CLARCOR UAS V Series User manual

VERSATILE/PORTABLE CARTRIDGE DUST COLLECTOR

V SERIES

MODELS - VB, VF, VP

OWNER’S MANUAL

Model VB

Model VP

Model VF

KNOW YOUR EQUIPMENT

READ THIS MANUAL FIRST.

Your V Series system should provide many years of trouble-free service. This manual will

help you understand the operation of your V Series unit. It will also help you understand

how to maintain it in order to achieve top performance. For quick future reference, fill in

the system and filter information in the spaces below. Should you need assistance, call

the United Air Specialists, Inc. customer service number shown below. To expedite your

service, have the following information available when contacting UAS.

UAS ORDER #:________________________________________________________________

UNIT MODEL #: _______________________________________________________________

UNIT SERIAL #: _______________________________________________________________

FILTER PART #:________________________________________________________________

SYSTEM ACCESSORIES:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

INSTALLATION DATE: __________________________________________________________

UNITED AIR SPECIALISTS, INC. CUSTOMER SERVICE

1-800-252-4647

TABLE OF CONTENTS

Page

SAFETY PRECAUTIONS……………………………………………………………ii

1. IMPORTANT NOTICE ................................................................................ 1

2. INTRODUCTION ........................................................................................ 1

2.1 Unit Nomenclature....................................................................................1

2.2 Description and Operation........................................................................1

2.3 Air Filtering Operation ..............................................................................1

2.4 Filter Cleaning Cycle ................................................................................1

3. SPECIFICATIONS ...................................................................................... 1

4. INSTALLATION .......................................................................................... 3

4.1 Off Loading and Inspection ..................................................................3

4.2 Installation ............................................................................................3

4.2.1 Portable Installation (VP Model) ..................................................3

4.2.2 Downdraft Table Assembly (VB Model) ........................................4

4.2.3 Fixed Unit Assembly (VF Model) ..................................................4

4.3 Pulse Cleaning ....................................................................................4

4.4 Electrical Installation ............................................................................4

4.4.1 Pulse Control Timer Board ..........................................................4

5. OPERATION ................................................................................................5

5.1 Start-Up ....................................................................................................5

5.2 Checklist ..................................................................................................6

6. SERVICE ....................................................................................................6

6.1 Filter Removal and Replacement ............................................................6

6.2 Dust Drawer Removal ..............................................................................7

6.3 After Filter Removal/Installation................................................................7

6.4 Servicing Direct Drive Blower ..................................................................8

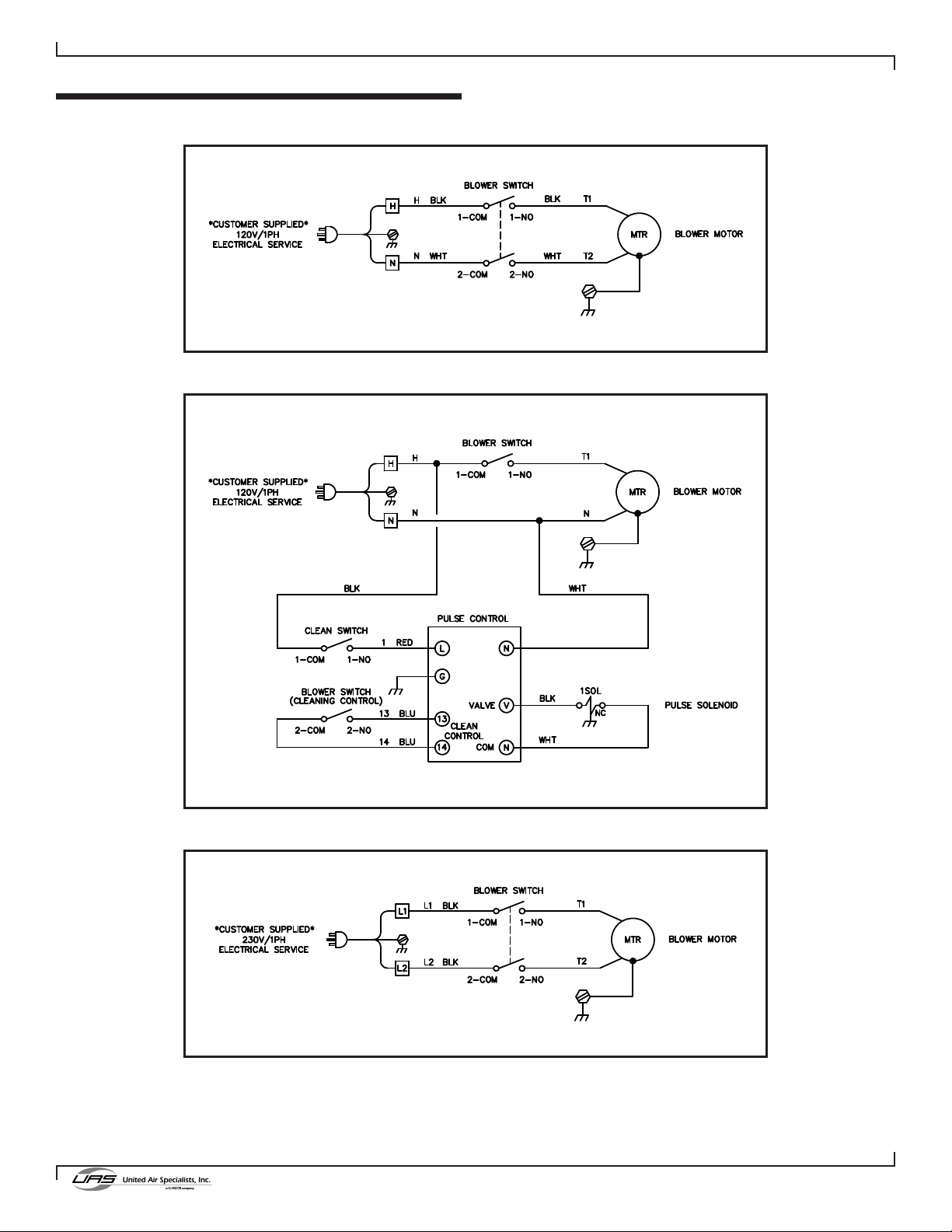

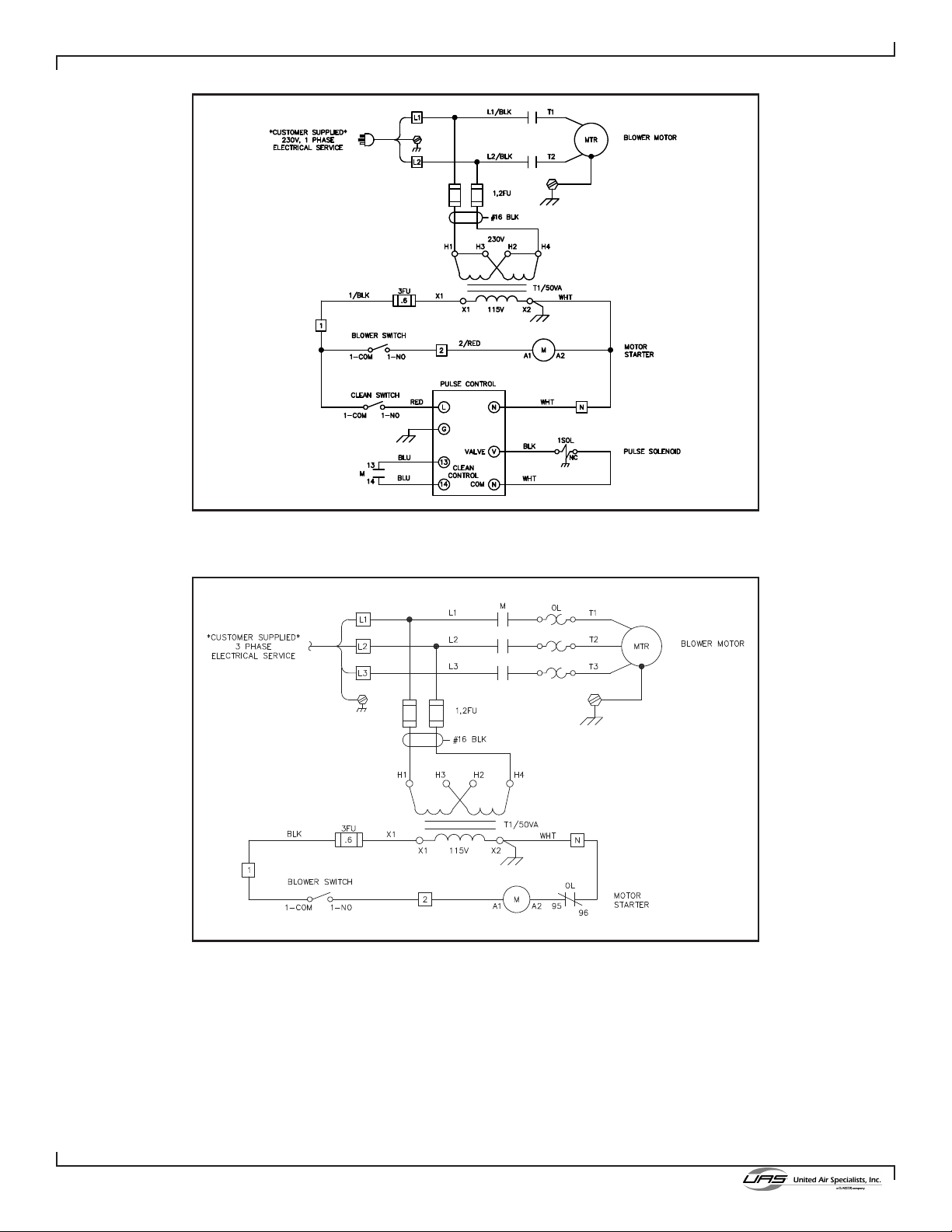

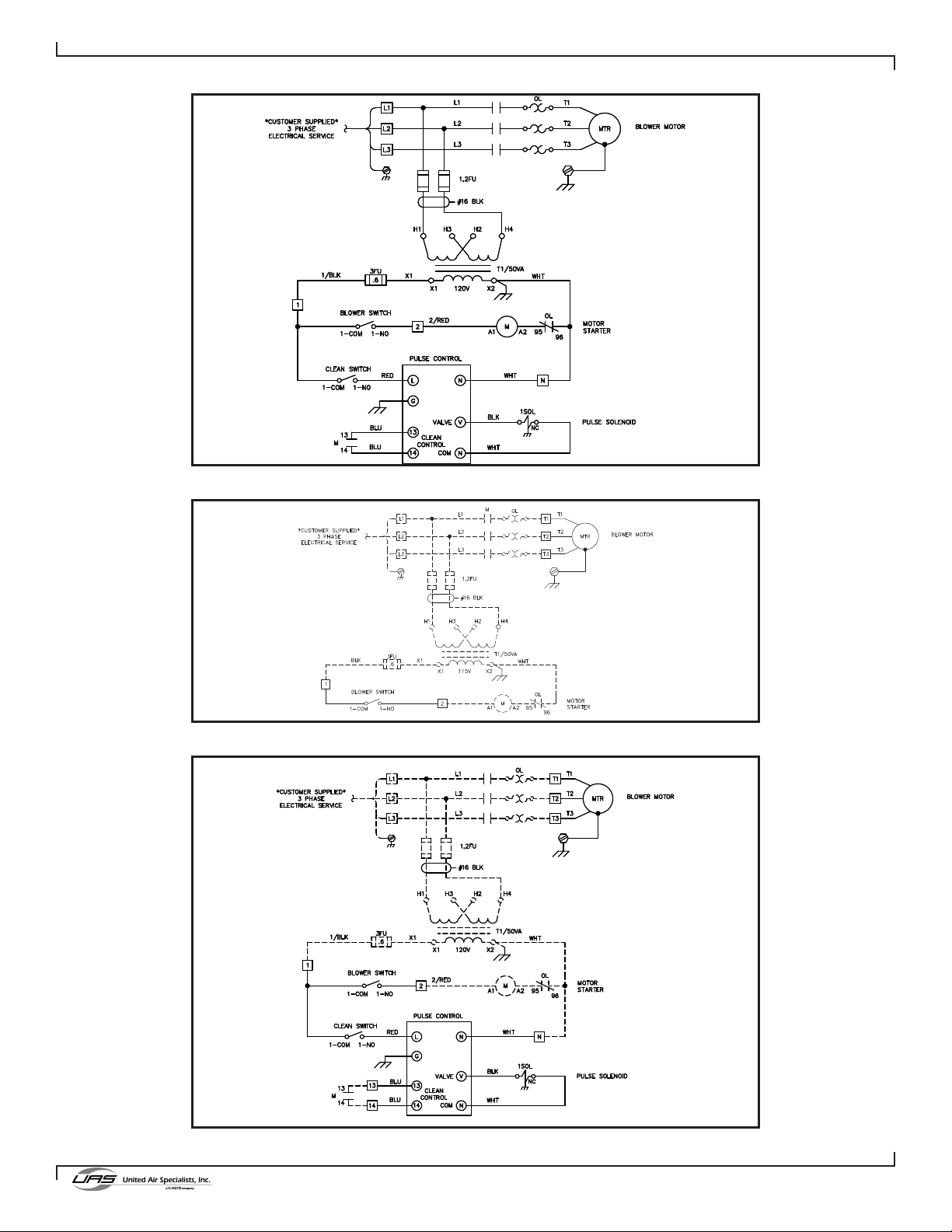

7. ELECTRICAL ..............................................................................................8

7.1 Unit Control (On/Off) ............................................................................8

7.2 Cleaning Control (On/Off) ....................................................................8

8. TROUBLESHOOTING ................................................................................9

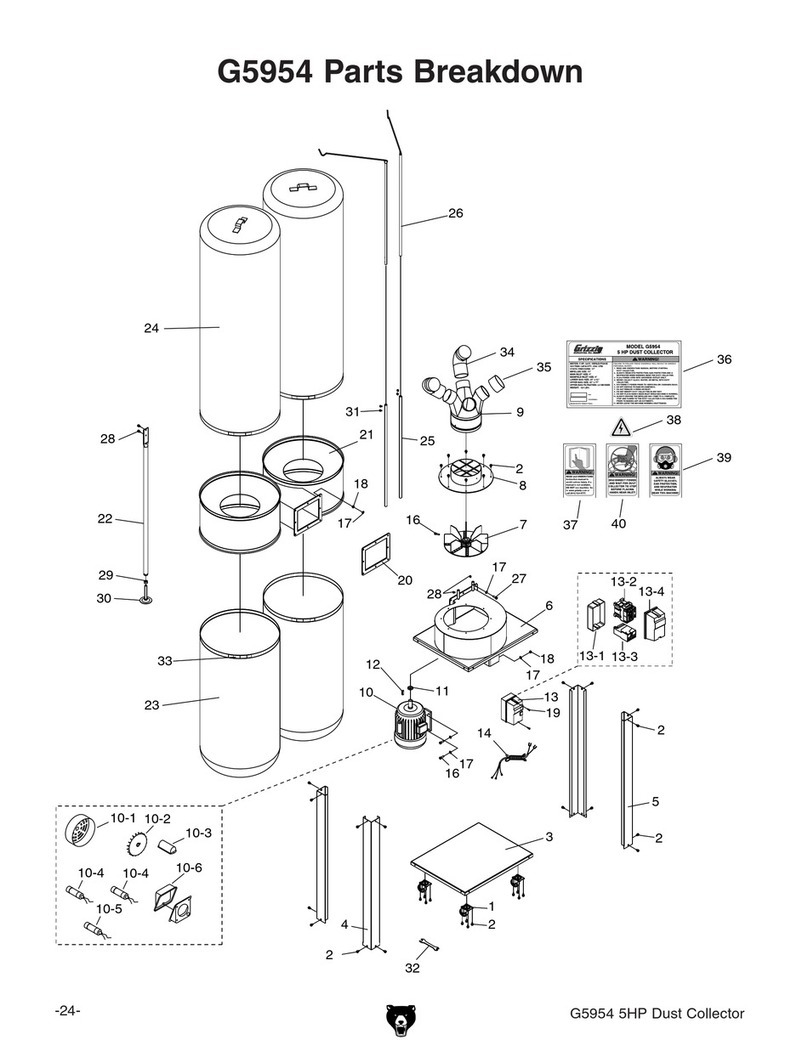

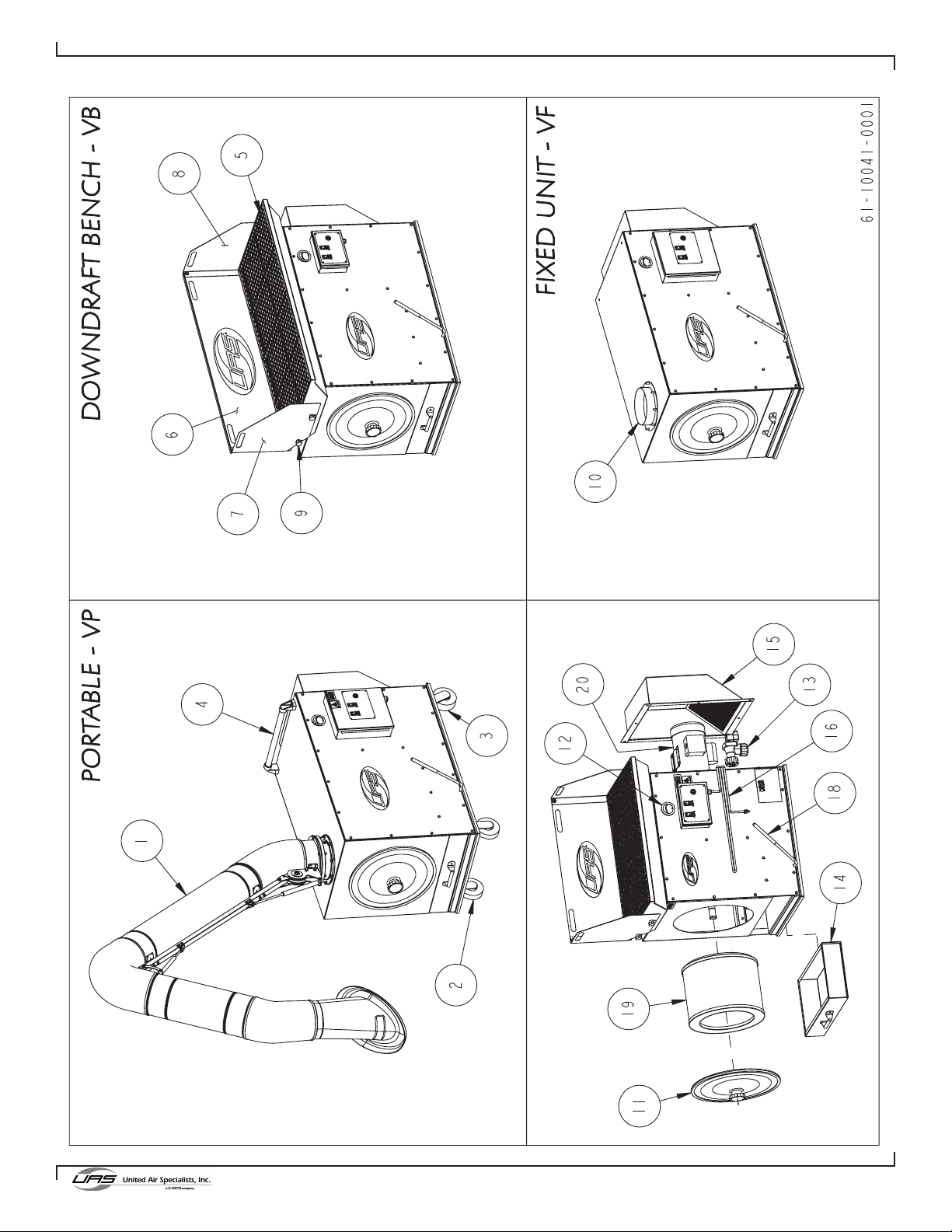

9. ILLUSTRATED PARTS LIST......................................................................10

10. APPENDIX ..............................................................................................12

i

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury, follow these basic precautions:

SAFETY PRECAUTIONS

We have provided many important safety messages in this manual and on the V Series source capture system. Always read

and obey all safety messages.

• Disconnect power before servicing.

• Do not use in explosive atmospheres.

• Do not collect emissions which are explosive.

• The V Series should not be used for support of

personnel or material.

• Operate only in a safe and serviceable condition.

• When collecting emissions from metal grinding or other

spark producing processes, care must be taken to

reduce any potential fire hazards.

• Do not allow operator to put cigarettes or any burning

object into the hood or ducting of the swing arm.

• Do not use the Swing Arm to move the portable air

cleaner (if applicable).

!

!DANGER

!WARNING

!CAUTION

CAUTION

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others. All safety messages will follow the

safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”. These words mean:

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

ii

1

Revised 08/09

V SERIES

Cartridge Dust Collector

1. IMPORTANT NOTICE

This manual contains specific information concerning

safety and precautionary measures. It is impossible to

list every potential hazard associated with dust

collection equipment or systems. Use of the equipment

must be discussed with a factory-trained, United Air

Specialists, Inc. (UAS) representative. As always,

please adhere to the most stringent safety procedures.

2. INTRODUCTION

Thank you for selecting United Air Specialists dust

collection equipment to assist you in your commitment

to a clean and safe environment.

2.1 UNIT NOMENCLATURE

Collection Method:

B = Downdraft Bench

F = Fixed Ducted Unit

P = Portable Unit w/ Swing Arm

Nominal Flow Rate:

750 = 750 CFM

1500 = 1500 CFM

Example:

VB-1500

This would be a downdraft bench with a nominal airflow

of 1500 CFM.

2.2 DESCRIPTION AND OPERATION

The V Series Dust Collection System is a high-

efficiency, cartridge dust collector designed to eliminate

airborne particles as they are generated. Contaminant

is captured at its source by a unit-mounted hood,

downdraft table or ducted inlet and then conveyed

through the cartridge filter section where it is collected.

Clean air is then recirculated back to the work area.

There are two primary cycles of normal operation for

the V Series — the air filtering operation and the filter

cleaning cycle utilizing a compressed air cleaning

system.

Figure 1 shows the basic system operation and

equipment of a V Series dust collector.

2.3 AIR FILTERING OPERATION

The contaminated air stream is drawn into the collector.

Once the dust-laden air enters the cabinet, it meets a

baffle plate that disperses the air and significantly

reduces the air stream velocity. This provides even

distribution of the air stream across the entire surface

area of the cartridge filters, allowing a uniform dust

cake to form. The reduced air stream velocity causes

the heavier particles to fall out and collect in the dust

drawer.

The air stream then passes through the cartridge filter

where it is stripped of the particles by the media.

Cleaned air flows through the center of the filter,

through the blower (and optional safety after filters and

exits through the rear of the cabinet, back into the

workplace.

2.4 FILTER CLEANING CYCLE

As the cartridge filter becomes loaded with

contaminants, it becomes necessary to clean the filter

to maintain adequate airflow.

The compressed air cleaning mechanism provides brief

bursts of compressed air into the cylindrical cartridge

filter. When actuated, the cleaning system directs 90-

100 PSI of customer supplied compressed air through a

pulse valve, into a blow pipe, creating a burst of

pressure through the inside of the cartridge filter. This

pressure dislodges the dust and reduces the pressure

drop across the filter so the system can maintain

adequate airflow.

3. SPECIFICATIONS

Air Collection Method:

The V Series dust collector comes in three basic dust

collection configurations.

1. Downdraft Bench Unit (VB)

2. Fixed Ducted Unit (VF)

3. Portable Unit w/ Swing Arm (VP)

Within these variations, the units have two different

models, the 750 and the 1500.

Cleaning Options:

There are two basic filter-cleaning options with the

V Series: a cleaning system utilizing compressed air

and an option where the filters are cleaned manually,

external to the dust collector cabinet by the customer.

Power Supply Options:

All 1-1/2 HP motors are available in 115-230/1/60 and

200,230,460,575/3/60. All 3 HP Motors are available in

200,230,460,575/3/60.

V X - X X X X

Collection Method

Nominal Flow Rate

2

Revised 08/09

V SERIES

Cartridge Dust Collector

61-10036-0001

Figure 1. Basic Unit Operation

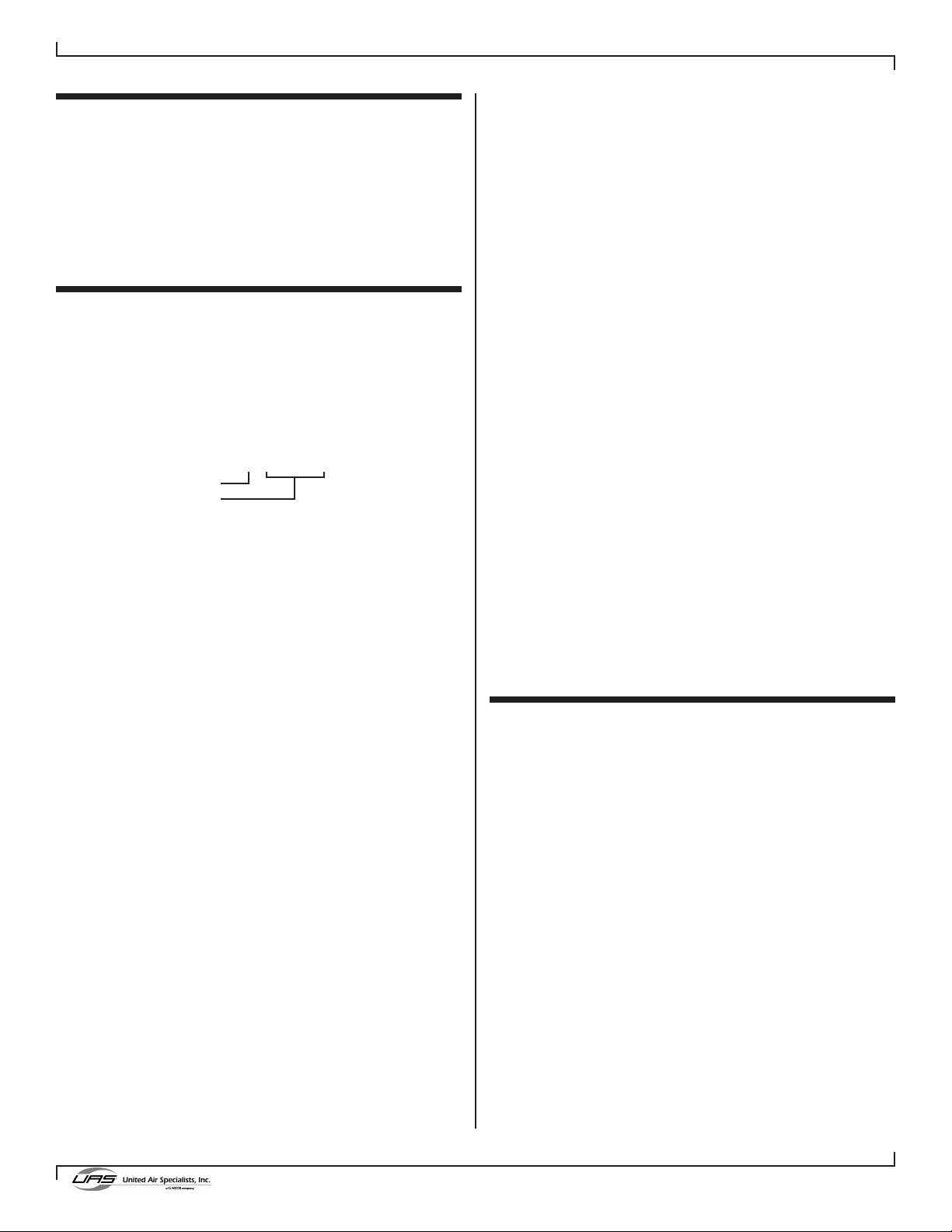

Table 1 - V Series Unit Specifications

V SERIES UNIT SPECIFICATIONS

Model

Nominal

Airflow

(CFM)

VB-1500

VB-750

VF-1500

VF-750

VP-1500

VP-750

1500

750

1500

750

1500

750

Cabinet Dimensions (inches)

Width Depth Height

30-1/4

30-1/4

27-7/16

27-7/16

27-7/16

27-7/16

52-3/4

38-13/16

52-3/4

38-13/16

52-3/4

38-13/16

46-13/16

46-13/16

31-3/4

31-3/4

38-7/16

38-7/16

Shipping

Weight

(lbs)

440

365

405

335

450

375

Filter

Area

(ft2)

283

141

283

141

283

141

SCF Per

Pulse

1.3

1.1

1.3

1.1

1.3

1.1

Sound

Level

(dBA)*

77.5

79.3

81.6

74.4

81.6

74.4

* AMCA tested sound levels at 5 feet

Horsepowers of V Series units are dependent upon the flow requirement and can vary within the model size.

3

Revised 08/09

V SERIES

Cartridge Dust Collector

See below for the amperage requirements of your unit,

given the horsepower and power supply. The unit

nameplate will provide the electrical specifications of

your V Series system.

Motor HP

1.5

1.5

1.5

1.5

1.5

1.5

3

3

3

3

Power Supply

115/1/60

230/1/60

200/3/60

230/3/60

460/3/60

575/3/60

200/3/60

230/3/60

460/3/60

575/3/60

Amp Draw

16.4

8.4

5.2

4.8

2.4

1.9

8.4

7.8

3.9

3.1

Standard Unit Options:

HEPA After Filter, Carbon Odor After Filter, Pre-Wired

Motor Starter Panels

Filter Media Options:

Protura®Nanofiber, Protura®Nanofiber Fire Retardant,

Poly-Fiberglass, Spun-Bond Polyester

See Table 1 on page 2 to see the operating

specifications on your V Series system.

4. INSTALLATION

4.1 OFF LOADING AND INSPECTION

The V Series dust collector is shipped in two or three

containers depending on the configuration and options

selected. The first consists of the unit cabinet and

filtration components. Other container(s) may contain

the extraction arm, downdraft bench, etc.

Upon receipt of your unit, check for any shipping

damage. A damaged carton indicates that the

equipment may have received rough handling during

shipping that may have caused internal damage. Notify

your delivery carrier and enter a claim if any damage is

found.

Remove the filter access cover (located on the front of

the unit) by turning the black knob counterclockwise to

release the cover. Examine the seal between the

tubesheet (the vertical panel between the blower

section and the filter section) and filter. Make sure filter

or gasket has not become displaced during shipment

(refer to Section 6.1, Cartridge Filter Removal and

Replacement). Replace covers once inspection is

complete.

4.2 INSTALLATION

Different models of the V Series collector require

different assembly techniques. Please see the

techniques in the subsequent sections for

your V Series dust collector.

All models of the V Series will require minimum

clearances and access in order to perform routine

maintenance and service. Be sure to leave access for

filter removal, the dust drawer release lever and

blower/pulse valve access through the discharge

panel as shown in Figure 1.

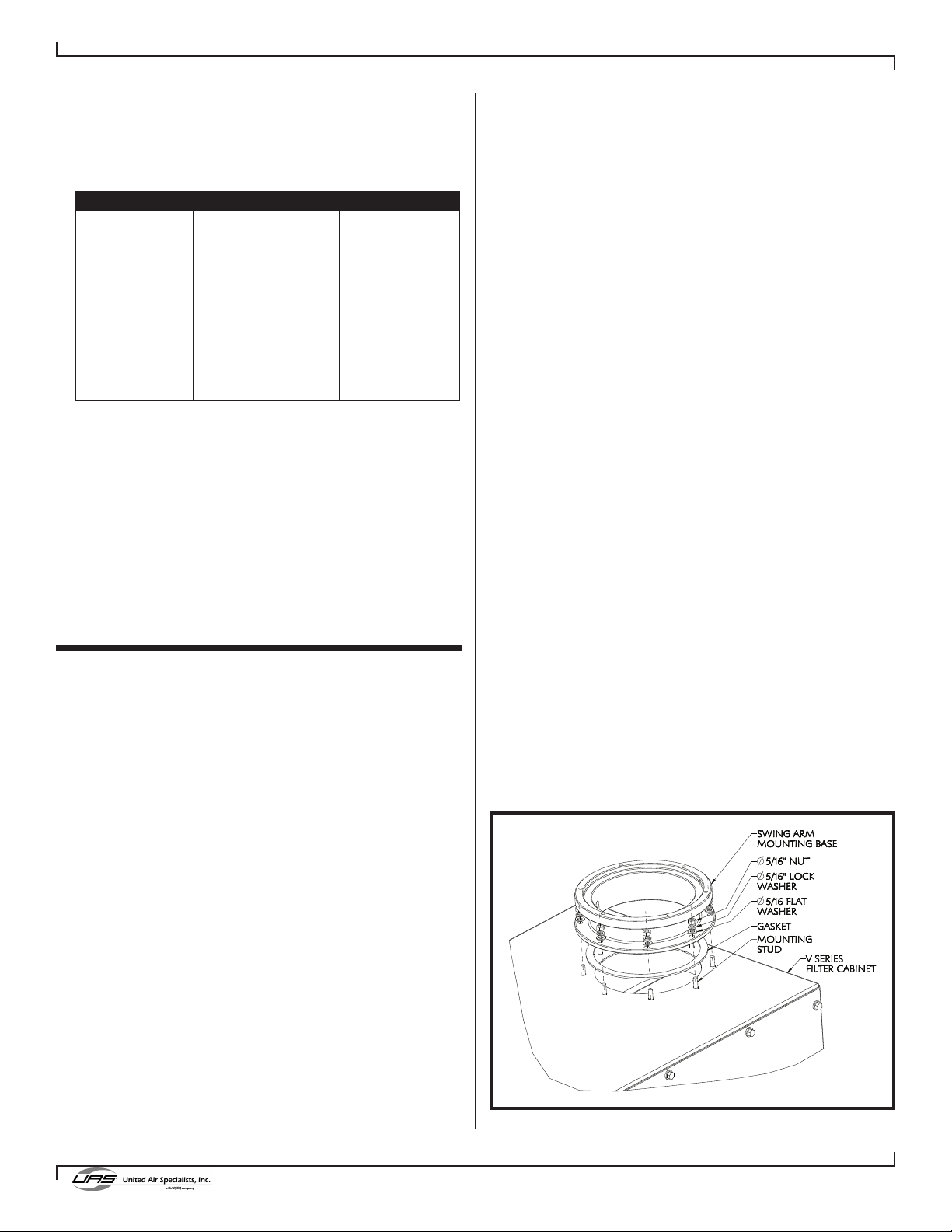

4.2.1 PORTABLE INSTALLATION (VP MODEL)

The top of the V Series cabinet has either one set

of six (VP-750) or eight (VP-1500) threaded studs to

mount the swing arm. The necessary hardware is

pre-assembled the studs. When mounting the arms

on the unit, a ceiling height of about 10’ is required for

adequate clearance. Two people are suggested for

positioning the swing arm and securing into place.

1. Remove the swing arm from its shipping

containers and assemble per the swing arm

manual provided.

2. Remove nuts, lock washer and flat washer from

the studs on the cabinet (refer to Figure 2).

3. Position flange gasket(s) inside the protruding

studs on top of the unit (refer to Figure 2).

4. Position the swing arm mounting base into place

over the mounting studs. Ensure gasket is

positioned properly between unit and base

flange. Secure swing arm to cabinet top with the

recently removed hardware (refer to Figure 2).

Avoid sharp pulls on the arm or hood as well as

over-tightening the pivot section since damage to

the arm components could result.

Figure 2. Swing Arm Installation Detail

Table 2 - Unit Amperage Requirements

61-10036-0002

4

Revised 08/09

V SERIES

Cartridge Dust Collector

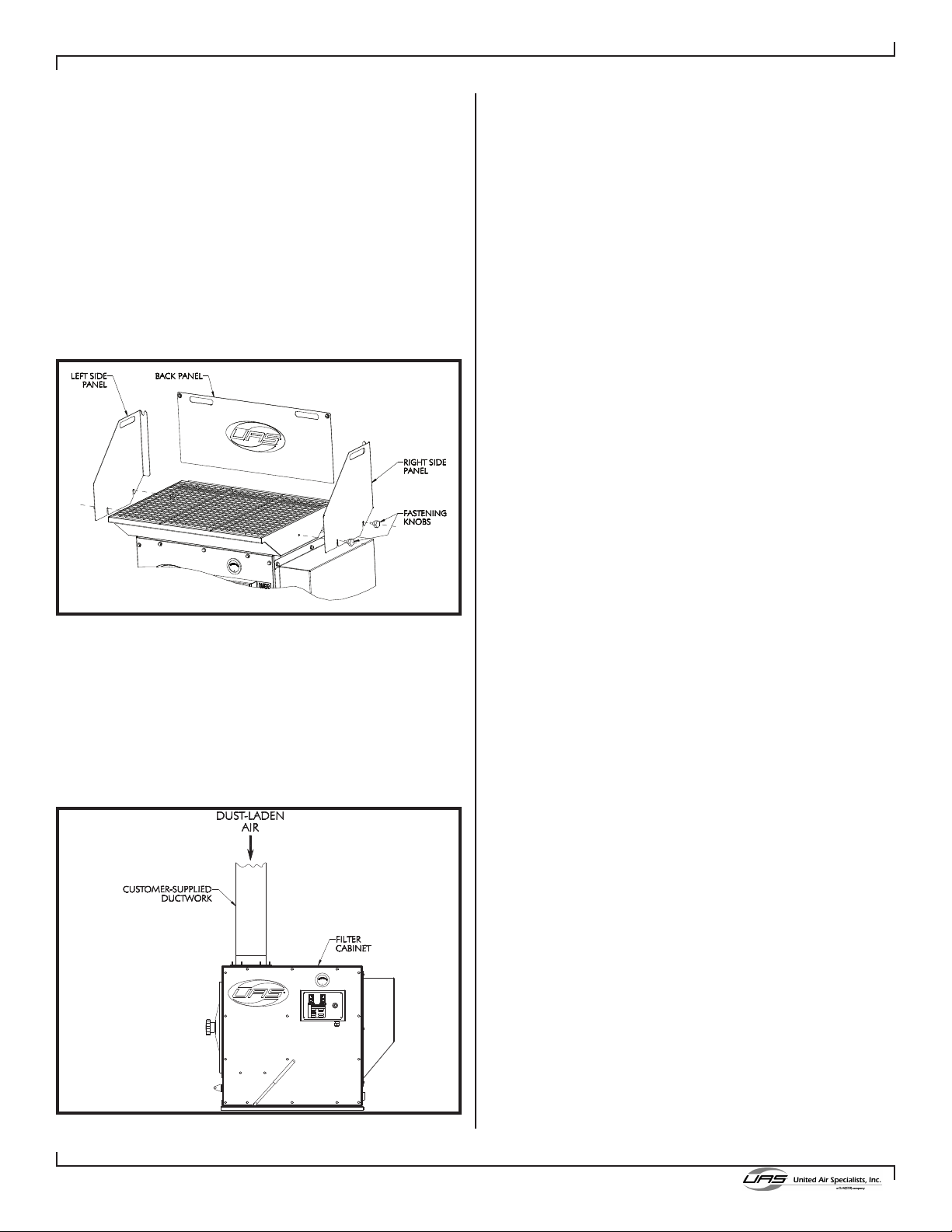

4.2.2 DOWNDRAFT TABLE ASSEMBLY (VB MODEL)

The V Series downdraft table (VB) comes packaged,

requiring some assembly before using. Follow the

steps below to complete the assembly.

1. Begin by securing the two side panels as shown

in Figure 3. Thread all four fastening knobs into

the cabinet leaving enough space for the side

panel to fit over top of threaded knob stud.

2. Lower each panel as shown onto the knob studs

and then tighten knobs until panel is secure.

3. Lower the back panel into rear aligning tray and

side panel guide slots.

4.2.3 FIXED UNIT ASSEMBLY (VF MODEL)

The fixed unit assembly typically requires some type of

customer-supplied ductwork to convey the dust from the

source to the collector. See Figure 4 for a typical

installation.

Care should be taken when sizing and laying out the

ductwork in order to minimize loses through the system.

Figure 3. Downdraft Table Installation Detail

61-10037-0001

4.3 PULSE CLEANING

If your V Series system came with a cleaning system,

please review the following section for optimum

performance.

Provide a clean, dry, 90-110 PSIG compressed air

supply to the compressed air manifold. The supply

coupling (1" NPT) is located on the lower center of the

unit’s rear panel as shown in Figure 7. A reducer

bushing may be required for your supply line.

Compressed air supply to the unit can be a flexible

quick disconnect air line from a ceiling-mounted hose

reel or similar supplied plant air. The hose size can be

between 1/4” and 1” diameter.

The compressed air usage per cleaning cycle can be

found in Table 1. Note that the cleaning system will only

operate when the motor/blower is off. See Section 4.4.1

for adjustments available with the timer board.

4.4 ELECTRICAL INSTALLATION

The V Series unit has a wide variety of available

electrical options to best meet your needs. Take care

to ensure proper installation in whatever configuration

you have selected.

For units only requiring a 115-volt, single-phase power

supply, your unit will be supplied with a 15-foot power

cord and plug and is electrically ready for operation. If

the unit has a 230-volt, single-phase power supply, the

unit will be provided with a power cord but the customer

will be responsible for supplying and attaching the

appropriate plug.

For units requiring three-phase power, there are two

basic options. If UAS is supplying the motor starter, the

unit will be equipped with a 15-foot power cord without

a plug.

NOTE: All VP Series units come standard with a UAS

supplied starter

If the customer is supplying the motor starter, no cord,

motor overload protection or control transformer will be

provided.

Refer to Appendix A of this manual for the

recommended wiring diagrams of your V Series unit.

4.4.1 PULSE CONTROL TIMER BOARD

Before making any changes to the Pulse Control

settings, please read this section of the manual.

The Pulse Control timer board has been designed to

pulse a single solenoid valve that supplies a pulse of

compressed air to a dust collector filter. Unless

otherwise specified, the timer board is factory set to a

0.1 second pulse duration, 10 second pulse delay, and

1 downtime cleaning cycle.

Figure 4. Typical Fixed Unit Installation

61-10038-0001

5

Revised 08/09

V SERIES

Cartridge Dust Collector

DOWNTIME CLEANING OPERATION

1. Turn the CLEAN switch to the ON position. The PWR

light will be ON.

2. When the CLEAN CONTROL contacts (#13 and 14)

are shorted, the CLEAN light will be ON.

3. When the CLEAN CONTROL contacts open, the

CLEAN light will flash for the duration of the cleaning

cycle.

4. After the 60-second blower coast down delay, the

valve output (V and N) will turn on for the selected

length of time (100 or 150mS).

5. If more than one pulse is selected (2, 4 or 6), there

will be a 10 or 30 second delay as selected between

the pulses.

6. When the cleaning cycle is complete, the CLEAN

light will turn OFF and the control board will wait for

the CLEAN CONTROL contacts to close again.

If at any time during the cleaning cycle the CLEAN

CONTROL contacts close, the cleaning cycle will be

aborted, the CLEAN light will stop flashing, and the unit

will wait for the CLEAN CONTROL contacts to open.

The unit will NOT remember how many pulses were

previously performed; and the cleaning cycle will start

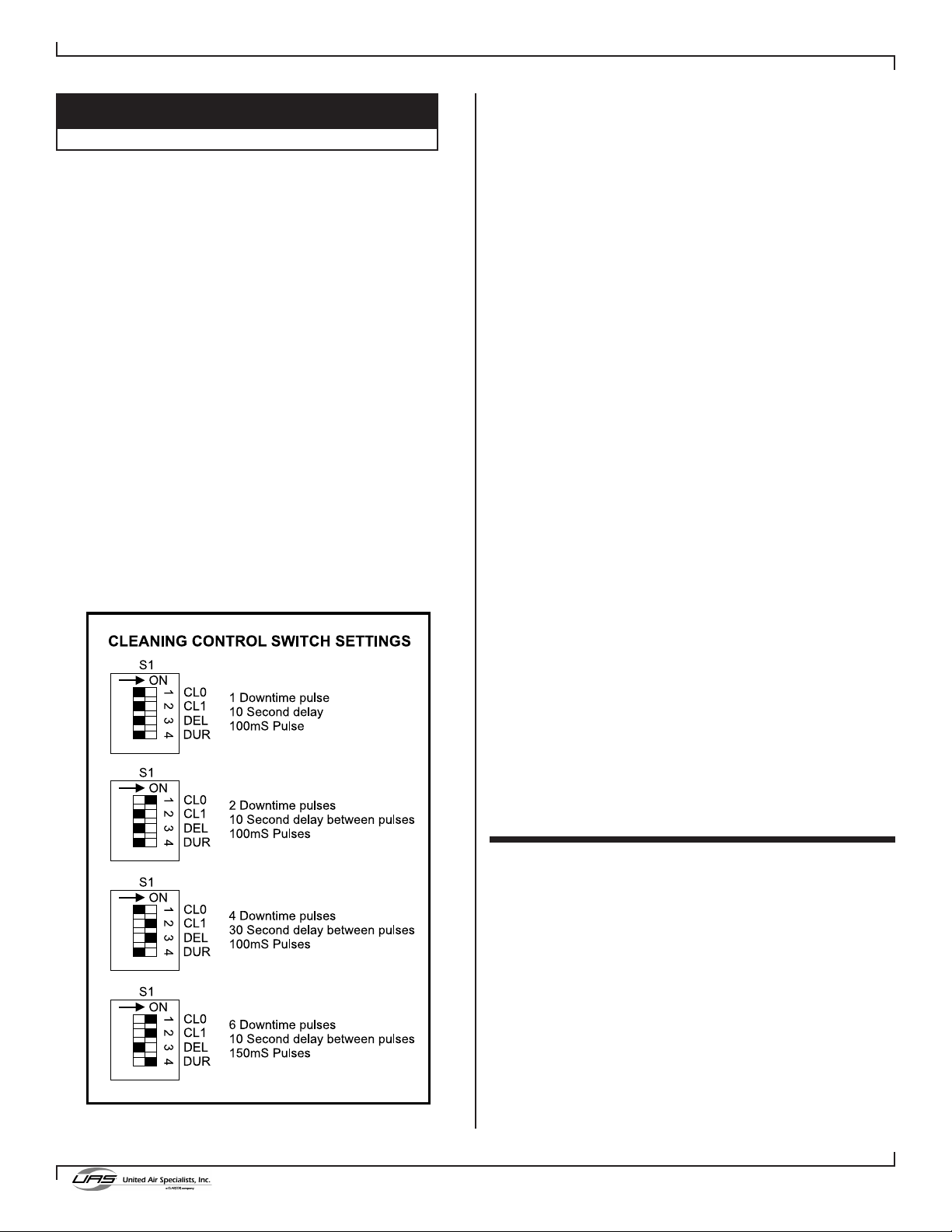

again from the beginning.The position of the four

"white" switches on S1 determine the number of pulses,

the length of the pulse and the delay between pulses.

The position of the switches are read when the CLEAN

CONTROL contacts open, and will not affect the

cleaning cycle if changed during a cleaning cycle. (See

Figure 5 for Cleaning Control Switch Settings)

Upon motor/blower shutdown, downtime cleaning will

only be performed if the CLEAN SWITCH is in the ON

position before the motor/blower is turned OFF. During

downtime cleaning, the CLEAN light will flash for the

duration of the cycles selected.

5. OPERATION

5.1 START-UP

1. Position unit in desired location.

NOTE: Do not attempt to move the portable unit by

pulling on the swing arm or hood. Use the full-

width, bar-type handle on the back of the unit to

push the V Series into the desired location. After

the unit is situated, use the locks on the rear

wheel casters to secure the unit.

2. Plug the unit into a properly grounded electrical

receptacle.

A separate motor starter auxiliary isolated dry contact

must be supplied with the motor/blower starter for all 3-

phase models and wired to terminals #13 and #14 of

the pulse control board.

TIMER BOARD SPECIFICATIONS

Power Requirement: 100-132VAC, 1 amp, 50/60Hz.

Operating Temperature: -40ºF to 140ºF (-40ºC to 60ºC),

Output: 1 solid-state switch at 1 amp max.

Required Input: Motor starter or switch isolated

normally open contact.

CLEANING CYCLE ADJUSTMENTS/TIMES

(See Figure 5 for Cleaning Control Switch Settings)

Blower coast down delay: 60 seconds, non-adjustable

Number of downtime pulses performed upon blower

shutdown: 1, 2, 4 or 6

Length of time between pulses: 10 or 30 seconds

Length of time output to valve is on: 100 or 150

milliseconds.

Figure 5. Cleaning Control Switch Settings

IMPORTANT

Information for units with 3-phase power

6

Revised 08/09

V SERIES

Cartridge Dust Collector

6. SERVICE

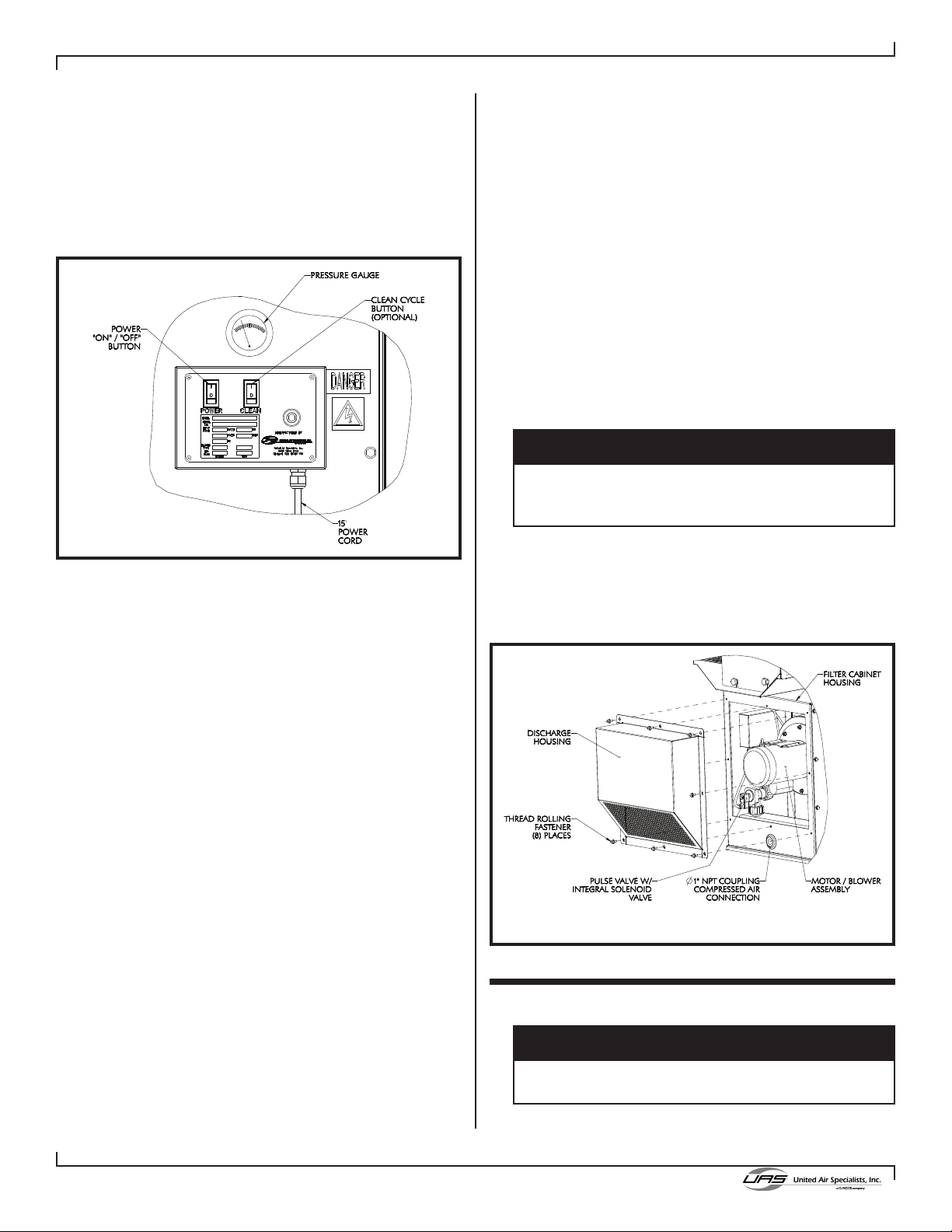

Figure 7. Rear Access

61-10039-0001

Collected dust may be hazardous. Consult proper

authorities for handling and disposal.

4. The filter monitor gauge should read between

0.1" and 0.5" w.g. while unit is operating with

clean filters.

5. The discharge plenum on the V Series collector

can be rotated in 90Ýincrements to direct the

discharge air in multiple directions. The discharge

housing will be factory installed with the discharge

pointing towards the floor as shown in Figure 7.

Collecting Particles

1. Locate the unit, arm and hood in the best position

to collect contaminants as generated by the

process or operation, and where operator

interference is minimal.

2. Position the hood to minimize the influence of

cross drafts from outside air sources or other

operations.

3. Position the hood slightly higher than the source,

with the face of the hood approximately 45° from

horizontal. The hood shape is designed for high-

velocity pick up. It should be located as close to

the source as practical and no further than 14-16"

from the contaminant source.

3. Check diaphragm valves to ensure proper pulse

cleaning. With the cleaning cycle activated, the valve

should pulse at approximately 10-second intervals.

Remove lid of control panel enclosure to view the

timer.

4. Check the filter monitor gauge at start-up. The

cleaning system should be activated when the gauge

has increased 0.5" w.g. above the start-up pressure

drop. Allow unit to pulse clean until the original

reading is achieved or until the gauge reading will

not decrease after six consecutive pulses.

5.2 CHECKLIST

1. Check the clean air outlet. Discharge air should

remain visibly clean. If a leak should develop, it will

be first noticed after a cleaning pulse as a puff of

dust.

2. Check pressure drop on the pressure gauge

(see Figure 6). Pressure drop across elements is

considered normal between 0.5-5.0" w.g. Pressure

drop will generally read between 1-2" for “seasoned”

filters.

The following procedure requires access to an area of

the unit where high voltage is present. Access should

be restricted to qualified personnel.

Figure 6. Control Panel Layout Detail

61-10039-0002

3. Turn the unit on by pushing the "Power" rocker

switch to the ON position (refer to Figure 6). On

3-phase units, fan rotation will need to be verified

by matching fan rotation with the rotation decal on

the blower housing. Rotation should be clockwise

as viewed from the motor or drive side. Any two

motor starter leads should be reversed if the

rotation is not correct.

7

Revised 08/09

V SERIES

Cartridge Dust Collector

1. Collected dust may be a potential fire hazard. Refer

to Section 1 of this manual.

2. Wear appropriate protective clothing.

3. Be environmentally aware of collected dust and its

proper disposal.

4. Press unit function switch to OFF position. Unplug

unit from electrical power source.

5. Disconnect compressed air supply to air manifold

inlet and bleed air supply from manifold.

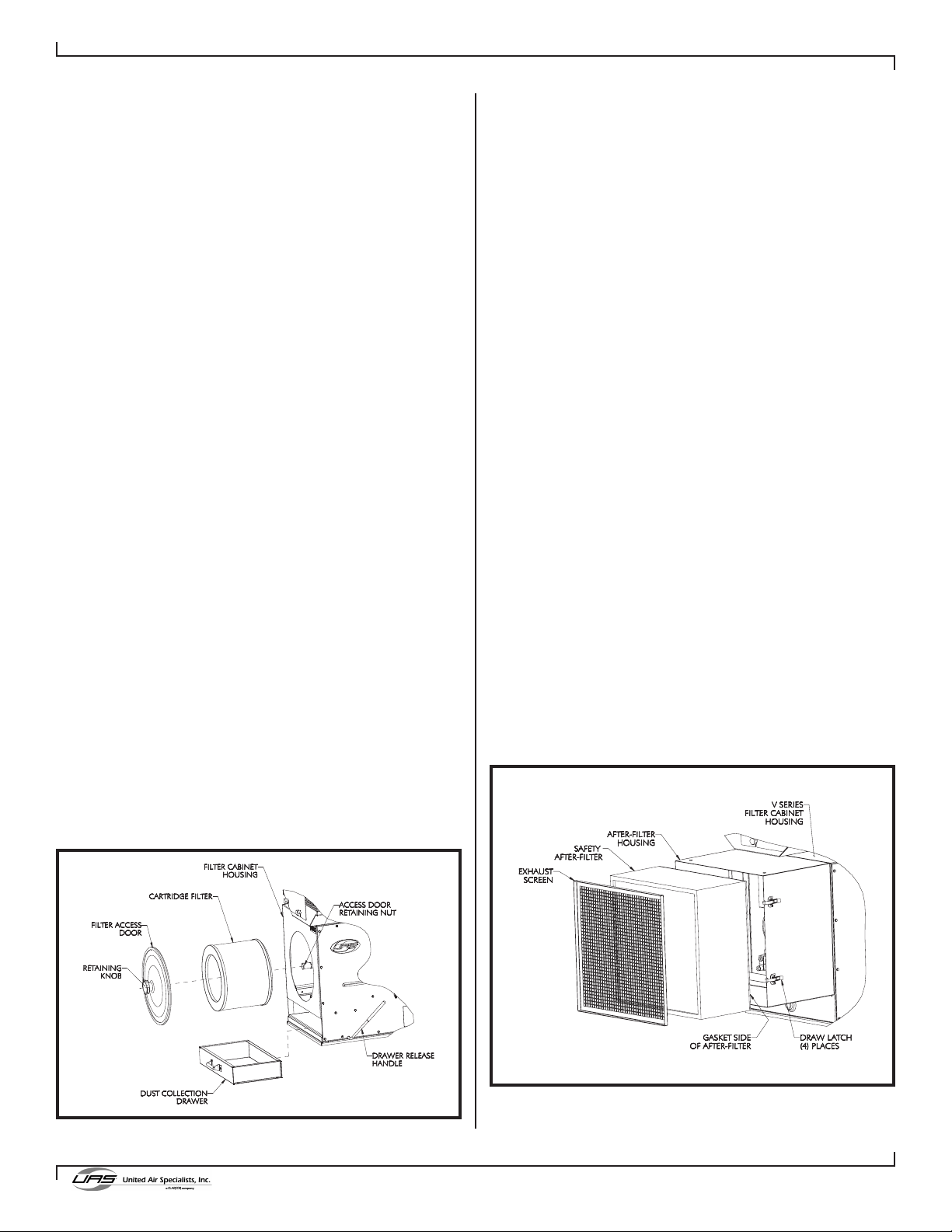

6.1 FILTER REMOVAL AND REPLACEMENT

As the V Series unit operates and the filter accumulates

dust, the flow rate of the unit will deteriorate. When the

pressure drop across the filter continuously reads

between 2"-3" or flow drops off to the point where the

dust generation process cannot adequately be

controlled, then it is time to change filters. To change

filters follow these steps:

1. Remove filter access cover by unscrewing the

retaining knob (see Figure 8). Tilt cover back away

from unit when freed from the retaining nut to trap

any fugitive dust on the inside of the access cover.

Dump dust into suitable disposal container.

2. Move filter from side to side to break gasket seal

between the filter and the tubesheet. Rotate the filter

180° to allow dust on top of the cartridge to fall into

the dust drawer.

3. Slide filter out along support rods and transfer to

suitable disposal container. Empty dust drawer as

described in Section 6.2.

4. Inspect tubesheet and make sure the gasket sealing

area is free of dust to ensure a proper seal.

5. Install a new filter element. Clean access cover

gaskets and reinstall cover by tightening the knob

securely to the retaining nut until the gasket is

adequately compressed.

Figure 8. Cartridge Filter Removal

61-10039-0003

6.2 DUST DRAWER REMOVAL

1. To access and remove the dust drawer located at the

base of the V Series unit, you must first unseal the

drawer by pulling the drawer release handle (see

Figure 8) toward the filter access side of the cabinet.

The drawer will move down and can be pulled out of

the front of the cabinet.

2. Dispose of the collected dust into a suitable

container. Any dust in the cabinet that was not

contained in the dust drawer should be vacuumed

out and disposed of.

3. Replace dust drawer by fully inserting into unit, and

reseal the drawer by pushing the drawer release

handle toward the control panel.

The collector should now be ready to operate. Reconnect

electrical power and air supply. Go through initial start-up

checklist to ensure proper unit performance.

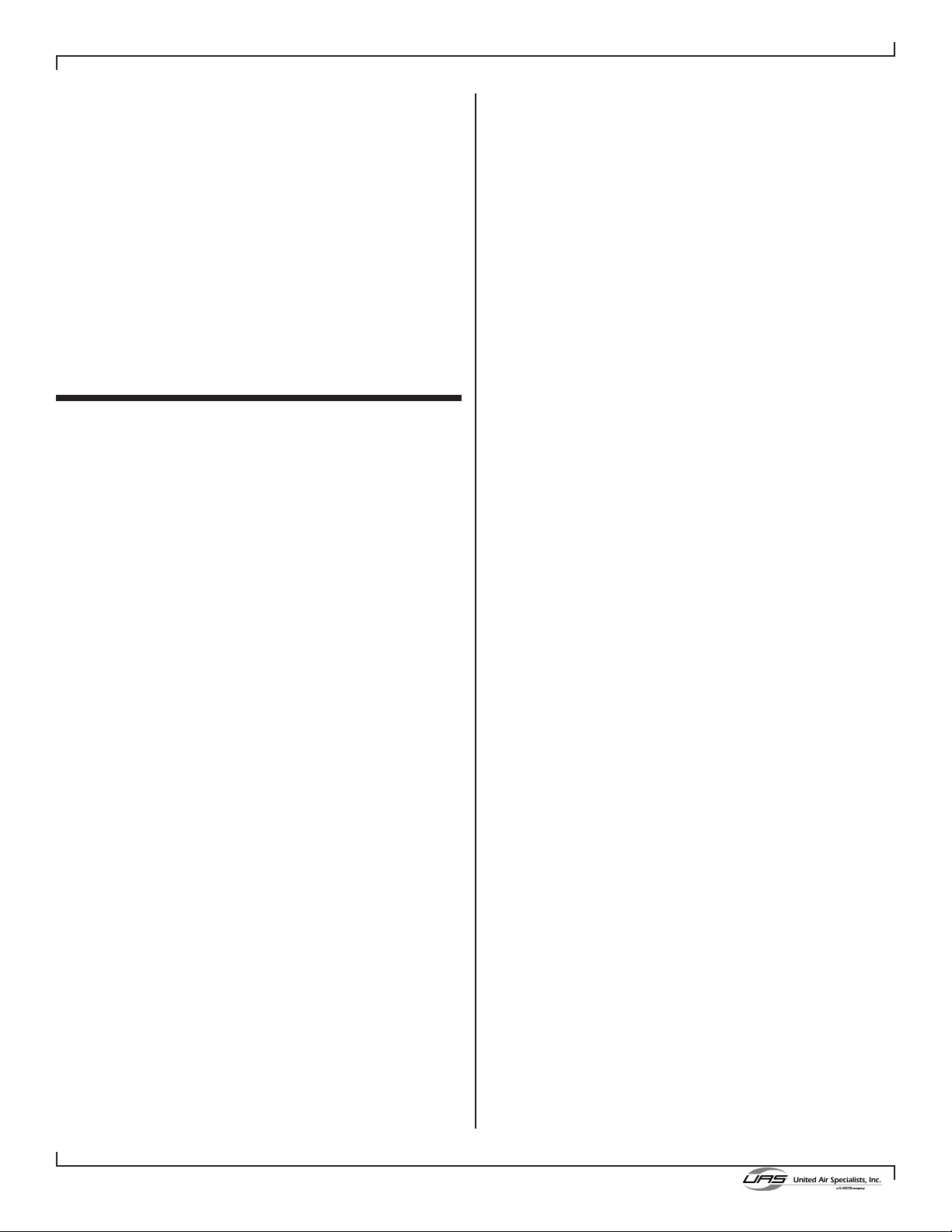

6.3 AFTER-FILTER REMOVAL/INSTALLATION

If your unit was ordered with a HEPA or carbon after-filter,

there will be an additional filter housing bolted to the

discharge side of the V Series unit. The following steps will

allow you to remove and replace the after-filter as shown in

Figure 9. NOTE: After-filter housings for portable units (VP)

have a push handle located on the top of the housing.

1. Release the four draw latches located on the filter

housing to release the seal of the after-filter.

2. Remove the exhaust screen.

3. The after-filter will slide out of the housing as shown

in Figure 9. Keep in mind that the filter weight may

significantly increase from the collected material.

Dispose of filter properly.

Figure 9. After-Filter Removal

61-10040-0001

8

Revised 08/09

V SERIES

Cartridge Dust Collector

4. Install a new filter element by sliding it into the filter

housing with the gasket of the after-filter leading.

5. Replace the exhaust screen and secure the four

draw latches to seal the filter.

6.4 SERVICING DIRECT DRIVE BLOWER

To gain access to the direct drive motor/blower you

must first remove the discharge air plenum as shown in

Figure 7.

NOTE: The blower rotation should be clockwise when

looking at the motor from the discharge side of

the cabinet.

See the troubleshooting guide in Section 8 of this

manual for clues on motor/blower problems.

7. ELECTRICAL

Tables 1 and 2 provide a listing of V Series model

numbers and their corresponding voltage, motor

horsepower and full load amperage draw.

Please complete the provided blanks on the inside

cover of this manual. This will help you to identify your

unit when dealing directly with United Air Specialists or

your local UAS representative.

7.1 UNIT CONTROL (ON/OFF)

All units will have the blower controlled from the unit

control panel (refer to Figure 6). A black ON/OFF rocker

switch is provided to start/stop the blower.

7.2 CLEANING CONTROLS (ON/OFF)

Section 4.4.1 of this manual clearly outlines the

available settings and operation of the pulse cleaning

system.

Control of the reverse pulse cleaning system is by a

rocker switch on the unit control panel (refer to Figure

6). The pulse cleaning system operates independent of

the blower. This provides for off-line cleaning.

NOTE: Compressed air must be connected prior to

engaging cleaning system to prevent damage to

diaphragm valves.

Electrical Schematics

An electrical schematic was included with your unit in

this packet. Please secure the drawing to this manual

for future reference. A copy of the appropriate wiring

diagram is also affixed on the inside of the control

panel.

9

Revised 08/09

V SERIES

Cartridge Dust Collector

8. TROUBLESHOOTING

The Swing Arm slips from

set position.

The joints require adjustment. Adjust the joints (refer to Section 8.2 of the

Swing Arm Manual)

Grease the rotation socket.

A) Clean out blockage.

B) Reconnect hose.

C) Replace damaged hose.

D) Open arm damper.

E) Check downstream filters, replace or clean

as needed.

Strong resistance during

rotation of the arm.

Decrease in air volume.

Motor/blower won’t start

or won’t stay running.

Dust emissions from clean

air discharge

Insufficient airflow

Continual excessive

pressure drop (over 5.0”)

on filter monitor gauge.

Pulsing failure of

diaphragm valve.

Filter element installed incorrectly; gasket not

sealing.

Inspect and reinstall filter cartridge (refer to

Section 6.1).

Replace damaged filter element.

Check fan rotation to ensure clockwise

rotation (refer to Section 5).

Check for obstructions and clear.

Replace filters.

Cleaning system not being used at required

frequency. Increase frequency.

Check air supply pressure (should be 90-110

PSIG).

Replace filters.

Check continuity of solenoid coil with

ohmmeter. Replace if necessary.

Filter element damaged.

Fan rotation backwards.

Air inlet restricted.

Filters at end of service life.

Plugged filter elements.

Inadequate compressed air supply for

cleaning mechanism.

Filter elements at end of useful life.

Open solenoid valve.

Improper electrical supply. Refer to Section 7 for electrical specifications.

Starter overloadtripped. Reset overloads.

Lack of grease in the rotating socket.

A) The ventilation duct is plugged.

B) Flexible hose not properly connected to

arm tubes.

C) The flexible hose is damaged.

D) The Swing Arm damper is closed.

E) Packed filters or other

restriction in system.

PROBLEM POSSIBLE CAUSE RECOMMENDED SOLUTIONS

Timer does not operate.

“PWR” light dose not illuminate.

Downtime cleaning does not function.

PWR light not illuminated.

Downtime cleaning does not function.

PWR light illuminated but CLEAN light not

illuminated or flashing.

Downtime cleaning does not function.

CLEAN light flashing but valve does not

pulse.

1. Make certain 120VAC power is at terminals L and N.

2. Check fuses F1 and F2 for open circuit. If F1 is open, check wiring and

replace fuse. If F2 is open, replace board.

1. Make certain 120VAC power is at terminals L and N even after the

motor/blower is turned off. The PWR light should be illuminated.

2. In units with motor starters: make certain an isolated normally open

motor starter auxiliary contact is wired to terminals 13 and 14 (downtime

cleaning begins when the motor/blower starter is turned off.)

1. Check terminals V and N for 120VAC pulse. If no output when PULSE

light flashes, replace board. If 120VAC pulse is detected, check wiring,

valve coil and air supply.

PROBLEM RECOMMENDED SOLUTIONS

ELECTRICAL ENCLOSURE REPLACEMENT PARTS

10

Revised 08/09

V SERIES

Cartridge Dust Collector

ELECTRICAL ENCLOSURE REPLACEMENT PARTS

Item No.

1

2

3

4

Not Shown

General Description

CONTACTOR, MOTOR

OVERLOAD RELAY (3-PHASE, 1-1/2 HP, 208,230 V)

OVERLOAD RELAY (3-PHASE, 1-1/2 HP, 460 V)

OVERLOAD RELAY (3-PHASE, 1-1/2 HP, 575 V)

OVERLOAD RELAY (3-PHASE, 3 HP, 208,230 V)

OVERLOAD RELAY (3-PHASE, 3 HP, 460,575 V)

CONTROL BOARD, CLEANING SYSTEM

TRANSFORMER, STEP-DOWN TO 120V (200-208V)

TRANSFORMER, STEP-DOWN TO 120V (230-460V)

TRANSFORMER, STEP-DOWN TO 120V (575V)

SWITCH, ROCKER, DPST

UAS Part No.

23-3124-9

23-3124-5.0

23-3124-3.1

23-3124-2.4

23-3124-8.5

23-3124-4.0

20-3232

21-1275-050

21-1274-050

21-1276-050

20-2920

61-10041-0002

Panel shown is with UAS supplied starter

11

Revised 08/09

V SERIES

Cartridge Dust Collector

PORTABLE V SERIES REPLACEMENT PARTS

12

Revised 08/09

V SERIES

Cartridge Dust Collector

Item No.

1

2

3

4

General Description

SWING ARM, W/PARAVENT HOOD, 6" DIA. x 7' EXTENSION

SWING ARM, W/PARAVENT HOOD, 6" DIA. x 10' EXTENSION

SWING ARM, W/PARAVENT HOOD, 6" DIA. x 14' EXTENSION

SWING ARM, W/PARAVENT HOOD, 8" DIA. x 7' EXTENSION

SWING ARM, W/PARAVENT HOOD, 8" DIA. x 10' EXTENSION

SWING ARM, W/PARAVENT HOOD, 8" DIA. x 14' EXTENSION

CASTER RIGID, 5" DIA.

CASTER-SWIVEL, 5" DIA.W/LOCK

PUSH HANDLE BAR

UAS Part No.

15-10028-000M

15-10029-000M

15-10030-000M

15-10031-000M

15-10032-000M

15-10033-000M

17-0026

17-0027

39-0268

Item No.

5

6

7

8

9

General Description

GRATE, BENCH, VS1500

GRATE, BENCH, VS750

PLATE, REAR, BENCH,VS1500

PLATE, REAR, BENCH,VS750

SIDE PLATE, FMD, LEFT,BENCH

SIDE PLATE, FMD, RIGHT, BENCH

KNOB,5-LOBE W/ STUD,1/4-20

UAS Part No.

10-11872-0001

10-11873-0001

10-11876-0001

10-11877-0001

10-11880-0001

10-11881-0001

39-10026-0001

Item No.

10

General Description

SLIP COLLAR, 6” DIA

UAS Part No.

45-10017-0001

Item No.

11

12

13

14

15

16

18

19

20

General Description

VS,FILTER COVER,ASM

GAUGE-MINIHELIC,0-5" S.P.

VALVE,DIAPHRAGM,1" COMP.,DM25,W/ INT SOL

DUST DRAWER, VS 1500

DUST DRAWER, VS750

DISCHARGE HOUSING, VS

CONTACT UAS FOR AFTER FILTER HOUSING INFORMATION

CORD, POWER, 14-3, W/PLUG, SJT, 15FT (SINGLE PHASE POWER)

CORD, POWER, 14-3, SJT, 15FT (3-PHASE POWER)

GRIP,BLACK VINYL,1/2" ROD

SEE STANDARD FILTERS BELOW

CONTACT UAS FOR INFORMATION

UAS Part No.

02-10709-0001

07-0081

07-10002-0002

18-10716-0001

18-10720-0001

18-10728-0001

20-2813

39-10025-0001

FILTER

MOTOR/BLOWER

General Description

FILTER,CARTRIDGE,NANOFIBER,VS-750

FILTER,CARTRIDGE,NANOFIBER FIRE RETARDANT,VS-750

FILTER,CARTRIDGE,NANOFIBER,VS-1500

FILTER,CARTRIDGE,NANOFIBER,FIRE RETARDANT,VS-1500

FILTER,HEPA 99.97,23.375x23.375x11.5,UP GASK>

FILTER,HEPA 99.97,23.375x23.375x5.875,UP GASK>

FILTER,CHARCOAL,24x24x6

UAS Part No.

33-10097

33-10097-1

33-10098

33-10098-1

33-10081-0001

33-10082-0001

33-1219

PORTABLE V SERIES REPLACEMENT PARTS

DOWNDRAFT BENCH V SERIES REPLACEMENT PARTS

FIXED UNIT V SERIES REPLACEMENT PARTS

V SERIES COMMON REPLACEMENT PARTS

V SERIES STANDARD FILTERS

13

Revised 08/09

V SERIES

Cartridge Dust Collector

APPENDIX A. V SERIES WRING DIAGRAM

Figure 10. Wiring Diagram 120 Volt, Single Phase, Manual Clean

Figure 11. Wiring Diagram 120 Volt, Single Phase, Pulse Cleaning

Figure 12. Wiring Diagram 230 Volt, Single Phase, Manual Clean

41-2537

41-2538

41-2541

14

Revised 08/09

V SERIES

Cartridge Dust Collector

Figure 14. Wiring Diagram, Three Phase, Manual Clean w/ UAS Supplied Starter

Figure 13. Wiring Diagram 230 Volt, Single Phase, Pulse Cleaning

41-2542

41-2543

15

Revised 08/09

V SERIES

Cartridge Dust Collector

Figure 15. Wiring Diagram, Three Phase, Pulse Cleaning w/ UAS Supplied Starter

Figure 16. Wiring Diagram, Three Phase, Manual Clean w/ Customer Supplied Starter

41-2544

Figure 17. Wiring Diagram, Three Phase, Pulse Cleaning

w/ Customer Supplied Starter

41-2546

41-2545

©2004 United Air Specialists

Part No. 44-10448-0001

08/09

United Air Specialists, Inc.

reserves the right to change

design or specifications

without notice.

4440 Creek Road • Cincinnati, Ohio 45242 USA

National Phone: 1-800-252-4647

Telephone: (513) 891-0400 • Fax: (513) 891-4882

www.uasinc.com

UNITED AIR SPECIALISTS, INC.

LIMITED WARRANTY

UAS warrants to the original purchaser that all equipment will be free from defects in materials and

workmanship for one year from the date of shipment from UAS (three years for Smokeeter® and

VisionAir™ models other than CC and DC series) and that major structural components on SFC and MCB

series will be free from defects in materials and workmanship for ten years from the date of shipment from

UAS. This warranty applies only if equipment is properly installed, maintained, and operated under normal

conditions and does not apply to damage caused by corrosion, abrasion, abnormal use or misuse,

misapplication, or normal wear and tear. This warranty will be void with respect to equipment that is subject

to unauthorized repairs or modifications. UAS makes no warranty as to goods manufactured or supplied by

others. This warranty is subject to any limitations in UAS’ quotation and may not be modified except by a

written instrument signed by the President or Vice President of Sales of UAS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER

WRITTEN, ORAL OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT.

As Purchaser's exclusive remedy for any defects in the equipment, UAS will exchange or repair any

defective parts during the warranty period, provided such parts are returned, prepaid, to UAS' factory. The

obligation of UAS is limited to furnishing replacement parts F.O.B. UAS' factory or making repairs at UAS'

factory of any parts that are determined, upon inspection by UAS, to be defective. In no event will UAS be

responsible for labor or transportation charges for the removal, reshipment or reinstallation of the parts.

IN NO EVENT WILL UAS BE RESPONSIBLE FOR ANY SPECIAL OR CONSEQUENTIAL

DAMAGES.

This manual suits for next models

9

Table of contents

Other CLARCOR Dust Collector manuals

Popular Dust Collector manuals by other brands

Grizzly

Grizzly G0440 owner's manual

Hitachi

Hitachi RP 30Y Instruction manual and safety instructions

Steel City

Steel City 65110 user manual

Hafco Woodmaster

Hafco Woodmaster DC-90 instruction manual

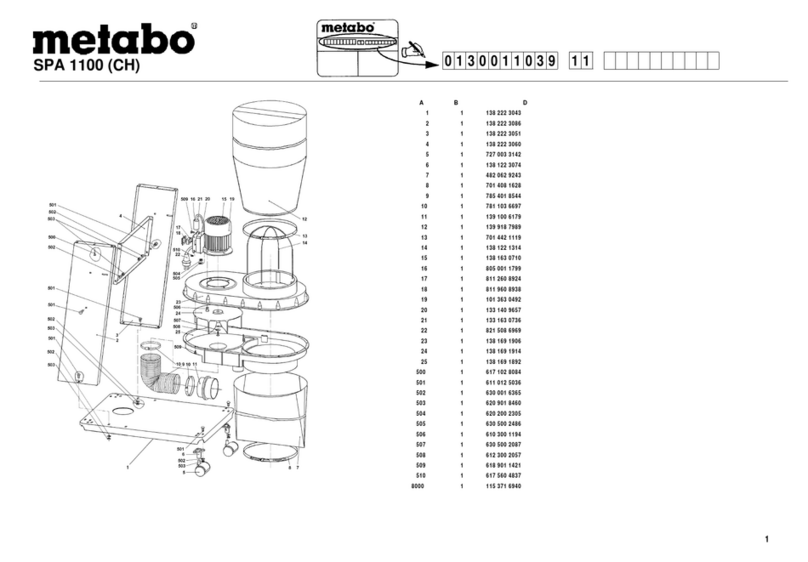

Metabo

Metabo SPA 1100 (CH) Spare parts

Rikon Power Tools

Rikon Power Tools POWER TOOLS 60-1750 Operator's manual

Grizzly

Grizzly G0443HEP manual

DustEZE

DustEZE EC-560 Booklet

Harbor Freight Tools

Harbor Freight Tools 31810 Set up and operating instructions

Metabo

Metabo SPA 1200 Original operating instructions

Villager

Villager DM 14 P Original instruction manual

King Industrial

King Industrial KC-3109C instruction manual