IMPORTANT

Failure to follow these precautions

could result in personal injury, and/or

damage to property.

1. ALWAYS wear approved impact resistant

safety goggles. (Eye glasses are NOT

safety glasses).

2. ALWAYS wear face or dust mask (where

dust is created), and ear defenders when

necessary.

3. ALWAYS disconnect the tool when not in

use, before changing accessories and

before carrying out any maintenance

4. ALWAYS have trigger in the OFF position

when connecting to an air supply.

5. ALWAYS keep a safe distance between

yourself and other people when using the

tool.

6. Maintain the tool with care. Keep it clean

for best and safest performance.

7. DO NOT wear ill fitting clothing, remove

watches and rings.

8. Quick change couplings should not be

located at the tool. They add weight and

could fail due to vibration.

9. DO NOT over-reach. Keep your proper

footing and balance at all times.

10. DO NOT force or misuse the tool. It will do

a better and safer job at the rate for which

it was designed.

11. DO NOT abuse hoses or connectors.

NEVER carry a tool by the hose, or yank it

to disconnect from the air supply. Keep

hoses away from heat, oil and sharp

edges. Check hoses for weak or worn

condition before use, and ensure that all

connections are secure.

12. DO NOT exceed 90 PSI at the tool.

13. DO NOT modify the tool in any way.

SAFETY PRECAUTIONS for AIR TOOLS

AIR SUPPLY

Tools of this type, operate on a wide range of

air pressures.

It is recommended that air pressure to this tool

does not exceed 90 PSI, at the tool when

running. Higher pressure and unclean air, will

shorten the tools’ life because of faster wear,

and could be a safety hazard.

Water in the air line will cause damage to the

tool. Ensure the tool is properly maintained at

all times. (See maintenance section) The

recommended procedure for connecting this

tools is shown at fig. 1.

The air inlet used for connecting the air supply,

has a 1/8" BSP thread.

Line pressure, or hose inside diameter, should be

increased to compensate for unusually long air

hoses (over 25 feet). Minimum hose diameter

should be 5/16" (8mm) ID., and fittings should

have the same inside dimensions.

OPERATION

Ensure the appropriate bit is pushed firmly

home, until it clicks into place in the drive. With

the air line attached and a pressure regulated

at 90 psi , depress the operating lever.

Forward and reverse is obtained by setting

the Reverse Valve (item 18) located

diagonally opposite the lever.

Pushing the valve ‘in’ against spring pressure,

and turning it anticlockwise to lock in that

position, will select forward or ‘screwing in’

mode. Turning the valve clockwise, allowing

it to spring ‘out’, and remain in that position,

will select reverse.

Three torque ranges are possible with this tool.

Two additional springs are provided, giving a

higher or lower range than that set during

manufacture. To change to a different range,

proceed as follows:

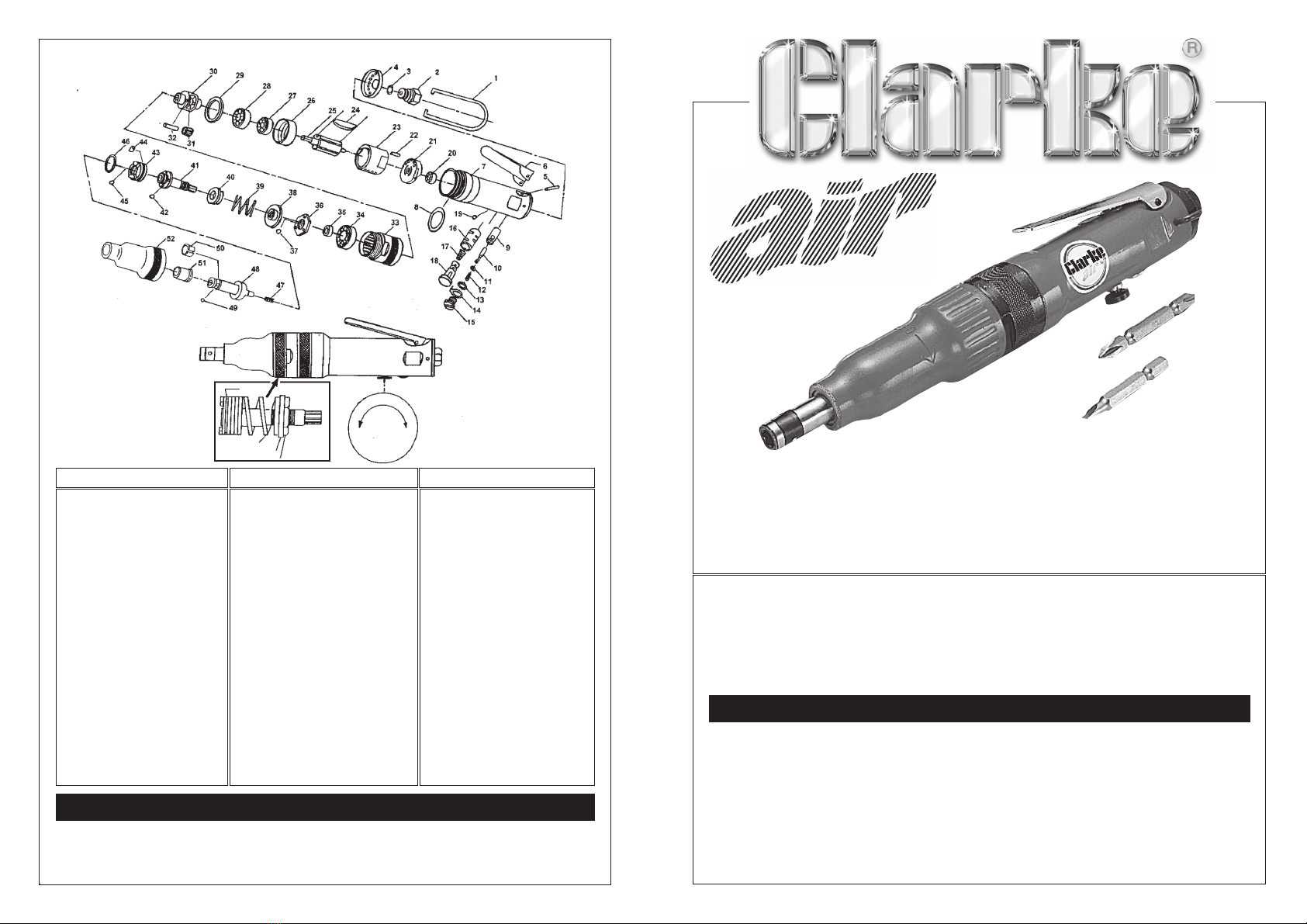

Refer to Parts Diagram inset

1. Unscrew the Clutch case (item 52) noting

that it has a left hand thread.

2. Pull the clutch assembly from the motor

taking care not to lose the collar on the

splined shaft.

3. Holding the splined shaft with the

appropriate wrench (supplied), turn the

top adjuster nut, and remove completely,

allowing the bottom adjuster and control

spring also to be removed.

4. Replace the spring with the one of your

choice, and re-assemble in reverse order.

5. Spring Tension and hence torque applied

to the bit, is increased by turning the top

adjuster clockwise.

MAINTENANCE

Daily

1. Before use, drain water from air tank, air

line and compressor.

2. If no line Lubricator is used, ensure that oil

is applied to the tool (see below).

Weekly

Clean the air inlet filter screen (within item 2).

Periodically

Remover the clutch case (item 52) and clean

and dry the clutch assembly.

Apply a little grease to the clutch assembly,

and into the clutch case to lubricate the

bearings in the nose.

For lubricating the air motor, an air line

lubricator should be used, with SAE 10 oil, (see

fig. 1) adjusted to 2 drops per minute.

If this is not possible, run a few drops of oil

through the tool as required. It may be

entered into the tool air inlet, (ensuring the

strainer is clear), or into the hose at the nearest

connection to the air supply. Then run the tool.

A rust inhibitive oil, available from auto supply

stores etc., is acceptable.

Be aware that factors other than the tool may

effect its operation and efficiency, such as

reduced compressor output, excessive drain

on the airline, moisture or restrictions in the line,

or the use of connectors of improper size or

poor condition which will reduce air supply.

Grit or gum deposits in the tool may also

reduce efficiency. This condition can be

corrected by cleaning the air strainer and

flushing out the tool with gum solvent oil, or

an equal mixture of SAE 10 oil and kerosene.

SPECIFICATIONS

Bit Size ............................... 1/4" Hex

Free Speed ...................... 1,600 RPM

Torque Range .................. 0 - 25 lbs in

Air Inlet .............................. 1/8" BSP

Min. Hose Size (ID) .......... 5/16" (8mm) ID

Ave. Air Consumption .... 4 CFM

Air Pressure Max. ............. 90 PSI

Vibration Level ................ > 2.5m/s2

Net Weight ....................... 0.6 kg

For Spare Parts and Service, please contact your nearest dealer,

or CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

or e-mail as follows:

PARTS AND SERVICE CONTACTS

FIG. 1