Clark-Reliance Jerguson LumaStar EPL-100 Guide

1

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

TM

®

Installation, Operation, & Maintenance Instructions

IOM J500.35

5/11/2016

Jerguson LumaStar

(EPL-100 & EPL-316 24VDC SUPPLY OPTION)

1

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

STORAGE and HANDLING

The Jerguson®LumaStar™ Intrinsically Safe LED Illuminator meets or exceeds all applicable

specifications when shipped from the factory.

All units should be inspected upon receipt to ensure that no damage has been incurred during transit. If there has

been damage, a claim should be filed with the carrier immediately. Unit should be stored in an area protected

from the elements and corrosive fumes, in a secure manner where they can neither fall, nor be struck by other

objects. Care should be taken to protect the window and the end connections from damage. Avoid placing any

objects directly on the light at any time.

COMPONENTS

There are 4 main components required for the LED illuminator system: the light bar, a 24VDC power

supply, zener diode barrier, and cable with optional field-wireable connector. The cable may have more than one

piece depending on the customer requirements. Questions regarding acceptable applications should be directed to

The Clark-Reliance®Corporation.

ELECTRICAL CONNECTION

CAUTION: All lights are tagged with the service conditions for that particular unit. These specifications

are located on the Jerguson®tag on the enclosure housing, and are contained in the “Specifications” section

of this manual. Review the ratings prior to installation and again prior to start-up.

NOTE: All installation steps should be performed by a qualified technician and should be executed in

accordance with all applicable national and local codes.

The light and field-wireable connector / enclosure should be checked to ensure that they contain no foreign

matter, and that the end connections are clean and undamaged.

NOTE: If desired, the light may be installed onto the glass gauge prior to connecting electrical.

CAUTION: Before wiring LED illuminator verify that the power circuit is off. The power supply and

zener diode barrier should be located in a non-hazardous area. The power supplied to the LED illuminator

is intrinsically safe. See figure 1.

Figure 1: Typical Layout

2

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

Led Illuminator with Connection enclosure

1) Open the cover of the connection enclosure. Insert the DC Line wires into the housing and connect to the

terminal block note the polarity of the wire. The terminal block has been label with V + and GND to aid

installation. The DC output is pre-wired to the light bar. If this connection is removed during installation,

reconnect the white wire to V+ and green wire to GND. Failure to do so could result in permanent damage

to the power supply. Terminal torque value 4.5 LBF-IN (0.5 N m) Wire size of #12-20 awg (2.05-.81mm)

input and Maximum of wire size of #18 awg (1.02 mm) output. See figure 2.

Figure 2: Enclosure

2) The cable length from the remote mount enclosure to the LED illuminator is 8 foot. Wire length from the

power supply and zener diode barrier to the remote mount enclosure is up to 1800 feet (548 Meters) using 2

strand #18 wire AWG (1.02 mm). Longer distances available depending on wire choice. See specifications

on page 3.

3) Replace the cover on the power supply housing.

4) Switch “ON” the power supply making sure the Illuminator is functioning properly, with all LED’s

illuminated.

5) Refer to the troubleshooting section in this manual if a portion or all of the LEDs do not illuminate.

Led Illuminator with Field-Wireable Connector

1) Disassemble the field-wireable connector. See figure 3.

Figure 3: Field Wireable Connector

3

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

2) Connect DC lines to the field-wireable connector, V+ to pin #2 and connect GND to pin #4. See figure 4.

Figure 4: Terminals

3) Wire length from the power supply and zener diode barrier using 2 strand #18 wire AWG (1.02 mm) is up

to 1800 feet (548 meters). Longer distances available depending on wire choice. Maximum wire size of #18

AWG (1.02 mm) and cable size of .236-.315 inches (6-8mm). See specifications below.

4) Reassemble the connector and attached to led illuminator.

5) Switch “ON” the power supply making sure the Illuminator is functioning properly, with all LED’s

illuminated.

6) Refer to the troubleshooting section in this manual if a portion or all of the LEDs do not illuminate

SELECTING WIRE AND BARRIER

Selecting a wire with a lower capacitance (F) will yield longer distances. Use the following equations and

diode parameters below to determine the distance of wire between the LED illuminator and zener diode barrier.

Pick the shortest distance from the two following equations:

IMPORTANT: FARAD and HENRY units must be consistent throughout the equations. Eg: all (uF),

not a mixture of (uF) and (F).

Cable Max Distance 1 = Total Allowable Capacitance (F) / [2 x Wire Capacitance (F)]

Cable Max Distance 2 = Total Allowable Inductance (H) / [2 x Wire Inductance (H)]

Values for recommended zener diode barriers:

Part Number Manufacture Manufacture Part

Number Allowable

Capacitance, Ca (µF) Diode Inductance, La

(mH)

V22098-1 R. STAHL 9001/01-280-110-101 .083 1.2

V22098-2 MTL 7728P+ .083 1.82

V22098-3 TURCK MZB28P .083 2.5

ROUTINE MAINTENANCE

Keep window on the front of the light clean using commercial glass cleaners. Never use harsh abrasives,

wire brushes, metal scrapers, or any material that could scratch the window. The window may be cleaned while

the unit is in operation.

4

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

UNIVERSAL BRACKET INSTALLATION ONTO GLASS GAUGE

*NOTE: Illuminators pictured are for reference only. The mounting instructions are the same across all Jerguson®

LumastarTM models. Model EPL-316 mounts in the same manner except the power supply is always remote mounted.

Identify your bracket type. Confirm the bracket style matches that in the below pictures. If the bracket received does not

match the illustrations below, see page 5 or 6 for alternate bracket styles.

Figure 5 Figure 6

Step 1: Check to make sure brackets are properly assembled on the illuminator. The cable should be fed through the stud

protruding from behind the illuminator, locking in the bracket as shown above in Figure 2. One end of the cable should be

crimped into an oval for pulling leverage and the other should be crimped securely around a thumb nut.

Figure 7

Step 2: Press Jerguson®LumaStar™assembly against rear of gauge as shown in Figure 3, aligning the bracket cutouts

over the gauge bolt heads as shown. Align the brackets with the 2nd set of bolts in from each end of the gage, when possible.

Note that all one-section size 7 models and smaller will require the power supply to be remote mounted.

5

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

Figure 8 Figure 9

Step 3: While holding the top bracket in place, grab the thumb nut end of the cable, wrap around entire gauge and thread

onto the stud until the bracket is secure. When wrapping the cable around the gauge, make sure to feed the cable above the

bolt as shown above in Figure 5. Snug the cable and secure the thumb nut, but do not fully tighten the thumb nut at this

time.

Figure 10

Step 4: Align bottom bracket, using the 2nd bolt if possible. Wrap thumb nut end of the cable around the entire gauge and

begin to thread. Pull the cable loop as tight as possible and fully tighten the thumb nut down as shown in Figure 6. The

lower bracket should now be tight and secure.

6

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

Figure 11

Step 5: After the lower bracket has been tightened, go back to the top bracket and loosen the thumb nut enough to allow the

cable to slide through freely. Pull cable as tight as possible, and fully tighten thumb nut as shown in Figure 7.

.Figure 12 Figure 13

Step 6: The Jerguson®LumaStar™is now properly installed. Feel free to tuck any excess cable inside itself or allow it to

hang freely. This adjustable assembly is appropriate for any gauge with a cover width not exceeding 4.375 inches (111 mm).

7

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

ALTERNATE BRACKET STYLE

*NOTE: Illuminator pictured is model EPL-100. Model EPL-316 mounts in the same manner except the power supply is

always remote mounted. Identify your bracket type. Confirm the bracket style matches that in the below pictures. If the

bracket received is different than shown here and on page 2, contact factory for assistance.

Figure 14

1) Align Jerguson®LumaStar™ assembly with rear (side with bolt heads) of gauge. Loosen bracket thumb nuts and

adjust the position of the brackets to line up with their respective bolts on the gauge as shown in Figure 10.

Tighten the thumb nuts to secure in place. When possible, use the 2nd set of bolts from the edge of the cover plate.

Note that all one-section size 7 models and smaller will require the power supply to be remote mounted.

Figure 15 Figure 16

2) Align one side of the brackets as shown in Figure 11, so that the clip of the brackets are gripping around the side of

the gauge. Roll the entire assembly over until it is flush with the rear flat of the gauge and press until the bracket

clips have locked into place as shown in Figure 12.

8

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

www.clark-reliance.com ●sales

@

clark-reliance.com

REFLEX BRACKET STYLE

*NOTE: Illuminator pictured is model EPL-100. Model EPL-316 mounts in the same manner except the power supply is

always remote mounted. Identify your bracket type. Confirm the bracket style matches that in the below pictures. If the

bracket received is different than shown here and on page 2, contact factory for assistance.

NOTE: installation onto a Reflex Gauge requires removal of nuts on the gauge. Do not install illuminator with

gauge in service.

1) Install the brackets onto the illuminator leaving the bracket thumb screws loose. The brackets should move freely

up and down in the illuminator channel.

2) Remove top and bottom nuts from the Reflex Gauge on the side of the gauge that the illuminator is to be installed

on.

3) Position brackets onto studs, reinstall gauge nuts and tighten to the torque specified for your gauge.

4) Position illuminator so it is centered on the Reflex Gauge and tighten the bracket thumb screws. The illuminator

should be mounted as shown in Figure 13.

Figure 17

Reflex Bracket Mounting

9

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

Jerguson

®

EPL-100 / EPL-316 LumaStar™ Spare Parts

Description Part Number

Universal Bracket Assembly (2 required / light bar) (1) S24245 (ea.) (EPL100 only)

(2) S24245 (set) (EPL100 only)

Assembly: Enclosure: FRP S24927

Assembly : Enclosure: 316SS S24928

Receptacle: Angle: Right (Field-Wireable) V22094

Receptacle: Angle: Right: 316SS (Field-Wireable) V22095

8’ Cable w/ 90 degree M12 Connector (Enclosure to 1st Light Bar) V21906

8’ Cable w/ 90 degree M12 Connector 316SS (Enclosure to 1st Light Bar) V21906-T

Zener Diode Barrier V22098-# (See Page 3)

Power Supply: 24VDC V22185

2-1/2 foot (.75 meter) Daisy-Chain Cable (Nickel Plated Brass Connectors) V20601

2-1/2 foot (.75 meter) Daisy-Chain Cable (316SS Connectors) V21319

LED Array Circuit Board (4 inch) S23174-4 (EPL100 only)

LED Array Circuit Board (6 inch) S23174-6 (EPL100 only)

LED Array Circuit Board (8 inch) S23174-8 (EPL100 only)

LED Array Circuit Board (10 inch) S23174-10 (EPL100 only)

LED Array Circuit Board (12 inch) S23174-12 (EPL100 only)

SPECIFICATIONS

Est. Life: 100,000 Hours (continuous)

Approvals: FM

Class I, Div. 1 Groups A, B, C, D T4

Class II, Div 1 Groups E, F, G T4

See Drawing: CI-26677

Ambient Temp: -40 F (-40 C) to 170 F (77 C)

Wire Size: See Selecting Wire Section

Max dist. power

supply to light: 1800 feet (548 meters), See Selecting Wire Section

Electrical

Connection EPL-316 = 1/2” FNPT

Size: EPL-100 = 1/2” Conduit Entry

Field-Wireable Connector

10

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

Troubleshooting

Description of Problem Possible Cause Troubleshooting

Procedure

All LEDs out

Loose or disconnected DC output wires

Blue Power Cord loose or connector damaged

Loose or damaged connections inside LED

Assembly

Damaged Power Supply

Blown Fuse in Barrier

Follow

troubleshooting

steps below

Set or sets of (4) LEDs out Defective LED Board Contact Factory

LEDs out above a certain point Loose connection between LED boards

Defective LED board Contact Factory

LEDs out in group (more than 4) Defective LED board Contact Factory

Troubleshooting Steps

Caution: Some of these troubleshooting steps are performed with live voltage applied. The

assembly should be moved to a safe area before beginning work. A qualified and properly trained

technician must perform these steps.

1) Verify Power supply has power.

2) Using a voltmeter set to DC; measure the voltage on the input of the barrier. Voltage should be

24VDC. If no power is present replace power supply.

3) Using a voltmeter set to DC; measure the voltage on the output of the barrier. Voltage should be

between 11VDC and 15VDC with the illuminator connected. 24VDC with no illuminator

connected. If no power is present replace barrier.

WARNING: DO NOT MEASURE VOLTAGE ACROSS INPUT AND OUTPUT. UNSAFE

LEVEL OF CURRENT COULD BE SENT INTO AN INTRISCIALLY SAFE AREA.

4) Verify wires are connected properly and no connections are loose.

5) Inspect wires for damage or loose connections. Replace as needed.

6) Unscrew blue power cord or field wireable connector at LED bar. Inspect the 4 pins inside end

connector to make sure they are straight and undamaged. If pins are bent, use a small pair of

needle-nose pliers to straighten bent pins. If pins are missing, contact factory.

7) Reconnect power cord making sure connectors are fully seated and tightened.

8) If all steps above check OK, contact factory for support.

11

16633 Foltz Parkway ●Strongsville, OH 44149 USA ●Telephone: +1 (440) 572-1500 ●Fax: +1 (440) 238-8828

Other manuals for Jerguson LumaStar EPL-100

1

This manual suits for next models

1

Table of contents

Other Clark-Reliance Work Light manuals

Popular Work Light manuals by other brands

BARRON

BARRON TRACE LITE FXA 350W Series installation instructions

SpeedTech Lights

SpeedTech Lights DUAL CARBINE 13 instruction manual

Conrad

Conrad 77 70 78 operating instructions

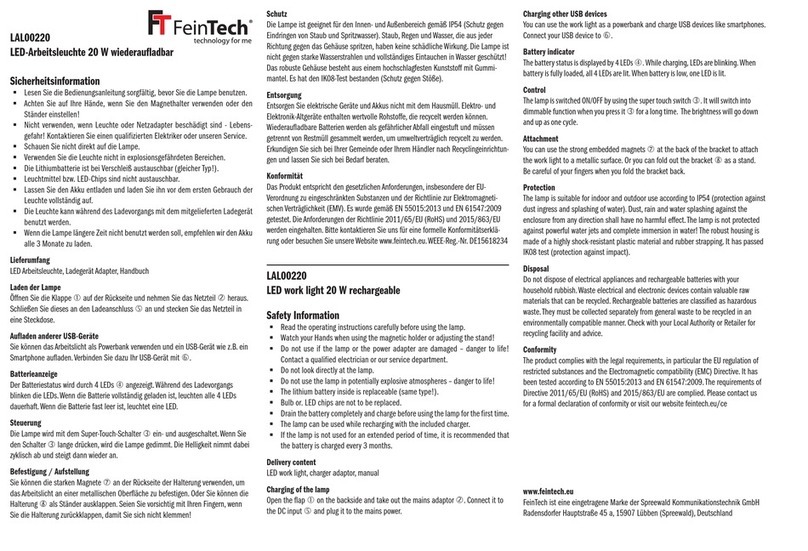

FeinTech

FeinTech LAL00220 quick start guide

Bunker Hill Security

Bunker Hill Security 64735 user manual

Cooper

Cooper Metalux SLES installation instructions