the motion processor installed in the controller. The

user is responsible for writing a program to control motors motion and serving specific

application. In the following sections [2.2.1. – 2.2.5] are samples of the functions to

perform some basic moves.

The C-MotionPlus software library provided by Cito Systems supersedes the C-Motion

supporting the Navigator motion processors. C-MotionPlus provides interfaces to the C

functions as well as to the methods of C++ classes. It also has an interface to the TCL

scripting language. Additionally, this library allows communicating with multiple cards

on the bus at the time and invoking directly from a terminal window all the functions on a

local computer or remote one via network or RS-232/RS-485 link. The library supports

functions specific to Millennium series motion control boards.

It can be used in the Windows and Linux operating systems environment.

2.1 Using EasyMotion Console

EasyMotion is an application software package that can be purchased from Cito Systems for

easy and fast setting of a motion system. It contains a set of tools that help and assist in

configuring the motion card. One of the tools is a Motion Console that works as a terminal

interface allowing direct calling of the C-MotionPlus library functions. This way, without

writing a single line of code one can talk to the board and quickly verify the system.

16

Figure 2-1. Motion Console - EasyMotion command interface

2.2 First Time System Verification

To verify that the Millennium board has been properly installed, it is useful to have each axis

of the system perform a short move.

For the MC2100 parts to perform this simple sequence it is necessary to specify two items:

• the motor amplifier type (PWM sign/mag, PWM 50/50, or analog)

• the filter gains

For the MC2300 parts it is necessary to specify these two items as well as to initialize the

motor commutation.

The following table summarizes this. Note that the step #'s reference specific steps, which

are detailed in the next section.

Chipset Step # Operation

MC2100 1 Set amplifier type (PWM

sign/mag, PWM 50/50, DAC)

4 Set filter parameters

5 Make a trajectory move

17

MC2300 1 Set amplifier type (PWM 50/50,

DAC)

2 Initialize commutation

3 Check Commutation

4 Set filter parameters

5 Make a trajectory move

Only perform the setup step sequences indicated above for the chipset installed on your board.

To start verification use the following Navigator commands

SetActualPosition 0

Update

SetKp 25

Refer to the “Programmers Reference Manual” for a full list of commands.

It is assumed that you will check out each axis of your system one at a time. Then to check

out other axes enter a new axis number and check that axis out entirely, etc.

2.2.1. Step #1 Set the Motor Amplifier Type

The card must be told what type of motor output mode to use, PWM sign/mag, PWM

50/50, or DAC. This can be set using the command SetOutputMode. Assuming the axis you

want to exercise is #1, you would use the command "SetOutputMode" followed by the

output mode: 0 for DAC, 1 for PWM sign/mag, and 2 for PWM 50/50. For example to

specifiy the output mode as PWM 50/50 the following command would be used:

SetOutputMode 2

2.2.2. Step #2 Initialize Commutation

Note: This sections applies to MC2300 and MC2800 chipsets only.

For the motor to be controlled properly using the MC2300, the chipset must select and

possibly initialize the commutation phasing. If you will be using Hall-based commutation

then no initialization is necessary. Simply specify this to the chipset using the command:

SetCommutationMode 1

No other commands are necessary and you may proceed to step #3.

If you will be commutating using a sinusoidal technique you must initialize the commutation

phasing. There are two ways this can be done. You will need to decide whether to initialize

using Hall-based or algorithmic methods. See the Navigator User's Guide for more

information on this.

Each of these two phase initialization methods requires a separate sequence, as follows (note

that // indicates a comment and should not be typed in):

Hall-based initialization command sequence:

SetPhaseInitializeMode 1 // set phase initialize mode to 'Hall-based'

SetNumberPhases x // where x is 2 or 3 depending on type of motor

InitPhase

18

Algorithmic-based initialization command sequence:

SetPhaseInitializeMode 0 // set phase initialize mode to 'algorithmic'

SetMotorMode 0 // places axis in open loop mode, required for algorithmic init.

SetNumberPhases x // x is 2 or 3 depending on type of motor

SetPhaseCounts yyyy // yyyy is # of encoder counts per elec. cycle

SetPhaseInitializeTime zzzz // zzzz is # of chipset cycles to initialize for

SetMotorCommand wwww // wwww is motor command.

InitPhase

To determine the values of x, yyyy, zzzz, and wwww you should refer to the Navigator

User's Guide, "commutation" section.

If your system has one or more of the following conditions present then the above

sequence will need to be expanded. To handle such systems you will need to use the

SetSignalSense command as well as the SetPhasePrescale command. Call Cito

Systems for assistance

1) One or more Hall signals must be inverted to commutate or initialize the

commutation correctly

2) # of encoder counts per electrical cycle exceeds 32,767

2.2.3. Step #3 Check Commutation

Note: This sections applies to MC2300 and MC2800 chipsets only.

After phase initialization has been completed it is useful to check the smoothness of the

motor rotation in open loop mode to verify that the motor phasing initialization and

commutation is correct. To do this use the following command sequence:

SetMotorMode 0 // set axis for open loop operation

SetMotorCommand xxxx // xxxx is the motor command from 0 to 32,767 to output

Update

The 'xxxx' value represents the fraction of the value 32,768 of total power that will be

applied to the motor. For example, a value of 1,000 sends roughly 3% of the total power to

the motor.

When the motor mode is set off, the motor is not under servo control. Beware that

the motor may spin rapidly after a motor command value is applied. Use small values

and increase slowly.

After this command sequence the motor should smoothly spin in one direction or the other.

The motor command is a signed number and the sign controls the rotation direction. When

a positive motor command is given the motor should rotate in the positive (increasing

encoder counts) direction. If the motor spins roughly, in the wrong direction, or if it moves

a short distance and then abruptly stops there may be a problem with the commutation.

Check your wiring and re-test. Once the motor is spinning smoothly in both directions

19

under open loop control re-enable closed-loop servo control by executing the following

command:

SetMotorMode 1

2.2.4. Step #4 Set Filter Parameters

For motion to occur, some amount of feedback gain must be specified. Initially use just a

proportional gain with a very low value between 1 and 25. Later you can add integral or

derivative gains as well as feedforward gains if desired. The following sequence shows how

to set the P, I, and D terms of the filter and how to 'update' them, making them active.

SetKp xxxx // xxxx is the desired proportional gain

SetKd yyyy // yyyy is the desired derivative gain

SetKi zzzz // zzzz is the desired integral gain

Update // make thee values active.

It is not necessary to specify all 3 gains. Just Kp, followed by an Update can be specified, just

a Kd, etc...

Important note:

When exercising the motor use extreme caution. It is the responsibility of the

user to observe safety precautions at all times.

2.2.5. Step #5 Make a Trajectory Move

To test that the motor is being driven properly, set up and execute a small trapezoidal move.

Specify a small distance of (for example) 5,000 counts, and a low velocity and acceleration of

(for example) 10,000 counts/sample time, and 10 counts/sample time2respectively. With a

cycle time of 400 µsec, these values correspond to roughly 381 counts/sec, and 954

counts/sec2, respectively.

Whatever profile values you use, be sure that they are safe for your system.

Here is the command sequence to use:

SetProfileMode 0 // Sets current profile mode to trapezoidal

SetPosition xxxx // xxxx is the desired destination position

SetVelocity yyyy // yyyy is the desired maximum velocity

SetAcceleration zzzz // zzzz is the desired acceleration

SetDeceleration wwww // wwww is the desired deceleration

Update // execute the move

After entering this sequence of commands you should see the axis smoothly move for about

15 seconds (if the suggested values are used and the cycle time of the chipset is 400 µsec). If

you do not see the axis moving, or if the axis jumps rapidly in one direction or the other,

there may be a problem with the board or software settings. Re-check and review the board

setup procedures, as well as the exerciser parameter settings.

20

Table of contents