3

SAFETY PRECAUTION

The use of the machine may be

hazardous. The impeller

rotating in the volute case may

be cut you if you try to touch it. It is

important that you read, fully

understand the following safety

precautions and warning.

Do not lend or rent your

sprayerduster

without the Owner ’s

Manual. Be sure that anyone

using your sprayer-duster reads

and understands the information

contained in this manual.

Safe use of a sprayer-duster:

1.The operator

The operator must be in good physical

condition and mental health.

Following personnel can’t use the

machine.

(1) Mental patients.

(2) Drunk.

(3) Under age or old person.

(4) Person who have just exercised

strenuously or slept not enough.

(5) Tired person or patient and others

who can’t operate the machine

normally.

(6) Person with no knowledge of the

machine.

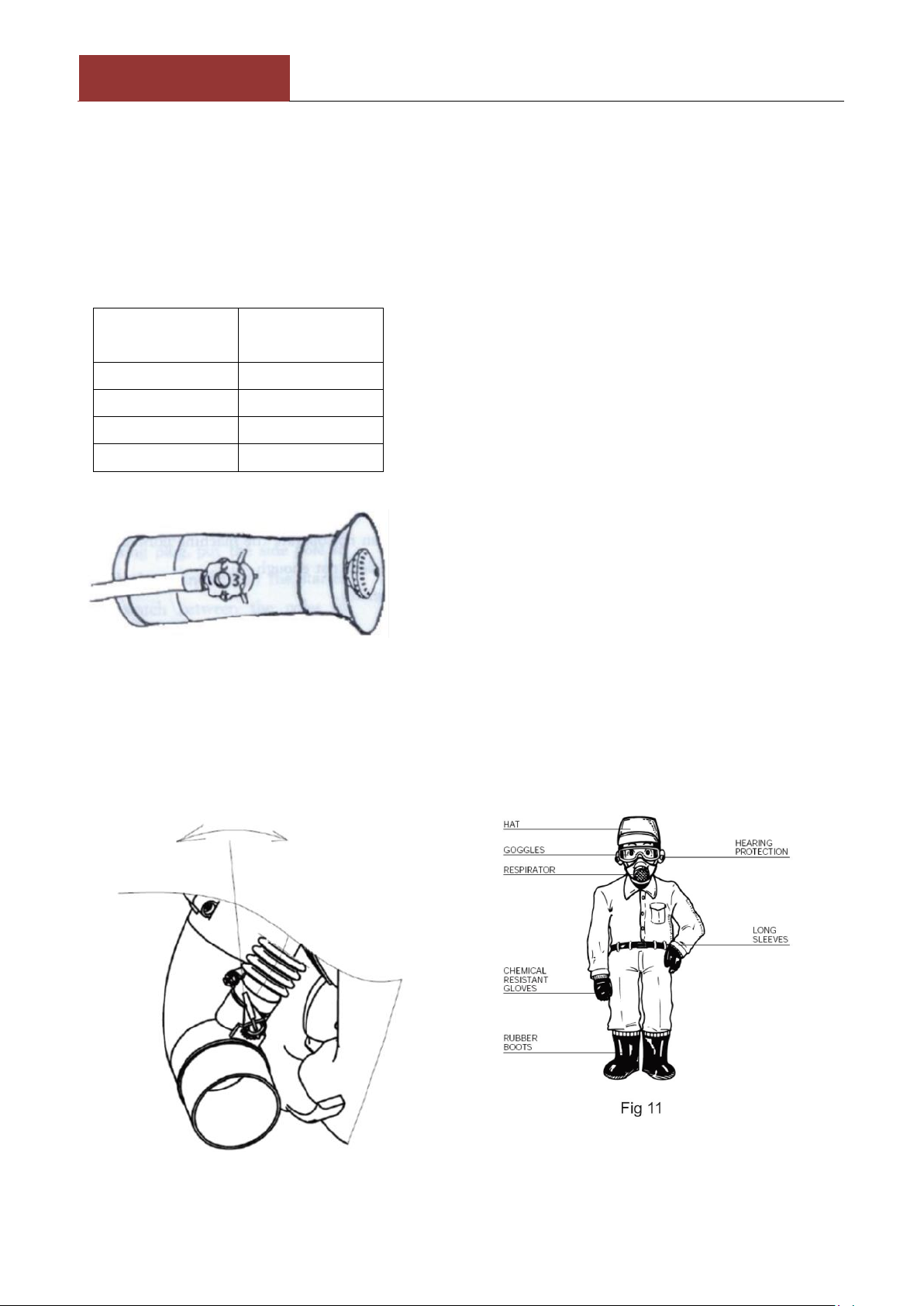

2.Proper clothing

To reduce the risk of injury, the

operator should wear proper

protective apparel.

•Clothing and gloves must be wear to

avoid contacting pesticide .

•Wear glasses and gauze mask to

protect your eye and; Wear the gauze

mask to prevent from poisoning

•The machine noise may damage your

Hearing so wearear mufflers to proect

your hearing.

•Pay attention to wear a face mask to

protect against dust and pesticide.

3.The use of the machine

Starting engine

(1) Put the dust gate handle to the

lowest position before starting the

engine, otherwise chemical will be

jetted when starting engine.

(2) Be sure nobody stands in front of

nozzle, even though dust gate closed,

residual dust in pipe will be blown out.

Spray operation

(1) It is fine to carry out operation

during cool weather with little wind.

For example, in the early morning or in

the late afternoon. This can reduce the

evaporation and drift of chemicals and

improve the protecting effect.

(2) Operator should move windward.

(3) If your mouth or eyes are spattered

with chemicals, wash them with clean

water and go to see a doctor.

(4) If the operator has a headache or

dizziness, stop working at once and go

to see a doctor in time.