CLARCOR UAS SFC Series User manual

Downward Flow Cartridge Dust Collector

l Model - SFC l PATENT NO: 6,902,592

OWNER'S MANUAL

KNOW YOUR EQUIPMENT

READ THIS MANUAL FIRST.

Your SFC system should provide many years of trouble-free service. This manual will

help you understand the operation of your SFC unit. It will also help you understand

how to maintain it in order to achieve top performance. For quick future reference, fill in

the system and filter information in the spaces below. Should you need assistance, call

the United Air Specialists, Inc. customer service number shown below. To expedite your

service, have the following information available when contacting UAS.

UAS ORDER #: ________________________________________________________________

UNIT MODEL #:________________________________________________________________

UNIT SERIAL #:________________________________________________________________

CARTRIDGE FILTER PART #: ____________________________________________________

SYSTEM ACCESSORIES:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

INSTALLATION DATE: __________________________________________________________

UNITED AIR SPECIALISTS, INC. CUSTOMER SERVICE

1-800-252-4647

i

TABLE OF CONTENTS

Page

SAFETY PRECAUTIONS ........................................................................................ iii

1. IMPORTANT NOTICE ........................................................................................1

2. INTRODUCTION.................................................................................................1

2.1 Unit Nomenclature ........................................................................................1

2.2 Description and Operation ............................................................................1

2.3 Air Filtering Operation...................................................................................2

2.4 Filter Cleaning Cycle.....................................................................................2

3. INSTALLATION ...................................................................................................3

3.1 Off Loading and Inspection...........................................................................3

3.2 Installation Planning......................................................................................3

3.3 Assembly of Standard Equipment.................................................................3

3.3.1 Hopper Assemblies ..............................................................................3

3.3.2 Fully Assembled Filter Module Sections ..............................................6

3.3.3 Multiple, Bolt-Together Module Sections

(applies to 4 or more modules) ............................................................6

3.4 Electrical Installation ...................................................................................11

3.4.1 Mounting the Controls ........................................................................11

3.4.2 Solenoid Valve Enclosure Wiring ....................................................... 11

3.4.3 Heater Wiring......................................................................................15

3.5 Compressed Air Connection .......................................................................15

3.6 Assembly of Optional Equipment................................................................15

3.6.1 Blower Package Installation ...............................................................15

3.6.2 Duct Silencer Installation....................................................................18

3.6.3 Rotary Air Lock Installation.................................................................18

3.6.4 Abrasive Inlet Installation ...................................................................18

3.6.5 Drum Lid Installation...........................................................................18

3.6.6 Inlet Cover and Blank Cover Plate Installation...................................19

3.6.7 Remote Blower Start/Stop Assembly .................................................19

3.6.8 Explosion Vents..................................................................................21

3.6.9 Extend Dirty Air Plenum (EDAP) for 5 high units...............................21

ii

Page

4. OPERATION .....................................................................................................21

4.1 Start-Up.......................................................................................................21

4.2 Checklist......................................................................................................23

4.3 Checking the Pulse Cleaning System.........................................................23

4.3.1 Digital Pulse Monitor Panel (DPM).....................................................23

4.3.2 Digital Pulse Control Panel (DPC) .....................................................24

5. SERVICE ..........................................................................................................24

5.1 Cartridge Filter Removal and Replacement................................................24

5.2 Dust Removal .............................................................................................24

5.3 Servicing the Compressed Air Components...............................................25

5.4 Servicing the Direct Drive Blower and Motor System.................................25

5.5 Servicing Cartridge Media .........................................................................25

5.6 Servicing Optional Return Air Safety Filters (HEPA/ASHRAE)...................25

5.7 ProTura®Nanofiber Cartridge Filters ..........................................................26

5.8 Explosion Vent Replacement ......................................................................26

5.8.1 Dome Style Explosion Vent Replacement .........................................26

5.8.2 Swing Door Re-Arming Instruction.....................................................27

6. TROUBLESHOOTING GUIDE..........................................................................27

7. ILLUSTRATED PARTS .....................................................................................30

SFC Series Bill of Materials ..............................................................................31

WELD FUME COLLECTOR” to read “DOWNWARD FLOW CARTRIDGE DUST COLLECTOR”.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury when using your air cleaner, follow these basic precautions:

iii

SAFETY PRECAUTIONS

We have provided many important safety messages in this manual and on your SFC dust collector. Always read and obey

all safety messages.

• Wear protective clothing and safety glasses when handling

collection filters or servicing the dust collector.

• Use proper lifting and rigging equipment to install your dust

collector.

• The dust collector must be properly grounded.

• Disconnect power before servicing.

• Replace all access panels before operating.

• Electrical connections should only be made by qualified

personnel, and be in accordance with local and national

codes and regulations.

• Do not use in explosive atmospheres unless the dust

collector is equipped with the appropriate accessories.

• Keep flammable materials and vapors, such as gasoline,

away from dust collector.

• The unit should be inspected frequently and dirt removed

to prevent excessive accumulation which may result in

flash-over or fire damage.

• The SFC system should not be used to support personnel

or material.

• Operate only in a safe and serviceable condition.

• Do not allow any individual to put lit cigarettes or any

burning objects into any hood which is ducted into the

dust control system.

!

!DANGER

!WARNING

!WARNING

!CAUTION

CAUTION

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others. All safety messages will follow the

safety alert symbol and the word “DANGER” “WARNING” or “CAUTION”. These words mean:

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

1

Revised 04/15 SFC

Cartridge Dust Collector

1. IMPORTANT NOTICE

This manual contains important safety information

and precautionary measures. It is impossible to

list all potential hazards associated with every

dust collection system in each application. Proper

use of the equipment should be discussed with

United Air Specialists, Inc. (UAS) or your local UAS

representative. Operating personnel should be aware

of, and adhere to, the most stringent safety procedures.

EXPLOSION HAZARD

• Avoid mixing combustible materials such as aluminum,

paper, wood or other organic dusts with dusts

generated from grinding materials. A fire hazard could

develop from sparks entering the dust collector. When

collecting flammable or explosive materials, the dust

collector should be located outdoors and incorporate

the appropriate safety measures and/or accessories.

• When collecting emissions from spark-producing

processes, care must be taken to reduce any potential

fire hazards. System design should

include methods to prevent sparks from entering

the dust collector. Dust collectors do not contain

fire extinguishing equipment unless specifically

ordered. Experts in the field of fire extinguishing

equipment should be consulted for recommendations

concerning proper fire detection and suppression

systems.

• Some dust collection systems require explosion

venting. Consult your insurance underwriter,

NFPA (National Fire Protection Association) manual

and your local fire authorities to determine the

requirements for explosion venting.

• Be careful and conscientious – consult national

and local fire codes, waste disposal, safety and

other appropriate authorities. Comply with their

recommendations for the proper installation and

operation of dust collection equipment.

• Your dust collector was selected for a particular

application. Consult UAS prior to making any

application or system changes.

• All explosion vent installations should be located to

allow full-unrestricted discharge when system pressure

exceeds the set pressure of the explosion vent. An

explosion vent should never be located where the

discharge from the vent will impact people or plant

equipment.

• Do not use the explosion vent as temporary work

surface for hand tools; i.e., wrenches, screw drivers,

etc. Such actions can cause premature failure to occur

via over stressing the explosion vent.

• All dust collectors handling hazardous or fire/

explosion risk dust, as determined by the user, are

recommended to be located outside the building in

non-traffic areas even though the dust collector is

equipped with an explosion vent.

2. INTRODUCTION

Thank you for selecting UAS dust collection equipment

to assist you in your commitment to a clean and safe

environment. We trust that in purchasing our product,

you have recognized our commitment to continually

offer air cleaning equipment engineered to each dust

collection need and manufactured to the highest

standards. If at any time you have a question about

dust collection, please do not hesitate to call your local

UAS representative.

The SFC is designed to collect process generated

dusts. The optimized pulse cleaning system coupled

with the QuickSeal filter access doors provide the most

dependable and maintenance friendly cartridge collector

in the market.

The SFC dust collector should not be used for any

purpose not listed in this manual.

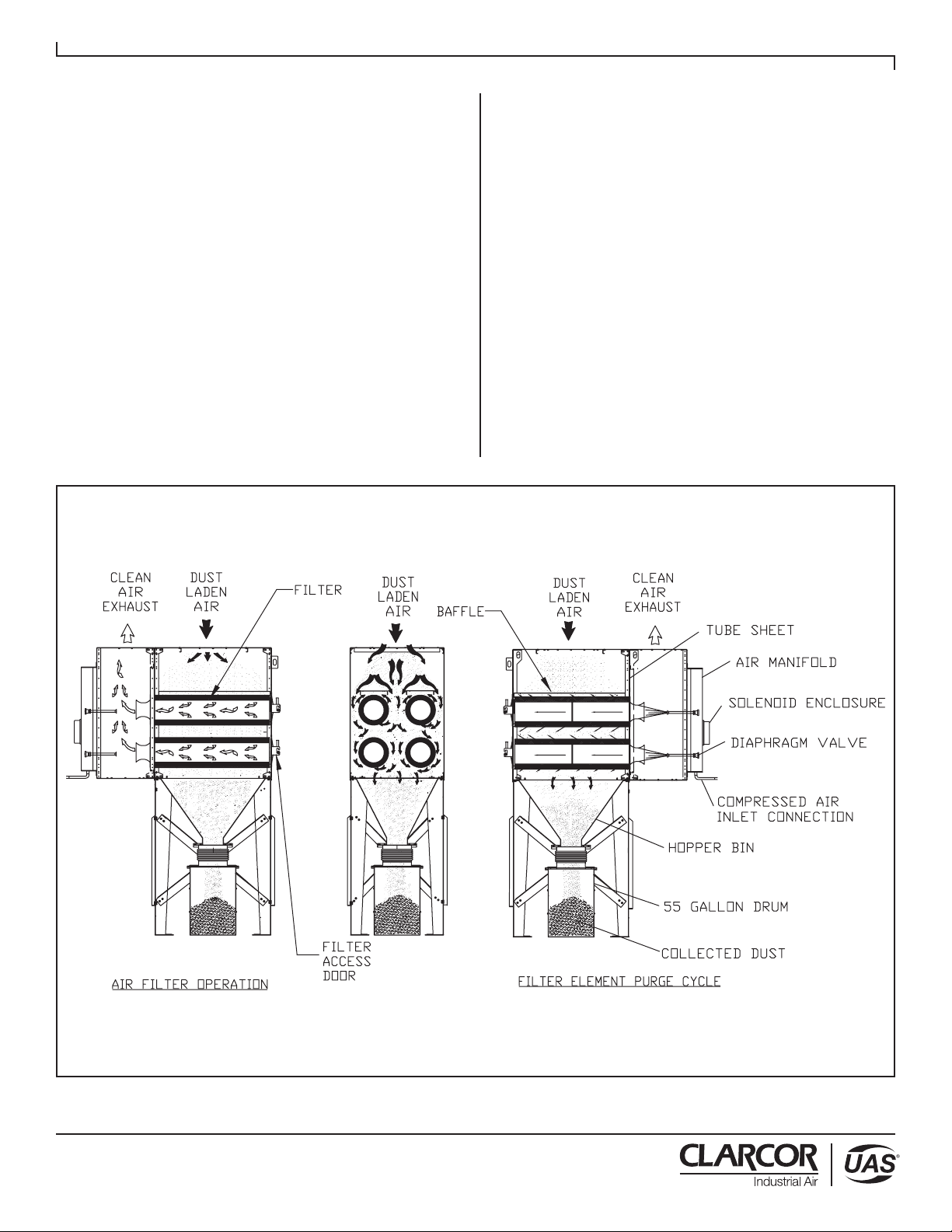

As you review this manual, refer to Figure 1 for

assistance in identifying dust collector parts. The SFC

Specification Table in Section 3 provides additional unit

information.

2.1 UNIT NOMENCLATURE

Example: SFC8-2-H55

SFC = Model collector

8 = number of cartridge filters

2 = number of filter tiers

H55 = unit base arrangement

H55 - hopper with 44” (112 cm) clearance for

standard 55 gallon (208 liter) drum

SD - hopper with 28” (66 cm) clearance for

UAS-supplied 20 gallon (76 liter) drum

OB - open bottom construction

BV - custom bin vent unit with open bottom

DD - dust drawer

2.2 DESCRIPTION AND OPERATION

The SFC is a high-efficiency cartridge dust collector

designed to eliminate airborne dust as it is generated.

Contaminants are captured at the source(s), then

conveyed through ducting to the cartridge filter section

(dirty air section) where the dust is collected. Clean air

is then discharged from the unit through the clean air

discharge.

The dust collector is designed for on-line or downtime

cartridge filter cleaning by means of a customer-supplied

compressed air system.

The SFC is a high-efficiency, horizontally-oriented

cartridge dust collector equipped with 9.48” I.D. and

13.87” O.D. cartridge filters. The larger diameter

ProTura®Nanofiber cartridge filter design allows for

lower pressure losses through the dust collector while

increasing the amount of media contained in each

filter. SFC Series dust collectors have pre-engineered

backward-inclined or radial-type optional blower

packages in 2, 3, 5, 7-1/2, 10, 15, 20, 25 and 30 hp (1.5,

2.2, 3.7, 5.5, 7.5, 11, 15, 18.8, 22.6 kW) assemblies.

There are two primary modes of operation — the air

filtering operation and filter cleaning cycle. Both modes

of operation are shown in Figure 1.

!DANGER

2

Revised 04/15 SFC

Cartridge Dust Collector

2.3 AIR FILTERING OPERATION

The contaminated airstream is drawn into the dust

collector where its velocity is reduced by inlet baffle

plates to provide even air distribution across the

entire surface area of the cartridge filters. This design

enhances filtration efficiency by establishing a uniform

“dust cake” on the filters. The airstream is then directed

around the cartridge filters and down toward the hopper,

where the heavier particles discharge to the dust

storage drum.

The contaminated air then passes through the

cartridge filters. The filter media strips the dust from the

airstream, allowing only clean air to pass through the

cartridge filter. The air then passes into the clean air

plenum, through a blower package and is discharged

from the unit.

2.4 FILTER CLEANING CYCLE

During normal operation, the surface of the cartridge

filters become loaded with contaminants. The reverse-

pulse cleaning mechanism provides brief bursts of

compressed air, directed through the diaphragm valves,

toward the cartridge filter. This pulsing action dislodges

the collected particles from the media, where they fall

into the hopper and are discharged to a dust storage

drum or drawer.

During the cleaning cycle, each pair of cartridge filters

is cleaned individually. The solid-state sequential

timer actuates a solenoid valve, which allows an

air diaphragm valve to open for approximately 100

milliseconds. High-pressure air from the air manifold

reservoir is directed through the diaphragm valve

toward the venturi mounted on the tubesheet in front

of the cartridge filters. The venturi, in conjunction with

the DIF nozzle, maximizes the compressed air energy

to maximize the amount of collected dust released from

the filter surface.

The dislodged dust removed from the filter is swept

downward into the hopper. The remaining filters are

cleaned sequentially. The sequencing is factory preset

at 10-second intervals and is adjustable to adapt to your

particular cleaning needs.

FIGURE 1

SFC Air Filter Operation & Cleaning

44-10334-0001

3

Revised 04/15 SFC

Cartridge Dust Collector

options are also possible. Structural calculations for

the foundation or other mounting arrangements must

include the weight of the collected material and the

weight of all auxiliary equipment installed with the

dust collector (ducting, abrasive inlet, blower package,

afterfilter assembly, etc.). These weights must be

considered together with wind loading, seismic

loading and other live load ratings when designing the

dust collector foundation support structure. Consult a

professional engineer when designing the foundation

for the unit.

The system should be designed with the ability to

regulate airflow. Two common ways to do this are

through the use of flow/volume control dampers or

variable frequency drives to control the speed of the

fan motor. UAS offers both of these options. If flow

control dampers are selected, the interconnecting

duct work should be designed to account for the

installation of said damper. These dampers can be

installed on the inlet or outlet ducting of the SFC unit.

Whether you control the flow through the use of

a damper or VFD, the ductwork must be properly

sized to meet the recommended air velocities for the

material being collected.

Follow ducting design methods as listed in the

Industrial Ventilation Manual as recommended by

the American Conference of Governmental

Industrial Hygienists.

3.3 ASSEMBLY OF STANDARD EQUIPMENT

CRUSH AND ELECTROCUTION HAZARD

Use adequate safety measures when lifting and

assembling any heavy components. Consult your

plant safety personnel for recommendations.

In preparing to attach the filter module to the

hopper, connect lifting slings and spreader bars

to all filter module lifting lugs with clevis pins. Use

spreader bars to distribute the load evenly.

Location must be clear of all obstructions, such as

utility lines or roof overhangs.

Remove all crating, strapping and hold-down bolts.

Locate all hardware bags, sealant and other assembly

materials provided with your unit.

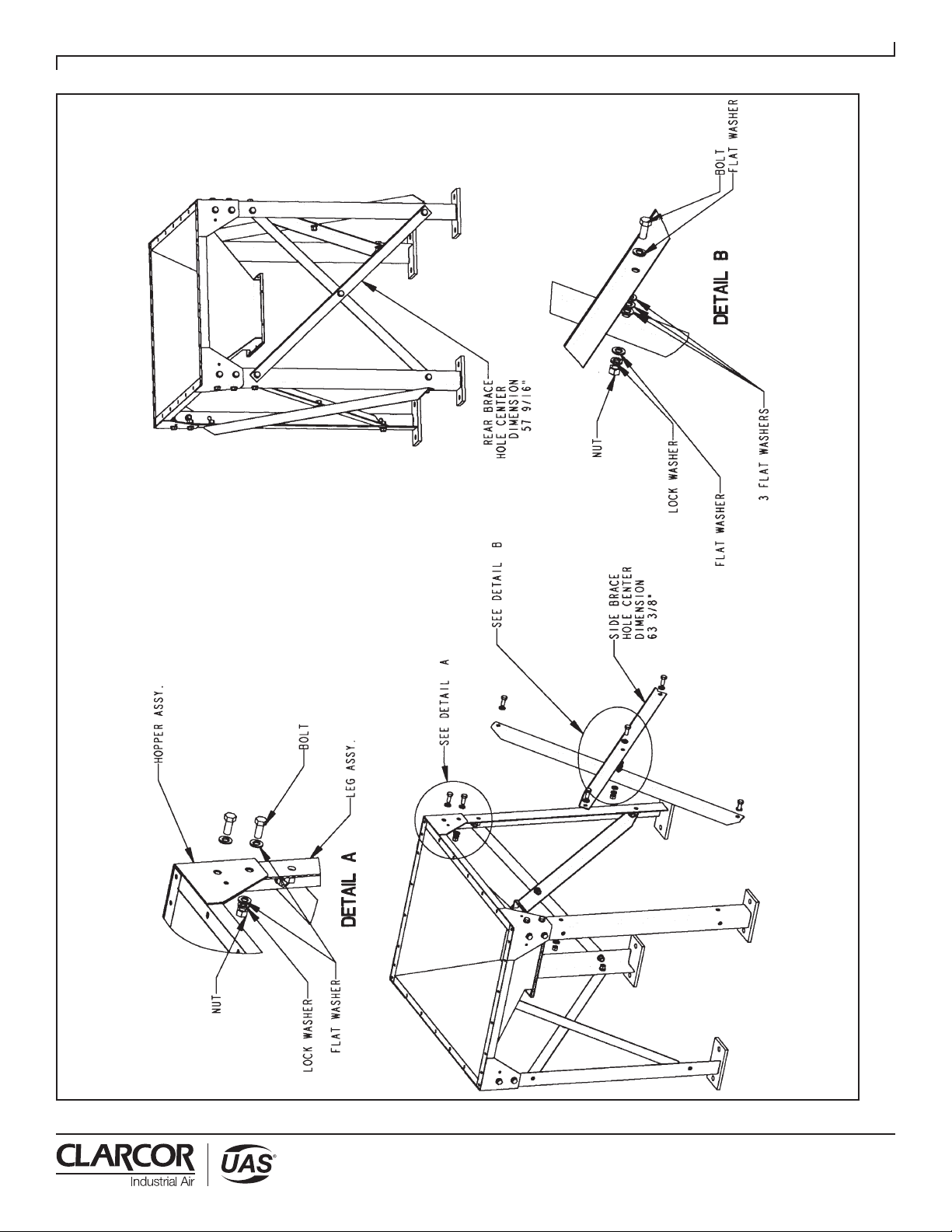

3.3.1 HOPPER ASSEMBLIES

The SFC Series filter module is designed to mount directly

on top of the hopper assembly. A hopper assembly

consists of a hopper bin, legs, side diagonal sway braces,

rear diagonal sway braces and the hardware installation

kit. Hopper assemblies will be shipped in pieces and will

need to be assembled at the site.

The hopper sections are shipped in pieces for field

assembly. Position the legs as shown in Figure 4 for

single module hopper assembly, or Figure 5 for multi-

modular hopper assemblies.

3. INSTALLATION

3.1 OFF LOADING AND INSPECTION

SFC dust collector modules are shipped assembled

(with cartridges installed) on skid(s). Other skids will

contain the hopper/leg assembly and other components.

Other accessories (afterfilter assemblies, blower

packages, dust storage drums, silencers, etc.)

may be on additional, separate skids.

TIP OVER HAZARD

Lift the dust collector components by the packing skids

or use the external lifting lugs provided on the filter

module. Do not lift the filter module of the dust collector

by placing lift truck forks through the cartridge filter

access doors. The filter support rails or venturi installed

on the tubesheet could be damaged.

Upon receipt of your unit, check for any shipping damage.

A damaged carton indicates that the equipment may

have received rough handling during shipping that may

have caused possible internal damage. Notify your

delivery carrier and enter a claim if any damage is found.

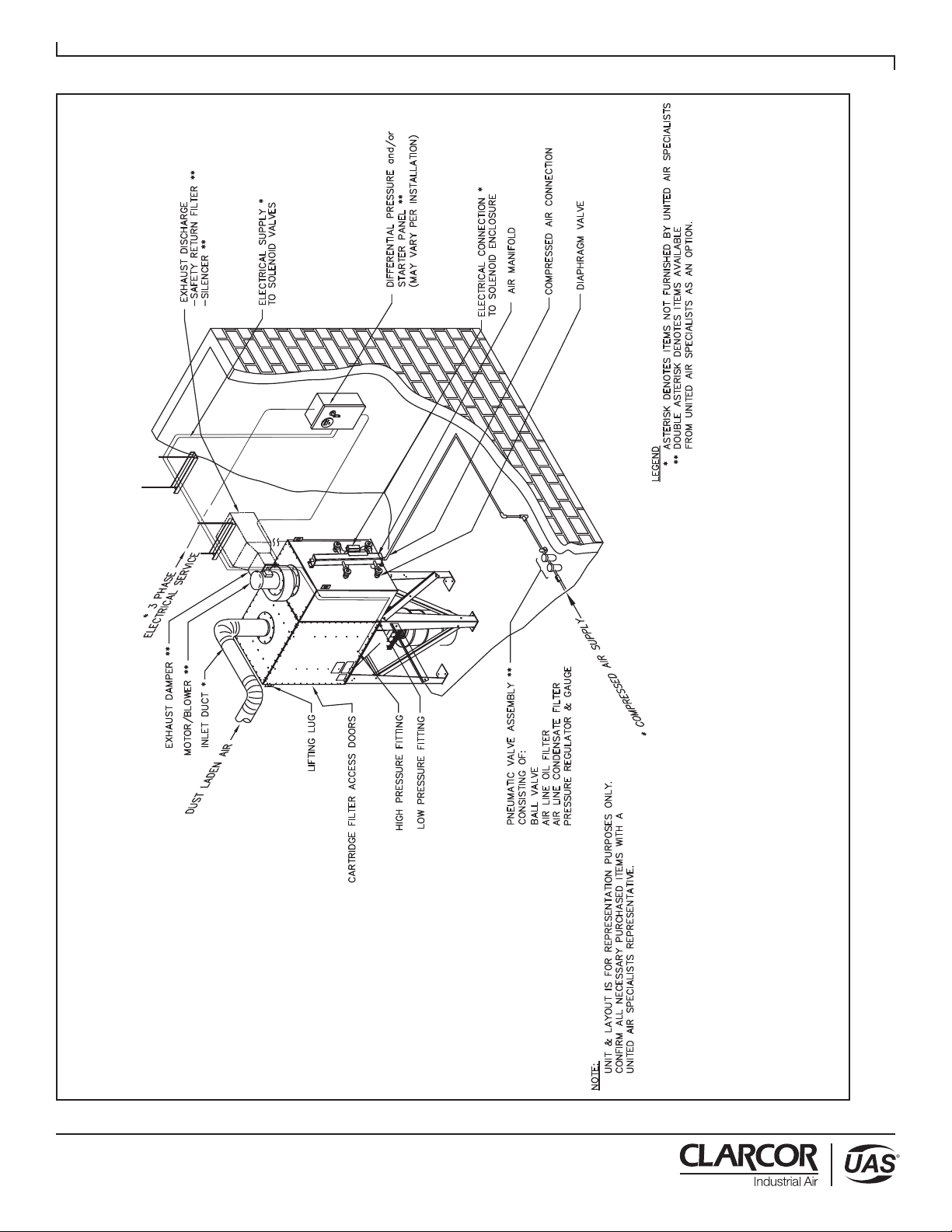

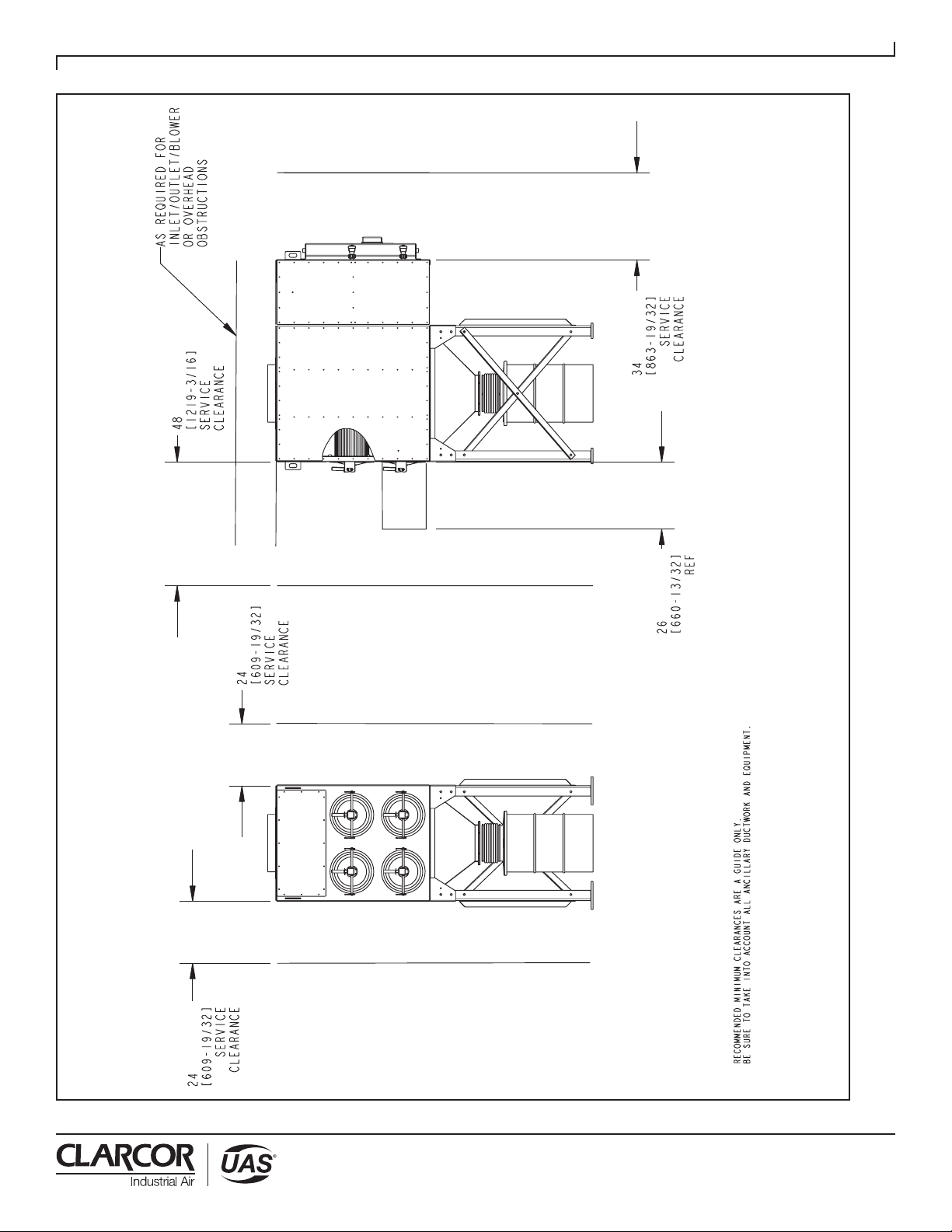

3.2 INSTALLATION PLANNING

The proper location of your dust collection equipment

is very important. Refer to Figures 2 and 3 for typical

installation details.

Certain items should be considered when locating the

unit, such as emptying of the dust storage drum(s), filter

removal requirements, compressed air connections,

access to the clean air plenum, electrical connections,

blower location and discharge direction. The shortest

duct length with a minimum number of elbows will

maximize the performance of the unit. Ease of

maintenance should also be considered when selecting

the location and orientation of the system. Refer to

Figure 3 for recommended clearances.

EXPLOSION HAZARD

In the case of spark producing processes, system

design should incorporate measures to prevent live

sparks from entering the dust collector. Consult local

authorities for the location of the unit and any additional

precautions to consider when collecting combustible,

explosive or hazardous dusts. General warnings and

cautions are provided on page iii and in Section 1.

TIP OVER HAZARD

The SFC dust collector should be mounted on a solid,

level, reinforced concrete foundation. Other mounting

!DANGER

!DANGER

!DANGER

!DANGER

4

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 2

SFC Typical SINGLE UNIT Installation Diagram

44-10335-0001

5

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 3

Recommended Unit Clearances

44-10337-0001

6

Revised 04/15 SFC

Cartridge Dust Collector

3.3.1.1 SINGLE MODULE HOPPER

ASSEMBLY

Assemble four leg weldments to hopper (refer to Figure

4, Detail A), making sure base pads are oriented as

illustrated. After four legs have been bolted to the

support hopper, locate the four support braces which

measure 60-11/16” between hole centers, and attach to

left and right side of hopper legs as shown in Figure 4.

Locate the two support braces, which measure 55-1/16”

between hole centers. These braces are to be attached

to back legs as illustrated in Figure 4.

After all support braces have been installed. Bolt brace

together as illustrated in Fig. 4, Detail B.

Secure hopper/leg assembly to concrete mounting

pad with appropriate mounting hardware. Anchors

should be provided by customer or contractor

according to local codes.

3.3.1.2 MULTIPLE MODULAR HOPPER

ASSEMBLIES

Position multiple hoppers side by side and bolt through

corner gussets as illustrated in Figure 5, Detail D. After

hoppers have been securely fastened, refer to Figure 6 to

locate your hopper configuration. Using this configuration

and Figure 5, Detail E, locate and attach the leg

weldments to the hopper assembly. Locate the diagonal

support brace which measures 60-11/16” and attach it to

the hopper corner brackets on left and right side of hopper

referencing Figure 5 hopper configuration and Figure 6,

making sure the base pads are oriented as illustrated

in Figure 6. Locate the support braces, which measure

55-1/16” between hole centers. These braces are to be

attached to the back legs as illustrated in Figure 5,

Details A and C.

After all support braces have been installed, bolt side

braces together where they cross as illustrated in

Figure 5, Detail B.

Secure hopper/leg assemblies to concrete

mounting pad with appropriate mounting hardware.

Anchors should be provided by customer or

contractor according to local codes.

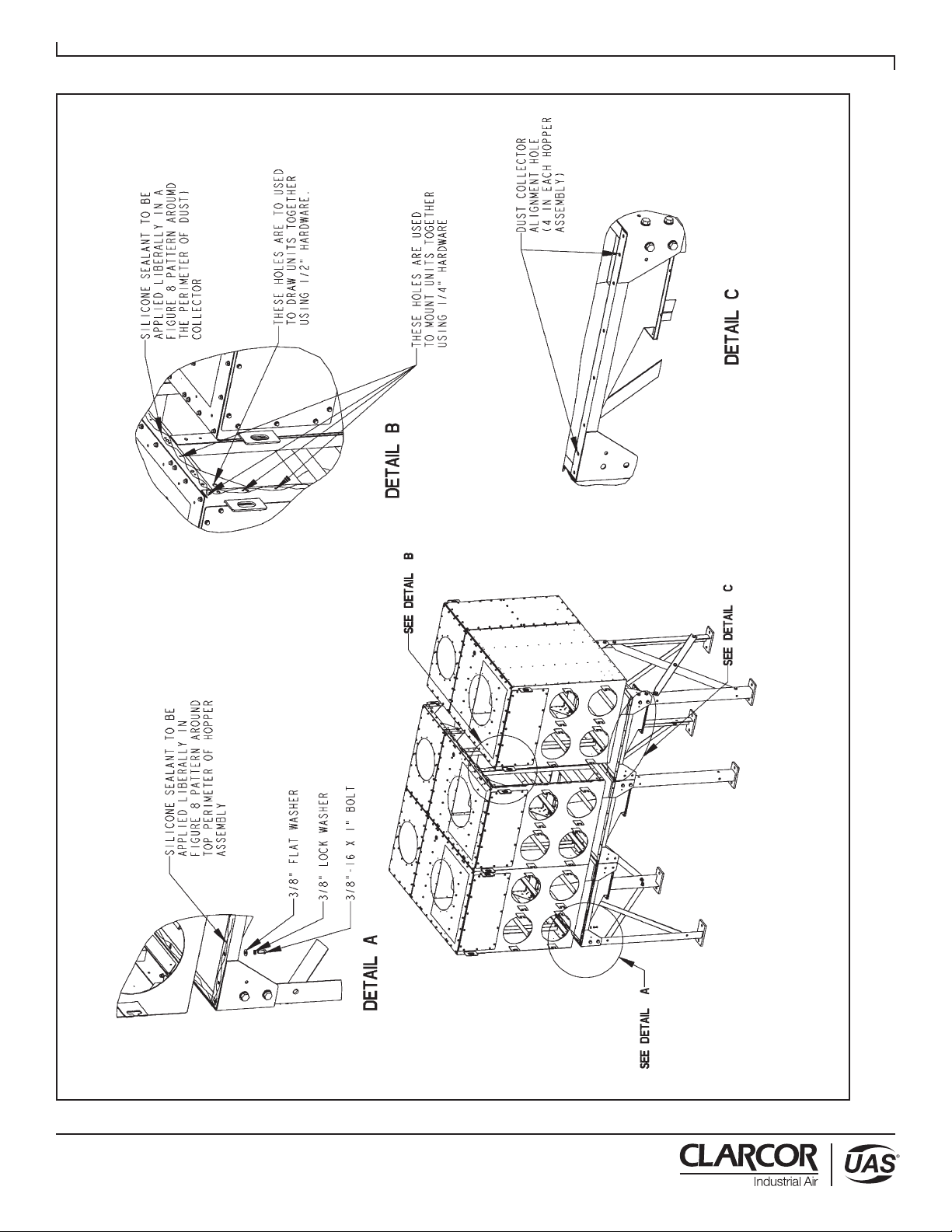

3.3.2 FULLY ASSEMBLED FILTER MODULE

SECTIONS

Apply two ribbons of sealant to hopper flange to

create “figure 8” pattern around mounting holes.

Refer to Figure 7, Detail A.

Place filter module onto hopper/leg assemblies (refer

to Figure 7). Drift pins will also be useful for locating

the filter module section onto the hopper.

NOTE: Each hopper assembly is equipped with four

1/2” (13mm) pry locations – two holes on front

flange and two holes on rear flange. Refer to

Figure 7, Detail C, to aid in aligning the hopper

flange with the module flange.

With filter module still supported, use hardware (refer

to Figure 7, Detail A) to bolt the hopper and filter

module together. Securely tighten all hardware at the

filter module and hopper. Recheck leg assembly sway

braces to ensure they are tight. Install fasteners (bolt,

flat washer, lock-washer, nut) to all four pry locations.

Disconnect lifting slings and spreader bars used for

installation.

3.3.3 MULTIPLE, BOLT-TOGETHER MODULE

SECTIONS (APPLIES TO 4 OR MORE

MODULES)

For units that have multiple bolt-together module

sections, remove the row of filters from the modules

nearest the bolting flange (refer to Section 5.1).

Protect the doors and filters removed by placing in a

safe area away from work area. Identify the different

module sections. There are left (bolt flange on right

side), right (bolt flange on left side) and possibly

center (bolt flanges on both sides) module sections.

Install all hopper/leg assemblies as previously

described in Section 3.3.1.1 and 3.3.1.2.

Apply two ribbons of sealant to hoppers that are

located under the dust collector section that is being

installed (refer to Figure 7, Detail A).

CRUSH AND ELECTROCUTION HAZARD

In preparing to attach the filter module to the hopper,

connect lifting slings and spreader bars to all filter

module lifting lugs with clevis pins. Distribute the

load evenly. Location must be clear of all

obstructions, such as utility lines or roof overhangs.

Place the appropriate filter module onto hopper/leg

assembly to which the sealant has been applied,

positioning filter module corner holes over alignment

holes (refer to Figure 7, Detail C). Drift pins will also

be useful for locating the filter module section onto

the hopper.

NOTE: Each hopper assembly is equipped with four

1/2” (13mm) pry locations – two holes on front

flange and two holes on rear flange. Refer to

Figure 7, Detail C, to aid in aligning the hopper

flange with the module flange.

With filter module still supported, use hardware (refer

to Figure 7, Detail A) to bolt the hopper and filter

module together. Securely tighten all hardware at the

filter module and hopper. Recheck leg assembly sway

braces to ensure they are tight. Install fasteners (bolt,

flat washer, lock-washer, nut) to all four pry locations.

!DANGER

!WARNING

!WARNING

7

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 4

Single Hopper, SFC

44-10309-0001

8

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 5

Multiple Hopper, SFC

44-10309-0002

9

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 6

Multiple Hopper, SFC

44-10309-0003

10

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 7

Multiple Modules, SFC

44-10310-0001

11

Revised 04/15 SFC

Cartridge Dust Collector

Disconnect lifting slings and spreader bars used for

installation.

Apply sealant to the next hoppers that will receive a

filter module (refer to Figure 7). Apply sealant to the

side bolting flange of the next filter module to be

installed using the “figure 8” pattern (refer to Figure 7,

Detail B). Place this module on its hopper. Use the

hardware provided (refer to Figure 7, Detail B).

Place this module on its hopper. Use the hardware

provided (refer to Figure 7, Detail B) and bolt the

module sections together. Bolt the filter module to

the hopper (refer to Figure 7, Detail A). Securely tighten

all hardware at the filter module and hopper. Recheck

leg assembly sway braces to ensure they are tight.

Install fasteners (bolt, flat washer, lock-washer, nut) to

all four pry locations..

Disconnect lifting slings and spreader bars used for

installation.

Repeat this process until all the module sections are in

place, securely fastened and anchored to the foundation.

Recheck all hardware connections to make certain they

are securely tightened. Remove lift slings and spreader

bars and clear all tools from the work area.

NOTE: Make certain all bolts (including the anchor

bolts) are properly tightened before proceeding

with the remainder of the installation.

Install all cartridge filters removed at the beginning

of the installation process and install the filter access

doors (refer to Section 5.1).

3.4 ELECTRICAL INSTALLATION

ELECTRICAL SHOCK HAZARD

All electrical work should be performed by a

qualified electrician in accordance with local

electrical codes. Disconnect electrical power before

installing or servicing any electrical component.

GENERAL

Several types of standard electrical components can

be installed to control and monitor your dust collector.

A VFD or a motor starter circuit (combination starter

panel) is required to safely start and stop the system.

A properly sized circuit breaker or fused disconnect

is also required to safely work on and service the

electrical system. In addition, a 115/1/60 (2 amp)

control circuit is required for the pulse control panel.

Some or all of the above items may be included in the

controls package you purchased from UAS. Any one

of the following control combinations can be used:

• Motor starter with Digital Pulse Monitor (DPM) for

continuous pulse cleaning.

• Motor starter with Digital Pulse Control (DPC) for

on-demand pulse cleaning.

• VFD with DPM for continuous pulse cleaning.

• VFD with DPC for on-demand pulse cleaning.

Refer to UAS sales order to verify the control

configuration purchased with your unit and whether

additional items are required to control and operate

your system.

3.4.1 MOUNTING THE CONTROLS

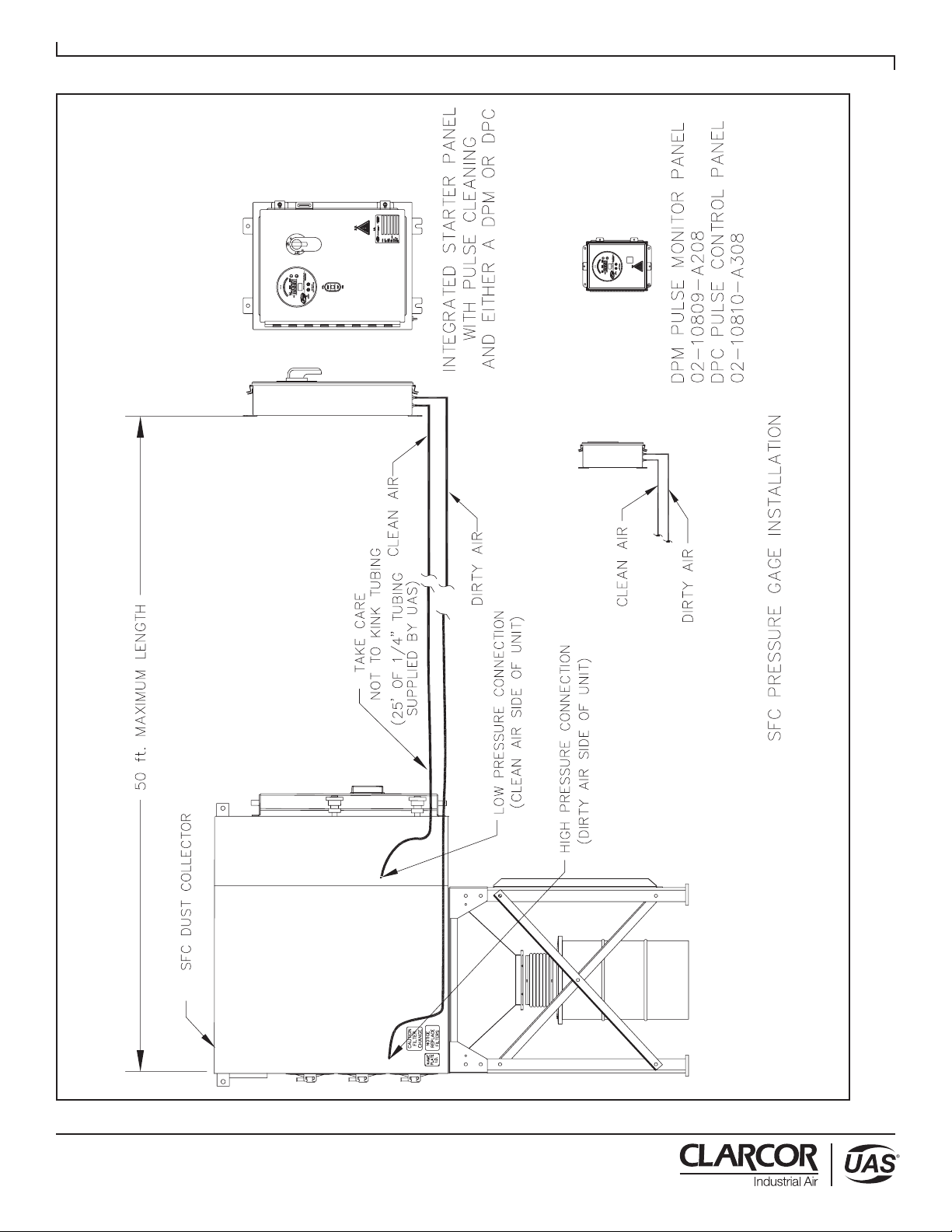

Mount the VFD or combination starter panel for the

fan motor in a convenient location. It is recommended

that these controls be mounted on a wall or pedestal

in an area subject to minimal vibration and electrical

noise. Mounting hardware is provided by the

customer or the contractor. If the panel includes

the DPM or the DPC gauge and UAS timer control

board, then the location of the panel must within close

proximity of the dust collection unit as shown in Figure

8. For additional setup and installation information

refer to the VFD and/or DPM/DPC Owner’s Manuals

provided.

Avoid mounting the panel on the collector due to

vibration generated from blower assembly and the

pulsing system.

For all pulse control panels, connect the black plastic

pressure tubing (25’ [7.5 meters] provided by UAS) to

the panel fittings and the SFC unit. Connect the dirty air

plenum of the SFC to the high pressure port (dirty air)

on the panel as shown in Figure 8. Connect the clean

air plenum of the SFC to the low pressure port (clean

air) on the panel.

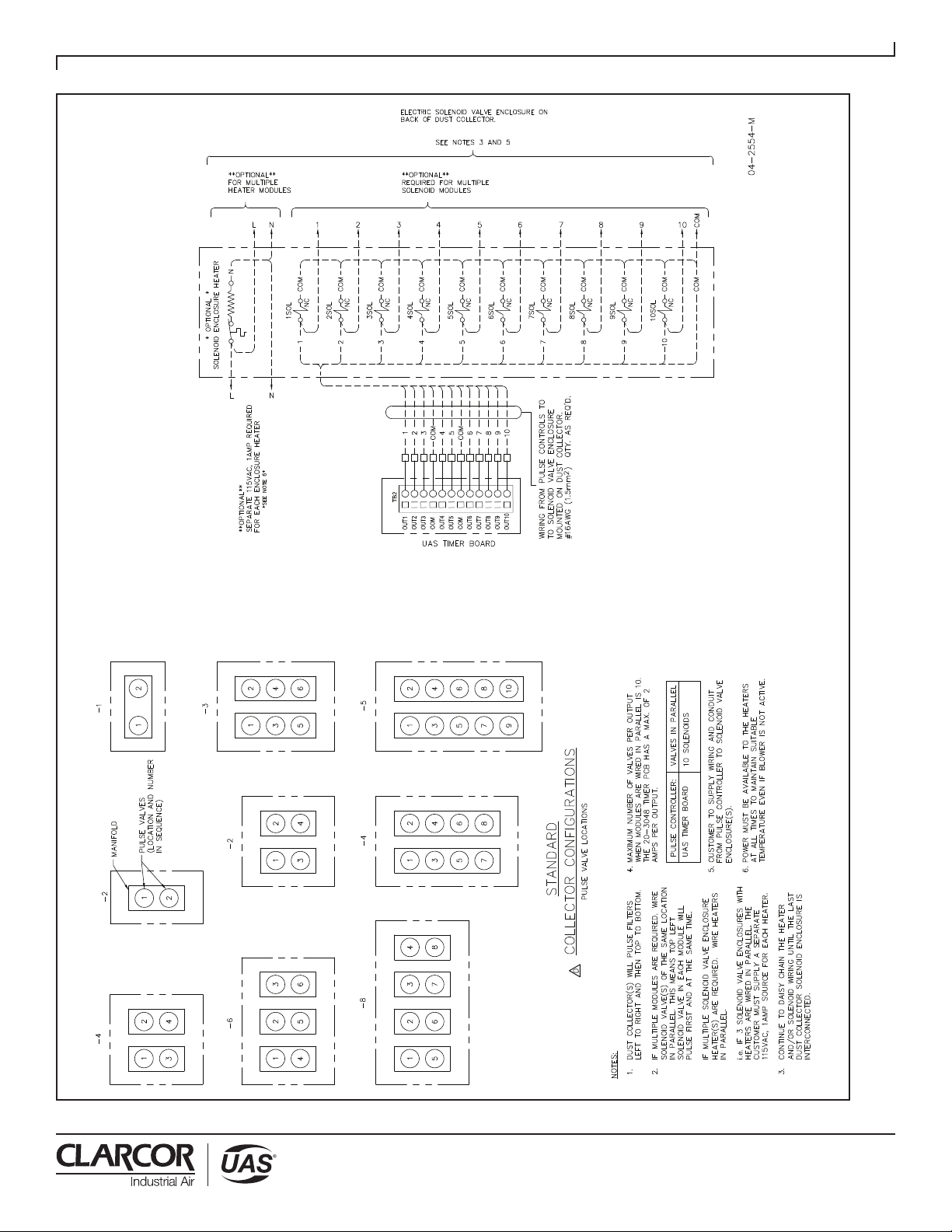

3.4.2 SOLENOID VALVE ENCLOSURE

WIRING

The solenoid valves at the dust collector must be

wired correctly to the pulse control panel. Refer to

Figure 9 when making connections from the pulse

control panel to the solenoid valve enclosure(s).

Example: Figure 9 shows the SFC having ten valve

locations per module. This means when the system

pulses, “1” is the first pulse in the sequence, “2” is

the second, “3” is the third, etc.

When multiple dust collector modules are installed,

daisy chain the wiring so that each solenoid valve

with the same module location will pulse at the

same time. This means all #1 solenoid valves are

connected together and wired to pulse control panel

“OUT 1,” #2 solenoid valves are connected together

and wired to pulse control panel “OUT 2,” etc. Refer

to Figure 9 for the SFC dust collector solenoid valve

wiring information. When cleaning, the pulse valves

sequence left to right, top to bottom.

Unless specified on the UAS sales order, the customer

will supply interconnecting material (conduit, wiring,

etc.) from the pulse control panel to the SFC.

CAUTION

!DANGER

12

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 8

SFC Pressure Gauge Installation

44-10333-0001, Rev A

13

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 9

Solenoid Wiring to Pulse Controls for 2, 3, 4 and 5 Tier Units

14

Revised 04/15 SFC

Cartridge Dust Collector

FIGURE 10

Pneumatic Valve Assembly

44-10332-0001

15

Revised 04/15 SFC

Cartridge Dust Collector

3.4.3 HEATER WIRING

In cold or damp environments, the heater serves to

prevent the electric solenoid valves from freezing

due to cold temperatures or condensation. If

optional solenoid valve heater is purchased, each

4 solenoid valve enclosures will contain a 70-watt

cartridge heater, 6, 8 and 10 solenoid valve

enclosures will contain a 120-watt cartridge heater

internally prewired to a thermostat.

The customer must provide a 100-130VAC,

50/60Hz, 1 amp power to the heater circuit for each

module. The power must be available to the module

solenoid valve enclosure(s) at all times (even when

the blower is shut down) to ensure temperature

regulation inside each solenoid valve enclosure

is continual. When multiple module solenoid

valve enclosures with heaters are installed, daisy

chain the wiring so that each heater will have

100/115VAC, 50/60 Hz at all times. Make certain

enough current is available to supply all heaters.

Example: If three solenoid valve enclosures are supplied

with cartridge heaters, make certain the voltage

supply can deliver 3 amps (1amp per heater).

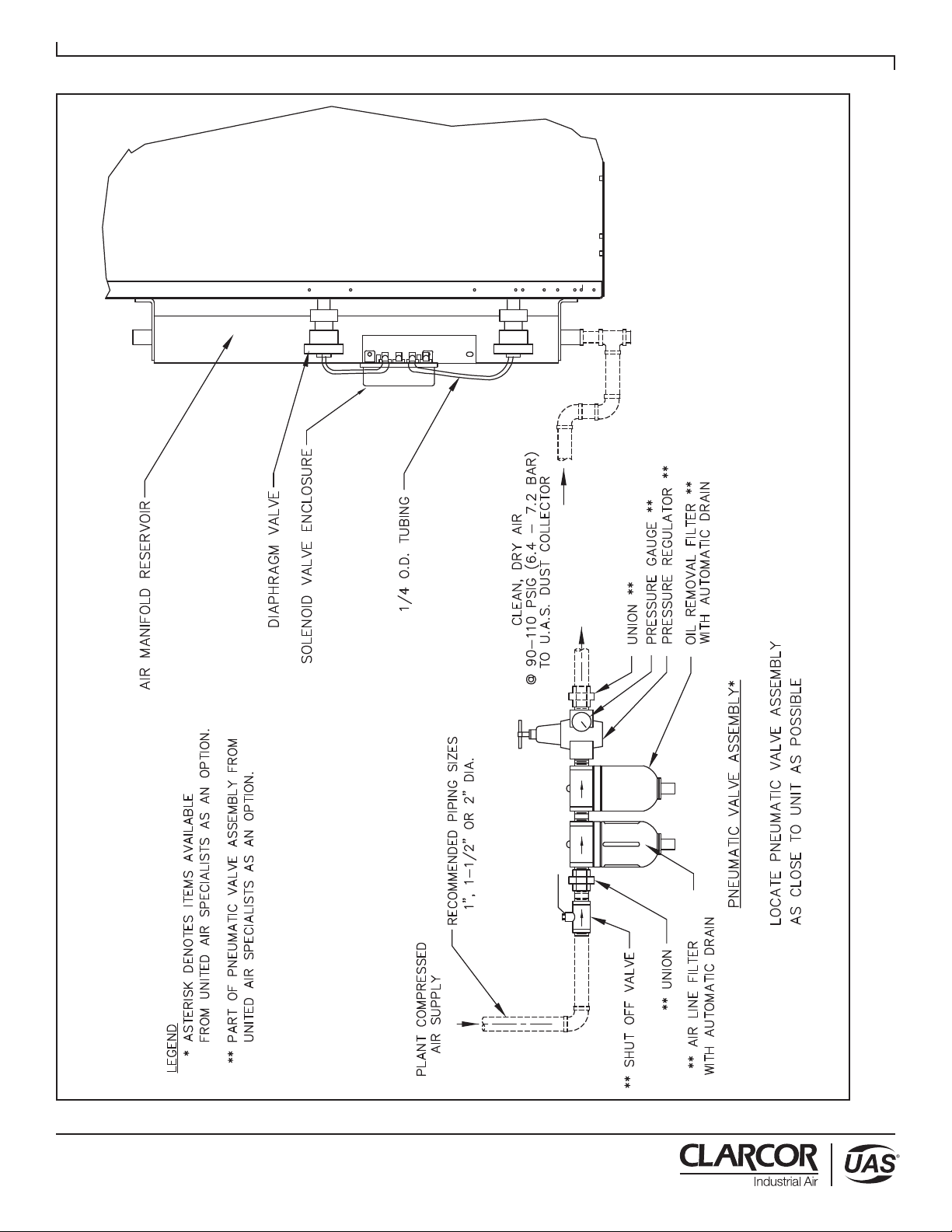

3.5 COMPRESSED AIR CONNECTION

Do not allow water and/or oil from the compressed

air system into the compressed air manifold

reservoir. To ensure a clean, dry air supply,

especially when the unit is installed outdoors, a

water filter with automatic drain and a coalescing

filter should be installed (refer to Figure 10).

Clean, dry, 90-110 PSIG (6.2-7.6 BAR) compressed air

is required for the pulse cleaning system to function

properly. Compressed air consumption is noted on

the UAS sales drawing. A shut-off valve, pressure

regulator and pressure gauge should be installed close

to the SFC unit. UAS recommends dedicated oil and

water removal filters be used to ensure clean, dry air is

delivered to the pulse system. Contact your local SFC

representative for information about UAS’ Pneumatic

Valve Assembly. Refer to Figure 10 for recommended

compressed air piping and Table 1 below for proper

compressed air line sizing.

NOTE: Using Table 1, select the proper diameter

compressed air line pipe to supply your dust

collector. The final connection size is a female

1” NPT fitting on each module.

NOTE: Purge the compressed air line to remove any

debris prior to making the final connection to

the SFC compressed air manifold(s). Apply

pipe fitting sealant on all compressed air supply

pipe fittings and connections.

3.6 ASSEMBLY OF OPTIONAL EQUIPMENT

3.6.1 BLOWER PACKAGE INSTALLATION

TIP OVER HAZARD

Anchor dust collector to concrete pad prior to

installing blower assembly. Make certain all

hardware is properly tightened.

If a top-mount blower package was ordered, read

the manufacturer’s Installation and Operation Manual

completely before installing the blower. The blower

Installation and Operation Manual is attached to the

fan package. Perform all pre-installation checks prior

to installing the blower.

TIP OVER HAZARD

If blower package has a 20 HP (15 kW) motor or

larger, ensure the blower support legs are installed

beneath the clean air plenum of the module to

which the blower will be mounted.

For top-mount blower packages of 20 HP (15 kW) or

larger, an additional set of support legs is provided.

The additional support legs must be mounted under the

filter module supporting the blower package (refer to

Figure 11). Bolt the mounting plate to the bottom of the

appropriate clean air plenum with the hardware provided.

Bolt the leg assemblies to the mounting plate with the

hardware provided. Secure leg assemblies to the concrete

mounting pad with appropriate anchoring hardware.

Remove the clean air plenum cover plate on top of the

filter module and save the mounting hardware. Ensure

ribbon gasket remains on the unit. Lift blower package

using safe, suitable means and position blower base holes

over filter module holes with blower discharge pointing in

the desired direction. Secure with bolt/washer assemblies

previously removed. Top-mount blower packages include

a blower outlet damper. Install blower damper to outlet of

blower assembly with hardware provided.

If the blower package is a ground-mount blower, read

the manufacturer’s Installation and Operation Manual

completely before installing the blower. The blower

Installation and Operation Manual is attached to the

fan package. Perform all pre-installation checks prior

to installing the blower.

Outlet ducting from the SFC unit to the blower

package can be connected to either the top or bottom

clean air section access panel(s). It is recommended

industry practice to provide vibration isolation between

the blower inlet and the dust collector outlet ducting.

!DANGER

!DANGER

Pipe Diameter

1 inch (25mm)

1-1/2 inch (38mm)

2 inch (51mm)

Number of

Filter Section

Modules

1-3

3-5

+5

or

Distance of Supply Air

Piping Run From Main

Compressor Line

50 feet (15 meters)

100 feet (31 meters)

+100 feet (+31 meters)

Table 1

CAUTION

Table of contents

Other CLARCOR Dust Collector manuals

Popular Dust Collector manuals by other brands

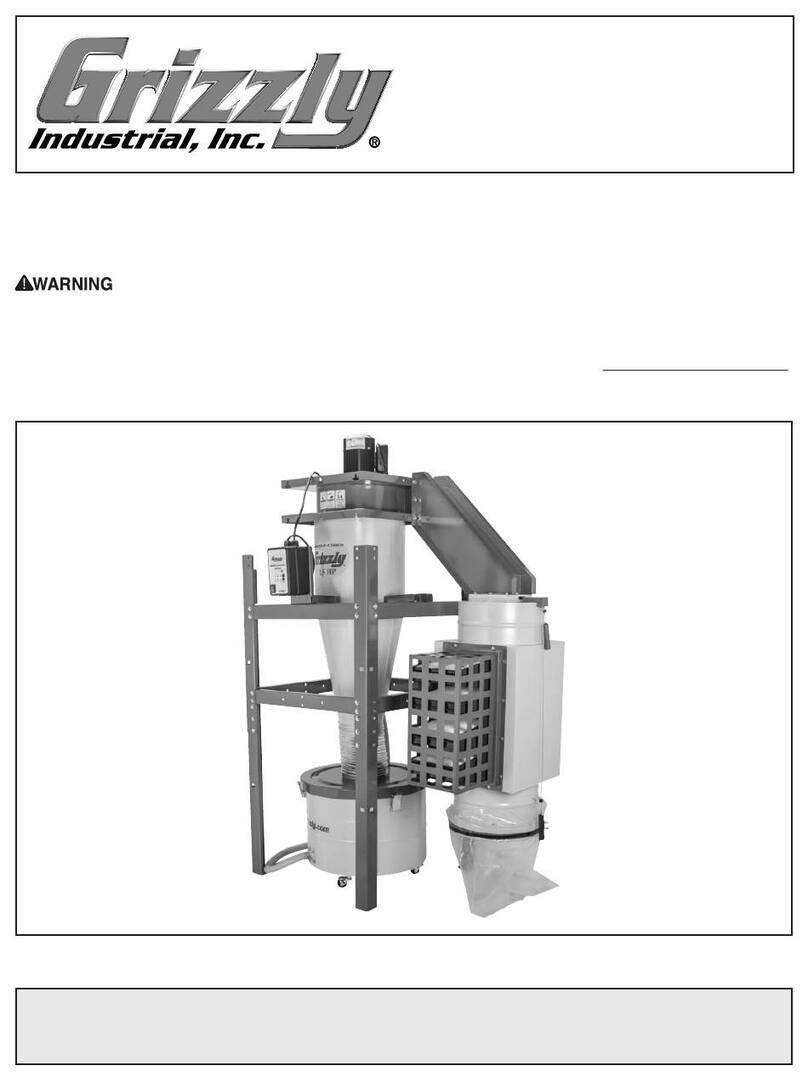

Grizzly

Grizzly G0440 owner's manual

Hitachi

Hitachi RP 30Y Instruction manual and safety instructions

Steel City

Steel City 65110 user manual

Hafco Woodmaster

Hafco Woodmaster DC-90 instruction manual

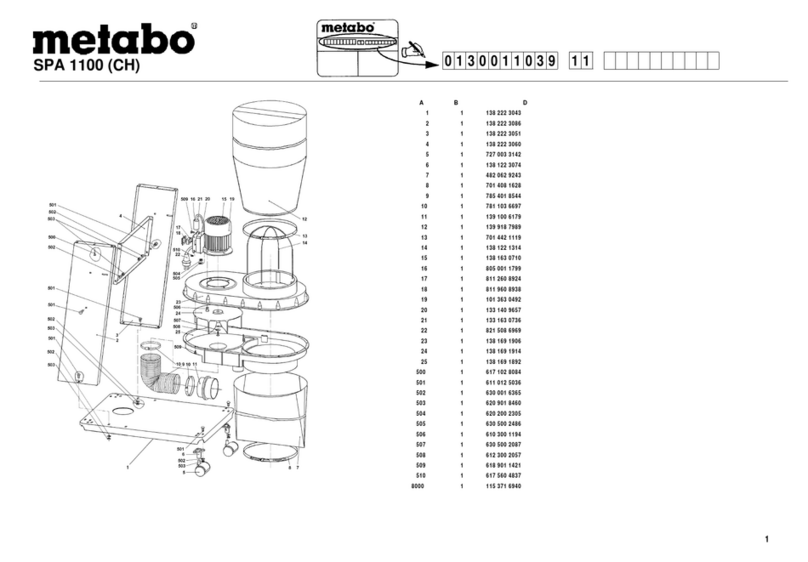

Metabo

Metabo SPA 1100 (CH) Spare parts

Rikon Power Tools

Rikon Power Tools POWER TOOLS 60-1750 Operator's manual

Grizzly

Grizzly G0443HEP manual

DustEZE

DustEZE EC-560 Booklet

Harbor Freight Tools

Harbor Freight Tools 31810 Set up and operating instructions

Metabo

Metabo SPA 1200 Original operating instructions

Villager

Villager DM 14 P Original instruction manual

King Industrial

King Industrial KC-3109C instruction manual