clare ClareOne 16 Zone Hardwired Input Module User manual

ClareOne 16 Zone

Hardwired Input Module

Manual

Model CLR-C1-WD16

Last modified: 12/15/20

DOC ID - 1992 • Rev 02.01

Copyright

© 05NOV20 Clare Controls, LLC. All rights reserved.

This document may not be copied in whole or in part or otherwise

reproduced without prior written consent from Clare Controls, LLC.,

except where specifically permitted under US and international

copyright law.

Trademarks and

patents

The ClareOne name and logo are trademarks of Clare Controls,

LLC.

Other trade names used in this document may be trademarks or

registered trademarks of the manufacturers or vendors of the

respective products.

Manufacturer

Clare Controls, LLC.

7519 Pennsylvania Ave., Suite 104, Sarasota, FL 34243, USA

FCC compliance

FCC ID: 2ABBZ-RF-CHW16-433

IC ID: 11817A-CHW16433

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation. Changes or modifications not expressly

approved by the party responsible for compliance could void the

user's authority to operate the equipment. This Class B digital

apparatus complies with Canadian ICES-3B. Cet appareil numérique

de la classe B est conforme à la norme NMB-003 du Canada.

Note: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Warning: changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to

operate the equipment.

•This equipment complies with FCC radiation exposure limits set

forth for an uncontrolled environment. This equipment should be

installed and operated with minimum distance 20cm between the

radiator and your body.

EU compliance

Complete additional sections according to the governing laws and

standards for the intended marketplace.

EU directives

1999/5/EC (R&TTE directive): Hereby, Clare Controls, Llc. declares

that this device is in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

2002/96/EC (WEEE directive): Products marked with this symbol

cannot be disposed of as unsorted municipal waste in the European

Union. For proper recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or dispose of it at

designated collection points. For more information see:

www.recyclethis.info.

2006/66/EC (battery directive): This product contains a battery that

cannot be disposed of as unsorted municipal waste in the European

Union. See the product documentation for specific battery

information. The battery is marked with this symbol, which may

include lettering to indicate cadmium (Cd), lead (Pb), or mercury

(Hg). For proper recycling, return the battery to your supplier or to a

designated collection point. For more information see:

www.recyclethis.info.

Contact information

For contact information, see www.clarecontrols.com.

16 Zone Hardwired Input Module i

Content

Introduction...1

Package contents...1

Specifications...1

Installation...3

Programming...6

Testing...7

Wiring...8

Reference information...10

Status definitions...10

EOL resistance...10

Multiple sensors on a zone...11

Troubleshooting...13

ii 16 Zone Hardwired Input Module

Important information

Limitation of liability

To the maximum extent permitted by applicable law, in no event will Clare

Controls, LLC. be liable for any lost profits or business opportunities, loss of use,

business interruption, loss of data, or any other indirect, special, incidental, or

consequential damages under any theory of liability, whether based in contract,

tort, negligence, product liability, or otherwise. Because some jurisdictions do not

allow the exclusion or limitation of liability for consequential or incidental

damages the preceding limitation may not apply to you. In any event the total

liability of Clare Controls, LLC. shall not exceed the purchase price of the

product. The foregoing limitation will apply to the maximum extent permitted by

applicable law, regardless of whether Clare Controls, LLC. has been advised of

the possibility of such damages and regardless of whether any remedy fails of its

essential purpose.

Installation in accordance with this manual, applicable codes, and the instructions

of the authority having jurisdiction is mandatory.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its contents, Clare Controls, LLC. assumes no

responsibility for errors or omissions.

16 Zone Hardwired Input Module 1

Introduction

The ClareOne 16 Zone Hardwired Input Module (HWIM), model number

CLR-C1-WD16, allows the takeover of hardwired security zones making them

compatible with the ClareOne panel. The HWIM has 16 hardwired zone inputs

each with LED status, a tamper switch input, a back-up battery charging terminal,

and 2 auxiliary power outputs for powered sensors, capable of outputting 500mA

@ 12VDC. The HWIM supports powered and unpowered sensors, including

contact zones (open/close), motion sensors, and glass break detectors.

Package contents

Note: Ensure all accessories are included. If not, contact your dealer.

•1 × ClareOne 16 Zone Hardwired Input Module

•1 × Power supply

•2 × Battery cables (one red and one black)

•2 × Antennas

•16 × Resistors (each one is 4.7 k)

•1 × Installation sheet (DOC ID 1987)

•Mounting hardware (screws and wall anchors)

Specifications

Compatible panel

ClareOne (CLR-C1-PNL1)

Input voltage

16 VDC Plug-in transformer

Auxiliary voltage output

12 VDC @ 500 mA

EOL supervision

4.7 k(resistors included)

Battery backup

12 VDC 5Ah (optional, not included)

Input zones

16

Tamper zone

Use external switch or wire to short

Dimensions

5.5 x 3.5 in. (139.7 x 88.9 mm)

Operating environment

Temperature

Relative humidity

32 to 122°F (0 to 50°C)

95%

2 16 Zone Hardwired Input Module

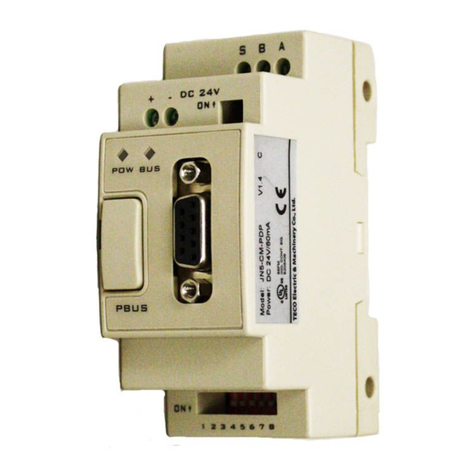

Figure 1: ClareOne 16 Zone Hardwired Input Module and main LEDs

Processor LED (red color): The Processor LED flashes to indicate processor

operation.

RF XMIT LED (green color): The RF XMIT LED illuminates when RF

transmission is sent.

Pairing LED (red color): The Pairing LED illuminates when the HWIM is in

“Pairing” mode and is extinguished when the HWIM is in “Normal” mode. If there

are no zones paired the Pairing LED flashes.

Note: The Pairing LED must be extinguished (not in “Pairing” mode) when testing

sensors.

Figure 2: Zone LEDs

16 Zone Hardwired Input Module 3

Zone LEDs (red color): During "Normal Operation Mode" each LED remains off

until its corresponding zone is opened, then the LED illuminates. When entering

"Pairing Mode" each zone LED flashes briefly, after which each zone LED

remains off until the zone is learned in. Once learned in, it illuminates until

"Pairing Mode" is complete.

DLY LEDs (yellow color): Zones 1 and 2 each have a DLY LED. When a zone’s

DLY LED is illuminated yellow, that zone has the 2-minute communication timer

delay enabled. When the DLY LED is off, that zone’s communication timer delay

is disabled. When the DLY LED flashes, the associated zone has been tripped,

and the 2-minute communication timer delay is in effect. All additional triggers

from that sensor are ignored for 2 minutes. We recommend using zones 1 and 2

for motion sensors. For more information, see Programming on page 6.

Figure 3: Buttons

Memory Reset Button: The Memory Reset button clears the HWIM’s memory

and returns it to the factory default settings. The Memory Reset button is also

used to enable/disable the communication timer delay for Zones 1 and 2.

Pair Button: The Pair button puts the HWIM in/out of “Pairing” mode.

Installation

Only qualified installation technicians should install the HWIM. Clare Controls

does not assume responsibility for damages caused by improper installation or

use of the device. The HWIM is intended to be mounted to a wall using the

included screws and anchors. The HWIM should be oriented with its antennas

facing upward. The included antennas should be used regardless of location, for

optimal RF communication. Once all sensors are wired to the HWIM, the HWIM

and each zone can be paired to the ClareOne panel.

Note: If the HWIM is being installed in a metal container or equipment rack, the

antennas must extend outside the container to ensure that the RF

communication is not interrupted. Do not bend or alter the antennas.

4 16 Zone Hardwired Input Module

To install the HWIM:

1. Carefully select the mounting location, verifying that the HWIM’s antennas are

pointing up, and then secure it in position using the provided screws and wall

anchors.

Note: The HWIM should be within 1000 ft (304.8 m) of the panel. Walls,

construction materials, and other objects may impede the signal and shorten

the distance.

2. Attach each antenna to the HWIM, placing one in each of the ANT terminals

on the top of the HWIM.

Note: The antennas should be clear of obstructions and if in a metal

enclosure, should extend outside of it.

3. Wire the sensors/leads to the desired terminals marked Zone 1 through 16.

Wiring Notes:

•The HWIM requires 4.7 kΩ of end of line (EOL) resistance on each zone.

Existing installations may already have EOL resistors installed. Determine

the current EOL resistance value and adjust as needed to get total

resistance to 4.7 kΩ.

•EOL resistor installation depends on if the sensor is normally open (N/O)

or normally closed (N/C). Refer to Determining EOL resistance and sensor

type on page 5, for details on determining EOL resistance and if a sensor

is N/O or N/C.

•Install one of the included 4.7 kΩ resistors to each zone with an attached

sensor. Install the resistor in parallel for N/O and in series with N/C

sensors.

•To provide power to powered sensors, such as motion and glass break

sensors, wire the Positive and Negative leads from the sensor to the

“AUX” (+) and “GND” (-) terminals. See Figure 4 and 5, on page 8.

4. Wire the tamper switch input.

Note: This is required for proper device operation.

Option 1: If using a tamper switch, wire the tamper switch directly to the

tamper terminals without the need for an EOL resistor.

Option 2: If not using a tamper switch, connect a jumper wire across the

tamper input terminals.

5. (Recommended) For any security system that is supervised, a battery should

be connected to the HWIM. To provide an independent battery back up to the

HWIM, connect the included battery leads to a 12VDC, 5Ah lead acid

rechargeable battery (battery not included). This battery type is common with

traditional hardwired security panels, otherwise it is recommended that you

connect the HWIM to an auxiliary 16VDC power supply (1 amp or greater)

with its own battery backup.

16 Zone Hardwired Input Module 5

6. Connect the power supply leads from the provided power supply to the

terminals labeled +16.0V and GND on the wired input HWIM.

Note: The dashed wire is positive.

7. Plug the power supply into a 120VAC outlet.

Note: Do not plug the HWIM into a receptacle controlled by a switch.

Determining EOL resistance and sensor type

Sometimes, it is not visually apparent what is physically connected to a zone in

terms of pre-existing EOL resistors and whether the sensor is N/O or N/C. Use a

multimeter to learn this information.

With a sensor in its active state (i.e. door/window contact separated from its

magnet), take a multimeter set to measure resistance and connect the multimeter

across the zone wires. If the multimeter reads a value of 10 kΩ or less, the

sensor is N/O. If the multimeter reads an open or extremely high resistance

(1 MΩ or higher) then the sensor is N/C. The table below provides guidance for

using the measurements to determine the EOL resistance value, as well as the

line resistance for N/O sensors. This is the case regardless of the number of

sensors connected to a single zone, so long as all sensors on the same zone are

in series or in parallel with one another.

Note: The HWIM will not work if there is a combination of series and parallel

sensors connected to the same input zone.

Multimeter reads for N/O

Multimeter reads for N/C

Sensors active

(sensor away from the

magnet)

Value for EOL resistor

Open

Sensors inactive

(Sensors connected to

the magnet)

Value of line resistance (10 Ω

or less)

Value of EOL resistor plus line

resistance

EOL resistance on existing installations typically ranges from 1 kΩ – 10 kΩ while

line resistance should be 10 Ω or less. However, some installations do not have

any EOL resistors installed and the measured EOL resistance may be the same

as the line resistance. If there are no EOL resistors installed, install the provided

4.7 kΩ resistor. Ideally, any existing EOL resistors would be removed and

replaced with a 4.7 kΩ resistor. If that is not an option, additional resistors must

be added, to get the EOL resistance to 4.7 kΩ.

6 16 Zone Hardwired Input Module

Programming

There are two portions of programming involved with the HWIM: adding the

HWIM to the panel and pairing zones.

Caution: For systems with motion sensors

When pairing a zone, tripping any motion sensor that is not already paired to the

ClareOne panel causes the motion sensor to pair in instead of the target zone.

This includes pairing in the HWIM. We recommend pairing in motion sensors

before pairing in the HWIM or other sensors. This includes wired and wireless

motion sensors.

To add the HWIM to the panel:

1. Once the HWIM is powered on, open the front cover.

2. Press and hold the Pair button on the HWIM for 2 seconds. All zone LEDs

flash and extinguish. The Pairing LED illuminates, indicating that the HWIM is

in “Pairing” mode.

3. Access the ClareOne panel’s Sensor Settings (Settings > Installer Settings >

Sensor Management > Add Sensor), and then select "Wired Input Module" as

the device type. For detailed programming instructions, refer to the ClareOne

Wireless Security and Smart Home Panel User Manual (DOC ID 1871).

4. Trip the tamper input, either by opening the tamper switch, or removing the

jumper across the inputs. Refer to “To install the WHIM,” step 4, on page 4.

Once complete, close the tamper switch or replace the jumper.

5. Follow the ClareOne panel on-screen prompts to complete the process.

Note: While a battery backup is recommended, if not adding a battery

backup, disable the low battery notifications. To do this, access the HWIM’s

sensor settings on the ClareOne panel and set “Low Battery Detection” to Off.

To pair the zones:

Notes

•Each zone must be paired individually, one at a time.

•If using a motion sensor, it is recommended to connect it to Zone 1 or 2,

and then enable the communication delay for that zone. If using more than

2 hardwired motions, allocate the most active areas on these zones. The

exception would be if using motions in an occupancy detection mode for

automation, in which case this setting should not be enabled, or a different

zone should be used for that motion sensor.

16 Zone Hardwired Input Module 7

•Motion sensors should be paired first. This includes both wired and

wireless motion sensors.

1. If using motion sensors, complete steps 1 through 3 of “To add the HWIM to

the panel” on page 6 before continuing.

2. Verify that the HWIM’s Pairing LED is illuminated.

If the LED is no longer illuminated, press and hold the Pair button for 2

seconds.

3. Access the ClareOne panel’s Sensor Settings (Settings > Installer Settings

>Sensor Management > Add Sensor), and then select desired zone type

as the device type. For detailed programming instructions, refer to the

ClareOne Wireless Security and Smart Home Panel User Manual (DOC ID

1871).

4. Trip the desired hardwired zone. Once a zone is tripped, its zone LED

illuminates and remains lit until the HWIM exits “Pairing”mode.

To enable communication delay for Zone 1 or 2:

a. Before tripping another sensor press the Memory Reset button.

b. The zone’s DLY LED illuminates, signifying that the 2-minute

communication timer delay is enabled for that zone.

5. Follow the ClareOne panel on-screen prompts to complete the process.

6. Repeat steps 2 through 5 for each zone.

7. Once all zones are paired, press the Pair button. The Pairing LED

extinguishes, signifying the HWIM is no longer in “Pairing”mode.

Note: The HWIM must be taken out of “Pairing”mode before continuing.

Testing

Once the HWIM is installed and programmed with all sensors paired, the system

should be tested to verify that the HWIM and zones are working correctly.

To test the HWIM:

1. Set the ClareOne panel to “Sensor Test”mode (Settings > Installer Settings >

System Test > Sensor Test).

2. Trip each zone on the HWIM one at a time. Monitor the system after tripping

the zones. Refer to the ClareOne Wireless Security and Smart Home Panel

User Manual (DOC ID 1871) for specific test information.

8 16 Zone Hardwired Input Module

Wiring

The graphic below details the HWIM wiring.

Figure 4: Wiring diagram

(1) 12 VDC Backup battery connection

(1.a) Negative wire (-)

(1.b) Positive wire (+)

(2) 16 VDC Power supply connection

(2.a) Positive wire (+)

(2.b) Negative wire (-)

(3) 12VDC Auxiliary Power Output 1

(3.a) Positive wire (+)

(3.b) Negative wire (-)

(4) 12VDC Auxiliary Power Output 2

(4.a) Positive wire (+)

(4.b) Negative wire (-)

(5) Tamper input

(6) Wired zone N/O loop

(7) Wired zone N/C loop

(8) Antenna connection

(9) Antenna connection

Figure 5: Wiring a powered sensor

16 Zone Hardwired Input Module 9

Note: When wiring a sensor that also has a tamper output, the alarm output and

tamper output should be wired in series so that the zone triggers on either an

alarm or tamper event. See figure below.

10 16 Zone Hardwired Input Module

Reference information

This section describes several areas of reference information that can be useful

when installing, monitoring, and troubleshooting an HWIM.

Status definitions

The ClareOne panel reports the status of the HWIM as Ready by default.

Additional HWIM states that may be indicated.

Ready: The HWIM is active and is working properly.

Tampered: The tamper input on the HWIM is open.

Troubled: The HWIM is offline, and nothing has been reported to the panel for 4

hours. At this point, for a monitored system the central station has been informed

that the HWIM is offline. Typically, this is either due to power for the HWIM being

removed or an object being placed between the panel and the HWIM blocking

the RF communication path. Glass, mirrors, and appliances are the most

common household items that cause interference.

Low Battery: The low battery indicator is only visible if the Battery Supervision

setting is enabled for the HWIM, and the HWIM is either not connected to a

battery, or the battery it is connected to is not adequate/low on charge.

Power Loss: When power is removed from the HWIM and there is a battery

connected, the HWIM reports a DC power loss. This is indicated on the ClareOne

panel as an alert notification. If there is no battery installed, as power starts to go

down, the HWIM attempts to send out a power loss event signal to the ClareOne

panel; in some instances the power loss event signal is fully received by the

ClareOne panel and the alert notification is given.

EOL resistance

The purpose of EOL resistors is two-fold: 1) to provide an additional layer of

security for wired sensors, 2) to check if there is an issue with the wiring going to

the sensor.

Without an EOR resistor, someone could short the terminals at the module to

make the zone appear to always be closed regardless of activity at the sensor.

Since the HWIM requires an EOL resistor, someone cannot short the zone input

on the module, as it would cause the module to report the zone in a tampered

state. Therefore, it is important for the EOL resistors to be placed as close to the

sensor as possible. The further away the EOL resistor from the module, the more

wiring can be monitored for unintentional shorts.

Note: If there is a short in the cable between the HWIM and the EOL resistor the

HWIM reports the zone as being in a tampered state.

16 Zone Hardwired Input Module 11

If the wrong value EOL resistor is used or the EOL resistor is installed incorrectly,

the zone will not function properly. This can lead to things such as the zone

status being reversed (i.e. reporting open when closed and closed when open). It

could also lead to the zone reporting a tampered state or being stuck in a Not

Ready state to the ClareOne panel.

Multiple sensors on a zone

The HWIM allows multiple sensors to be connected on a single zone. For

normally closed sensors, the sensors should all be in series with the EOL resistor

in series and located at the sensor furthest from the panel. For normally open

sensors, the sensors should all be in parallel with the EOL resistor connected

across the sensor located at the sensor furthest from the panel.

Figure 6: Multiple N/O sensors on a zone

Figure 7: Multiple N/C sensors on a zone

Multiple powered sensors on one zone

For multiple powered sensors on the same zone, the sensors should be wired to

the zone as shown in Figures 6 and 7, based on sensors being N/O or N/C. The

EOL resistor should be placed at the sensor furthest away from the panel. The

power wiring should be run to one sensor and then a second run of wiring should

go from the first sensor to the second. Alternatively, the power wiring could go

directly from each sensor back to the panel; this requires longer cable runs.

Note: The power connections should be in parallel for each sensor.

12 16 Zone Hardwired Input Module

Figure 8: Multiple powered sensors on one zone

Multiple powered sensors on multiple zones

For multiple powered sensors on different zones, the sensors should be wired to

the zones independently. The power wiring should go directly from the AUX

output on the panel to each sensor.

Figure 9: Multiple powered sensors on different zones

16 Zone Hardwired Input Module 13

Troubleshooting

There is a simple sequence of steps that can be taken to troubleshoot most

issues that might arise when using the HWIM. The first step before proceeding

with troubleshooting is to make sure that the issue is not network related. It is

best to troubleshoot the HWIM using the ClareOne panel and not through the

ClareHome application, ClareOne Auxiliary Touchpad, or FusionPro.

1. Check status of the HWIM and wired sensors on the ClareOne panel.

a. Check for alert notifications on the ClareOne panel, such as DC power

loss for the HWIM.

b. The HWIM and its wired sensors will continue to report as Ready for 4

hours after losing the RF communication to the panel. A sensor and

the HWIM may appear to be in a Ready state, but not appear to be

generating events on the panel if there is no power at the HWIM or

there is something blocking the RF transmission.

2. Check status of the LEDs on the HWIM.

a. If the HWIM’s Processor LED is not flashing red, then the HWIM is not

functioning properly. It may have insufficient power, or the LED is

broken. Check that the power supply is properly connected and that

there is 16VDC on the power input terminals on the HWIM. Power

cycling the HWIM may help.

b. The sensors will not report properly if the HWIM is still in “Pairing”

mode, indicated by the Pairing LED being illuminated red. In this case

some sensors may report being in a tampered state instead of a Ready

state. Pressing the Pair button will end the “Pairing”mode and return

the HWIM to “Normal”mode.

c. If a Zone LED is flashing red, that indicates that the zone is in a

tampered state. Check the wiring on the zone to make sure everything

is connected properly, the EOL resistor is properly installed, and is

4.7 k. Check to make sure there is not an inadvertent short between

the wires.

d. If a Zone LED does not change state when the sensor is triggered,

then there may be an issue with either the wiring to the sensor, power

to the sensor, or the sensor itself.

i. For powered sensors, verify that the voltage input on the sensor

is measured to be within specification for the sensor. If there is a

significantly long cable run, the voltage may have a significant

drop. This can happen if too many powered sensors are sharing

the auxiliary output power causing insufficient current to power

the sensor.

14 16 Zone Hardwired Input Module

Some powered sensors have a LED to indicate that the sensor

is working properly. If the LED on the sensor is functioning when

the sensor is triggered, then check the wiring from the HWIM to

the sensor.

ii. For unpowered sensors, check the wiring from the HWIM to the

sensor, including verifying that the EOL resistor is the correct

value (4.7 k) and connected properly. Replacing an

unpowered sensor with another sensor can help eliminate a

fault in the sensor itself. Take the wires from a known working

zone and connect them to the zone of the “bad” sensor. Does

the known good sensor continue working? If this is true, then

there is an issue with the wiring on the "bad" zone.

e. If using the communication delay on Zone 1 or 2, the DLY LED is

illuminated yellow for the appropriate zone. If the DLY LED is not

illuminated, then the communication delay is not enabled. This could

lead to multiple events being received by the panel when only one

event is expected, or for long delays for other events from being

reported.

To enable the communication delay after a sensor is paired:

1. Enter “Pairing”mode by pressing the Pair button.

2. Trigger the sensor on the desired zone.

3. Before triggering any other sensor press the Memory Reset

button.

Once this is done the DLY LED turns on. Be sure to press the

Pair button again to exit “Pairing”mode.

f. If using Zone 1 or 2 and the DLY LED is illuminated, the zone will not

report open events for 2 minutes after the first event is reported. If this

feature is not desired, then the feature should be disabled.

To disable the communication delay:

1. Enter “Pairing”mode by pressing the Pair button.

2. Trigger the sensor on the desired zone.

3. Before triggering any other sensors press the Memory Reset

button.

Once this is done the DLY LED extinguishes. Be sure to press

the Pair button again to exit “Pairing”mode.

This manual suits for next models

1

Table of contents